Electrical Controls Engineer Resume Guide

Electrical Controls Engineers design, develop and test electrical control systems used to operate machinery. They use computers and other software applications to create circuit diagrams and wiring schematics as well as program controllers for automated processes. Additionally, they troubleshoot existing systems, modify them according to customer specifications or industry standards, and ensure that the equipment operates safely in compliance with all applicable regulations.

Your expertise in electrical controls engineering is unparalleled, and any organization would benefit from having you on their team. To make them aware of your achievements and abilities, you must write a resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

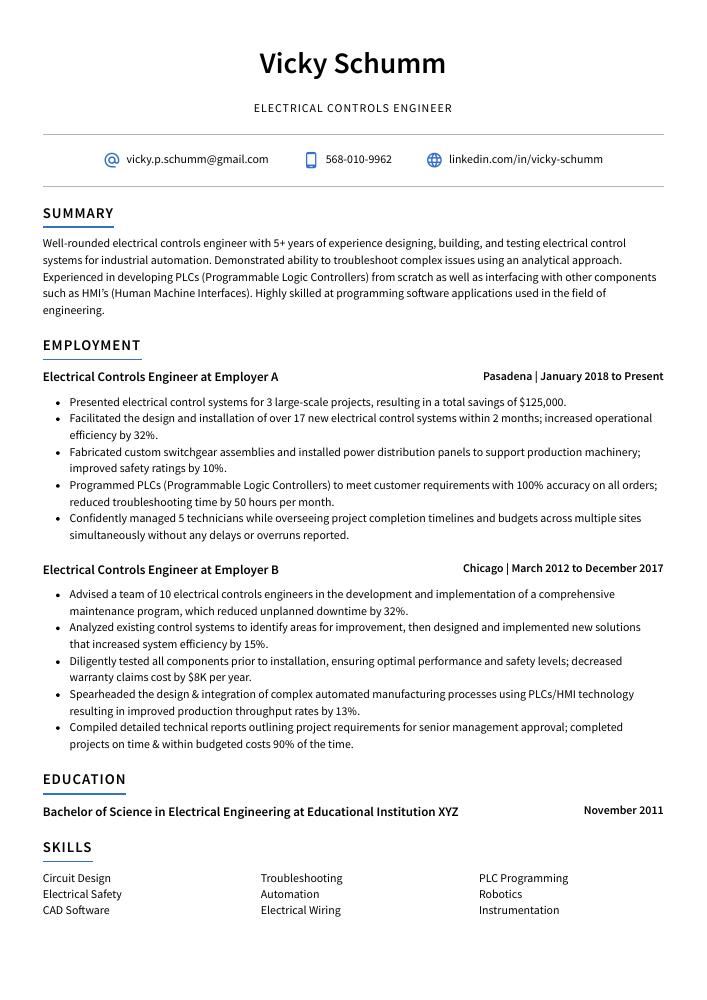

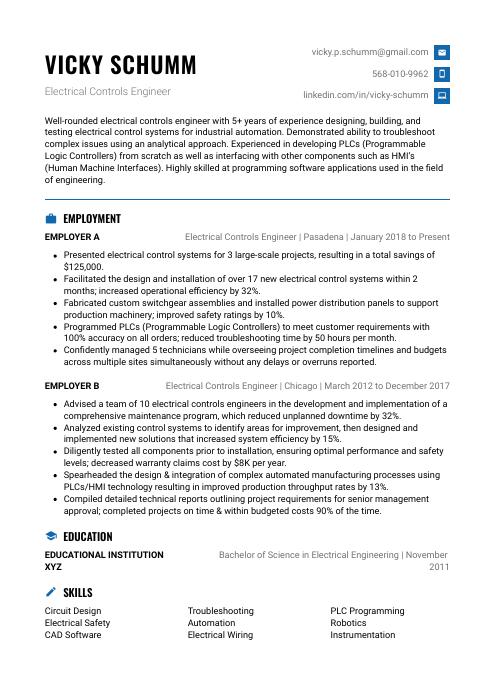

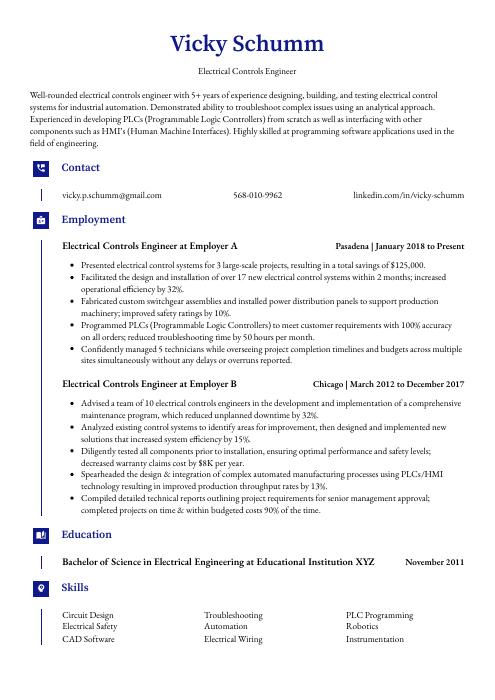

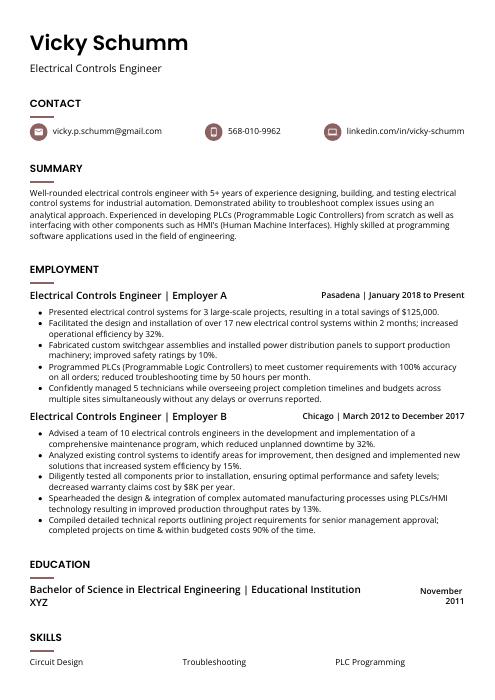

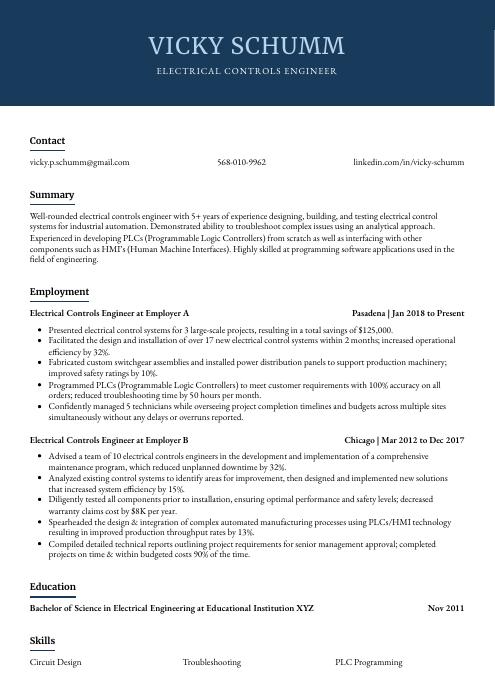

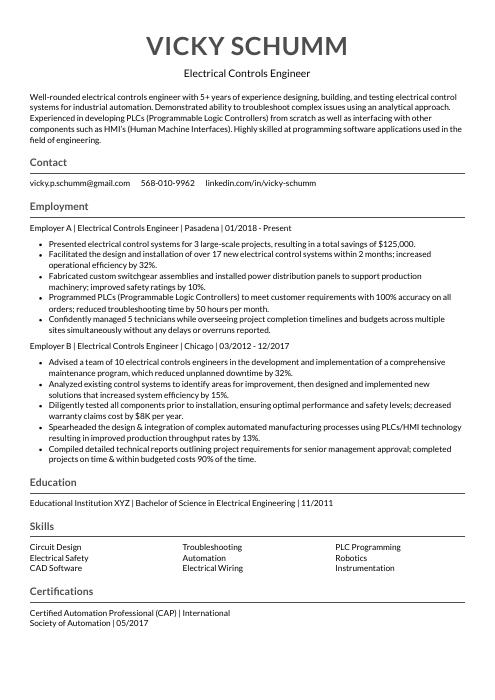

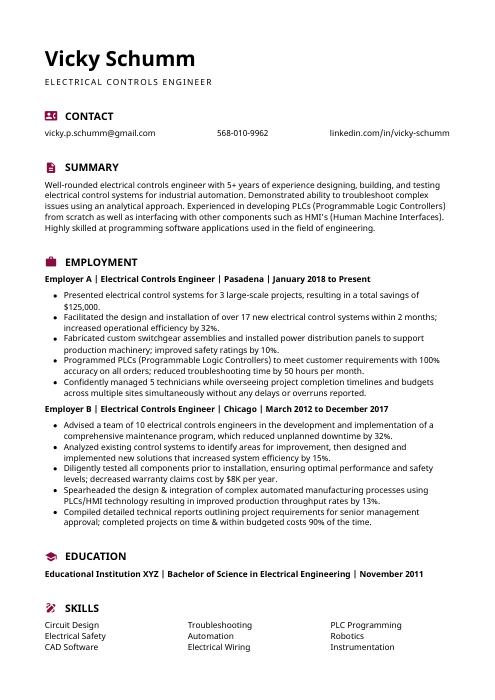

