Drilling Fluids Engineer Resume Guide

Drilling fluids engineers are responsible for designing, monitoring, and analyzing the properties of drilling fluid systems used in oil and gas extraction. They work to ensure that the fluid systems maintain their desired viscosity levels as well as other parameters so that they can effectively support various types of drill bits. Additionally, these engineers also provide technical advice regarding how best to use different kinds of additives or chemicals in order to maximize efficiency.

As a drilling fluids engineer, you know how to handle the most challenging tasks with ease. But potential employers don’t yet realize your expertise—you must create an eye-catching resume to make them take notice of your unique qualifications and experience.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

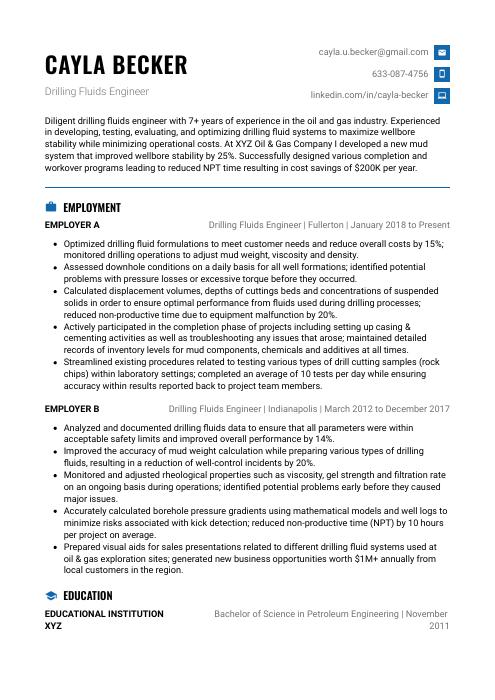

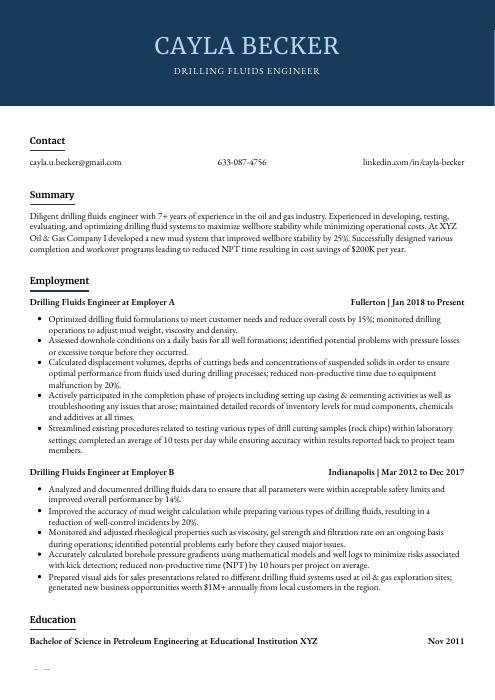

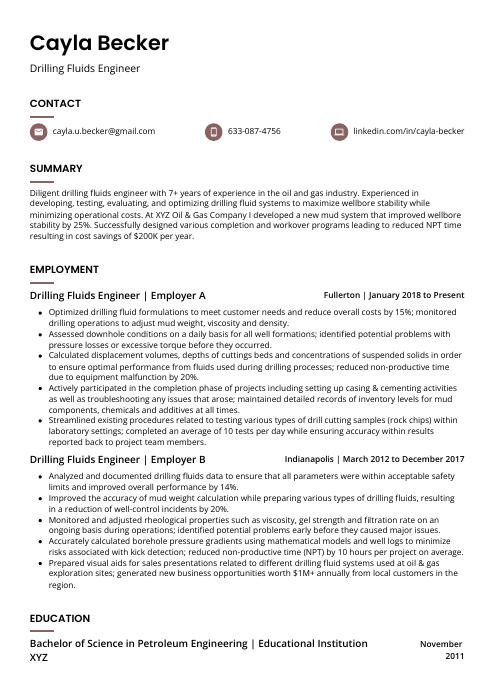

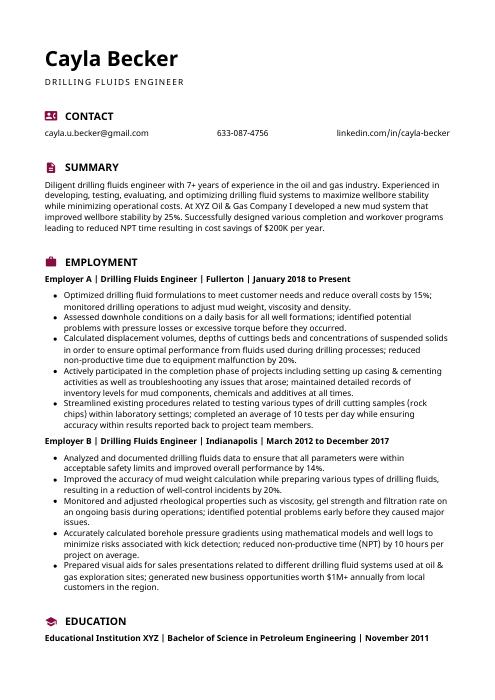

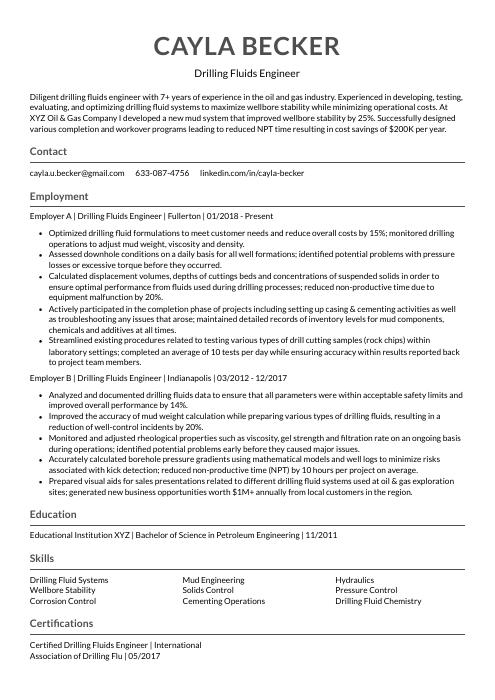

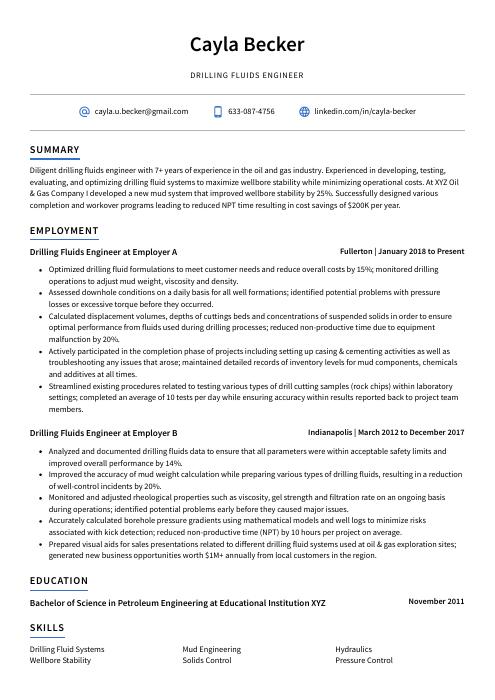

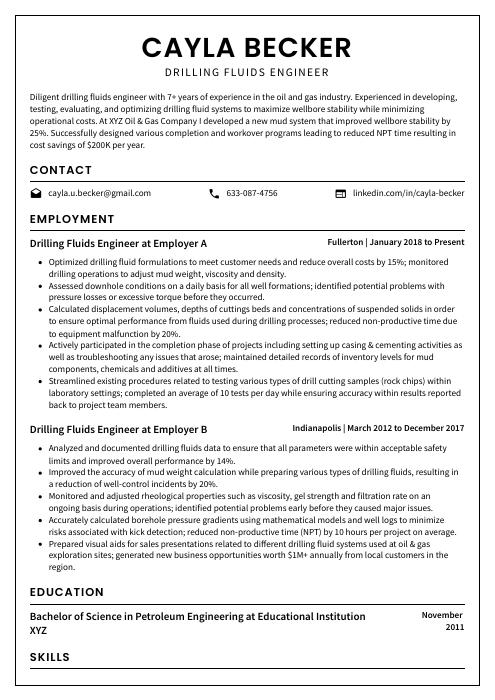

