Aircraft Maintenance Engineer Resume Guide

Aircraft maintenance engineers are responsible for inspecting, testing, and repairing aircraft components to ensure they meet safety standards. They diagnose any malfunctions or damages on the engines and other parts of an aircraft before it is flown. Furthermore, they also perform routine inspections throughout the life cycle of an aircraft in order to maintain its airworthiness.

As an aircraft maintenance engineer, you have the know-how to keep planes in top condition. But hiring managers won’t be aware of your experience unless you create a resume that stands out from the competition.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

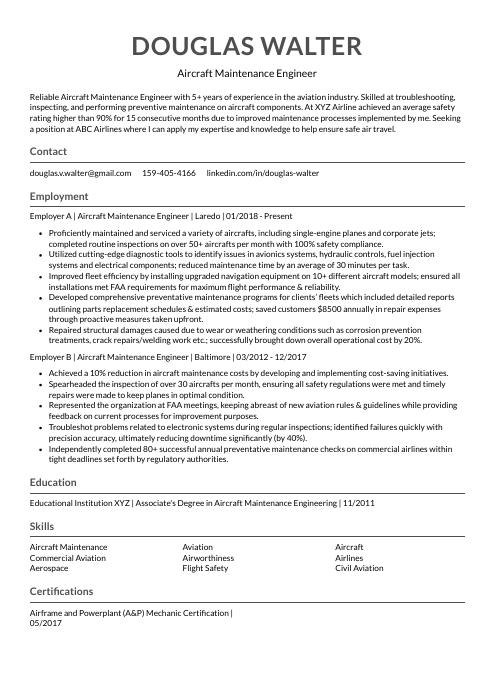

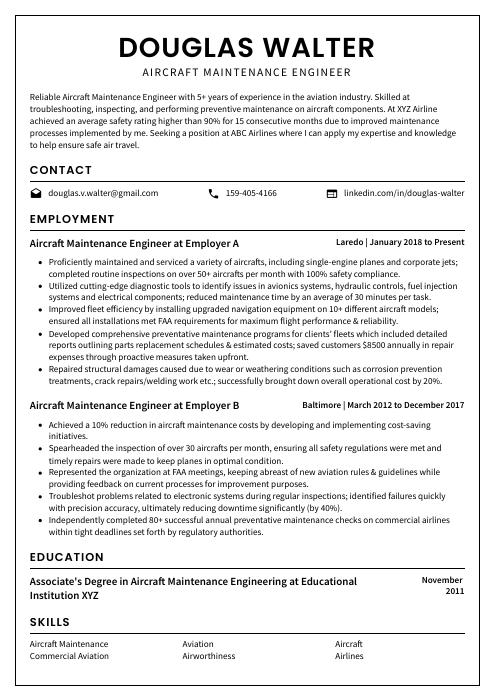

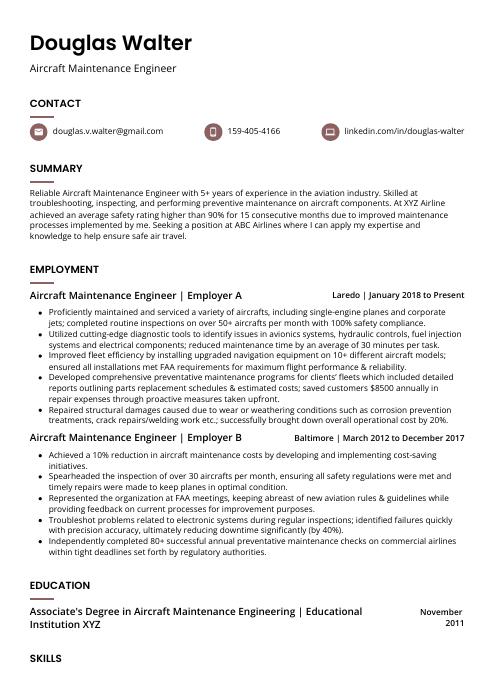

