Asphalt Plant Operator Resume Guide

Asphalt Plant Operators are responsible for operating and maintaining asphalt plants, which produce hot mix asphalt. They monitor the production process to ensure a quality product is produced, according to specifications set by their employer. Additionally, they inspect equipment and make necessary repairs or adjustments as needed.

You have the experience and know-how to run an asphalt plant like a pro. Construction companies need your expertise, but they won’t find out about you unless you create a resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

Asphalt Plant Operator Resume Sample

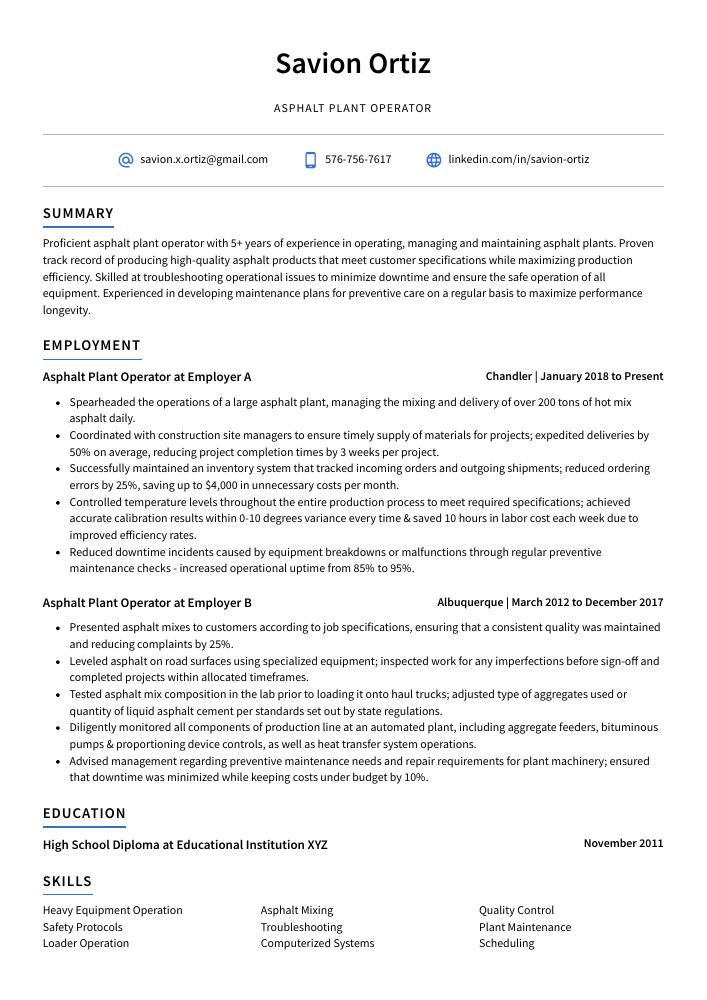

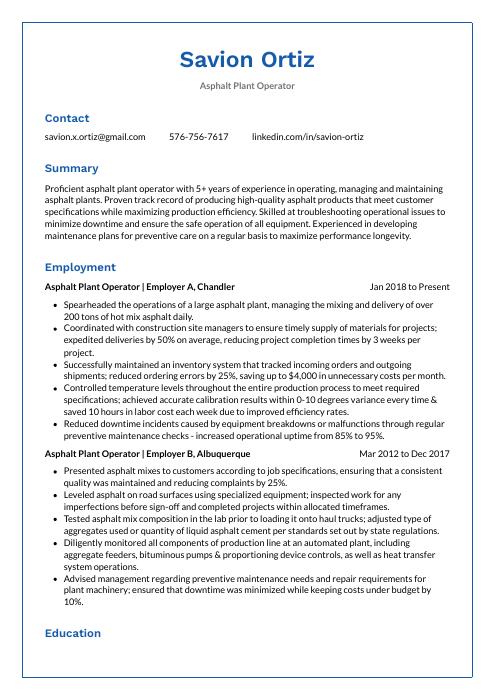

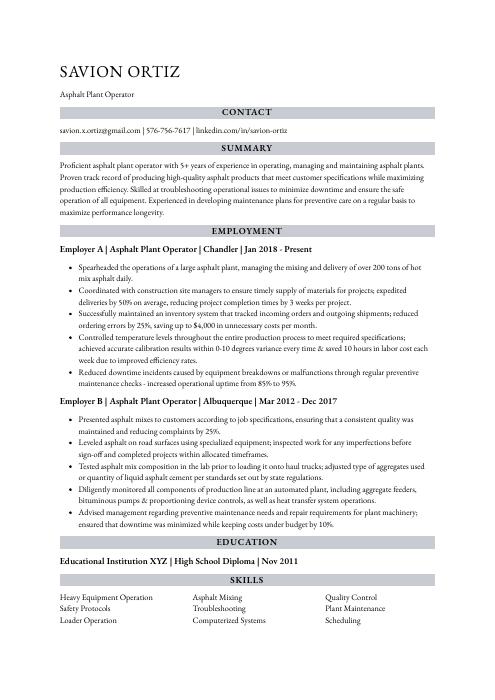

