Aircraft Sheet Metal Mechanic Resume Guide

Aircraft sheet metal mechanics work to repair, maintain, and fabricate components of aircraft. They use a variety of tools such as drills, saws, rivet guns and other tools to cut out pieces from sheets of aluminum or steel for replacement parts. They also assemble the new parts using bolts and screws in order to ensure that the repaired component meets safety standards before installation into an aircraft.

You have all the skills required to work on aircraft sheet metal, but potential employers don’t know who you are. To make them aware of your expertise and experience, you must write a resume that stands out from the competition.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

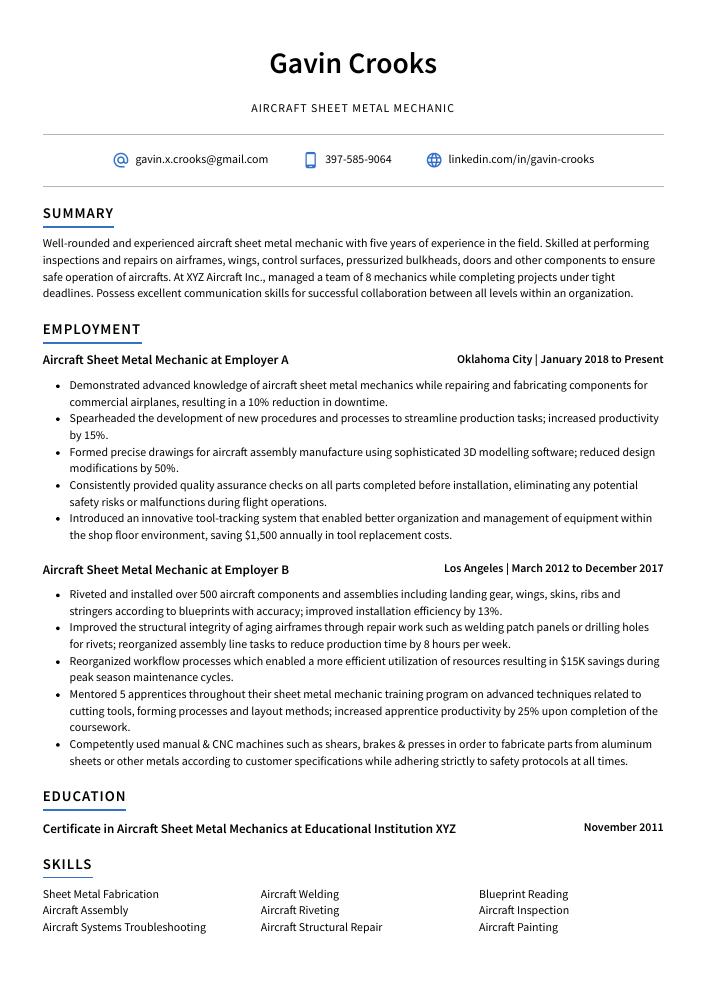

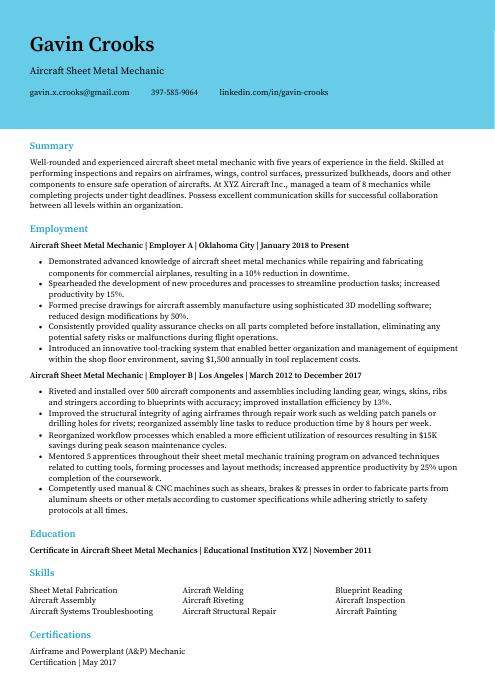

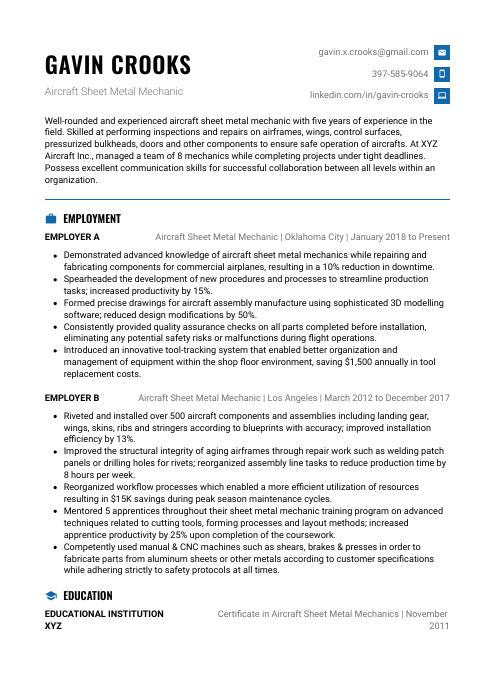

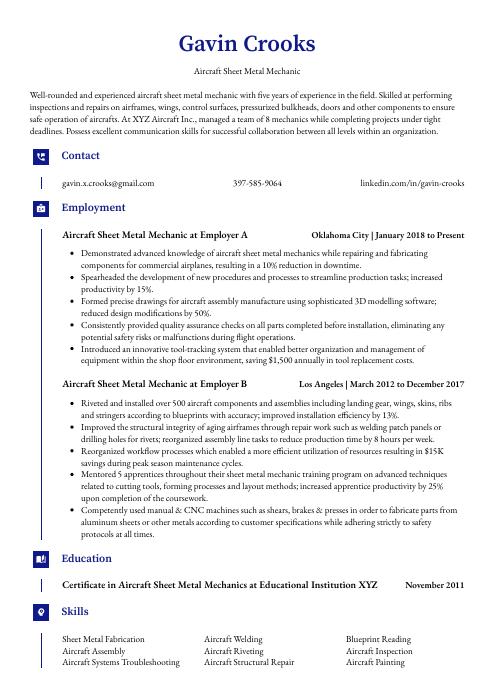

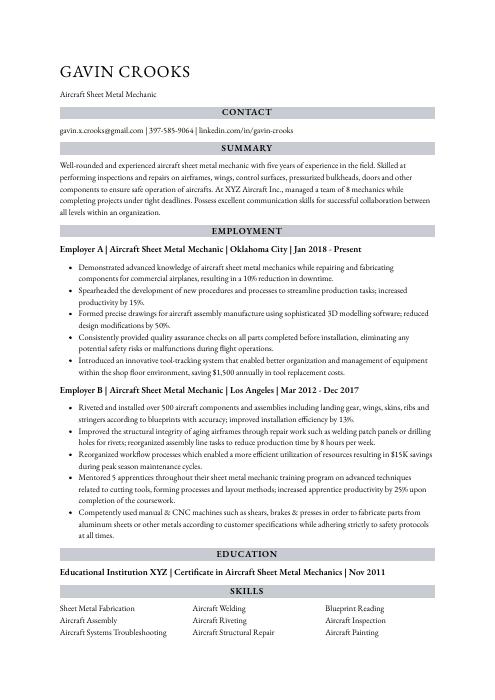

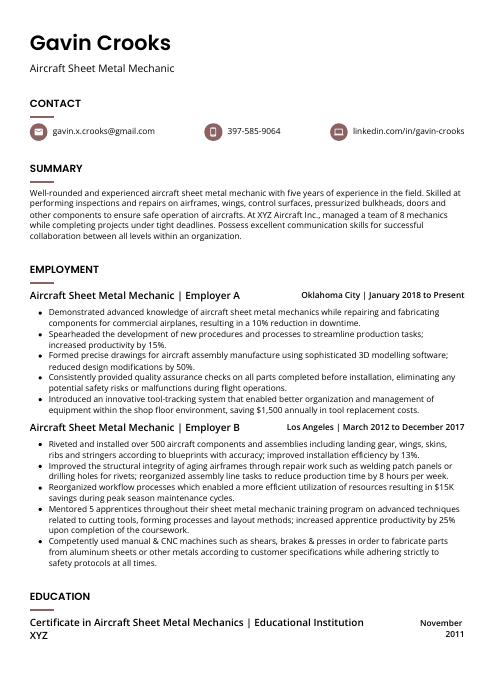

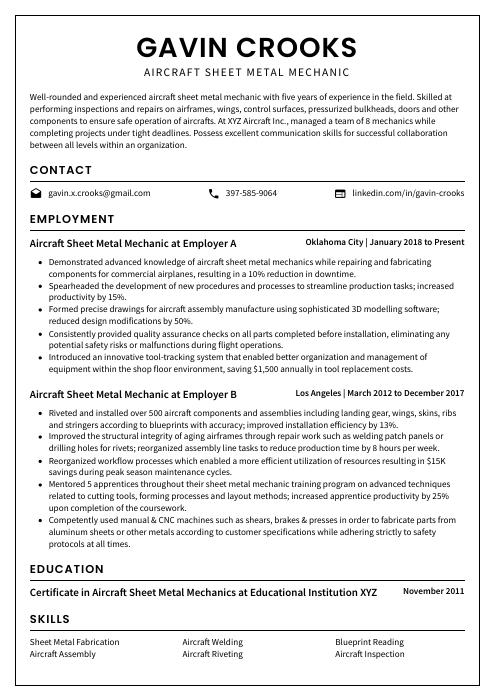

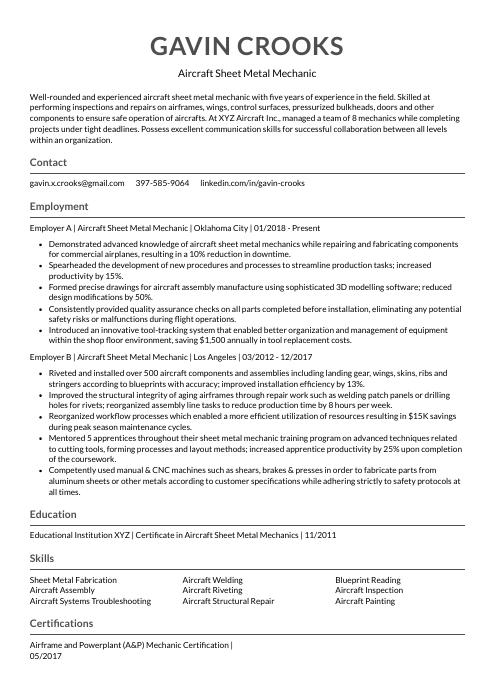