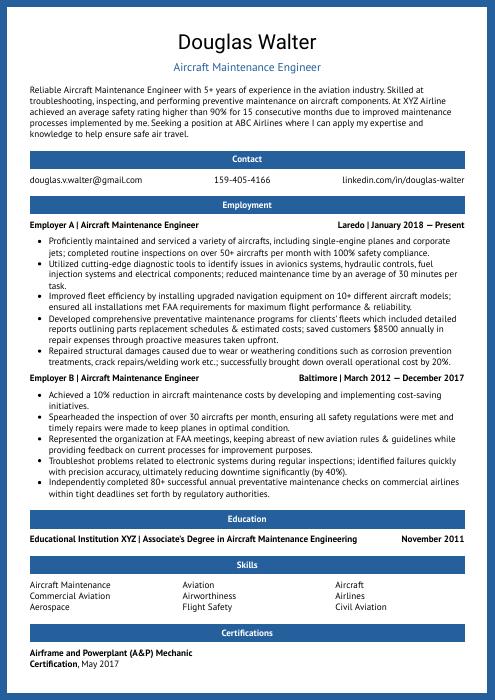

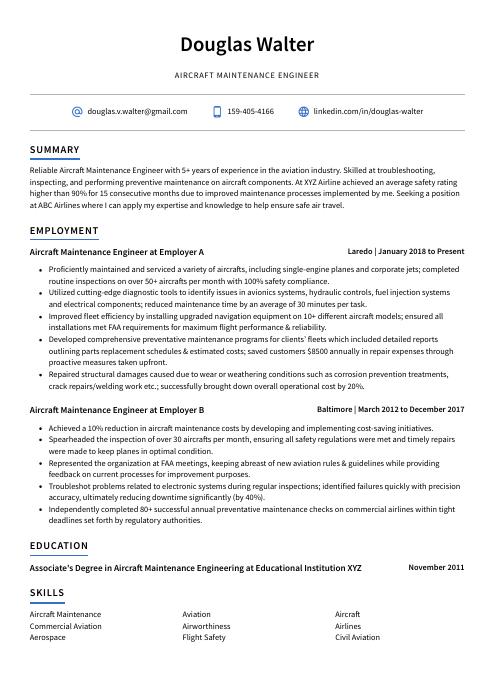

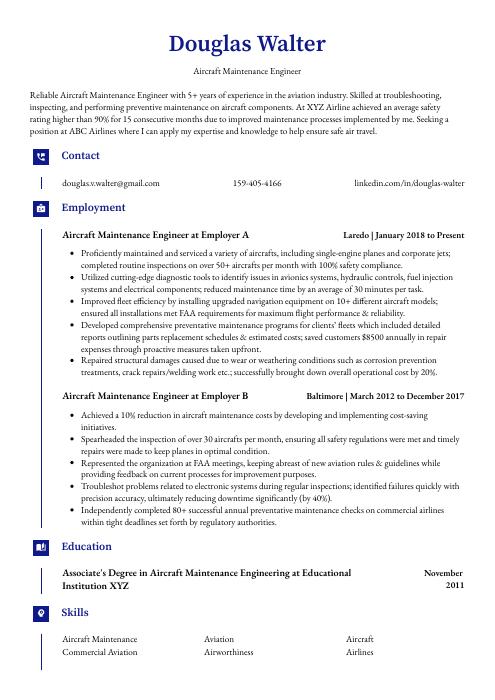

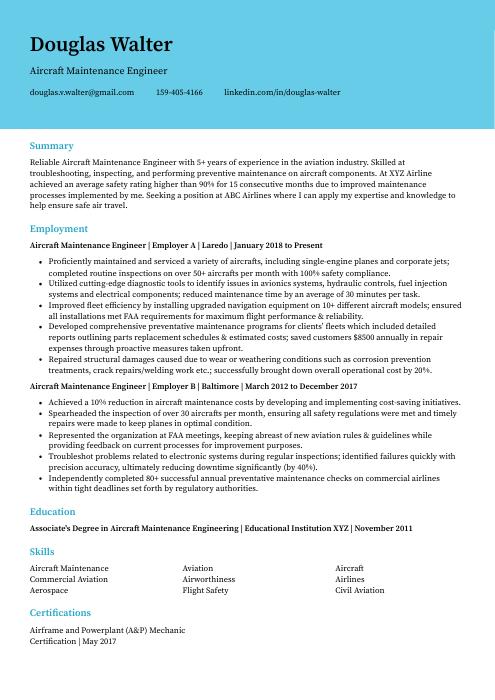

Aircraft Maintenance Engineer Resume Sample

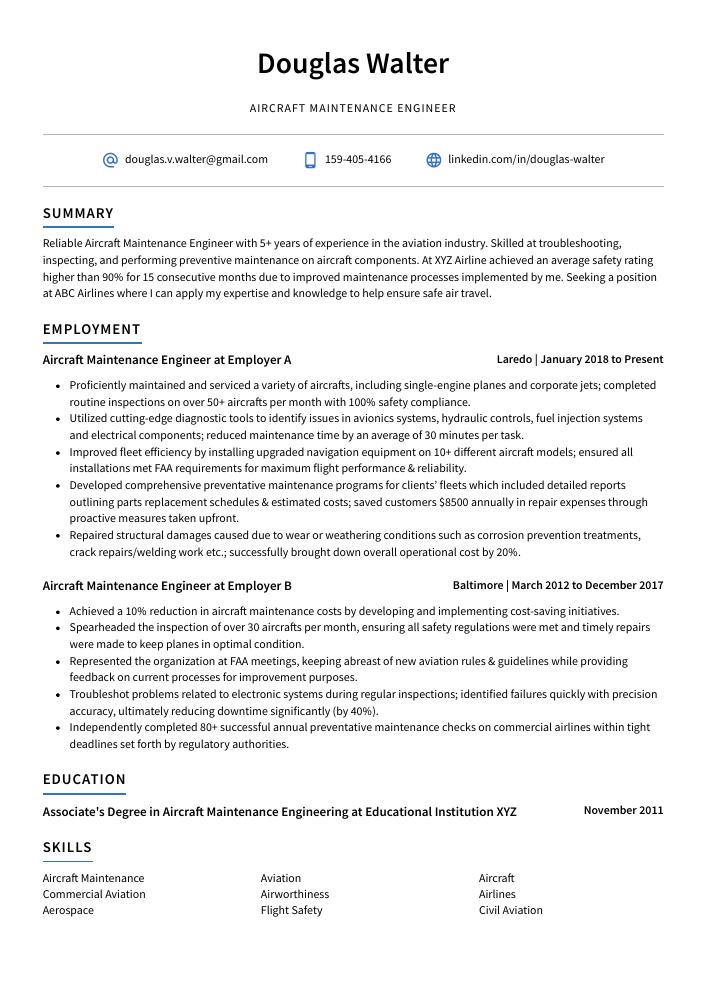

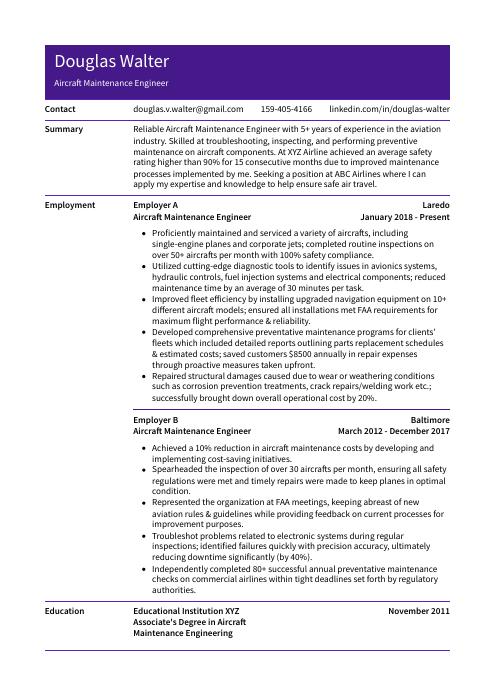

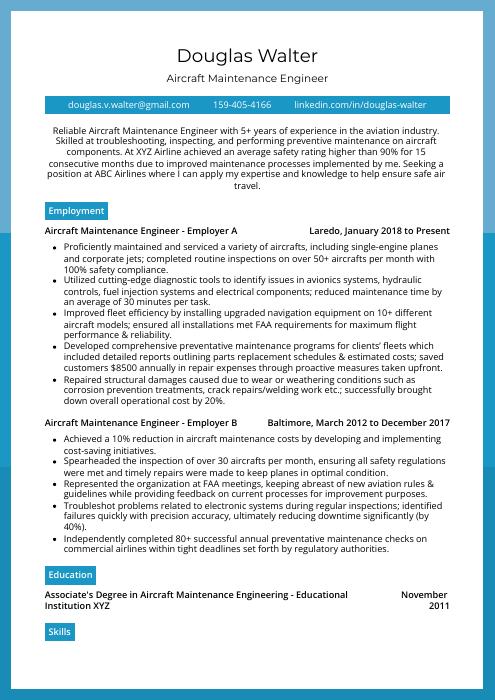

Douglas Walter

Aircraft Maintenance Engineer

[email protected]

