Additive Manufacturing Engineer Resume Guide

Additive Manufacturing Engineers design, develop and manufacture products using 3D printing technology. They work with various materials to create prototypes and produce parts for a variety of industries such as aerospace, automotive, medical and consumer goods. The engineers also use software programs to prepare designs in order to optimize the process of additive manufacturing.

You have a knack for additive manufacturing, and you’d be an asset to any engineering team. But before they can consider hiring you, they must know who you are – that’s where your resume comes in. Craft one that highlights all of your relevant skills and experience so employers take notice!

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

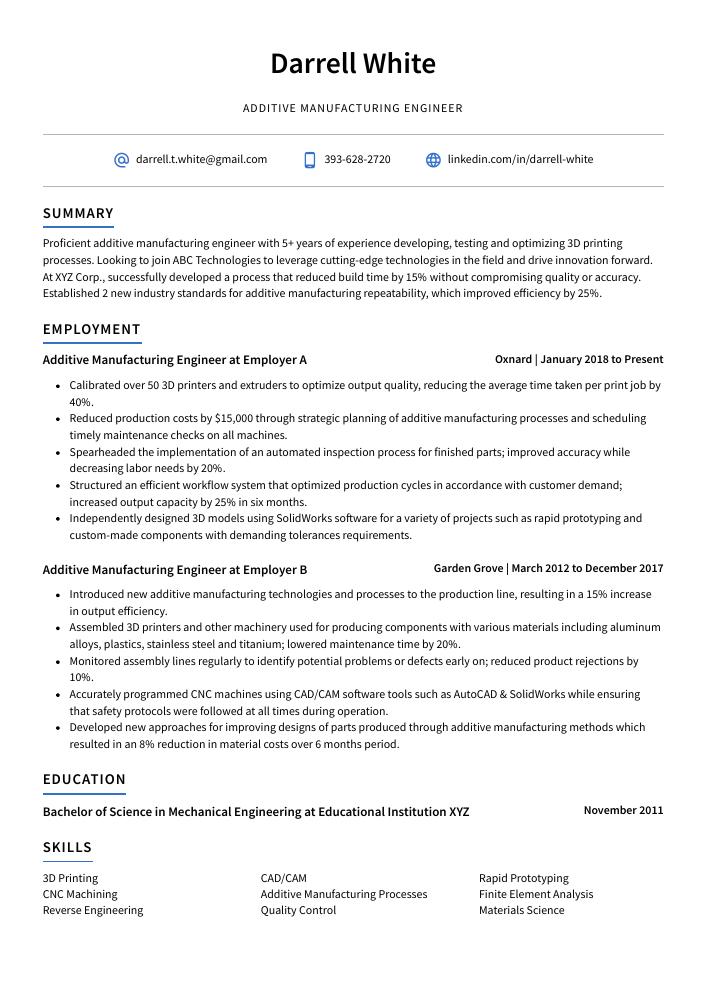

Additive Manufacturing Engineer Resume Sample

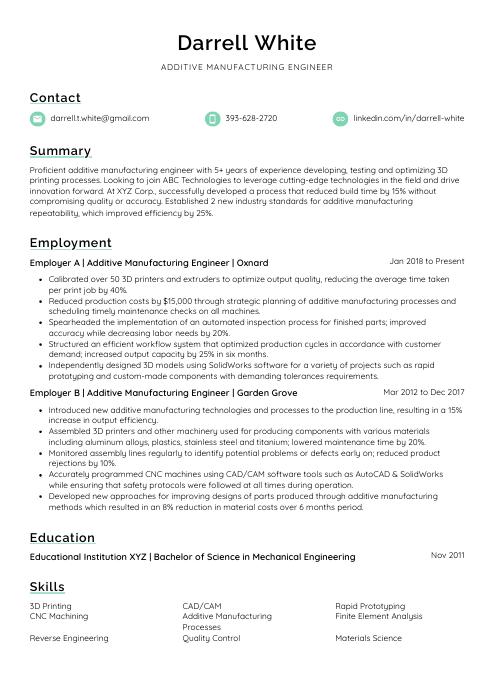

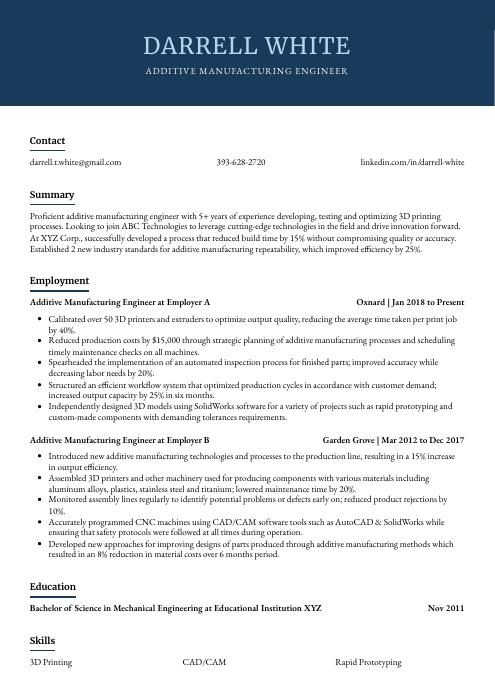

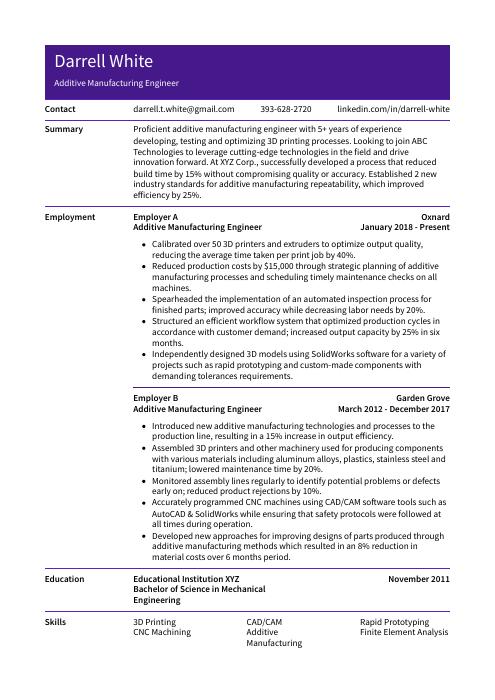

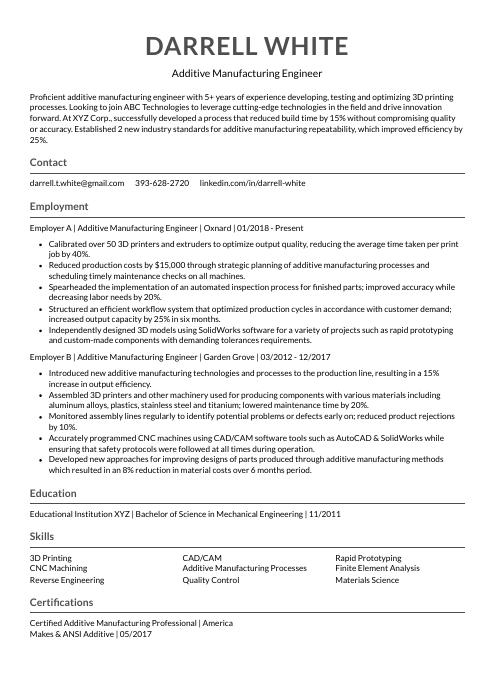

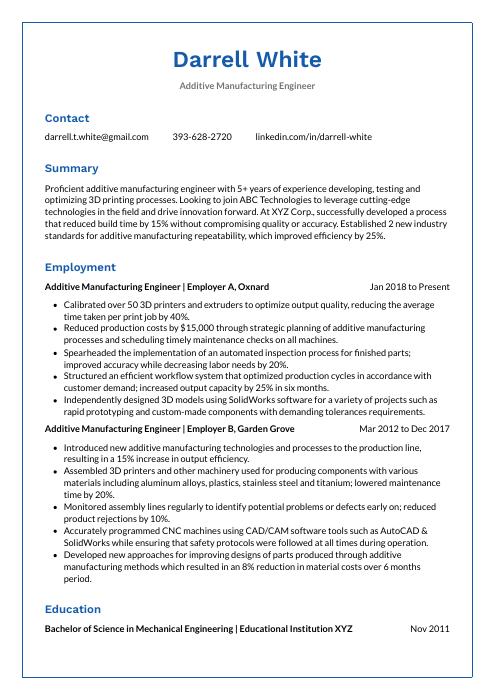

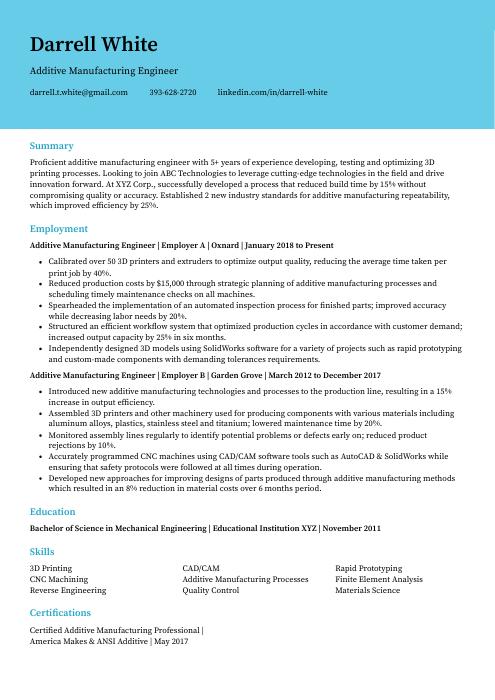

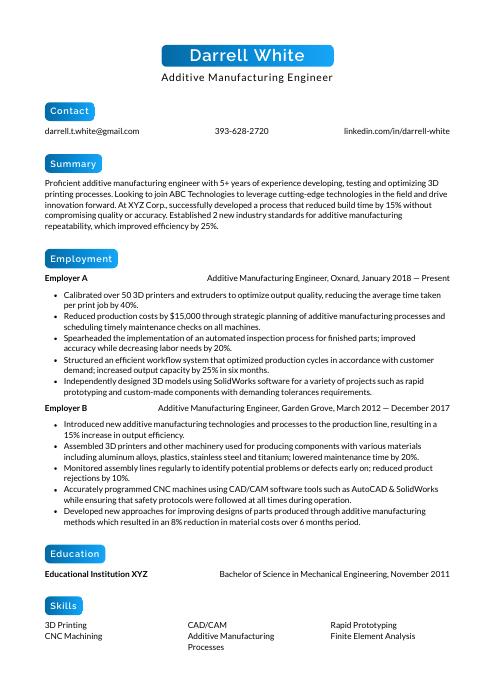

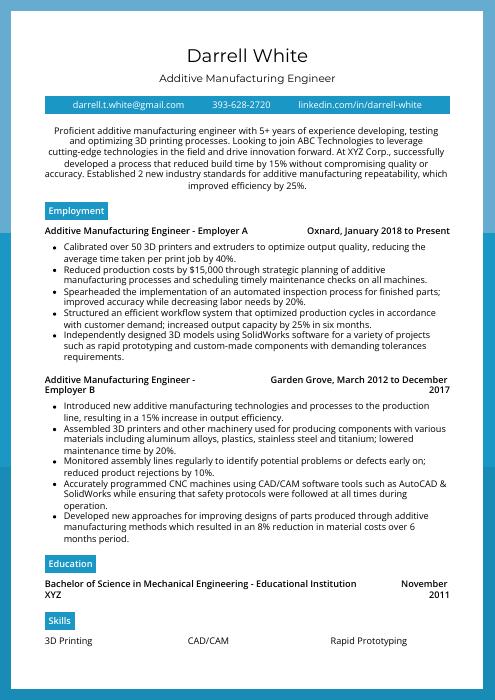

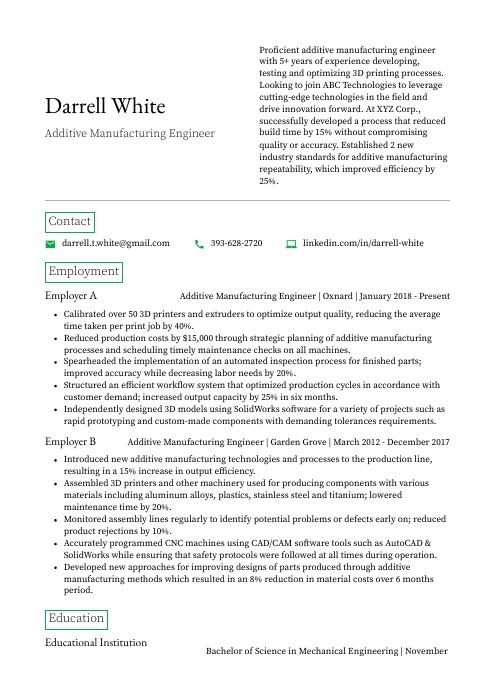

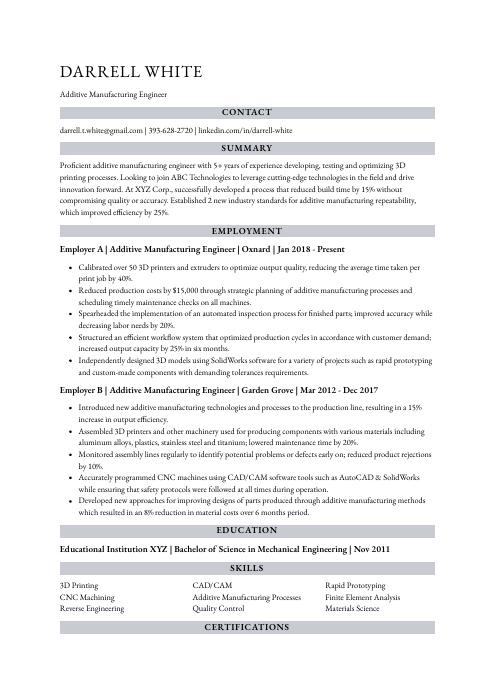

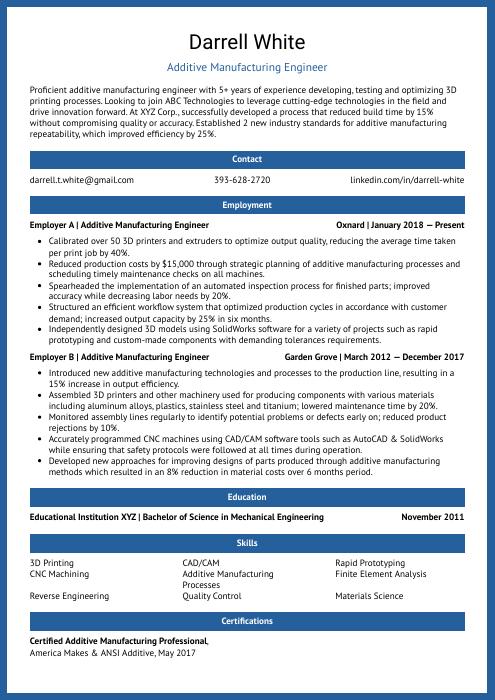