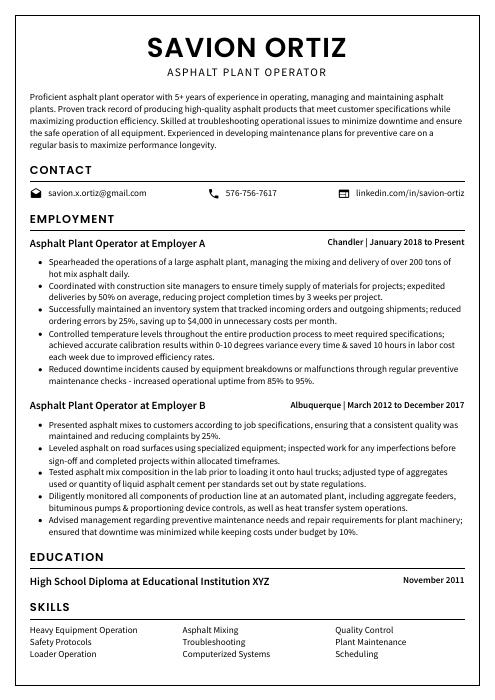

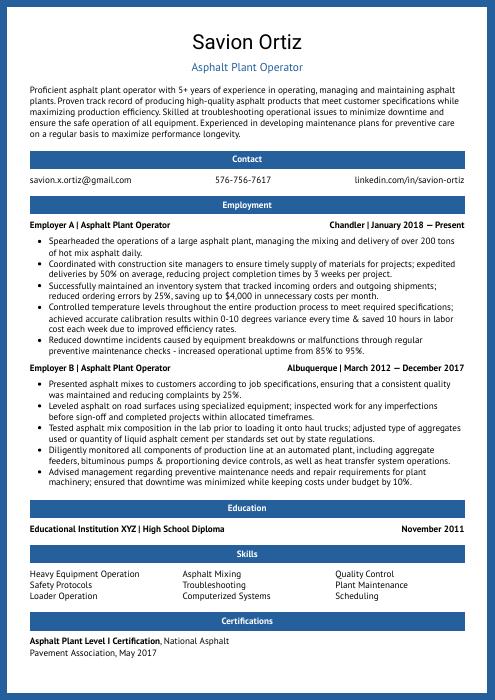

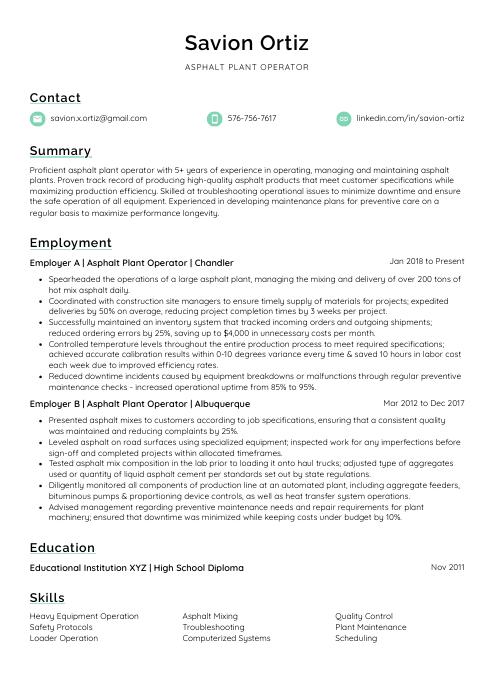

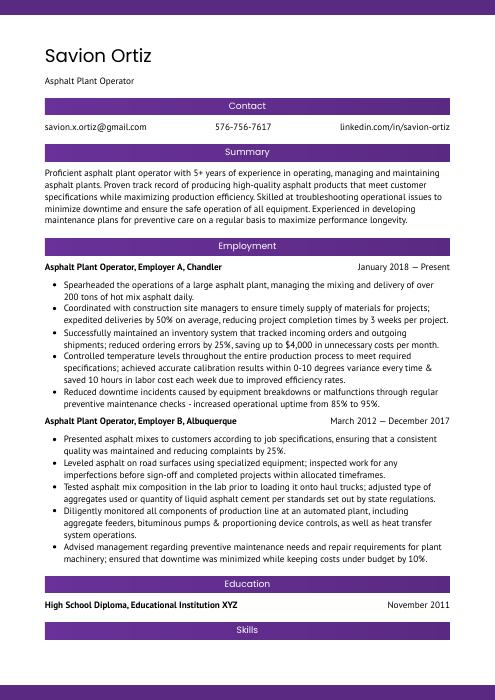

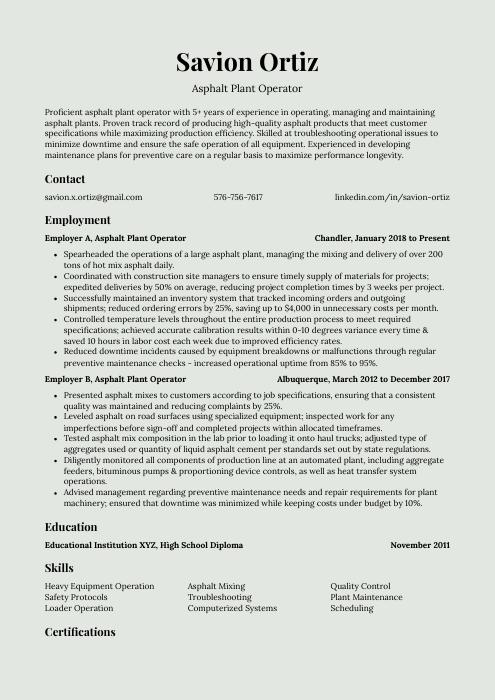

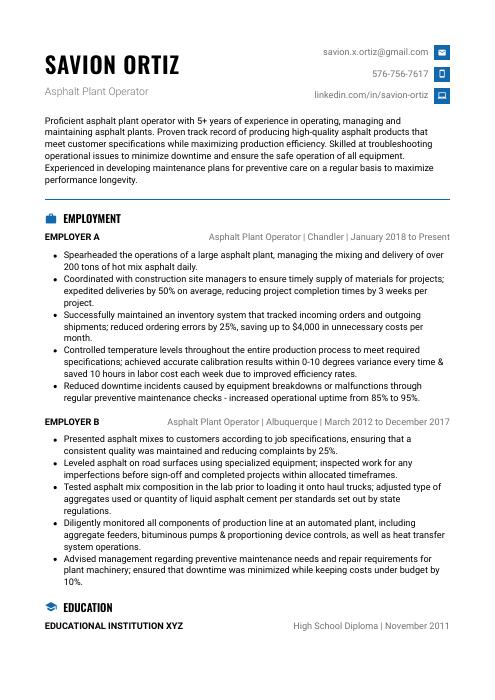

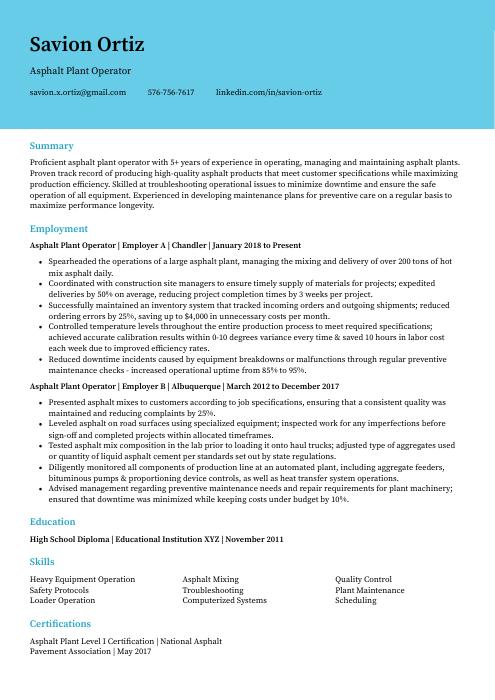

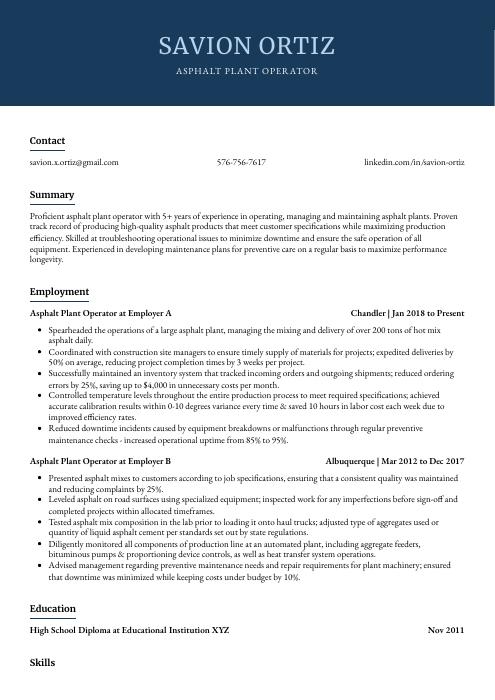

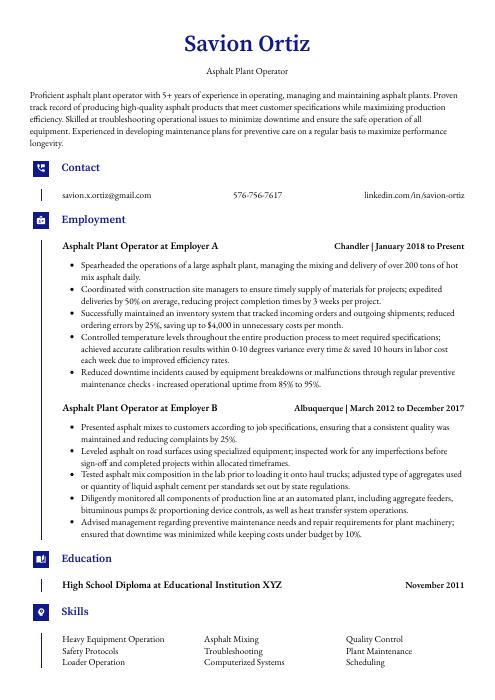

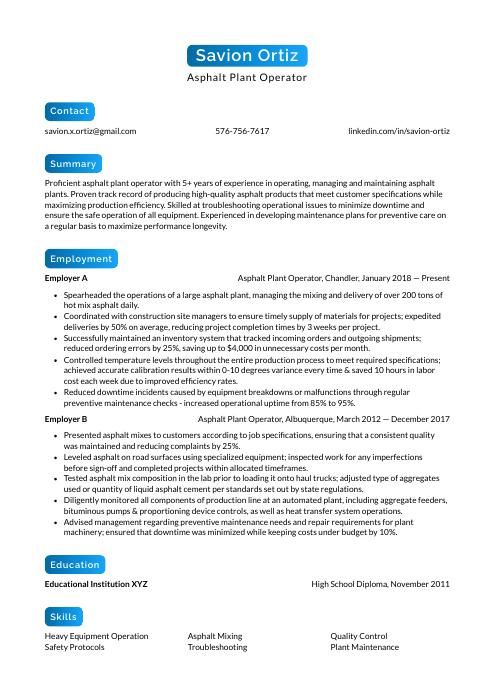

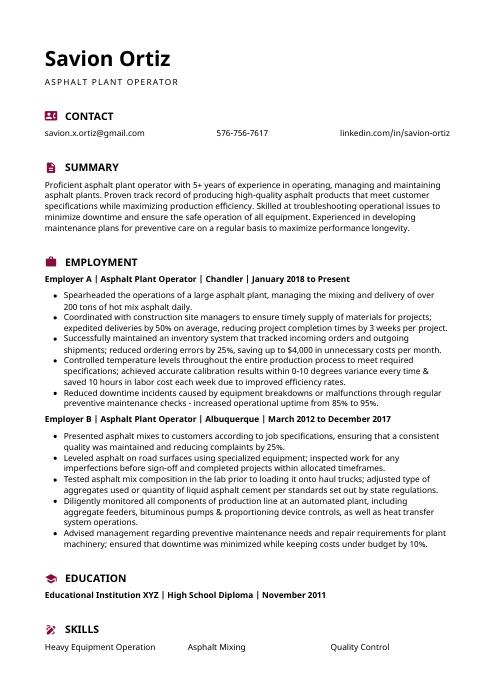

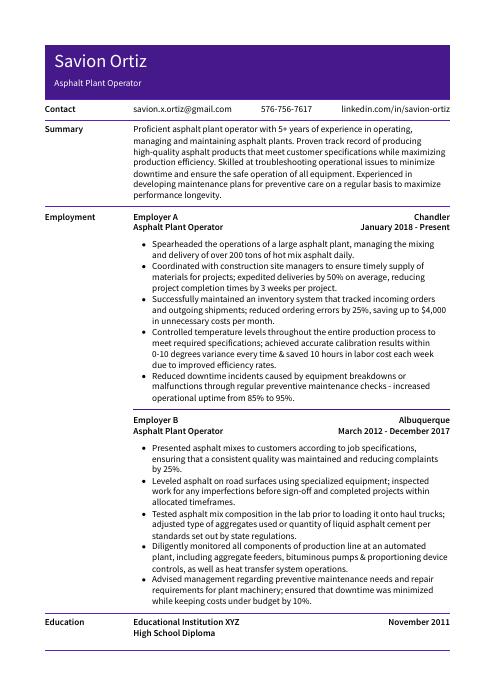

Savion Ortiz

Asphalt Plant Operator

[email protected]

576-756-7617

linkedin.com/in/savion-ortiz

Summary

Proficient asphalt plant operator with 5+ years of experience in operating, managing and maintaining asphalt plants. Proven track record of producing high-quality asphalt