Alignment Technician Resume Guide

Alignment Technicians are responsible for inspecting and adjusting the alignment of vehicles, including brakes, suspension systems, wheels and tires. They use specialized equipment to measure wheel angles relative to each other and the chassis in order to ensure proper vehicle handling and performance. Alignment Technicians also inspect steering components such as tie rods, ball joints, rack-and-pinion gears or power steering pumps for wear or damage that could affect a vehicle’s ability to operate safely.

You have the experience, knowledge and expertise to be a great alignment technician. But employers don’t know who you are yet, so it’s essential that your resume stands out from all other applicants. Write a resume that highlights why you’re the best fit for the job.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

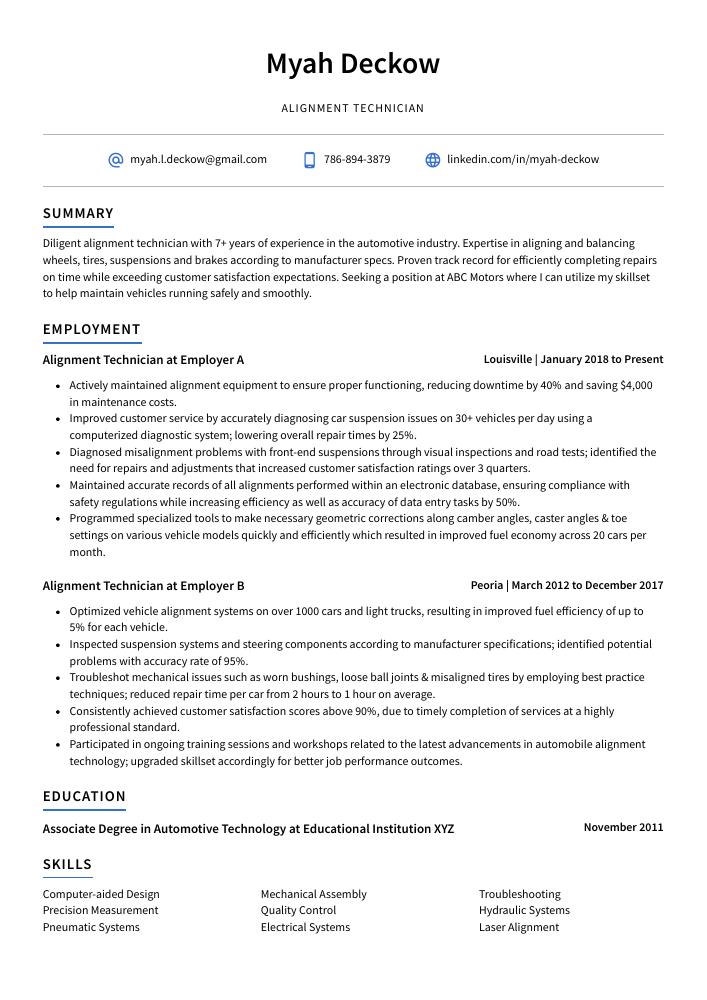

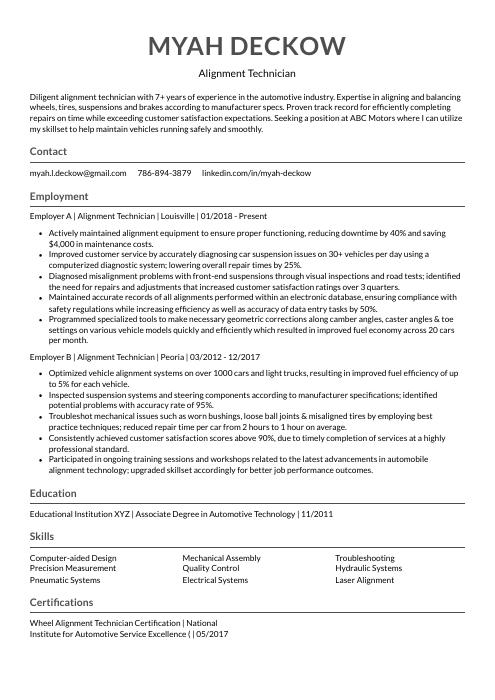