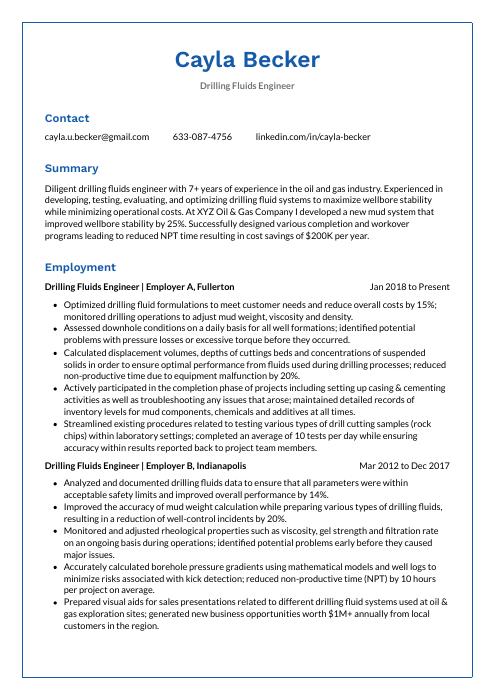

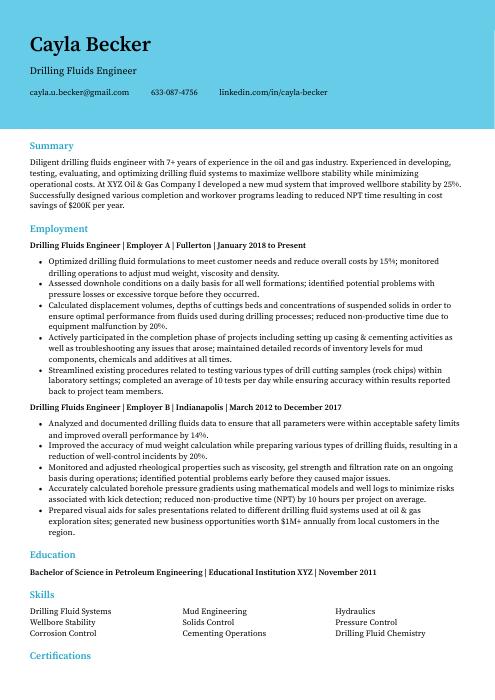

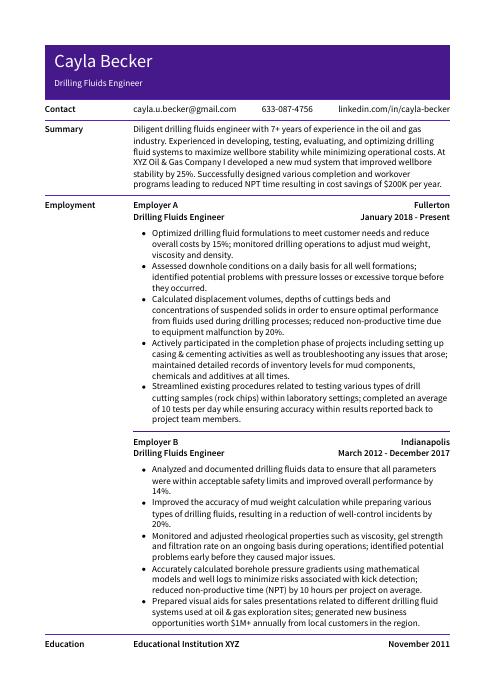

Drilling Fluids Engineer Resume Sample

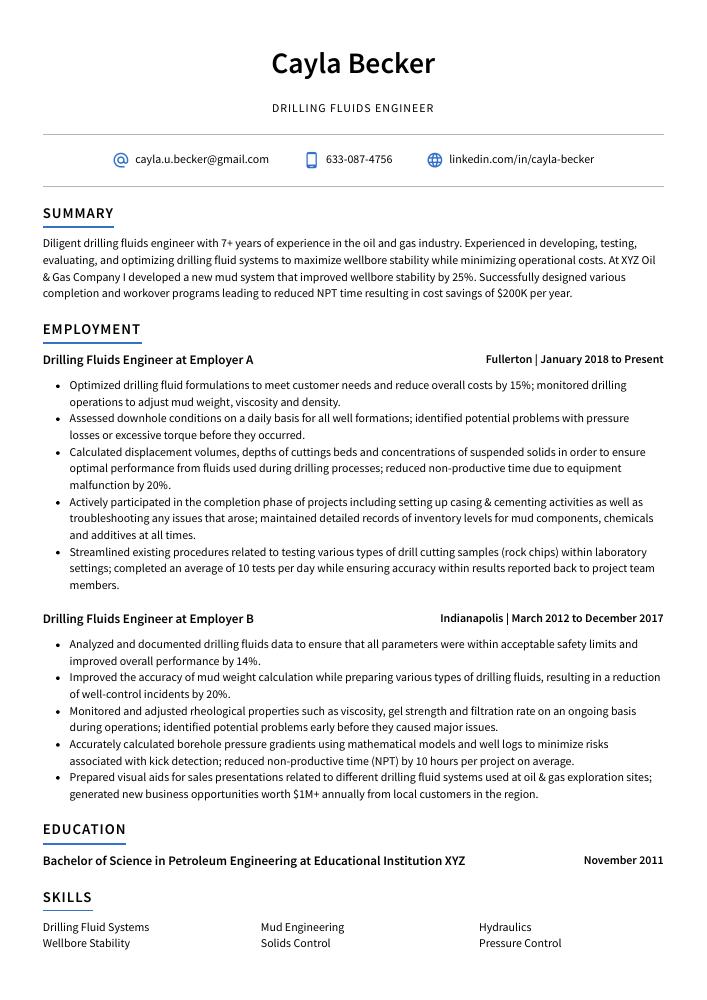

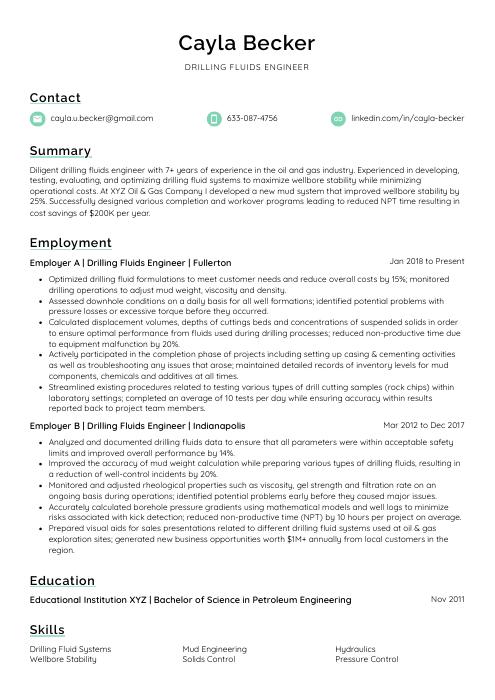

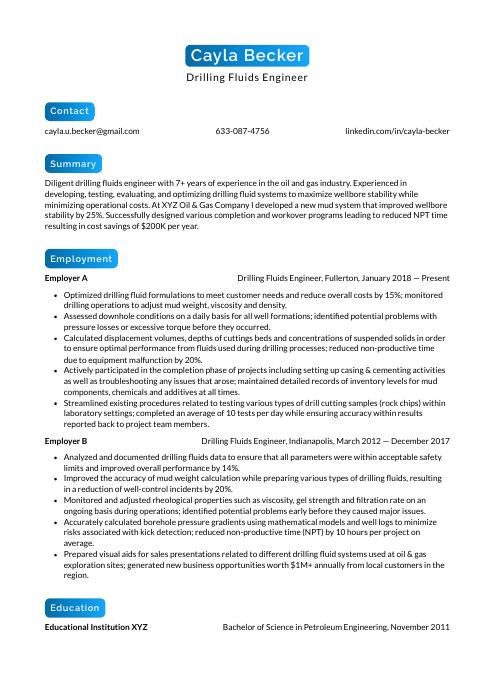

Cayla Becker

Drilling Fluids Engineer

[email protected]

633-087-4756

linkedin.com/in/cayla-becker

Summary

Diligent drilling fluids engineer with 7+ years of experience in the oil and gas industry. Experienced in developing, testing, evaluating, and optimizing drilling fluid systems to maximize wellbore stability while minimizing operational costs. At XYZ Oil & Gas Company I developed a new mud system that improved wellbore stability by 25%. Successfully designed various completion and workover programs leading to reduced NPT time resulting in cost savings of $200K per year.

Experience

Drilling Fluids Engineer, Employer A

Fullerton, Jan 2018 – Present

- Optimized drilling fluid formulations to meet customer needs and reduce overall costs by 15%; monitored drilling operations to adjust mud weight, viscosity and density.