159-405-4166

linkedin.com/in/douglas-walter

Summary

Reliable Aircraft Maintenance Engineer with 5+ years of experience in the aviation industry. Skilled at troubleshooting, inspecting, and performing preventive maintenance on aircraft components. At XYZ Airline achieved an average safety rating higher than 90% for 15 consecutive months due to improved maintenance processes implemented by me. Seeking a position at ABC Airlines where I can apply my expertise and knowledge to help ensure safe air travel.

Experience

Aircraft Maintenance Engineer, Employer A

Laredo, Jan 2018 – Present

- Proficiently maintained and serviced a variety of aircrafts, including single-engine planes and corporate jets; completed routine inspections on over 50+ aircrafts per month with 100% safety compliance.

- Utilized cutting-edge diagnostic tools to identify issues in avionics systems, hydraulic controls, fuel injection systems and electrical components; reduced maintenance time by an average of 30 minutes per task.

- Improved fleet efficiency by installing upgraded navigation equipment on 10+ different aircraft models; ensured all installations met FAA requirements for maximum flight performance & reliability.

- Developed comprehensive preventative maintenance programs for clients’ fleets which included detailed reports outlining parts replacement schedules & estimated costs; saved customers $8500 annually in repair expenses through proactive measures taken upfront.

- Repaired structural damages caused due to wear or weathering conditions such as corrosion prevention treatments, crack repairs/welding work etc.; successfully brought down overall operational cost by 20%.

Aircraft Maintenance Engineer, Employer B

Baltimore, Mar 2012 – Dec 2017

- Achieved a 10% reduction in aircraft maintenance costs by developing and implementing cost-saving initiatives.

- Spearheaded the inspection of over 30 aircrafts per month, ensuring all safety regulations were met and timely repairs were made to keep planes in optimal condition.

- Represented the organization at FAA meetings, keeping abreast of new aviation rules & guidelines while providing feedback on current processes for improvement purposes.

- Troubleshot problems related to electronic systems during regular inspections; identified failures quickly with precision accuracy, ultimately reducing downtime significantly (by 40%).

- Independently completed 80+ successful annual preventative maintenance checks on commercial airlines within tight deadlines set forth by regulatory authorities.

Skills

- Aircraft Maintenance

- Aviation

- Aircraft

- Commercial Aviation

- Airworthiness

- Airlines

- Aerospace

- Flight Safety

- Civil Aviation

Education

Associate’s Degree in Aircraft Maintenance Engineering

Educational Institution XYZ

Nov 2011

Certifications

Airframe and Powerplant (A&P) Mechanic Certification

May 2017

1. Summary / Objective

Your resume summary is like a movie trailer – it should provide the employer with an outline of your skills and experience as an aircraft maintenance engineer. In this section, you can highlight what makes you stand out from other candidates; for example, mention any certifications or qualifications that make you unique, such as FAA certification in airframe & powerplant mechanics. You could also talk about how many years’ experience you have working on commercial aircrafts and list some of the major projects/repairs that you’ve completed successfully.

Below are some resume summary examples:

Detail-oriented aircraft maintenance engineer with 5+ years of experience in the aviation industry. Experienced in troubleshooting and repairing all components of aircrafts, including engines, hydraulics systems and avionics. At XYZ Airlines, identified a recurring issue which improved fuel efficiency by 12% and reduced engine noise levels by 10%. Skilled at interpreting complex engineering documents such as technical manuals for efficient repairs.

Hard-working and experienced Aircraft Maintenance Engineer with 5+ years of experience performing maintenance, repairs and inspections on commercial aircraft. Possess FAA-approved certification for airframe, powerplant repair and avionics systems. At XYZ Airlines successfully completed over 150 A & C checks with zero discrepancies. Committed to providing superior customer service while ensuring safety standards are met or exceeded at all times.