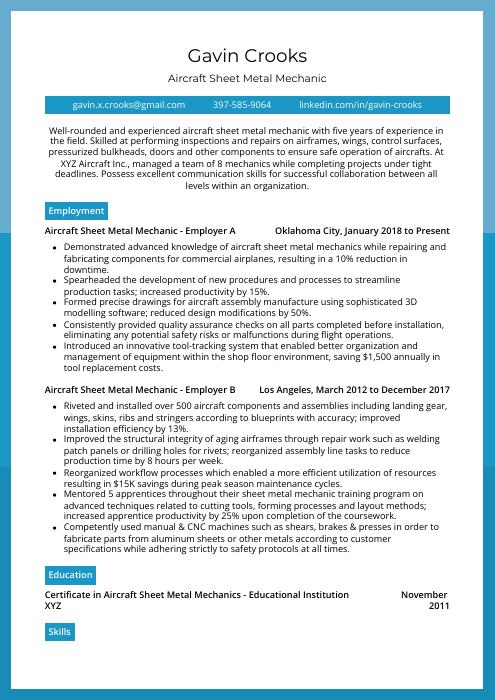

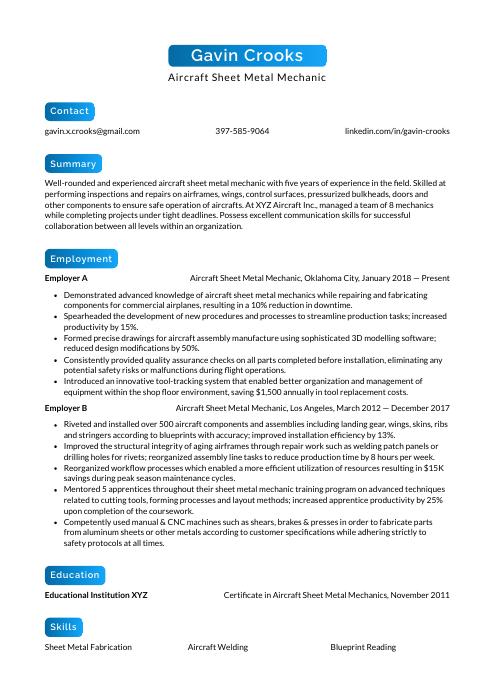

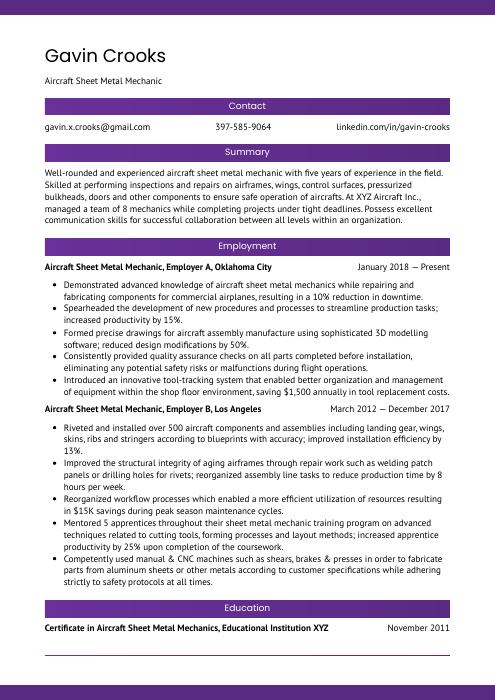

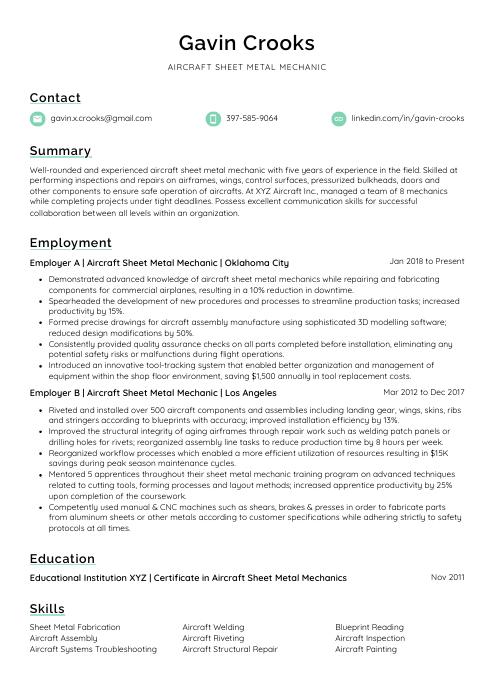

Aircraft Sheet Metal Mechanic Resume Sample

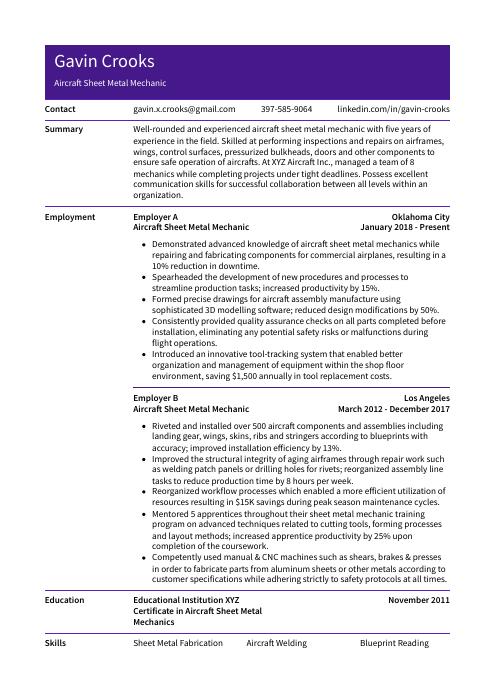

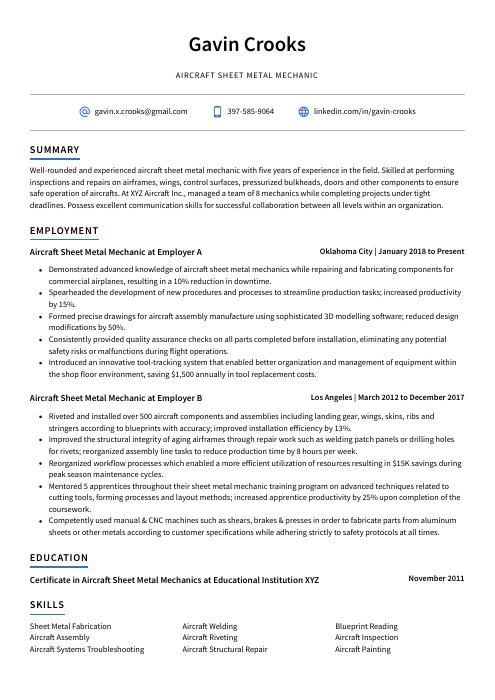

Gavin Crooks

Aircraft Sheet Metal Mechanic

[email protected]