- Assessed downhole conditions on a daily basis for all well formations; identified potential problems with pressure losses or excessive torque before they occurred.

- Calculated displacement volumes, depths of cuttings beds and concentrations of suspended solids in order to ensure optimal performance from fluids used during drilling processes; reduced non-productive time due to equipment malfunction by 20%.

- Actively participated in the completion phase of projects including setting up casing & cementing activities as well as troubleshooting any issues that arose; maintained detailed records of inventory levels for mud components, chemicals and additives at all times.

- Streamlined existing procedures related to testing various types of drill cutting samples (rock chips) within laboratory settings; completed an average of 10 tests per day while ensuring accuracy within results reported back to project team members.

Drilling Fluids Engineer, Employer B

Indianapolis, Mar 2012 – Dec 2017

- Analyzed and documented drilling fluids data to ensure that all parameters were within acceptable safety limits and improved overall performance by 14%.

- Improved the accuracy of mud weight calculation while preparing various types of drilling fluids, resulting in a reduction of well-control incidents by 20%.

- Monitored and adjusted rheological properties such as viscosity, gel strength and filtration rate on an ongoing basis during operations; identified potential problems early before they caused major issues.

- Accurately calculated borehole pressure gradients using mathematical models and well logs to minimize risks associated with kick detection; reduced non-productive time (NPT) by 10 hours per project on average.

- Prepared visual aids for sales presentations related to different drilling fluid systems used at oil & gas exploration sites; generated new business opportunities worth $1M+ annually from local customers in the region.

Skills

- Drilling Fluid Systems

- Mud Engineering

- Hydraulics

- Wellbore Stability

- Solids Control

- Pressure Control

- Corrosion Control

- Cementing Operations

- Drilling Fluid Chemistry

Education

Bachelor of Science in Petroleum Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Drilling Fluids Engineer

International Association of Drilling Flu

May 2017

1. Summary / Objective

The summary or objective at the beginning of your drilling fluids engineer resume should be used to highlight your experience and qualifications. For example, you could mention the number of years you have been in this field, any certifications or awards that demonstrate excellence in your work, and how you successfully managed a large-scale project for an oil company. Additionally, it’s important to emphasize any specialized knowledge or skills related to drilling fluid engineering that make you stand out from other applicants.

Below are some resume summary examples:

Driven drilling fluids engineer with 5+ years of experience in designing, implementation and optimization of drilling fluid programs for oil and gas wells. Experienced in working on complex projects that involve multiple stakeholders. Demonstrated track record of improving efficiency by reducing cost over-runs while maintaining quality standards. Proven ability to develop long-term relationships with clients due to superior customer service skills.