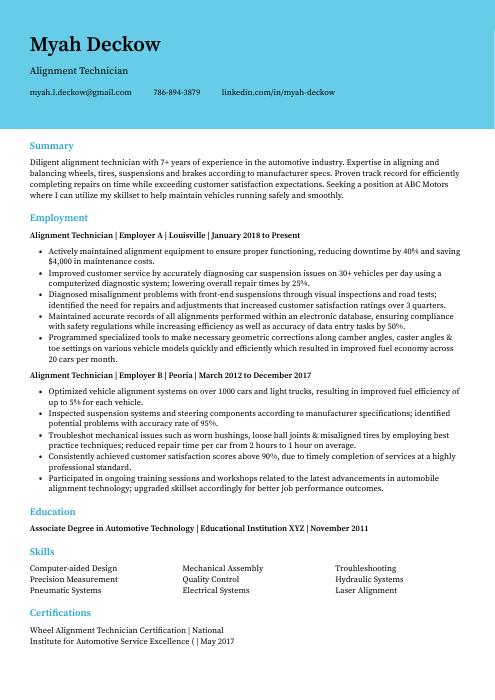

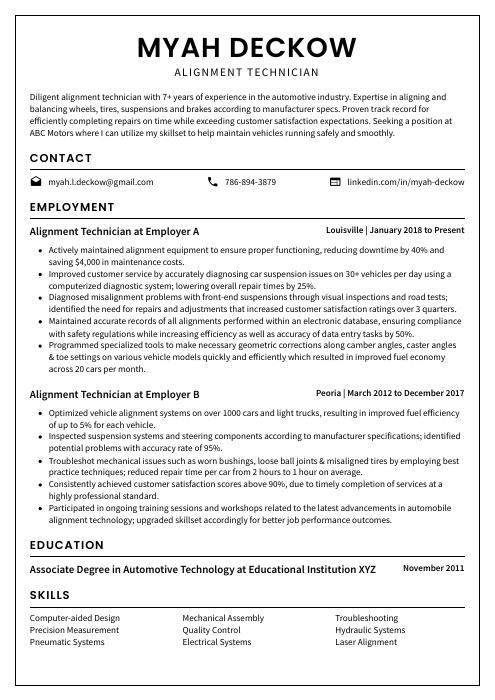

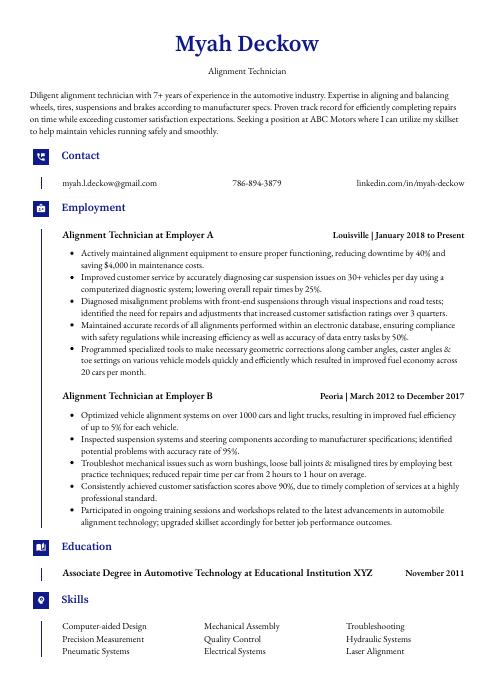

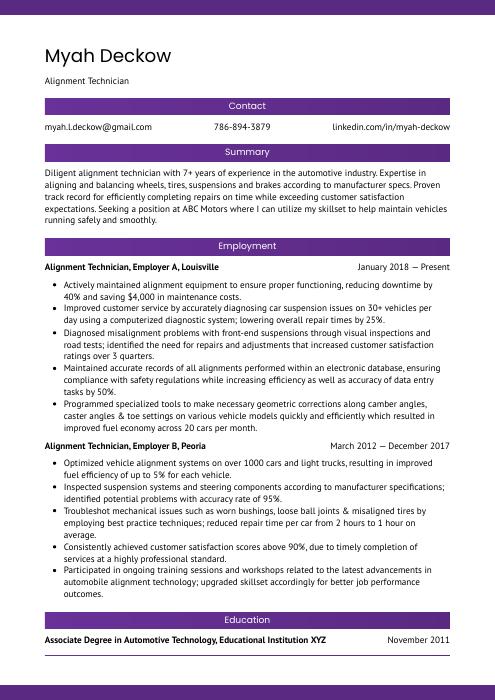

Alignment Technician Resume Sample

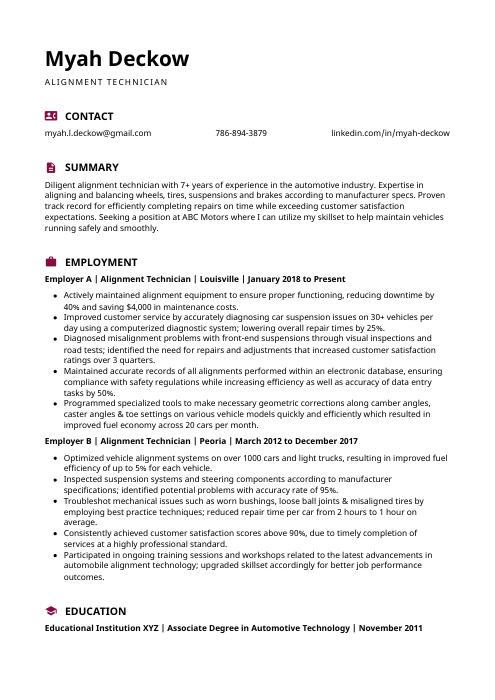

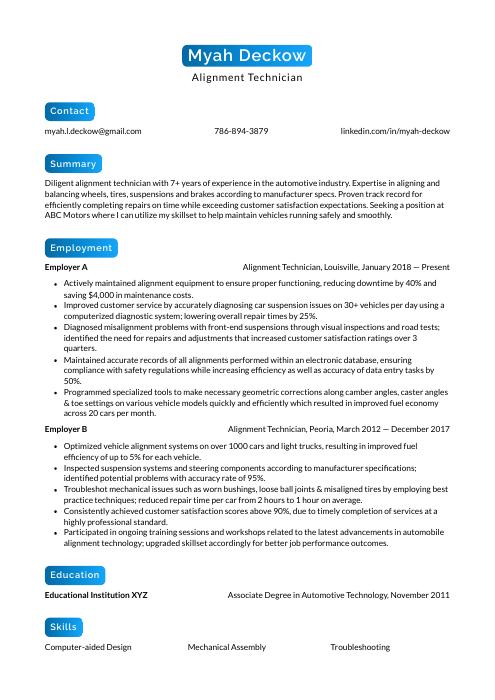

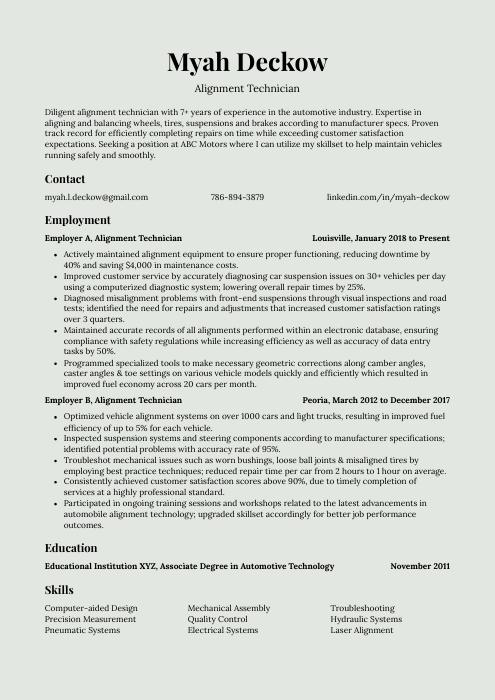

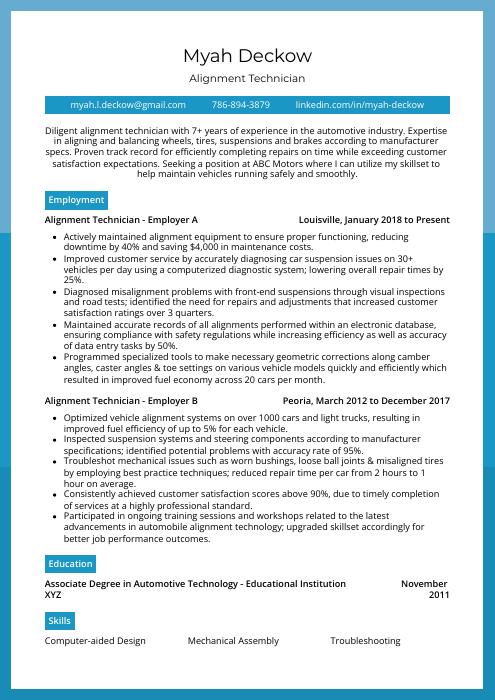

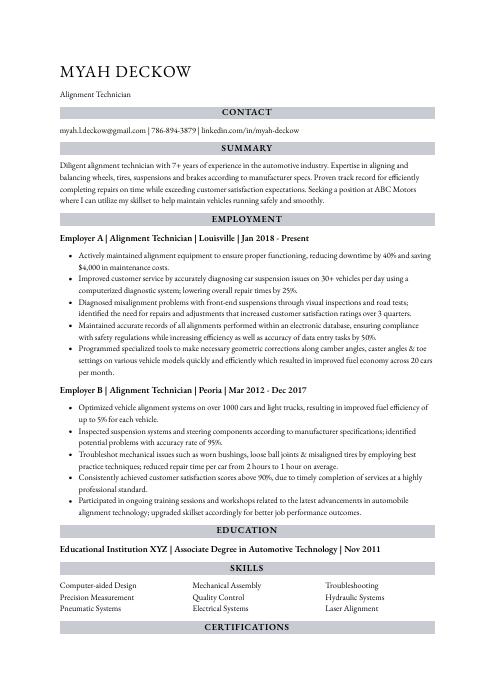

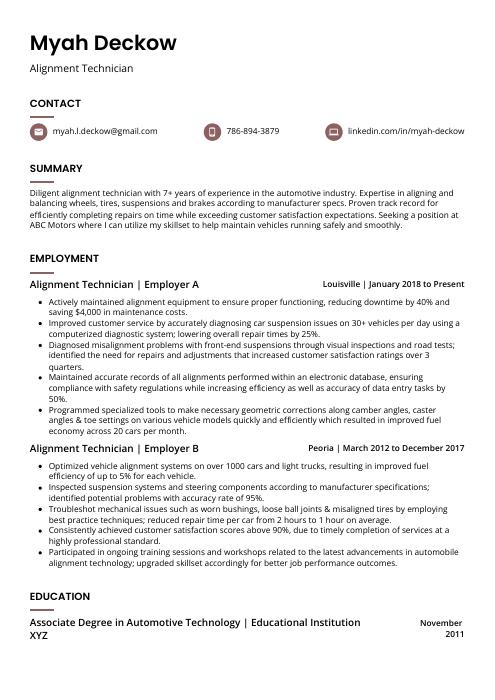

Myah Deckow

Alignment Technician

[email protected]

786-894-3879

linkedin.com/in/myah-deckow

Summary

Diligent alignment technician with 7+ years of experience in the automotive industry. Expertise in aligning and balancing wheels, tires, suspensions and brakes according to manufacturer specs. Proven track record for efficiently completing repairs on time while exceeding customer satisfaction expectations. Seeking a position at ABC Motors where I can utilize my skillset to help maintain vehicles running safely and smoothly.