397-585-9064

linkedin.com/in/gavin-crooks

Summary

Well-rounded and experienced aircraft sheet metal mechanic with five years of experience in the field. Skilled at performing inspections and repairs on airframes, wings, control surfaces, pressurized bulkheads, doors and other components to ensure safe operation of aircrafts. At XYZ Aircraft Inc., managed a team of 8 mechanics while completing projects under tight deadlines. Possess excellent communication skills for successful collaboration between all levels within an organization.

Experience

Aircraft Sheet Metal Mechanic, Employer A

Oklahoma City, Jan 2018 – Present

- Demonstrated advanced knowledge of aircraft sheet metal mechanics while repairing and fabricating components for commercial airplanes, resulting in a 10% reduction in downtime.

- Spearheaded the development of new procedures and processes to streamline production tasks; increased productivity by 15%.

- Formed precise drawings for aircraft assembly manufacture using sophisticated 3D modelling software; reduced design modifications by 50%.

- Consistently provided quality assurance checks on all parts completed before installation, eliminating any potential safety risks or malfunctions during flight operations.

- Introduced an innovative tool-tracking system that enabled better organization and management of equipment within the shop floor environment, saving $1,500 annually in tool replacement costs.

Aircraft Sheet Metal Mechanic, Employer B

Los Angeles, Mar 2012 – Dec 2017

- Riveted and installed over 500 aircraft components and assemblies including landing gear, wings, skins, ribs and stringers according to blueprints with accuracy; improved installation efficiency by 13%.

- Improved the structural integrity of aging airframes through repair work such as welding patch panels or drilling holes for rivets; reorganized assembly line tasks to reduce production time by 8 hours per week.

- Reorganized workflow processes which enabled a more efficient utilization of resources resulting in $15K savings during peak season maintenance cycles.

- Mentored 5 apprentices throughout their sheet metal mechanic training program on advanced techniques related to cutting tools, forming processes and layout methods; increased apprentice productivity by 25% upon completion of the coursework.

- Competently used manual & CNC machines such as shears, brakes & presses in order to fabricate parts from aluminum sheets or other metals according to customer specifications while adhering strictly to safety protocols at all times.

Skills

- Sheet Metal Fabrication

- Aircraft Welding

- Blueprint Reading

- Aircraft Assembly

- Aircraft Riveting

- Aircraft Inspection

- Aircraft Systems Troubleshooting

- Aircraft Structural Repair

- Aircraft Painting

Education

Certificate in Aircraft Sheet Metal Mechanics

Educational Institution XYZ

Nov 2011

Certifications

Airframe and Powerplant (A&P) Mechanic Certification

May 2017

1. Summary / Objective

Your resume summary/objective should give the employer an overview of your experience and qualifications as an aircraft sheet metal mechanic. In this section, you can highlight any certifications or specializations you have obtained, such as FAA certification in airframe repair or specialized training in composite materials. You should also mention how many years of experience you have working with different types of aircrafts and what sets you apart from other applicants.

Below are some resume summary examples:

Energetic and detail-oriented aircraft sheet metal mechanic with 5+ years of experience in the aerospace industry. Skilled at performing repairs and modifications on a variety of airframes, from single-engine piston to high-performance jets. Recognized for consistently meeting tight deadlines without compromising safety standards or quality assurance. Seeking to join ABC Airline as an Aircraft Sheet Metal Mechanic and help ensure safe maintenance operations for its fleet.

Talented and experienced aircraft sheet metal mechanic with 10+ years of experience in the aviation industry. Highly skilled in performing a wide range of maintenance and repair tasks on fuselage, wings, tail assemblies, engines and propellers. Proven ability to troubleshoot problems efficiently while ensuring safety regulations are strictly followed at all times. At XYZ Airline received numerous awards for outstanding performance and commitment to excellence.