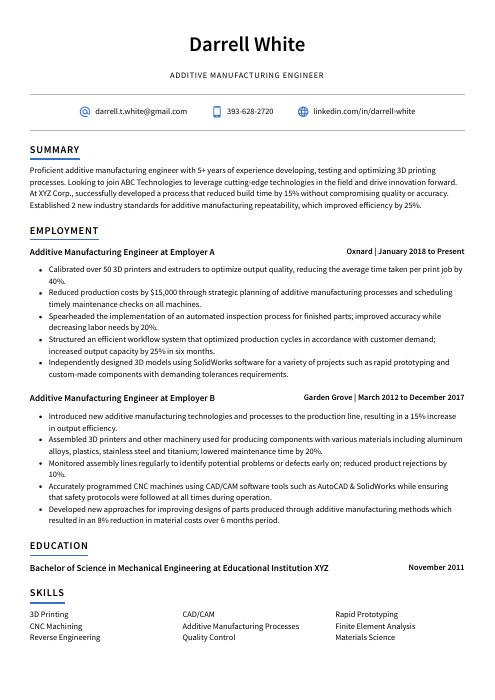

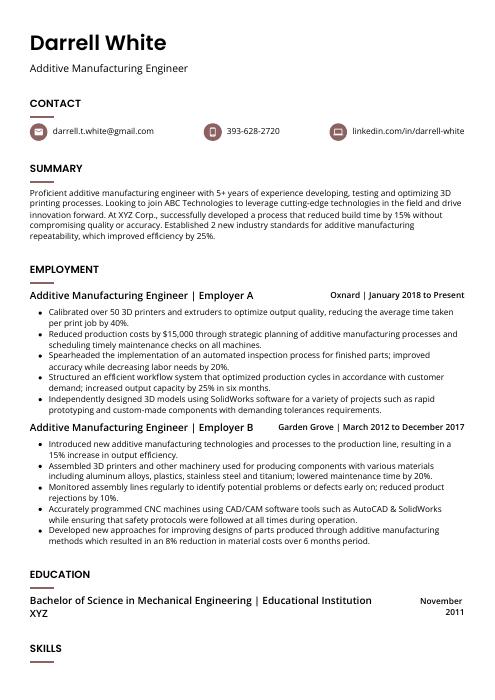

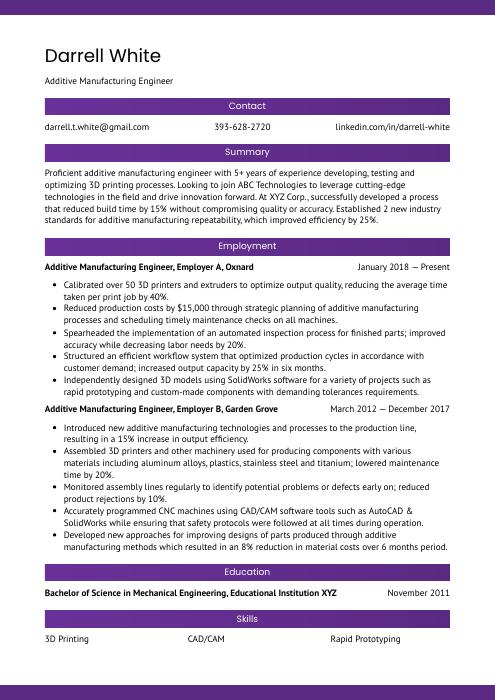

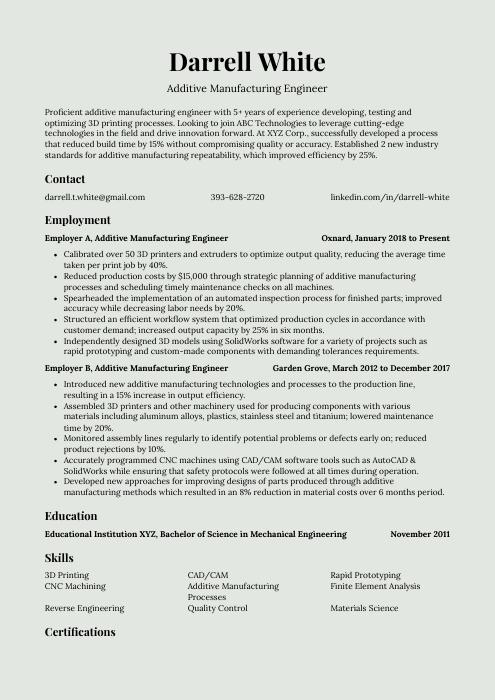

Darrell White

Additive Manufacturing Engineer

[email protected]

393-628-2720

linkedin.com/in/darrell-white

Summary

Proficient additive manufacturing engineer with 5+ years of experience developing, testing and optimizing 3D printing processes. Looking to join ABC Technologies to leverage cutting-edge technologies in the field and drive innovation forward. At XYZ Corp., successfully developed a process that reduced build time by 15% without compromising quality or accuracy. Established 2 new industry standards for additive manufacturing repeatability, which improved efficiency by 25%.

Experience

Additive Manufacturing Engineer, Employer A

Oxnard, Jan 2018 – Present

- Calibrated over 50 3D printers and extruders to optimize output quality, reducing the average time taken per print job by 40%.

- Reduced production costs by $15,000 through strategic planning of additive manufacturing processes and scheduling timely maintenance checks on all machines.

- Spearheaded the implementation of an automated inspection process for finished parts; improved accuracy while decreasing labor needs by 20%.

- Structured an efficient workflow system that optimized production cycles in accordance with customer demand; increased output capacity by 25% in six months.

- Independently designed 3D models using SolidWorks software for a variety of projects such as rapid prototyping and custom-made components with demanding tolerances requirements.

Additive Manufacturing Engineer, Employer B

Garden Grove, Mar 2012 – Dec 2017

- Introduced new additive manufacturing technologies and processes to the production line, resulting in a 15% increase in output efficiency.

- Assembled 3D printers and other machinery used for producing components with various materials including aluminum alloys, plastics, stainless steel and titanium; lowered maintenance time by 20%.