Amicable and highly experienced aircraft maintenance engineer with 8+ years of experience on different types of commercial and military aircrafts. Seeking to join ABC Aviation as a part of the team, where I can utilize my expertise in troubleshooting and repair to ensure the safety and reliability of their flight operations. In previous roles, identified potential defects before they became major issues saving over $200K in repairs.

Diligent aircraft maintenance engineer with 8+ years of experience in aircraft inspection and repair. Adept at troubleshooting, analyzing data for trends and anomalies, creating preventive maintenance plans, and working collaboratively to ensure optimal performance of all aircraft components. Seeking to join ABC Technologies as a Maintenance Engineer where I can utilize my expertise to maintain the safety standards of their fleet.

Proficient aircraft maintenance engineer with 8+ years of experience in providing technical support, troubleshooting and diagnosing mechanical problems on a variety of aircrafts. Recognized for the ability to use advanced tools, techniques, and procedures while quickly resolving issues related to aircraft performance. Seeking to apply expertise at ABC Aerospace where I can help ensure safe flight operations.

Professional aircraft maintenance engineer with 6+ years of experience in scheduled and unscheduled aircraft maintenance. Skilled in troubleshooting and providing technical support for a variety of commercial, military, and private aviation customers. Looking to leverage my expertise as an Aircraft Maintenance Engineer at ABC Aviation Solutions to ensure the highest quality standards are met on each project.

Passionate and experienced aircraft maintenance engineer with a proven track record of overseeing the successful completion of complex repairs and overhauls. 8+ years in delivering safe, efficient, and cost-effective maintenance solutions for commercial airlines across the world. At XYZ Airlines, reduced unscheduled downtime by 15% while maintaining strict adherence to safety regulations.

Talented aircraft maintenance engineer with 8+ years of experience in the aviation industry. Adept at performing preventive and corrective maintenance on various aircraft systems, including engines, landing gears, hydraulic components, avionics systems and instruments. Proven track record of ensuring that all work is completed according to FAA regulations and manufacturer guidelines.

2. Experience / Employment

Next comes the work history section, which should be written in reverse chronological order, meaning your most recent job is listed first.

When writing the bullet points for this section, you want to provide detail and explain what you did as well as any results obtained. For example, instead of saying “Performed maintenance on aircraft,” you could say, “Conducted routine inspections and repairs on a variety of commercial aircrafts including Boeing 737s and Airbus A320s; reduced repair time by 15% through improved troubleshooting techniques.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Troubleshot

- Repaired

- Replaced

- Assembled

- Tested

- Adjusted

- Calibrated

- Certified

- Monitored

- Operated

- Diagnosed

- Serviced

- Documented

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Reduced maintenance costs by 20% through the implementation of efficiency and cost-saving measures.

- Presented aircraft safety reports to management, providing detailed analysis of mechanical systems performance and recommending repairs or upgrades where necessary.

- Streamlined engine maintenance process; developed new procedures that reduced average repair time for various parts from 6 hours to 3 hours with no decrease in quality control standards met.

- Accurately diagnosed faults with aircraft components using advanced diagnostic equipment; solved technical issues on a wide range of airframes including Boeing 767s & 747s, Airbus A320s & A330s and ATR 42/72 series turboprops within 24 hours or less on average.

- Operated specialist tools such as torque wrenches, hydraulic jacks and rivet guns while performing scheduled inspections, troubleshooting tasks and carrying out general repairs under FAA regulations at all times.

- Mentored and trained six new aircraft maintenance engineers, raising the overall team proficiency levels by 15%.

- Facilitated routine inspections and repairs on 20+ commercial aircrafts, ensuring compliance with FAA regulations while minimizing downtime.

- Introduced a preventive maintenance program that improved operational efficiency of airplanes by 10% and reduced repair costs by $30K annually.

- Successfully complemented major airframe components on all Boeing 737 models within 1 hour; decreased engine replacement time to just 45 minutes per plane model in average.

- Diagnosed mechanical problems quickly using advanced diagnostic equipment such as borescopes, pressure gauges and micrometers; ultimately resulted in 60% reduction in fault assessment durations for jet-powered aircrafts.