Committed drilling fluids engineer with 5+ years of experience in the oil and gas industry. Proven ability to consistently maintain safe operations while optimizing processes for efficiency and cost-effectiveness. At XYZ, oversaw drilling fluid programs on offshore rigs that resulted in a 23% decrease in annual nonproductive time (NPT) costs. Seeking to join ABC Co.’s team as a drilling fluids specialist to further improve performance metrics.

Proficient drilling fluids engineer with 5+ years of experience. Expertise in managing drilling mud engineering operations, optimizing process performance and developing cost-effective solutions for oil and gas companies. At XYZ Inc., analyzed the production data to identify problems related to drill bit hydraulics, resulting in a 20% increase in efficiency. Successfully developed integrated fluid systems that lowered operational costs by 25%.

Hard-working drilling fluids engineer with 8+ years of experience in the oil and gas industry. Skilled at designing, developing, testing, analyzing and optimizing drilling fluid systems for wellbore stability. Successfully managed a project that improved mud weight control by 10%, resulting in savings of over $2 million for Company X. Looking to join ABC Drilling Fluids as a senior-level engineer to continue making an impact on business goals.

Professional drilling fluids engineer with 8+ years of experience in overseeing drilling operations and optimizing performance. Skilled at designing, testing and implementing new mud systems for various types of wells to ensure optimal efficiency while maintaining safety standards. Experienced in developing cost-saving strategies that reduced expenses by 20%. Looking forward to contributing my expertise to XYZ Oil & Gas Company’s success.

Reliable drilling fluids engineer with 4+ years of experience in the oil and gas industry. Skilled in designing, creating, and testing drilling fluid systems for horizontal wells to ensure safe operations. Successfully reduced costs by 20% through optimized system design at XYZ Company. Looking to join ABC Corp as a Drilling Fluids Engineer to further develop my technical expertise and problem-solving abilities.

Well-rounded drilling fluids engineer with 5+ years of experience in the oil and gas industry. Skilled at conducting lab experiments, analyzing data, troubleshooting equipment problems, and supervising operations on-site. Seeking to join ABC Oil & Gas as a drilling fluids engineer to utilize my expertise in developing innovative solutions that improve safety while ensuring optimal efficiency and cost savings.

Enthusiastic drilling fluids engineer with 5+ years of experience in the oil and gas industry. Achieved a 13% reduction in drilling time by optimizing mud systems during well planning stages, while consistently adhering to environmental regulations. Seeking to use problem-solving skills and expertise at ABC Oil Company for efficient production optimization and cost savings.

2. Experience / Employment

The employment (or experience) section is where you talk about your work history. It should be written in reverse chronological order, meaning the most recent job is listed first.

When writing this section, stick to bullet points primarily; doing so makes it easier for the reader to take in what you want to convey. When writing each bullet point, provide detail on what you did and any quantifiable results that were achieved as a result of your work.

For example, instead of saying “Maintained drilling fluids,” you could say, “Developed and implemented an innovative system for monitoring mud properties during operations which resulted in improved safety and reduced downtime by 15%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Monitored

- Calculated

- Analyzed

- Optimized

- Operated

- Troubleshot

- Inspected

- Adjusted

- Formulated

- Blended

- Measured

- Sampled

- Stored

- Disposed

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Sampled and tested drilling fluids to ensure compliance with safety and environmental regulations, resulting in a 20% decrease of non-compliance incidents.

- Demonstrated strong analytical skills when analysing reservoir data, interpreting flow rate tests and resolving drilling issues; reduced downtime by 25%.

- Compiled detailed reports on the properties of different types of drill muds while providing recommendations for cost-effective solutions that increased efficiency by 15%.

- Developed and implemented strategies for controlling wellbore pressures to reduce risk during deepwater operations; decreased blowout potentials by 30%.

- Effectively collaborated with other engineers as part of an offshore team responsible for planning long lateral horizontals, thereby increasing production output by $400K+ per month.