- Monitored assembly lines regularly to identify potential problems or defects early on; reduced product rejections by 10%.

- Accurately programmed CNC machines using CAD/CAM software tools such as AutoCAD & SolidWorks while ensuring that safety protocols were followed at all times during operation.

- Developed new approaches for improving designs of parts produced through additive manufacturing methods which resulted in an 8% reduction in material costs over 6 months period.

Skills

- 3D Printing

- CAD/CAM

- Rapid Prototyping

- CNC Machining

- Additive Manufacturing Processes

- Finite Element Analysis

- Reverse Engineering

- Quality Control

- Materials Science

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Additive Manufacturing Professional

America Makes & ANSI Additive

May 2017

1. Summary / Objective

Your resume summary/objective should be a brief but powerful statement that captures the hiring manager’s attention. In this section, you can highlight your experience in additive manufacturing engineering, such as the 3D printing processes and materials you are familiar with or any certifications related to this field. You could also mention how you have successfully implemented cost-saving measures for clients or improved production efficiency at previous companies.

Below are some resume summary examples:

Seasoned additive manufacturing engineer with extensive experience in designing and developing 3D printed products. Experienced in all aspects of the design process, from concept to product launch. Expertise includes CAD modeling, material selection and optimization, rapid prototyping & testing, post-processing techniques for AM parts as well as FEA/CFD analysis. Achieved a 20% reduction in project costs through improved part designs at XYZ Corporation.

Committed additive manufacturing engineer with a background in 3D printing, rapid prototyping and associated software. Experienced in multiple processes including fused deposition modeling (FDM), selective laser sintering (SLS) and direct metal laser sintering (DMLS). Skilled at troubleshooting issues related to the design of parts for additive manufacture. Successfully developed an automated system that increased production efficiency by 30%.

Determined Additive Manufacturing Engineer with 5+ years of experience in 3D printing and rapid prototyping. Experienced in designing, developing, and testing a wide range of products using the latest 3D printing technologies. Skilled at optimizing production processes to reduce costs while ensuring quality standards are met. Seeking new challenges to utilize my skillset and expertise within an additive manufacturing environment.

Skilled additive manufacturing engineer with 8+ years of experience leveraging 3D printing and simulation technologies to develop innovative solutions for complex engineering problems. Proven track record in designing, testing, validating, and troubleshooting components for the aerospace industry. Seeking to join ABC Company as an additive manufacturing engineer where I can use my expertise to drive product innovation.

Driven and ambitious engineer with 3+ years of experience in additive manufacturing and design. Experienced in using CAD/CAM software for rapid prototyping, building complex components from scratch, improving processes to increase quality and efficiency, and overseeing the production process at XYZ Company. Seeking to join ABC Tech as a key contributor towards creating innovative solutions with the latest technologies.

Amicable and experienced Additive Manufacturing Engineer with 8+ years of experience in 3D printing, rapid prototyping and reverse engineering. In previous roles developed comprehensive knowledge of CAD/CAM systems to design and improve products for end-users. Seeking to join ABC Technologies as an Additive Manufacturing Engineer where I can utilize my expertise in the field to create high-quality solutions.

Diligent additive manufacturing engineer with 5 years of experience in designing and developing 3D printed models. Proficient in using Fusion 360, Solidworks, AutoCAD and other software to create intricate designs for a variety of industries. Developed novel solutions that reduced production time by 30%, improved product accuracy by 25% and increased customer satisfaction scores from 75% to 95%.

Energetic and innovative additive manufacturing engineer with 5+ years of experience in designing, building and testing 3D printing machinery. Experienced in working with a variety of materials for prototyping and small-scale production runs. Seeking to join ABC Technologies to bring the latest technologies into their product development process and help them achieve their goals faster.

2. Experience / Employment

The employment (or experience) section is where you talk about your past work history. It should be written in reverse chronological order, which means that the most recent job is listed first.

When writing this section, stick to bullet points mainly; it makes it easier for the reader to take in what you have to say quickly and efficiently. When listing out each of your roles, provide detail on what exactly you did and any quantifiable results obtained as a result of your efforts.