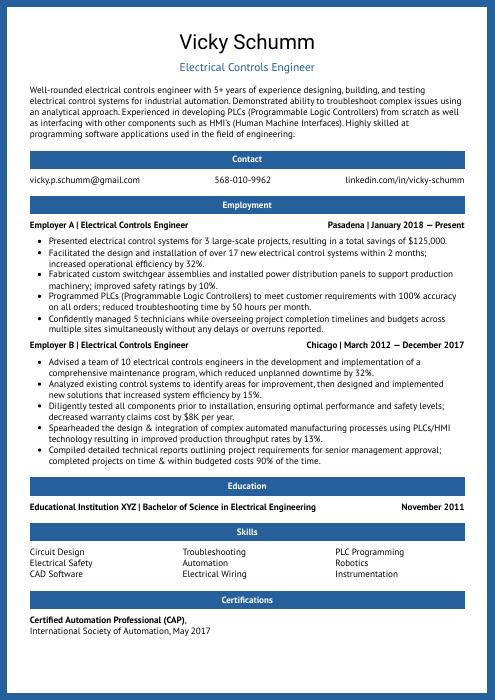

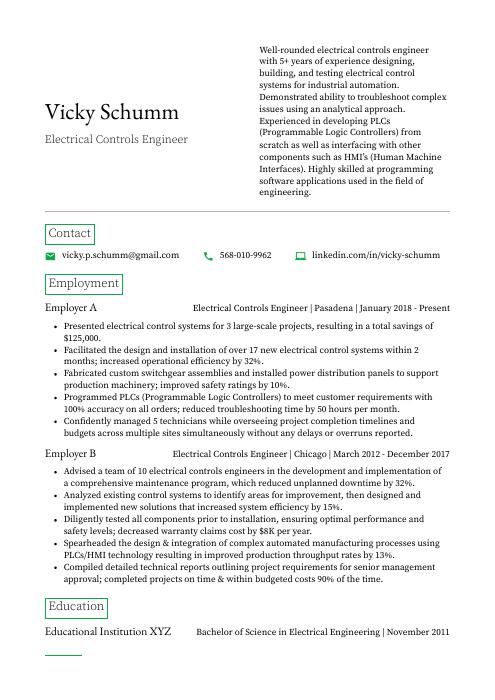

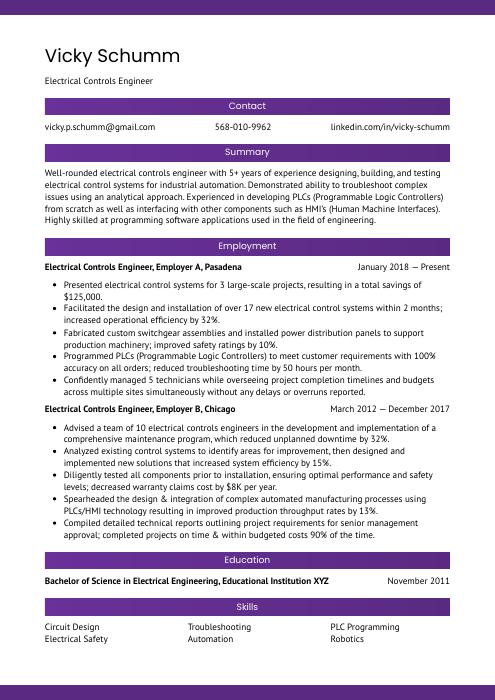

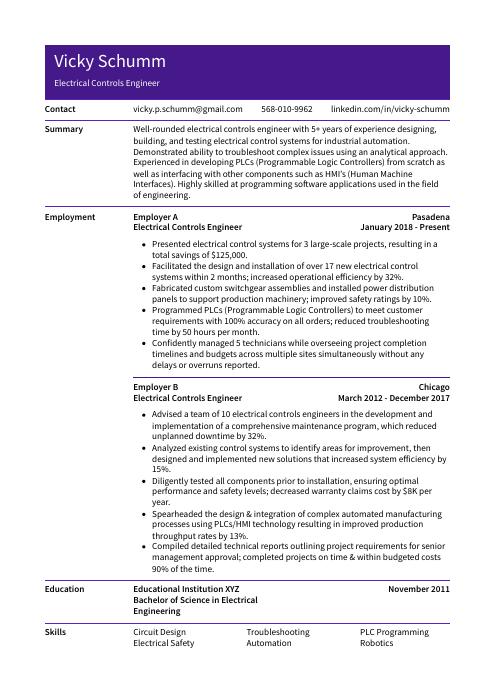

Electrical Controls Engineer Resume Sample

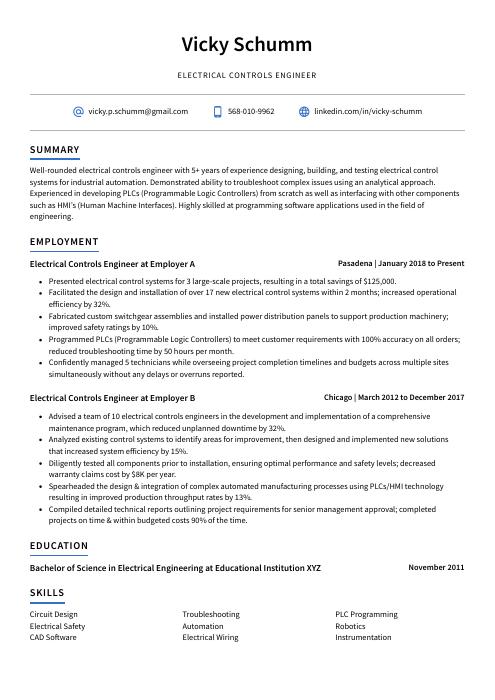

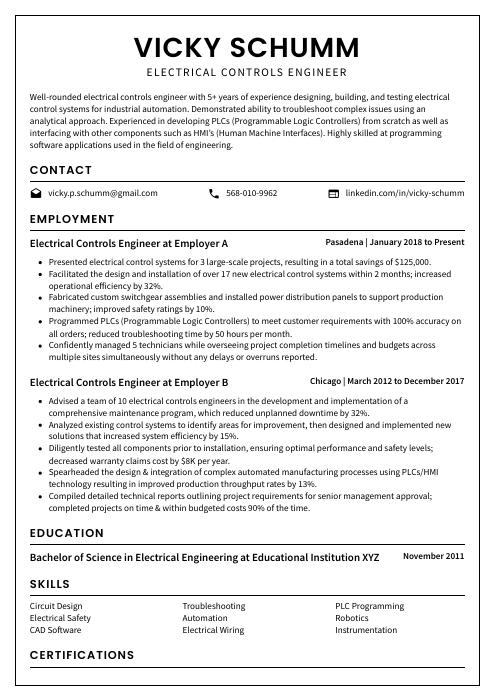

Vicky Schumm

Electrical Controls Engineer

[email protected]

568-010-9962

linkedin.com/in/vicky-schumm

Summary

Well-rounded electrical controls engineer with 5+ years of experience designing, building, and testing electrical control systems for industrial automation. Demonstrated ability to troubleshoot complex issues using an analytical approach. Experienced in developing PLCs (Programmable Logic Controllers) from scratch as well as interfacing with other components such as HMI’s (Human Machine Interfaces). Highly skilled at programming software applications used in the field of engineering.

Experience

Electrical Controls Engineer, Employer A

Pasadena, Jan 2018 – Present

- Presented electrical control systems for 3 large-scale projects, resulting in a total savings of $125,000.