products that meet customer specifications while maximizing production efficiency. Skilled at troubleshooting operational issues to minimize downtime and ensure the safe operation of all equipment. Experienced in developing maintenance plans for preventive care on a regular basis to maximize performance longevity.

Experience

Asphalt Plant Operator, Employer A

Chandler, Jan 2018 – Present

- Spearheaded the operations of a large asphalt plant, managing the mixing and delivery of over 200 tons of hot mix asphalt daily.

- Coordinated with construction site managers to ensure timely supply of materials for projects; expedited deliveries by 50% on average, reducing project completion times by 3 weeks per project.

- Successfully maintained an inventory system that tracked incoming orders and outgoing shipments; reduced ordering errors by 25%, saving up to $4,000 in unnecessary costs per month.

- Controlled temperature levels throughout the entire production process to meet required specifications; achieved accurate calibration results within 0-10 degrees variance every time & saved 10 hours in labor cost each week due to improved efficiency rates.

- Reduced downtime incidents caused by equipment breakdowns or malfunctions through regular preventive maintenance checks – increased operational uptime from 85% to 95%.

Asphalt Plant Operator, Employer B

Albuquerque, Mar 2012 – Dec 2017

- Presented asphalt mixes to customers according to job specifications, ensuring that a consistent quality was maintained and reducing complaints by 25%.

- Leveled asphalt on road surfaces using specialized equipment; inspected work for any imperfections before sign-off and completed projects within allocated timeframes.

- Tested asphalt mix composition in the lab prior to loading it onto haul trucks; adjusted type of aggregates used or quantity of liquid asphalt cement per standards set out by state regulations.

- Diligently monitored all components of production line at an automated plant, including aggregate feeders, bituminous pumps & proportioning device controls, as well as heat transfer system operations.

- Advised management regarding preventive maintenance needs and repair requirements for plant machinery; ensured that downtime was minimized while keeping costs under budget by 10%.