Seasoned aircraft sheet metal mechanic with 5+ years of experience in aerospace manufacturing. Experienced in inspecting, repairing, and fabricating aircraft components according to OEM specifications. At ABC Aerospace I successfully completed various projects including the overhauling of three Boeing 747s under tight deadlines. Received numerous recognition awards for my exceptional workmanship and attention to detail from senior management at XYZ Airlines.

Enthusiastic aircraft sheet metal mechanic with 7+ years of experience in the aviation industry. Skilled at performing maintenance, repairs and inspections on aircraft components to ensure airworthiness. Adept at troubleshooting malfunctions quickly and efficiently while adhering to safety protocols set forth by the FAA. At ABC, reduced total time spent completing routine tasks from 4 hours to 2 hours per day via streamlining techniques.

Committed aircraft sheet metal mechanic with 8+ years of experience performing maintenance and repairs on a variety of aircraft. Proven track record in improving the performance, efficiency, and safety of aircrafts through preventative maintenance. Skilled at interpreting technical documents such as blueprints and schematics for repair work. Received company award for developing an innovative technique to reduce downtime by 20%.

Professional aircraft sheet metal mechanic with 7+ years of experience in the aviation industry. At XYZ, responsible for all aspects of aircraft repair and maintenance: troubleshooting, welding/fabrication, sheet metal work, painting, and inspection. Dedicated to ensuring safety standards are met while providing quality customer service. Proven track record of successful projects on time and under budget.

Driven aircraft sheet metal mechanic with more than 5 years of experience in aircraft assembly, welding, and fabrication. Seeking to join ABC Technologies to utilize my expertise in airplane maintenance and repair processes. In previous roles, consistently met tight deadlines without compromising quality or safety standards while working on several military aircrafts.

Reliable aircraft sheet metal mechanic with 10+ years of experience in assembling, fabricating and repairing aircraft structures. Skilled at troubleshooting issues, reading blueprints and maintaining a safe work environment. Seeking to join ABC Airline as an aircraft sheet metal mechanic to help keep its fleet of planes in pristine condition.

2. Experience / Employment

The employment (or experience) section of your resume is where you provide details about your work history. It should be written in reverse chronological order, starting with the most recent job and moving backward from there.

Stick to bullet points when writing this section; doing so allows the reader to quickly take in what you have to say. When stating what you did, make sure that each point has detail and quantifiable results if possible.

For example, instead of saying “Repaired aircraft sheet metal,” you could say, “Successfully repaired damaged aircraft sheet metal components using a variety of tools including rivet guns and drill presses; reduced repair time by 15%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Fabricated

- Assembled

- Installed

- Inspected

- Aligned

- Drilled

- Formed

- Welded

- Riveted

- Sanded

- Filed

- Bolted

- Soldered

- Repaired

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Welded aircraft structural components using MIG and TIG welding techniques, achieving a successful repair rate of 95% on over 300 aircrafts in the last year.

- Repaired damaged sheet metal structures by fabricating replacement pieces and riveting them into place; completed projects up to 8 hours ahead of schedule with zero errors or omissions.

- Compiled detailed reports on inspection results for each aircraft’s fuselage, wings, empennage & landing gear assembly; identified potential safety risks before they had a chance to cause harm or delays in flight operations.

- Effectively managed all parts inventory for assigned projects ensuring that supplies were always available when needed, resulting in $12K worth of cost savings during the past fiscal year due to reduced downtime from ordering new materials/parts.

- Revised existing technical manuals related to airframe maintenance procedures upon request from management team members; successfully updated documentation within 24-hours without compromising accuracy or detail of information provided.

- Fabricated and assembled aircraft sheet metal components to exact specifications, accurately meeting tolerances over 90% of the time and reducing assembly times by 30%.

- Formulated solutions for all mechanical issues related to airframes and supported structures; successfully resolved 15+ technical cases in a timely manner without compromising safety standards.

- Advised other mechanics on proper operation techniques regarding advanced vehicle systems such as hydraulics, pneumatics, electronics and fuel system maintenance tasks.

- Completed repairs on more than 50 damaged parts within two days using riveting tools and hot-work processes while strictly adhering to FAA regulations at all times.