- Facilitated the design and installation of over 17 new electrical control systems within 2 months; increased operational efficiency by 32%.

- Fabricated custom switchgear assemblies and installed power distribution panels to support production machinery; improved safety ratings by 10%.

- Programmed PLCs (Programmable Logic Controllers) to meet customer requirements with 100% accuracy on all orders; reduced troubleshooting time by 50 hours per month.

- Confidently managed 5 technicians while overseeing project completion timelines and budgets across multiple sites simultaneously without any delays or overruns reported.

Electrical Controls Engineer, Employer B

Chicago, Mar 2012 – Dec 2017

- Advised a team of 10 electrical controls engineers in the development and implementation of a comprehensive maintenance program, which reduced unplanned downtime by 32%.

- Analyzed existing control systems to identify areas for improvement, then designed and implemented new solutions that increased system efficiency by 15%.

- Diligently tested all components prior to installation, ensuring optimal performance and safety levels; decreased warranty claims cost by $8K per year.

- Spearheaded the design & integration of complex automated manufacturing processes using PLCs/HMI technology resulting in improved production throughput rates by 13%.

- Compiled detailed technical reports outlining project requirements for senior management approval; completed projects on time & within budgeted costs 90% of the time.

Skills

- Circuit Design

- Troubleshooting

- PLC Programming

- Electrical Safety

- Automation

- Robotics

- CAD Software

- Electrical Wiring

- Instrumentation

Education

Bachelor of Science in Electrical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Automation Professional (CAP)

International Society of Automation

May 2017

1. Summary / Objective

A resume summary or objective is like a trailer for the rest of your resume – it should provide an overview of who you are and why you would be a great electrical controls engineer. In this section, mention any certifications or qualifications that make you stand out from other applicants. Additionally, highlight some of your most impressive accomplishments in the field such as developing innovative solutions to complex problems or successfully managing large-scale projects.

Below are some resume summary examples:

Passionate electrical controls engineer with 4+ years of experience in designing and implementing electrical control systems for a variety of industrial applications. Experienced in developing PLC programs, debugging issues, and troubleshooting hardware problems to ensure optimal performance. At XYZ Corporation, designed an automated system that resulted in reducing downtime by 40%. Excellent communication skills; able to work independently or collaboratively within teams.

Detail-oriented electrical controls engineer with a proven track record of successfully designing and executing innovative electrical control systems. Experienced in all aspects of the engineering process, from concept to delivery. Skilled at working with various programming languages, frameworks, and tech stacks to develop high-quality solutions for clients. Consistently recognized as an efficient team player who can effectively collaborate on complex projects.

Dependable electrical controls engineer with 8+ years of experience developing and maintaining high-efficiency electrical systems. At XYZ Inc., reduced downtime by 15% while increasing production output by 10%. Proven ability to analyze system requirements, develop detailed plans, and execute complex projects within tight deadlines. Highly motivated to join ABC Corp.’s team of engineers in order to bring cutting-edge solutions that drive operational excellence.

Professional electrical controls engineer with 7+ years of experience designing and programming robotic systems. Proven record of success in creating innovative solutions to challenging engineering problems. Skilled in PLCs, HMI, CAD/CAE software, electrical troubleshooting, and robot control systems. Seeking to join ABC Technologies where I can use my expertise to develop automated production processes that meet customer needs and exceed expectations.

Driven electrical controls engineer with 8+ years of experience in software and hardware development, testing, and debugging. Skilled at managing projects from concept to completion while ensuring adherence to quality standards. At XYZ Corp., developed a control system that automated processes by 30% and reduced energy consumption by 20%. Aiming to leverage expertise in electrical engineering principles for ABC’s challenging projects.

Reliable electrical controls engineer with 8+ years of experience providing design and engineering solutions for complex electrical systems. Proven track record in streamlining processes, increasing energy efficiency, and reducing costs by up to 38%. Looking to join ABC Engineering as a Senior Electrical Controls Engineer and bring my expertise in analyzing system performance to the team’s projects.

Seasoned electrical controls engineer with 8+ years of experience in designing, troubleshooting and programming industrial control systems. Experienced with all aspects of electrical engineering including circuit design, signal analysis, component selection and system integration. Proven success delivering complex projects on time and within budget while providing excellent customer service.