Skills

- Heavy Equipment Operation

- Asphalt Mixing

- Quality Control

- Safety Protocols

- Troubleshooting

- Plant Maintenance

- Loader Operation

- Computerized Systems

- Scheduling

Education

High School Diploma

Educational Institution XYZ

Nov 2011

Certifications

Asphalt Plant Level I Certification

National Asphalt Pavement Association

May 2017

1. Summary / Objective

The summary/objective at the top of your resume is like a trailer – it gives the employer an overview of who you are and why you excel as an asphalt plant operator. Here is where you can showcase your best qualities. For example, you could talk about how many years experience in operating asphalt plants that have given you, the safety record that has earned recognition from management, and any specialized training or certifications related to this field.

Below are some resume summary examples:

Seasoned Asphalt Plant Operator with 10+ years of experience running and maintaining the production of asphalt products. Skilled in troubleshooting, equipment maintenance, safety protocols, and quality control regulations. Adept at operating multiple types of asphalt plants while ensuring compliance with all applicable laws and standards. Looking to join ABC Asphalt as a Plant Operator to use my expertise in producing high-quality projects efficiently.

Professional asphalt plant operator with over 10 years of experience in asphalt production, maintenance, and safety. Skilled at working independently as well as collaboratively to achieve desired results on time. Expertise in operation and troubleshooting of automated equipment used for asphalt mixing processes and quality control measurements. Proven track record of creating high-quality mixes while minimizing waste material output.

Passionate and experienced asphalt plant operator with a strong work ethic and solid understanding of the asphalt production process. At XYZ, operated an Asphalt Plant for 8 years as part of a team that consistently met or exceeded expected output goals. Highly organized individual who is capable of supervising, monitoring, and controlling all aspects of operation while ensuring safety regulations are followed at all times.

Detail-oriented asphalt plant operator with 5+ years of experience in the construction industry. Skilled at operating asphalt plants, as well as various other heavy equipment and machinery. At XYZ Construction Company, successfully ran a crew of 10 to complete all tasks on schedule while ensuring compliance with safety standards. Adept at troubleshooting mechanical issues and optimizing processes for increased efficiency.

Dependable asphalt plant operator with 5+ years of experience working in various asphalt plants. Adept at operating and maintaining equipment, managing inventory levels, ensuring safety regulations are met and quality standards are upheld. Recently achieved a 95% success rate on all projects while simultaneously cutting costs by 10%. Seeking to join ABC Asphalt Plant to utilize expertise in efficient production processes.

Skilled asphalt plant operator with 15 years of experience in asphalt production. Proven record of maintaining high standards for quality control and safety compliance. Experienced in troubleshooting mechanical issues, monitoring all operational metrics and preparing daily reports on production activities. At ABC Corporation, increased efficiency by 20% through process improvements and optimization techniques.

Driven asphalt plant operator with 10+ years of experience in the field and a proven track record of safely producing high-quality mixes on time and under budget. Skilled at troubleshooting equipment, monitoring asphalt production processes, and overseeing material handling operations. Looking to join ABC Paving as an experienced asphalt plant operator to help ensure projects are completed efficiently.

Accomplished asphalt plant operator with 8+ years of experience operating and maintaining a variety of asphalt production plants. Skilled in conducting daily inspections, troubleshooting malfunctions, and making necessary repairs. Looking to join ABC Industries as an Asphalt Plant Operator in order to utilize my expertise in the industry while contributing to the company’s success.

2. Experience / Employment

In the experience/employment/work history section, you should provide details on your past roles in reverse chronological order, with the most recent job listed first.

When writing this section, use bullet points to make it easier for the reader to digest what you have written. You want to include detail here and explain not only what you did but also any results or accomplishments that were achieved because of your efforts.

For example, instead of saying “Operated asphalt plant,” you could say, “Managed daily operations at a large-scale asphalt plant; successfully increased production by 20% while reducing costs by 10%. ”.

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Operated

- Monitored

- Adjusted

- Inspected

- Troubleshot

- Loaded

- Unloaded

- Mixed

- Paved

- Leveled

- Repaired

- Calibrated

- Tested

- Recorded

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Paved over 8.5 miles of highways and 12,000 square feet of asphalt parking lots each week using a variety of paving machines; optimized the production process to reduce costs by 15%.

- Resourcefully managed the operations at an asphalt plant with 20 employees; introduced new safety protocols that reduced job-related accidents by 45%.

- Optimized daily equipment maintenance activities to increase machine life expectancy from 2 years up to 5 years while ensuring compliance with OSHA regulations.