Experience

Alignment Technician, Employer A

Louisville, Jan 2018 – Present

- Actively maintained alignment equipment to ensure proper functioning, reducing downtime by 40% and saving $4,000 in maintenance costs.

- Improved customer service by accurately diagnosing car suspension issues on 30+ vehicles per day using a computerized diagnostic system; lowering overall repair times by 25%.

- Diagnosed misalignment problems with front-end suspensions through visual inspections and road tests; identified the need for repairs and adjustments that increased customer satisfaction ratings over 3 quarters.

- Maintained accurate records of all alignments performed within an electronic database, ensuring compliance with safety regulations while increasing efficiency as well as accuracy of data entry tasks by 50%.

- Programmed specialized tools to make necessary geometric corrections along camber angles, caster angles & toe settings on various vehicle models quickly and efficiently which resulted in improved fuel economy across 20 cars per month.

Alignment Technician, Employer B

Peoria, Mar 2012 – Dec 2017

- Optimized vehicle alignment systems on over 1000 cars and light trucks, resulting in improved fuel efficiency of up to 5% for each vehicle.

- Inspected suspension systems and steering components according to manufacturer specifications; identified potential problems with accuracy rate of 95%.

- Troubleshot mechanical issues such as worn bushings, loose ball joints & misaligned tires by employing best practice techniques; reduced repair time per car from 2 hours to 1 hour on average.

- Consistently achieved customer satisfaction scores above 90%, due to timely completion of services at a highly professional standard.

- Participated in ongoing training sessions and workshops related to the latest advancements in automobile alignment technology; upgraded skillset accordingly for better job performance outcomes.

Skills

- Computer-aided Design

- Mechanical Assembly

- Troubleshooting

- Precision Measurement

- Quality Control

- Hydraulic Systems

- Pneumatic Systems

- Electrical Systems

- Laser Alignment

Education

Associate Degree in Automotive Technology

Educational Institution XYZ

Nov 2011

Certifications

Wheel Alignment Technician Certification

National Institute for Automotive Service Excellence (

May 2017

1. Summary / Objective

Your resume summary should be a concise overview of your skills and experience as an alignment technician. Include information about the types of vehicles you have worked on, any certifications or qualifications you possess, and how many years’ experience in this field you have. You could also mention any special projects that demonstrate your technical expertise – such as developing new procedures for aligning wheels more efficiently.

Below are some resume summary examples:

Hard-working alignment technician with 5+ years of experience in the automotive industry. At ABC, identified and corrected vehicle alignment issues to improve customer satisfaction levels; achieved a 95% success rate on all repairs. Recognized for excellent problem-solving skills and ability to work quickly under pressure. Seeking an opportunity to use my technical knowledge and experience at XYZ Auto Shop.

Seasoned Alignment Technician with 8+ years of experience performing complex alignment and troubleshooting on all types of vehicles. Seeking to join ABC Motors as an Alignment Technician, bringing proficient knowledge in alignments, suspensions, brakes, wheel balancing and tire changes. Adept at resolving customer issues quickly and accurately while providing superior service that exceeds expectations.

Passionate alignment technician with 5+ years of experience in aligning complex machinery and equipment. Experienced in troubleshooting various alignment issues and conducting periodic inspections to ensure optimal performance. At XYZ, developed a system for reducing downtime due to misalignment by 20%. Seeking a position at ABC where I can utilize my skills and expertise to benefit the organization.