- Adjusted and maintained drilling fluids to ensure optimal performance and completion of the wellbore, saving $5,000 in costs over the course of 6 months.

- Operated a variety of oilfield equipment for mixing, testing and treating drilling fluid systems; completed 500+ operations within established timeframes with no incidents or injuries reported.

- Reorganized existing inventory processes to streamline ordering procedures for mud chemicals and related supplies by 25%, resulting in an 11% reduction in overall expenses.

- Proficiently monitored changes to underground pressure conditions using specialized software programs during drillings; minimized risk exposure by adhering strictly to safety protocols at all times while onsite.

- Measured rheological properties such as viscosity, gel strengths & filtrate loss regularly according to industry standards; updated database records accurately with findings from each test conducted.

- Represented the drilling fluids engineering team in over 75 projects and successfully completed them within allocated budgets, resulting in a 20% reduction of operating costs.

- Mentored 10 junior engineers on the principles of drilling fluid technology and techniques related to oil-well operations; improved their technical knowledge by 30%.

- Competently designed specialized chemical formulations for mud control systems used during wellbore construction activities, that saved an average of $15,000 per project due to reduced material sourcing costs.

- Spearheaded 8 research initiatives involving novel technologies for efficient extraction from reservoirs located at different depths; developed breakthrough solutions that increased production efficiency by 40%.

- Revised existing processes regarding testing, sampling & analyzing data collected while monitoring underground formation conditions; optimized procedures which resulted in 50 hours saved annually on field trips alone.

- Troubleshot and solved technical issues with drilling fluids, resulting in a 20% decrease in downtime.

- Designed and implemented customized fluid systems for oil wells, increasing efficiency by 15%.

- Stored and monitored high-viscosity chemical inventory to ensure appropriate quantities were available for use; reduced costs by $4,000 over the course of 6 months.

- Structured routine maintenance plans to monitor mud properties throughout various stages of well construction projects; completed 8 projects ahead of schedule within budget constraints.

- Independently oversaw operations related to mixing chemicals and testing physical properties onsite at customer locations; identified 3 potential safety hazards before they became an issue reducing risk exposure by 50%.

- Efficiently designed and implemented oilfield drilling fluids programs, resulting in a 15% reduction in costs associated with mud engineering operations.

- Utilized advanced data analysis techniques to assess the performance of drill string components, helping identify operational issues and reduce downtime by 8%.

- Participated in weekly meetings with directors and other stakeholders to share new ideas for improving fluid management processes; introduced novel solutions that led to an increase of $1 million dollars in cost savings over two years.

- Introduced innovative technologies such as polymer flooding systems which enabled accurate real-time monitoring of wellbore conditions; this resulted in better control over mud characteristics during drilling operations and improved safety outcomes overall.

- Advised senior staff on compliance matters regarding environmental regulations related to drilling activities, ensuring all procedures were conducted according to industry standards at all times.

- Expedited the design and implementation of drilling fluid systems for over 40 wells; reduced total project times by 25% on average.

- Disposed of used fluids in a safe and environmentally conscious manner, adhering to all applicable regulations and standards.

- Presented weekly progress reports to the engineering team highlighting key developments related to wellbore stability analysis, including torque & drag calculations and hole cleaning strategies; saved 4 hours/week of administrative time due to improved reporting practices.

- Reduced nonproductive time (NPT) from 5% down to 2%, resulting in an additional $5000 savings per month for clients in oil & gas operations across 3 countries worldwide.

- Confidently operated various types of equipment utilized for logging-while-drilling activities such as mud motors, MWD tools and coring assemblies with zero safety incidents reported during tenure.

- Formulated drilling and completion fluids, including oil-based muds, synthetic oils & water systems for over 200 wells; achieved a 20% reduction in rig time utilization.

- Achieved cost savings of $60K annually by optimizing the design of drilling fluid formulations to increase operational efficiency and reduce environmental impact.

- Facilitated effective teamwork between different departments such as procurement, engineering & safety to ensure that all project objectives were met on schedule.