- Introduced automated systems for more efficient mixing and storage processes, which led to a 30% reduction in material wastage over 3 quarters.

- Facilitated smooth production runs through proactive troubleshooting and creative problem solving techniques, reducing downtime hours by 25% on average per month.

- Participated in the daily operations of an asphalt plant, overseeing production processes and controlling equipment to ensure compliance with safety regulations.

- Demonstrated expertise in operating various pieces of machinery such as haul trucks, loaders, pavers, rollers and spreaders; increased efficiency rate by 15%.

- Prepared records on quality control checks for all materials used in paving projects; tested material samples for consistency before releasing them for use.

- Competently operated a computer-aided system to accurately monitor temperature levels and adjust mixtures accordingly during production cycles; reduced wastage by 20%.

- Operated asphalt plants at 3 different locations within a 200km radius from base location over 6 months period while ensuring high standards of safety were maintained throughout each shift worked.

- Achieved a daily average of 2,000 tons of asphalt production using a variety of equipment and tools; increased production output by 10% in the last quarter.

- Calibrated and adjusted conveyor belts, mixers, pumps and other machinery to ensure optimal performance during operations.

- Effectively operated cranes for efficient loading/unloading activities at the plant site while adhering to safety regulations & lifting techniques; reduced crane-related accidents by 24%.

- Inspected various areas around the asphalt plant on a regular basis including working surfaces, lube levels on machines & oil tanks inside vehicles; identified potential hazards before they caused damage or injury incidents.

- Unloaded delivery trucks containing raw materials such as sand, stone dusts & bitumen emulsions upon arrival at the facility according to established protocols and procedures with no delays or errors recorded in 3 years’ time span.

- Improved asphalt production process by 20%, loading materials into the asphalt plant and operating equipment in a safe and efficient manner.

- Streamlined maintenance operations for five asphalt plants, carrying out necessary repairs to ensure optimal performance of machinery and reducing downtime by 25%.

- Loaded aggregate material onto conveyor belts as well as fuel tanks with diesel or gasoline; ensured that all safety protocols were followed when handling hazardous chemicals/materials.

- Repaired broken components on the asphalt mixing machines such as engines, motors, pumps and other parts using specialized tools resulting in increased productivity per hour by 30%.

- Substantially reduced energy costs at each facility through monitoring temperature levels during mixing cycles, adjusting feed rates accordingly and optimizing output quality thereby saving over $20K annually.

- Utilized asphalt plant machinery to produce a variety of asphalt mixes, ensuring that safety requirements were adhered to at all times.

- Meticulously monitored the production process from start-to-finish and consistently delivered batches with an accuracy rate over 95%.

- Structured daily operations for maintenance and repairs of equipment; reduced downtime by 25% in last quarter.

- Monitored inventory levels, placed orders for necessary materials on time and ensured proper storage conditions for raw materials received at the facility.

- Troubleshot mechanical issues arising during operation as well as identified opportunities for improvement in plant efficiency leading to increased output by 15%.

- Reorganized asphalt plant operations, resulting in a 12% increase in efficiency and an 18% decrease in production costs.

- Compiled daily reports on the asphalt mixing process for management review; analyzed results to make recommendations for improvements.

- Represented company at state-wide safety meetings, ensuring that all employees followed OSHA regulations when operating machinery and handling hazardous materials safely.

- Consistently maintained high quality standards of asphalt mix production by regularly calibrating equipment and modifying processes as needed throughout shifts; ensured accuracy with weekly laboratory tests on finished products produced from the plant operator controls panel system.

- Revised existing procedures to incorporate new technologies into asphalt mixing processes while optimizing output levels; reduced labor time per batch by 20%.

- Assessed asphalt plant to ensure proper functioning of equipment and optimal production rate; successfully reduced downtime by 25%.

- Recorded daily asphalt usage, temperature readings and other key metrics for quality control purposes; identified issues in the process that saved an estimated $7000 annually.

- Mixed various grades of aggregate material, bitumen & additives according to customer specifications with a high level of accuracy, producing over 200 tons per day at maximum efficiency rates.

- Developed strategies to reduce costs associated with asphalt manufacturing while ensuring top-notch product quality was maintained throughout the process; led cost savings initiatives resulting in 10% reduction year-over-year expenses related to asphalt production operations.