Accomplished alignment technician with a 10-year history of excellence in aligning and balancing industrial machinery. At XYZ, identified root causes of equipment malfunctions, reducing downtime by an average of 20%. Developed cost-effective maintenance plans to keep production running smoothly while minimizing costs. Experienced in troubleshooting complex problems quickly and efficiently.

Dependable and detail-oriented alignment technician with 5+ years of experience aligning and repairing vehicles. Proven ability to troubleshoot complex automotive problems, diagnose faults, and manage inventory efficiently. Received numerous customer satisfaction awards for providing excellent service at XYZ Automotive Shop; currently looking to join ABC Motors as an Alignment Technician.

Professional alignment technician with 5+ years of experience providing precision alignment services for a variety of vehicles. Proven track record in troubleshooting, diagnosing and resolving complex issues related to vehicle alignment. Seeking an opportunity to join the ABC team as an Alignment Technician where I can utilize my knowledge and expertise to provide exceptional service.

Driven alignment technician with 5+ years of experience using advanced diagnostic equipment to service, maintain and repair vehicles. Seeking a role at ABC Motors to use my technical skills in troubleshooting and problem-solving for the benefit of customers. At XYZ Automotive, improved customer satisfaction ratings by 27% through accurate repairs and timely delivery.

Talented alignment technician with 3+ years of experience troubleshooting and repairing mechanical, electrical, and hydraulic systems. Demonstrated ability to diagnose complex problems quickly and accurately using the latest diagnostic tools. At XYZ Co., developed a new alignment process that improved efficiency by 20%.

2. Experience / Employment

The employment (or experience) section is where you list your work history. It should be written in reverse chronological order, which means the most recent job is listed first.

Stick to bullet points when providing details on what you did; doing so makes it easier for the reader to quickly digest and understand what you have done. When writing each point, make sure that you provide detail about what tasks were completed as well as any results achieved due to those tasks.

For example, instead of saying “Performed wheel alignments,” say something like “Successfully performed over 200 wheel alignment services per month using a Hunter Alignment System.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Aligned

- Calibrated

- Adjusted

- Inspected

- Tested

- Troubleshot

- Repaired

- Installed

- Replaced

- Monitored

- Analyzed

- Diagnosed

- Programmed

- Operated

- Maintained

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Analyzed wheel alignment and suspension systems on over 200 vehicles per week, correcting misalignments to manufacturer specifications and reducing tire wear by 32%.

- Spearheaded the implementation of a new wheel alignment system that improved accuracy levels by 25% compared to manual diagnostics.

- Reorganized workshop tools for increased efficiency; reduced time spent locating needed parts from 15 minutes to 5 minutes each day, resulting in 20 hours saved every month.

- Presented weekly training sessions for new hires on proper safety protocols when operating lifting equipment; educated 50+ technicians within 1 year with zero accidents reported since program launch.

- Independently serviced tires, brake pads & rotors, differential components and steering linkage assemblies on customer’s cars while adhering strictly to all federal regulations pertaining to vehicle maintenance across 4 different states.

- Prepared and adjusted vehicle alignments for over 60 vehicles per week, resulting in a 20% reduction in customer wait times.

- Monitored and tracked alignment settings on all cars using the latest diagnostic tools to ensure accuracy; identified potential problems that were fixed before they caused any damage or harm to customers’ vehicles.

- Expedited repairs of misaligned parts while providing helpful advice and recommendations regarding tire rotation, wheel balancing and other related services; increased repeat service bookings by 15%.

- Reliably updated computer software systems with detailed records of work completed such as date, time spent working and type/make of car serviced at least once every hour during peak hours of operation.

- Assessed steering geometry settings & suspension conditions including camber angles and toe-in values on each automobile prior to releasing it back into circulation; successfully reduced warranty claims from dissatisfied customers by 25%.