- Reliably performed maintenance and repair operations on aircraft components, including engines, hydraulics systems, electrical wiring and landing gear; successfully reduced downtime by 25%.

- Calibrated flight control system instruments in accordance with Federal Aviation Administration (FAA) regulations to ensure the safety of passengers; inspected parts for wear & tear before certifying them as airworthy.

- Optimized mechanical systems through regular preventive maintenance programs which extended the service life of over 10 aircrafts by an average of 3 years each.

- Inspected all major components such as fuel tanks, navigation systems and communication radios according to technical manuals specifications; identified malfunctions in advance that saved up to $20K/year from costly repairs or replacements due to failure during use.

- Advised team members on proper handling techniques when servicing plane units for a wide range of commercial airlines’ fleets across North America; trained 50+ technicians in total who are now competently performing their duties autonomously at multiple airports nationwide.

- Tested and inspected aircraft components and systems to ensure airworthiness, completing over 150 maintenance check activities in the last quarter with 100% accuracy.

- Assembled and installed new engines, landing gear, fuel systems and other parts per manufacturer guidelines while adhering to all safety regulations; reduced repair costs by 15%.

- Competently diagnosed mechanical problems using advanced diagnostic tools such as oscilloscopes & electronic test equipment; resolved 80+ technical issues within a 3-month period.

- Adjusted engine controls for proper operation during flight tests according to FAA requirements; improved performance of 10+ planes significantly over the past year.

- Reorganized spare parts inventory system resulting in an additional $8,000 worth of cost savings annually due to optimized space utilization strategies.

- Compiled detailed maintenance logs for a fleet of 10+ aircrafts, ensuring that all records were up-to-date and in compliance with FAA regulations; increased safety standards by 25%.

- Assessed mechanical systems such as engines, brakes and landing gear to identify any potential issues or malfunctions before flight takeoff; decreased emergency repairs rate by 30% over the past year.

- Efficiently solved complex technical problems on board the aircraft during preflight checks while adhering strictly to industry protocols; improved customer satisfaction ratings by 14%.

- Structured rigorous engineering processes according to manufacturer specifications when performing inspections, tests & troubleshooting activities on Airbus A321 LR/XLR models; reduced total inspection time per plane from 8 hours down to 6 hours averagely.

- Monitored ongoing performance of aircraft components using advanced diagnostic tools as well as visual inspections techniques throughout each journey cycle; identified 50+ defective parts in need of immediate replacement before take off date which prevented hazardous incidents from occurring onboard planes.

- Formulated preventative maintenance plans for 15+ aircrafts, resulting in a 10% decrease of unplanned downtime.

- Prepared complete and detailed reports on each aircraft’s condition after completing inspections; identified potential defects prior to take-off and repaired them quickly with minimal disruption to flight schedules.

- Replaced worn parts or components per manufacturer guidelines, ensuring that all mechanical systems met stringent aviation safety standards; decreased accident rate by 12%.

- Expedited complex repairs through the use of advanced diagnostic tools such as engine analyzers & stress testers, reducing labor costs by $8,000 over the past year alone.

- Diligently followed up on preventive maintenance checks and post-flight tests to ensure compliance with government regulations regarding airworthiness; completed 24 inspection tasks within 3 hours ahead of schedule every week on average without compromising quality control standards.

- Documented aircraft maintenance activities, ensuring that all records and logbooks were updated in accordance with FAA regulations; successfully achieved 100% accuracy rate for aircraft maintenance documentation.

- Certified to work on over 50 types of jet engines, including turbofan and turbojet models; obtained authorization from the Federal Aviation Administration (FAA) to perform preventive maintenance on airframes and power plants.

- Demonstrated ability to troubleshoot complex mechanical issues within a short span of time, reducing downtime by 25%.

- Thoroughly inspected aircraft systems before each flight as part of an extensive pre-flight check system; identified potential defects or malfunctions early on in order to prevent accidents or delays during take-off/landing operations.

- Serviced various components such as landing gears & hydraulic assemblies per manufacturer specifications using specialized computerized testing equipment and increased overall performance efficiency by 10%.

- Revised maintenance procedures for aircrafts and ensured that all safety regulations were adhered to, reducing repair time by 35%.

- Participated in the inspection of 12 commercial & military aircrafts every month, identifying issues within mission-critical components and recommending necessary repairs.