Hard-working electrical controls engineer with 10+ years of experience in designing and developing automated solutions to improve production processes. At ABC Company, designed a process control system that increased efficiency by 40% and reduced downtime costs by $10K annually. Skilled at troubleshooting complex issues to identify root causes quickly and efficiently.

2. Experience / Employment

The employment (or experience) section is where you provide details on your professional history. This should be written in reverse chronological order, meaning that the most recent job is listed first.

When describing what you did for each position, stick to bullet points as much as possible; this makes it easier for the reader to take in all of the information quickly and efficiently. When writing each point, focus on providing detail and quantifiable results obtained from your work.

For example, instead of saying “Created electrical control systems,” you could say: “Designed complex electrical control systems using AutoCAD software while adhering to strict safety protocols; resulting in a 10% decrease in system failure rates.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Programmed

- Installed

- Troubleshot

- Tested

- Commissioned

- Debugged

- Calibrated

- Documented

- Analyzed

- Fabricated

- Assembled

- Configured

- Monitored

- Optimized

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Documented electrical system designs, modifications and schematics for 15+ control systems, resulting in improved operational efficiency by 35%.

- Improved cost-effectiveness of projects by devising innovative electrical solutions that reduced materials usage and installation time by 20%.

- Proficiently programmed PLCs, HMIs, VFDs and other complex automation equipment to meet customer needs; developed a new programming language which cut testing times from 8 hours to 4 hours.

- Introduced 5+ advanced technologies into existing production lines that enabled the organization to reduce energy consumption costs by $20K annually while maintaining quality standards.

- Designed automated processes that increased production rate capacity up to 30% with minimal downtime due to troubleshooting issues or maintenance requirements.

- Structured and maintained electrical control systems for 10+ manufacturing plants, reducing downtime by 15% and increasing efficiency of production processes.

- Mentored junior control engineers on the development and implementation of new automation technologies; trained 4 team members to become certified in controls engineering over a 6-month period.

- Represented company at 8 industry conferences and seminars, presenting findings from successful projects that had streamlined operations costs by 25%.

- Streamlined existing electrical controls for 5 production facilities across 3 states, resulting in an overall reduction in energy consumption costs by $10K annually per facility.

- Actively participated in troubleshooting activities to identify root cause issues within automated processes using advanced diagnostic tools; reduced total repair times by 30 hours each month on average across all sites monitored.

- Assessed existing electrical control systems to identify potential areas for improvement and cost savings, resulting in a 15% reduction in energy consumption.

- Successfully designed and tested numerous PLC programs for industrial automation applications while adhering to established safety protocols.

- Developed an automated process monitoring system used by operators that increased production efficiency by 20%.

- Participated in the maintenance of programmable logic controllers (PLCs) and Human Machine Interfaces (HMIs), troubleshooting issues with software/hardware components when necessary.

- Coordinated teams of technicians during the installation of new equipment, ensuring all tasks were completed on time and within budget parameters; managed projects up to $1 million USD in value without any delays or errors reported from customers’ end users.

- Calibrated complex electrical controls systems for over 50 machines, resulting in a 15% higher production rate.

- Expedited installations and repairs of new or existing electrical components onsite; reduced downtime by 40 hours per month on average.

- Accurately troubleshot problems related to wiring, electronic programming and circuit boards with minimal errors; identified root causes of defects within 2 minutes each time.

- Installed control systems that met all industry standards while ensuring user safety protocols were observed at all times; eliminated hardware malfunctions due to improper installation by 98%.

- Troubleshot various issues such as low-voltage drops, power surges & overloaded circuits using diagnostic tools like multi-meters & oscilloscopes; resolved customer complaints within 48 hours or less 90% of the time.

- Optimized the electrical controls systems of 13 production lines, leading to a 10% increase in automation output and energy savings of over $30K.

- Consistently monitored the performance of existing equipment and implemented corrective measures when necessary; improved system efficiency by 25%.

- Commissioned new control systems on 6 automated manufacturing lines; successfully completed project objectives within budget and 4 weeks ahead of schedule.

- Formulated detailed plans for installation, testing, commissioning & troubleshooting operations involving PLCs, HMIs/SCADA systems and other related components; reduced downtime by 20 hours/week on average across all projects.

- Reorganized entire network architecture with updated wiring diagrams which allowed better communication between machines while keeping operation costs at minimum levels ($6K saved annually).

- Reduced electrical system malfunctions by over 40% through meticulous troubleshooting and maintenance of complex electrical controls systems.