- Diagnosed complex structural problems with sound knowledge of best practices in aviation industry through visual inspection methods & non-destructive testing (NDT) procedures; decreased overall repair costs by 40%.

- Participated in the maintenance and repair of aircraft fuselages, wings, engine nacelles and other sheet metal components; inspected parts for wear or damage and replaced any defective items.

- Installed new structural components with precision using riveting tools, welding equipment, C-clamps & clecos as needed to ensure a secure fit; reduced labor time per inspection by 10%.

- Confidently worked on complex repairs involving aluminum alloys such as 2024-T6/T73/T81 while following blueprints accurately; produced quality sheet metal assemblies that met manufacturer specifications in half the standard time frame.

- Soldered together airframe structures according to drawing requirements using oxyacetylene torches for cutting operations; successfully completed 50+ joinery tasks within tight deadlines without compromising safety standards or product integrity.

- Troubleshot electrical systems related issues including wiring harnesses used in modern aircrafts utilizing test equipment such as ohmmeters & multimeters when necessary; identified faulty components quickly resulting in cost savings of $1k over 3 months period.

- Proficiently repaired, maintained and replaced sheet metal components on aircrafts using various tools including grinders, drills and rivet guns; reduced downtime of aircrafts by an average of 2 hours per repair.

- Facilitated the installation of new skin panels or replacement parts to existing door frames, fuselages and wings while ensuring compliance with safety regulations; completed repairs for over 40 planes in the last year.

- Utilized a variety of materials such as aluminum alloys, steel alloyed metals and titanium for manufacturing aircraft sheets according to specifications provided by engineers/designers in a timely manner.

- Reduced labor costs associated with sheetmetal repairs by 10% through efficient time management techniques when working on complex tasks across multiple projects simultaneously.

- Streamlined inventory processes within the hangar facilities which included tracking material shipments from suppliers & stockroom shelves; managed storage space usage efficiently resulting in cost savings up to $1K monthly.

- Sanded, grinded, and painted aircraft sheet metal components to install and repair structures on over 350 planes in the last 2 years; achieved an average of 20 repairs per week with no quality issues.

- Achieved 95% accuracy when drilling holes into panels and fuselage during installation projects; expedited turnaround time by 30 minutes on all parts replacement tasks.

- Reliably cleaned, inspected, repaired or replaced defective structural components such as frames, stringers & ribs according to safety standards and manufacturer specifications at all times.

- Structured maintenance programs for routine inspections of airframes while performing pre-flight tests to ensure that all systems were functioning properly before each flight took off from the runway safely; reduced incidents of faulty engines/aircrafts by 25%.

- Collaborated closely with aviation engineers to troubleshoot any mechanical errors in a timely manner using precision instruments like micrometers & calipers; saved $8K+ spent on external technician services over 6 months period due diligence efforts.

- Actively inspected, maintained and repaired over 100+ aircraft sheet metal parts including fuselages, wings and tail surfaces to ensure safety regulations were met; reduced repair time by 10% compared to industry standard.

- Drilled rivets into aluminum alloy skins for the installation of stringers and bulkheads in order to rebuild damaged components on planes according to manufacturer specifications.

- Coordinated with other technicians in a team environment for the fabrication of complex parts such as flight control systems, airframes, fuel tanks or landing gear actuators; achieved perfect accuracy levels every time when working on these projects from start-to-finish.

- Filed down rough edges & burrs while using manual hand tools like grinders & shears; improved overall product quality by 15%.

- Optimized productivity through effective use of machinery such as hydraulic brakes & presses that were used for forming frames around windows or door openings on commercial airplanes – completed tasks 35% faster than expected!

- Assessed the condition of aircraft sheet metal components and identified repair needs while using various tools such as x-ray machines, hammers, drills and rivet guns; reduced turnaround time for repairs by 30%.

- Prepared detailed work plans for the installation of new parts to ensure that all safety regulations were followed during the process.

- Successfully replaced over 150 damaged or worn out sheet metal components on a range of commercial aircrafts within an allotted timeframe of nine hours each day; improved production efficiency by 15%.

- Bolted together structural frames with fasteners like bolts, screws and rivets; inspected completed joints to verify accuracy in accordance with blueprints and engineering specifications.

- Aligned subassemblies into position using jigs & fixtures before final welding operations, achieving precision tolerances up to 0.1 millimeters per component part manufactured – leading to zero customer complaints about product quality in past year(s).