- Accurately followed all safety protocols when operating heavy machinery such as haul trucks, loaders and conveyor belts onsite without any incident reported during shifts or overtime hours worked.

- Actively operated asphalt plant machinery and equipment to produce, blend and heat up to 200 tons of asphalt mix per hour; decreased production times by 30%.

- Adjusted temperature settings on the mixing drum based on material properties in order to ensure a homogeneous mixture was produced at all times; increased product quality ratings from customers by 24%.

- Mentored 2 junior operators in proper usage of safety protocols while operating heavy machinery as well as efficient troubleshooting techniques when responding to system malfunctions; reduced downtime incidents by 22%.

- Formulated customized recipes for different types of pavement mixtures with consideration given towards local climate conditions such as extreme temperatures or humidity levels, resulting in an improved lifespan for each application.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may need a candidate with experience operating a specific type of asphalt plant, while Organization XYZ may require someone who is familiar with the operation and maintenance of multiple types.

Therefore, it is important to tailor your skills section to each job you are applying for; this will ensure that employers can easily identify whether or not you possess the necessary qualifications they seek in an ideal candidate. This also allows applicant tracking systems (which many companies use) to scan resumes for certain keywords before passing them on to human recruiters.

In addition, try elaborating on some of your most relevant skills in other sections such as the summary or work experience area – this will give potential employers more insight into how well-suited you are for their position.

Below is a list of common skills & terms:

- Asphalt Mixing

- Computerized Systems

- Heavy Equipment Operation

- Loader Operation

- Material Handling

- Plant Maintenance

- Quality Control

- Safety Protocols

- Scheduling

- Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below the objective statement. However, if you have a lengthy professional history to showcase, including an education section might not be necessary or beneficial.

If you do include an education section, try to highlight courses related to asphalt plant operation that demonstrate relevant knowledge and skills for the job role.

High School Diploma

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the necessary skills and knowledge required for a particular job. They are also proof of your commitment to professional development, as they require time and effort to obtain.

Including certifications on your resume can be an excellent way of showing off your qualifications in a given field or industry. Make sure you list any relevant certifications so that hiring managers can easily see what makes you stand out from other applicants.

Asphalt Plant Level I Certification

National Asphalt Pavement Association

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Savion Ortiz, this would be Savion-Ortiz-resume.pdf or Savion-Ortiz-resume.docx.

7. Cover Letter

Providing a cover letter as part of your job application is a great way to show potential employers that you are serious about the role. A cover letter should be made up of 2-4 paragraphs and provide more detail than what’s mentioned in your resume.

By writing a well-crafted, personalized cover letter, you can demonstrate why you’re an ideal candidate for the position and how your skillset will benefit their company. It also gives recruiters valuable insight into who you are as a person and makes it easier for them to remember you during their decision making process.

Below is an example cover letter:

Dear Wendell,

I am interested in applying for the Asphalt Plant Operator position at your company. With more than 10 years of experience working in asphalt plants, I have the skills and knowledge to operate your plant efficiently and effectively.

In my previous role as an Asphalt Plant Operator, I was responsible for all aspects of plant operation, including start-up and shut down procedures, raw material handling, mixing operations, finished product loading, and quality control. I have a strong understanding of how each component of an asphalt plant works together to produce a high-quality product. In addition, I have experience troubleshooting problems that arise during plant operation.

I am confident that I can be a valuable asset to your team. My attention to detail and commitment to safety will help ensure that your plant is operated according to best practices. In addition, my ability to work independently or as part of a team makes me adaptable to any situation that may arise at the plant.

Thank you for considering me for this position! Please do not hesitate to contact me if you have any questions about my qualifications or experience. I look forward hearing from you soon!

Sincerely,

Savion

Asphalt Plant Operator Resume Templates

Fossa

Fossa Indri

Indri Axolotl

Axolotl Quokka

Quokka Markhor

Markhor Numbat

Numbat Cormorant

Cormorant Ocelot

Ocelot Lorikeet

Lorikeet Jerboa

Jerboa Saola

Saola Echidna

Echidna Dugong

Dugong Bonobo

Bonobo Gharial

Gharial Kinkajou

Kinkajou Hoopoe

Hoopoe Pika

Pika Rhea

Rhea Rezjumei

Rezjumei