- Monitored the performance of all automated control systems, detecting any issues or discrepancies in real-time to ensure smooth operation.

- Assembled new circuitry for various electrical engineering projects; responsible for wiring and connecting components according to blueprints as well as testing for functionality and accuracy before release.

- Meticulously inspected every component used in manufacturing processes, including PLCs, AC/DC motors, relays & hydraulic pumps to guarantee safety compliance and seamless operations at all times; completed 200+ inspections per month without fail.

- Utilized CAD software programs such as AutoCAD Electrical & SolidWorks Electrical Professional in order to design efficient automation schematics that could be implemented across multiple industries with minimal errors or delays.

- Debugged and resolved complex electrical system issues with minimal downtime, resulting in a 35% increase in operational efficiency.

- Achieved 98% customer satisfaction across all process control and automation projects, ensuring that quality standards were consistently met.

- Competently designed and implemented efficient control systems for more than 30 production lines; optimized processes to reduce energy consumption by 20%.

- Configured Human-Machine Interface (HMI) software for machines as per client requirements; trained 15+ team members on using the HMI software effectively within 8 hours of deployment time frame.

- Revised existing designs of PLC ladder logic diagrams according to updated safety regulations without compromising performance or functionality; enhanced overall safety rating by 45%.

- Demonstrated strong problem-solving abilities in developing electrical control systems for automated machinery, resulting in a 15% improvement of productivity.

- Independently designed, programmed and tested PLCs to ensure the proper operation of equipment across multiple industries; reduced downtime by 25%.

- Prepared detailed technical documentation outlining design specifications, test results and troubleshooting procedures; achieved an on-time completion rate of 95%.

- Tested prototypes using various methods such as debugging tools, oscilloscopes and signal generators to verify accuracy before full production release; successfully identified over 150 defects prior to launch.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require the candidate to have experience in designing and programming PLCs, while organization XYZ may need someone who is proficient with SCADA systems.

It’s important to tailor the skills section of your resume for each job you are applying for. This is due to many employers using applicant tracking systems (computer programs that scan resumes) which look out for certain keywords before passing them on to a human.

Once listed here, it would be beneficial to discuss these skills further in other areas such as the summary or experience sections – this will help make sure you stand out from other applicants!

Below is a list of common skills & terms:

- Automation

- CAD Software

- Circuit Design

- Electrical Safety

- Electrical Wiring

- Instrumentation

- PLC Programming

- Process Control Systems

- Robotics

- Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention the relevant courses, subjects and assignments related to electrical controls engineering below your resume objective. However, if you have significant work experience that is more important than highlighting what college or university classes you took, omitting an education section altogether would be fine as well.

If including an education section is necessary for the job application process then make sure to include specific coursework related to electrical controls engineering such as circuit theory, control systems design and analysis etcetera.

Bachelor of Science in Electrical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They can be obtained through courses, workshops or exams and are often recognized by employers as proof of knowledge and experience.

Including certifications on your resume is an excellent way to show potential employers that you have the necessary skills for the job. It also demonstrates that you are committed to staying up-to-date with industry trends and best practices.

Certified Automation Professional (CAP)

International Society of Automation

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Vicky Schumm, this would be Vicky-Schumm-resume.pdf or Vicky-Schumm-resume.docx.

7. Cover Letter

Providing a cover letter when applying for a job is highly recommended and can be the difference between standing out from other candidates or being overlooked. It’s an opportunity to explain why you’re perfect for the role, provide more detail than what your resume allows and give recruiters insight into who you are as a professional.

Cover letters usually consist of 2 to 4 paragraphs separate from your resume. They allow you to highlight particular skills, experiences or interests that could make you suitable for the position in question. Writing one may also help demonstrate your enthusiasm and commitment towards getting hired by this company!

Below is an example cover letter:

Dear Felipa,

I am writing in response to your posting for an Electrical Controls Engineer. With 10+ years of experience designing, developing, and implementing electrical control systems, I am confident I will be an asset to your organization. My experience includes working with a variety of control system platforms including PLCs, HMIs, and SCADA systems. In addition, I have experience troubleshooting electrical and controls issues as well as providing training on the use of control systems.