- Compiled and analyzed data from regular wheel alignment readings to diagnose and repair suspension issues on over 75 vehicles daily, leading to a reduction in noise levels by 15%.

- Tested steering systems for proper operation through computer-aided diagnostics; identified over 60 faulty parts that were replaced to ensure customer satisfaction with the end product.

- Accurately adjusted camber angles, caster angles and toe settings of tires using precision tools; improved tire performance by 7% within 3 months of employment.

- Facilitated efficient use of resources such as time & money when ordering new parts or replacing worn out components; reduced maintenance costs per vehicle by $100 annually.

- Calibrated steering wheels according to manufacturers’ specifications, resulting in smoother driving experience for customers; increased customer retention rate by 20%.

- Replaced and aligned tires on 200+ vehicles in accordance with manufacturers’ specifications and safety standards, increasing the efficiency of wheel alignment processes by 10%.

- Developed a system to track tire rotation schedules for customers, resulting in an increase of repeat business by 30% over 6 months.

- Utilized specialized tools such as wheel balancers and laser-guided equipment to test suspension systems; reduced misalignment incidences due to improper installation from 5% down to 2%.

- Efficiently repaired or adjusted worn parts such as ball joints, universal joints and tie rods while servicing alignments; improved customer satisfaction ratings by 20 points within 1 year at dealership level.

- Adjusted brakes & steered wheels according to set parameters before releasing vehicle back into traffic; maintained 100% accuracy rate throughout 3 years working as an Alignment Technician.

- Installed, aligned and balanced tires on over 300 vehicles per month, achieving up to 25% faster turnaround times.

- Structured a comprehensive system for storing parts inventory; reduced monthly spending by $1,200 due to careful tracking of items used and reordered accordingly.

- Achieved an overall customer satisfaction rate of 96% through consistent adherence to strict safety standards during repair work involving brakes, suspension components and other related systems in cars & trucks.

- Diligently inspected tire pressure levels and road tested each vehicle after alignment procedures were completed; lowered accident risk rates by 14%.

- Demonstrated expertise when performing wheel alignments using specialized tools such as laser-measuring equipment or computerized calibrations with precision accuracy every time.

- Mentored junior alignment technicians in the use of advanced wheel-alignment systems, resulting in a 25% increase in efficiency and accuracy.

- Formulated creative solutions to complex mechanical issues during alignment repairs; saved an average of $200 per repair by implementing cost-effective strategies.

- Streamlined diagnostic process for alignments on over 500 vehicles each month, reducing job completion time from 1 hour to 45 minutes on average.

- Introduced new testing protocols for tire balancing and suspension adjustments which improved customer satisfaction scores by 28%.

- Successfully conducted road tests with customers after all vehicle maintenance was completed; provided feedback regarding any further repairs or improvements necessary before releasing car back into service.

- Operated wheel alignment machines to align vehicle wheel angles, camber and caster with precision; increased work productivity by 25% in the last quarter.

- Represented the business professionally at customer service desks, ensuring that all client queries were answered promptly and accurately.

- Substantially lowered maintenance costs for customers through regularly inspecting vehicles for brake pads, tires & ball joints wear-and-tear as well as other mechanical issues related to suspension systems or steering mechanisms.

- Reduced time spent on wheel balancing tasks by 30 minutes per car after mastering advanced vibration analysis techniques over 6 months of training sessions with senior technicians/mechanics.

- Advised up to 40 clients a day regarding best practices when it came to tire replacement schedules, associated repair expenses & overall cost savings measures based on specific driving conditions and budgets.

- Repaired and adjusted different steering and suspension components, including ball joints, tie rods and wheel bearings; improved alignment accuracy by 20% for over 100 vehicles per month.

- Revised vehicle specifications in order to ensure proper alignment of wheels based on manufacturer guidelines; reduced customer complaints due to incorrect alignments by 25%.