- Blended chemicals into specialized mixes with exacting accuracy according to customer specifications using various equipment; reduced nonconformance incidences by 12%.

- Meticulously monitored properties such as viscosity, density & sand content throughout the entire process while adhering strictly to safety protocols at all times.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization may require a drilling fluids engineer with experience in the oil and gas industry, while another may be looking for one who has expertise in shale operations.

For this reason, it is important to tailor the skills section of your resume to each job you apply for. This will help ensure that applicant tracking systems (ATS) recognize relevant keywords when scanning resumes and pass them on to human recruiters.

You should also mention these skills elsewhere within your resume – such as in the summary or work experience sections – so that employers have an even clearer understanding of what you can bring to their organization.

Below is a list of common skills & terms:

- Cementing Operations

- Corrosion Control

- Drilling Fluid Additives

- Drilling Fluid Chemistry

- Drilling Fluid Systems

- Hydraulics

- Mud Engineering

- Pressure Control

- Solids Control

- Wellbore Stability

4. Education

Mentioning your education on your resume depends on how far along you are in your career. If you just graduated and have no work experience, include an education section below the objective statement of your resume. However, if you have significant work experience that is relevant to the drilling fluids engineer role, it may be more beneficial to omit the education section altogether.

If including an education section is necessary or desired, try mentioning courses and subjects related to a drilling fluids engineering job such as fluid mechanics or chemical engineering.

Bachelor of Science in Petroleum Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have taken the time and effort to become proficient in a certain field. This shows dedication, commitment, and knowledge of the industry which can be highly valued by hiring managers.

Including certifications on your resume is an effective way to demonstrate your expertise in a particular area or skill set relevant for the job you are applying for. It will also show that you take professional development seriously and are committed to staying up-to-date with industry trends.

Certified Drilling Fluids Engineer

International Association of Drilling Flu

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Cayla Becker, this would be Cayla-Becker-resume.pdf or Cayla-Becker-resume.docx.

7. Cover Letter

Cover letters provide a great opportunity to make yourself stand out from other applicants. They are usually composed of 2-4 paragraphs and serve as an extension to your resume, offering the hiring manager more insight into who you are and why you’re right for the job.

Although cover letters aren’t always mandatory when applying for jobs, writing one can give you an edge that sets you apart from other candidates. It also allows recruiters to get a better understanding of how well suited you might be for the role they’re looking to fill.

Below is an example cover letter:

Dear Lorenz,

I am excited to apply for the Drilling Fluids Engineer position at XYZ Corporation. With more than 10 years of experience in drilling fluids engineering and a strong background in fluid mechanics, I am confident I will be an asset to your organization.

In my current role as Drilling Fluids Engineer at ABC Corporation, I oversee all aspects of drilling fluids operations for a team of 15 engineers. I have extensive experience designing and implementing custom fluid systems for various drilling projects, and my knowledge of mud chemistry has helped me troubleshoot many complex issues. In addition, I have developed strong relationships with vendors and service providers, which has helped me negotiate favorable terms and pricing.

I am knowledgeable about all aspects of drilling operations and well completion, and my understanding of reservoir dynamics has been critical in developing successful fluid systems. My ability to think creatively has allowed me to develop innovative solutions to challenging problems, and my attention to detail ensures that all projects are completed safely and on schedule.

I believe my skills and experience would be a valuable addition to your organization, and I look forward to speaking with you about this opportunity. Thank you for your time & consideration.

Sincerely,

Cayla

Drilling Fluids Engineer Resume Templates

Saola

Saola Jerboa

Jerboa Gharial

Gharial Numbat

Numbat Echidna

Echidna Bonobo

Bonobo Fossa

Fossa Hoopoe

Hoopoe Indri

Indri Axolotl

Axolotl Cormorant

Cormorant Markhor

Markhor Dugong

Dugong Pika

Pika Quokka

Quokka Ocelot

Ocelot Lorikeet

Lorikeet Rhea

Rhea Kinkajou

Kinkajou Rezjumei

Rezjumei