For example, instead of saying “Created 3D printed parts,” you could say, “Designed over 50 complex 3D-printed components using CAD software that were used in various medical devices.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Fabricated

- Programmed

- Optimized

- Analyzed

- Simulated

- Monitored

- Troubleshot

- Assembled

- Calibrated

- Tested

- Operated

- Improved

- Documented

- Inspected

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Assessed the product requirements of 10+ clients and designed bespoke 3D models to meet their needs, resulting in a 70% reduction in production costs.

- Reliably operated various types of additive manufacturing machines such as laser sintering systems and FDM 3D printers while ensuring adherence to safety protocols; increased efficiency by 15%.

- Streamlined the design process for all projects using CAD software packages including Solidworks, Fusion 360 & AutoCAD; reduced prototyping time from 4 hours to 2 hours per model on average.

- Expedited the entire fabrication cycle with quick problem-solving skills during any issues that arose throughout the printing process, thereby saving 200+ man-hours over three months’ period.

- Coordinated closely with other departments like quality control and assembly teams for timely delivery of finished products within deadlines set by customers; successfully delivered 95% orders ahead of schedule.

- Mentored 3 junior engineers in the principles of additive manufacturing, enabling them to independently design and fabricate components for complex projects; reduced turnaround time by 25%.

- Achieved cost savings of $20,000 within 6 months through the implementation of innovative techniques such as laser sintering and 3D printing.

- Prepared detailed reports on all completed projects that included measurements taken from prototypes with an average accuracy rate higher than 95%.

- Actively monitored quality control processes throughout production cycles ensuring consistency in end-product performance standards; increased acceptance rates among customers by 10%.

- Compiled comprehensive documentation outlining key safety procedures associated with additive manufacturing operations while also performing regular maintenance tasks to ensure optimum machine performance at all times.

- Troubleshot and optimized 3D printing processes for 15+ products, reducing production time by 23% and increasing throughput rate from 8 to 10 parts per hour.

- Presented new strategies in additive manufacturing projects at a variety of conferences; increased awareness about the potentials of 3D printing technology among attending professionals.

- Tested the performance and durability of printed components using advanced analysis methods; identified areas of improvement that resulted in an 18% decrease in post-printing defects over 6 months.

- Operated various 3D printers such as FDM, SLA, DLP & SLS with proficiency to produce high-quality end products; reduced scrap output rate by 32%.

- Competently developed 9 customized CAD models with support structures suitable for different types of materials used while maintaining accuracy within 0.1 mm tolerances on all iterations.

- Participated in the design and development of 3D printing components for 10+ additive manufacturing projects, resulting in a 15% reduction in time-to-market.

- Developed custom STL files to be used with rapid prototyping machines, allowing product designs to meet customer specifications within just one week.

- Revised existing CAD models based on client feedback, successfully increasing model accuracy by 20%.

- Meticulously managed all aspects of prototype production from start to finish; closely monitored key parameters such as temperature and humidity levels at all times during the process.

- Inspected completed parts through rigorous quality control tests before shipping them off for final assembly; ensured zero defects in over 500 shipments shipped out last year alone.

- Resourcefully designed and implemented a suite of advanced additive manufacturing processes for the production of complex components, resulting in cost savings of $50,000.

- Demonstrated expertise with 3D printing technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA) and Selective Laser Sintering (SLS); developed 4 new part designs using these methods that met all customer requirements.

- Analyzed existing product specifications to identify areas where additive manufacturing could be used to reduce costs while maintaining quality; suggested modifications that resulted in an 11% increase in efficiency across operations over 2 months.

- Coordinated maintenance schedules for laser-based equipment and other machinery used on the shop floor; kept up-to-date records detailing repair times which enabled accurate turnaround estimates for customers orders by 10%.

- Facilitated daily calibration checks on welding robots & CNC machines necessary for successful manufacture of parts via Additive Manufacturing techniques; reduced scrap rates from 5% to 1%, saving 400 man hours per month overall.

- Improved additive manufacturing process and reduced production costs by 15% through innovative 3D printing solutions.

- Advised senior management on new technologies and techniques for optimizing the additive manufacturing workflow, leading to improved customization capabilities of products.

- Simulated several parts using CAD/CAM software prior to actual manufacture in order to ensure accuracy; delivered product components with zero defects during each run cycle.

- Diligently monitored the operation of 3D printers, troubleshooting any issues that arose during production runs; successfully mitigated 20 potential roadblocks over a 6-month period without compromising quality or efficiency standards.