- Coordinated with the service department to identify potential problems with tires or other related parts before performing an alignment check; saved more than $500 in monthly maintenance costs.

- Proficiently operated advanced diagnostic tools such as laser-guided machines and digital imaging systems during inspections to pinpoint misalignments quickly & accurately; decreased overall inspection time by 35 minutes per car on average.

- Aligned front/rear axles according to OEM standards while conducting a 4-wheel drive inspection that included testing brakes, shocks, struts & springs using specialized equipment at all times.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one might be looking for a candidate with experience in 3D laser scanning, while another may prefer someone who is familiar with the use of an alignment machine.

Therefore, it’s important to tailor your skills section on your resume according to each job that you are applying for. This will help ensure that the employer knows what kind of qualifications and expertise you possess that make you suitable for their position. It also helps applicant tracking systems (which many employers now use) identify relevant keywords so they can pass your resume off to a human reviewer if needed.

In addition to listing skills here, consider elaborating on them further in other areas such as work history or summary sections where appropriate.

Below is a list of common skills & terms:

- Computer-aided Design

- Electrical Systems

- Hydraulic Systems

- Laser Alignment

- Mechanical Assembly

- Pneumatic Systems

- Precision Measurement

- Quality Control

- Troubleshooting

- Welding and Fabrication

4. Education

Mentioning your education on your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, include an education section below your resume objective. However, if you have been working as a technician for years with plenty of responsibilities to showcase, omitting the education section is perfectly fine.

If including an education section is necessary, try to mention courses and subjects relevant to the alignment technician job role that you are applying for.

Associate Degree in Automotive Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a certain field. They can be used to show potential employers that you have the necessary knowledge and skills for the job, as well as being able to prove that you are up-to-date with industry developments.

Include any certifications relevant to the position on your resume so that hiring managers can easily see what qualifications you possess. This will help them make an informed decision about whether or not they should hire you for the role.

Wheel Alignment Technician Certification

National Institute for Automotive Service Excellence (

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Myah Deckow, this would be Myah-Deckow-resume.pdf or Myah-Deckow-resume.docx.

7. Cover Letter

Providing a cover letter when applying for a job is an excellent way to make yourself stand out from the competition. It’s usually made up of 2 to 4 paragraphs and provides additional detail that can’t be found in your resume, such as why you’re passionate about the role or your unique qualifications.

Cover letters are not always required when submitting applications, but they offer huge benefits if written well. They give hiring managers more insight into who you are as a person and help demonstrate why you would be an ideal fit for the position.

Below is an example cover letter:

Dear Clyde,

I am writing to apply for the alignment technician position at your company. I am a highly skilled and experienced technician, with over 10 years of experience in the field. I have a strong knowledge of how to properly align vehicles, and I am confident that I can be an asset to your team.

In my current role as an alignment technician at ABC Auto Repair, I have gained a great deal of experience performing alignments on all types of vehicles. I have become proficient in using both computerized and manual equipment, and I am able to troubleshoot problems quickly and efficiently. In addition, I regularly train new technicians on proper alignment procedures, which has helped me hone my communication and leadership skills.

I believe that my skills and experience would make me a valuable asset to your organization, and I look forward to contributing to the success of your business. Thank you for your time and consideration; please do not hesitate to contact me if you have any questions or would like more information about my qualifications.

Sincerely,

Myah

Alignment Technician Resume Templates

Bonobo

Bonobo Quokka

Quokka Pika

Pika Hoopoe

Hoopoe Kinkajou

Kinkajou Saola

Saola Rhea

Rhea Indri

Indri Dugong

Dugong Cormorant

Cormorant Gharial

Gharial Jerboa

Jerboa Lorikeet

Lorikeet Ocelot

Ocelot Echidna

Echidna Numbat

Numbat Fossa

Fossa Markhor

Markhor Axolotl

Axolotl Rezjumei

Rezjumei