- Coordinated with a team of 6 technicians to conduct maintenance checks on over 150 airframes annually; improved overall efficiency by 50% through strategic scheduling & resource allocation techniques.

- Actively identified outdated parts or materials used in aviation systems, replaced them promptly with high-quality options and reduced system malfunctions incidents by 40%.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization may require experience with specific aircraft models and another may not.

It is important to tailor the skills section of your resume to each job you are applying for, as many employers use applicant tracking systems (ATS) these days. These programs scan resumes for certain keywords before passing them on to a human – so if yours doesn’t contain any relevant ones, it won’t make it through the filter!.

Once listed here, you can further elaborate on your skillset by discussing it in more detail in other areas such as the summary or experience section.

Below is a list of common skills & terms:

- A320

- Aeronautics

- Aerospace

- Aircraft

- Aircraft Engines

- Aircraft Maintenance

- Aircraft Systems

- Airframe

- Airlines

- Airports

- Airworthiness

- Aviation

- Avionics

- B737

- Civil Aviation

- Commercial Aviation

- Engineering

- Flight Safety

- Flights

- Helicopters

- Human Factors

- Inspection

- Line Maintenance

- Maintenance

- Maintenance and Repair

- Overhaul

- PowerPlant

- Team Leadership

- Troubleshooting

4. Education

Mentioning your education on your resume will depend on how much experience you have in the aircraft maintenance engineering field. If you just graduated and lack work experience, include your education section below your resume objective. On the other hand, if you are an experienced engineer with plenty of professional accomplishments to showcase, omitting the education section may be appropriate.

If including an education section is necessary for this role, make sure to mention any courses or subjects related to aircraft maintenance engineering that may be relevant.

Associate’s Degree in Aircraft Maintenance Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They show potential employers that you have been tested and certified by an accredited organization, which can make you more attractive as an applicant than someone without any certifications.

Include any relevant certifications on your resume when applying for jobs that require specific skills or knowledge of certain topics. Doing so will help set you apart from other applicants and give hiring managers the assurance they need to know that you are qualified for the job.

Airframe and Powerplant (A&P) Mechanic Certification

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Douglas Walter, this would be Douglas-Walter-resume.pdf or Douglas-Walter-resume.docx.

7. Cover Letter

Providing a cover letter alongside your resume is a great way to introduce yourself and explain why you believe you’re the right person for the job. It usually consists of 2-4 paragraphs that summarize your skills, experience, and qualifications in relation to the role.

Cover letters are not always required but they can provide recruiters with additional information about who you are as an individual and what makes you stand out from other applicants. Writing one could be just what it takes to land your dream job!

Below is an example cover letter:

Dear Nolan,

I am writing to apply for the Aircraft Maintenance Engineer position with XYZ Airways. As a licensed aircraft maintenance engineer with 10 years of experience, I am confident I would be a valuable asset to your team.

In my current role as an aircraft maintenance engineer at ABC Airlines, I oversee all aspects of aircraft maintenance and repair, from scheduled servicing to emergency repairs. My experience has taught me how to troubleshoot complex problems quickly and efficiently, and I have developed a strong reputation among my colleagues for being able to get the job done right the first time.

I am also well-versed in aviation safety regulations and have extensive experience conducting safety audits and investigations. In my previous role as lead investigator for ABC Airlines’ accident investigation team, I was responsible for leading teams of investigators in determining the root cause of accidents and incidents. This experience has given me a keen eye for detail and a thorough understanding of how to properly document findings in order to meet all regulatory requirements.

I am confident that I can put my skills and experiences to work for XYZ Airways and contribute to the safe operation of your fleet. I look forward to speaking with you about this opportunity soon.

Sincerely,

Douglas

Aircraft Maintenance Engineer Resume Templates

Bonobo

Bonobo Markhor

Markhor Kinkajou

Kinkajou Indri

Indri Cormorant

Cormorant Quokka

Quokka Jerboa

Jerboa Fossa

Fossa Ocelot

Ocelot Saola

Saola Axolotl

Axolotl Gharial

Gharial Dugong

Dugong Numbat

Numbat Hoopoe

Hoopoe Lorikeet

Lorikeet Pika

Pika Rhea

Rhea Rezjumei

Rezjumei