- Reorganized digital design files into an organized system which enabled faster access and retrieval when needed for future projects; saved 400 hours per month in search time alone as a result.

- Optimized 3D printing processes, leading to a 25% improvement in production throughput and 10% reduction in manufacturing cost.

- Utilized CAD/CAM software tools like SolidWorks and Fusion 360 to create 3D models of components according to customer specifications; successfully completed 40+ additive manufacturing projects within tight deadlines.

- Fabricated high-precision plastic parts for medical equipment using selective laser sintering (SLS) technology; reduced defects by 15%.

- Formulated innovative solutions that addressed specific limitations of various additive manufacturing techniques such as Fused Deposition Modeling (FDM).

- Efficiently managed the operation & maintenance of complex 3D printers across multiple sites; achieved 99% uptime rate over 6 months with no major breakdowns or service delays reported.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require experience with 3D printing and Organization XYZ may need a candidate who is knowledgeable about laser sintering.

It is essential to keep this in mind because of the applicant tracking systems utilized by many companies. Their role is to analyze resumes for certain characteristics, filtering out those that they deem not to be a high-quality match for that particular job.

Once listed here, you can further elaborate on your skillset by discussing it in more detail in other areas such as the summary or experience section.

Below is a list of common skills & terms:

- 3D Printing

- Additive Manufacturing Processes

- CAD/CAM

- CNC Machining

- Finite Element Analysis

- Materials Science

- Quality Control

- Rapid Prototyping

- Reverse Engineering

- Robotics

4. Education

Adding an education section to your resume is dependent on how much work experience you have in the field of additive manufacturing engineering. If you are just starting out and don’t have any relevant job history, include an education section below your objective statement. However, if you already have a few years under your belt, it may be best to omit this section altogether as there will likely be more important information to showcase from previous positions instead.

If including an education section, try to mention courses or subjects related specifically to additive manufacturing engineering that demonstrate your knowledge in the field.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field and can be an important factor when applying for jobs. They show employers that you have taken the time to learn new skills, stay up-to-date with industry trends, and are committed to professional development.

If you have any certifications related to the job or industry you’re applying for, make sure they are included on your resume as it could give you an edge over other applicants who don’t possess them.

Certified Additive Manufacturing Professional

America Makes & ANSI Additive

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Darrell White, this would be Darrell-White-resume.pdf or Darrell-White-resume.docx.

7. Cover Letter

Attaching a cover letter to your resume is a great way to make yourself stand out from the other job applicants. It should be made up of 2 to 4 paragraphs and provide more detail than what’s already mentioned in your CV.

Cover letters allow you to introduce yourself, explain why you’re an ideal candidate for the role, and give employers further insights about who you are as a professional. Although they aren’t always required, it’s highly recommended that you write one when applying for jobs – it could be just the thing that helps get your foot in the door!

Below is an example cover letter:

Dear Jermey,

I am writing to apply for the Additive Manufacturing Engineer position at XYZ Corporation. As an experienced additive manufacturing engineer with a strong background in quality control and process improvement, I am confident I can make a significant contribution to your organization.

In my current role at ABC Company, I oversee all aspects of additive manufacturing operations, from design and development to production and delivery. I have a proven track record of streamlining processes to increase efficiency and reduce costs, as well as developing new methods of production that improve product quality. In addition, my experience managing teams of engineers and technicians has taught me the importance of effective communication and collaboration in achieving success.

I believe my skills and experience would be valuable assets to XYZ Corporation. In particular, my ability to improve manufacturing processes and develop innovative solutions to challenges would be beneficial in helping your organization achieve its goals. I look forward to discussing how I can contribute to your team in further detail during an interview. Thank you for your time and consideration.

Sincerely,

Darrell

Additive Manufacturing Engineer Resume Templates

Cormorant

Cormorant Gharial

Gharial Echidna

Echidna Hoopoe

Hoopoe Lorikeet

Lorikeet Bonobo

Bonobo Pika

Pika Indri

Indri Markhor

Markhor Dugong

Dugong Kinkajou

Kinkajou Rhea

Rhea Quokka

Quokka Numbat

Numbat Ocelot

Ocelot Axolotl

Axolotl Fossa

Fossa Jerboa

Jerboa Saola

Saola Rezjumei

Rezjumei