Your listed requirements closely match my background and skillset. A few that stand out that would enable me to contribute to your bottom line are:

– Proven experience in designing and developing electrical control systems

– Strong understanding of PLCs, HMIs, and SCADA systems

– Ability to troubleshoot electrical and controls issues quickly and effectively

– Experience providing training on the use of control systems

– Excellent communication skills

I’ve attached a copy of my resume detailing my projects and experiences. I can be reached anytime via phone or email. Thank you for your time.

Sincerely,

Vicky

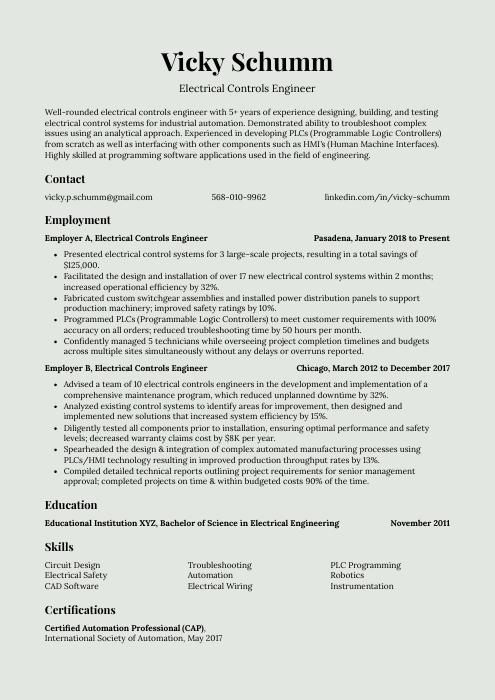

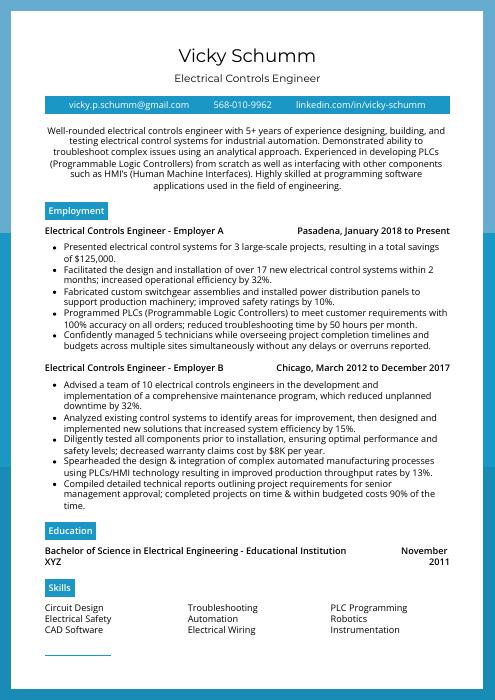

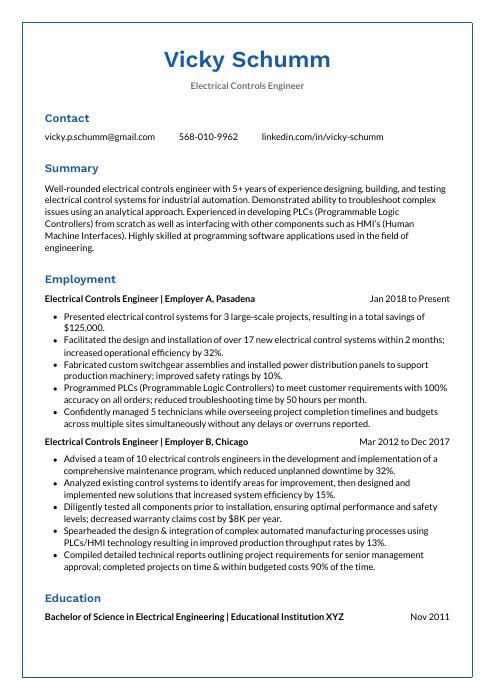

Electrical Controls Engineer Resume Templates

Saola

Saola Rhea

Rhea Markhor

Markhor Echidna

Echidna Lorikeet

Lorikeet Gharial

Gharial Fossa

Fossa Bonobo

Bonobo Indri

Indri Hoopoe

Hoopoe Numbat

Numbat Kinkajou

Kinkajou Ocelot

Ocelot Quokka

Quokka Jerboa

Jerboa Pika

Pika Axolotl

Axolotl Dugong

Dugong Cormorant

Cormorant Rezjumei

Rezjumei