- Meticulously inspected and repaired aircraft sheet metal components according to FAA regulations, resulting in a 20% reduction in time required for scheduled maintenance.

- Presented the new safety procedures to over 80 mechanics on staff, leading to improved quality control protocols and increased efficiency of production processes by 10%.

- Represented the company at trade shows and conferences throughout the region; acquired 25+ new clients as a result.

- Developed innovative solutions for complex aircraft problems while collaborating with engineering teams; reduced repair costs by $50K annually through process improvements alone.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in aircraft repair, while another may be looking for someone with knowledge of sheet metal fabrication.

Therefore, it is important to tailor the skills section of your resume to each job you are applying for. This will help ensure that applicant tracking systems (which many employers use) pick up on the relevant keywords and pass your resume along to a human reviewer.

In addition, this section should not just list out all applicable skills; rather, it’s best practice to also elaborate on them further in other areas such as the summary or work history sections.

Below is a list of common skills & terms:

- Aircraft Assembly

- Aircraft Inspection

- Aircraft Maintenance and Repair

- Aircraft Painting

- Aircraft Riveting

- Aircraft Structural Repair

- Aircraft Systems Troubleshooting

- Aircraft Welding

- Blueprint Reading

- Sheet Metal Fabrication

4. Education

Adding an education section to an aircraft sheet metal mechanic resume will depend on your experience level. If you just graduated and have no work history, it is important to mention your education below the resume objective. However, if you have several years of experience in this field, including the education section may be optional or unnecessary depending on how much other relevant information you can include in its place.

If an education section is included, make sure to list any courses related to aircraft sheet metal mechanics that are applicable for the job position being applied for.

Certificate in Aircraft Sheet Metal Mechanics

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and expertise in a particular field. They show potential employers that you have been tested by an accredited organization, which can give you an edge over other applicants who may not be certified.

When applying for jobs, include any certifications relevant to the position on your resume so hiring managers can see how qualified you are for the role. This will help them make their decision when it comes time to choose between candidates.

Airframe and Powerplant (A&P) Mechanic Certification

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Gavin Crooks, this would be Gavin-Crooks-resume.pdf or Gavin-Crooks-resume.docx.

7. Cover Letter

Submitting a cover letter with your job application is a great way to provide the employer with more insight into who you are and why you’re an ideal fit for the role. A cover letter should be made up of 2-4 paragraphs, separate from your resume, that explain in detail what makes you suitable for the position.

Although it’s not always necessary to include a cover letter in every application, writing one can really set you apart from other applicants and showcase your unique skillset. It also gives employers an opportunity to get to know more about who they are considering hiring on a personal level.

Below is an example cover letter:

Dear Krista,

I am writing to apply for the Aircraft Sheet Metal Mechanic position at XYZ Aviation. With more than 10 years of experience in aircraft sheet metal maintenance and repair, I am confident I can make a positive contribution to your organization.

In my current role as an Aircraft Sheet Metal Mechanic with ABC Airlines, I am responsible for performing a variety of tasks related to the maintenance and repair of aircraft sheet metal components. These tasks include inspecting components for damage, repairing or replacing damaged components, and installing new components. In addition, I often work closely with other members of the maintenance team to troubleshoot problems and ensure that all repairs are completed correctly and in a timely manner.

Through my experience working on a variety of different types of aircraft, I have developed strong skills in both manual and computer-aided sheet metal fabrication methods. In addition, my attention to detail and commitment to safety has allowed me to consistently produce high-quality work that meets or exceeds the expectations of my employers.

I believe that my skills and experience would be an asset to your organization, and I look forward to speaking with you about this opportunity in the future. Thank you for your time and consideration.

Sincerely,

Gavin

Aircraft Sheet Metal Mechanic Resume Templates

Dugong

Dugong Ocelot

Ocelot Quokka

Quokka Hoopoe

Hoopoe Echidna

Echidna Gharial

Gharial Bonobo

Bonobo Markhor

Markhor Numbat

Numbat Fossa

Fossa Cormorant

Cormorant Indri

Indri Rhea

Rhea Kinkajou

Kinkajou Jerboa

Jerboa Lorikeet

Lorikeet Saola

Saola Pika

Pika Axolotl

Axolotl Rezjumei

Rezjumei