CAE Engineer Resume Guide

Cae Engineers work to design, develop and analyze aircrafts. They are responsible for making sure that the aircraft meets safety standards as well as customer requirements. Cae Engineers also use computer-aided engineering (CAE) tools to simulate how an aircraft will perform in flight and on the ground.

You have the technical knowledge and experience to be an excellent civil engineer at any construction firm. But potential employers are not yet familiar with your skills, so you must craft a resume that gives them confidence in hiring you.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

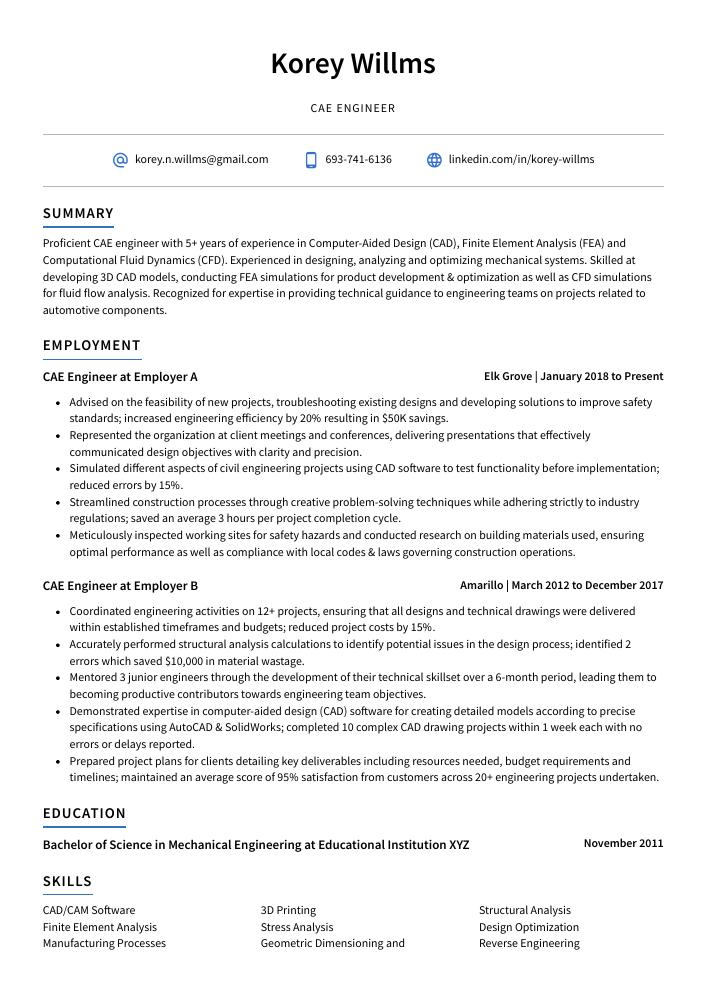

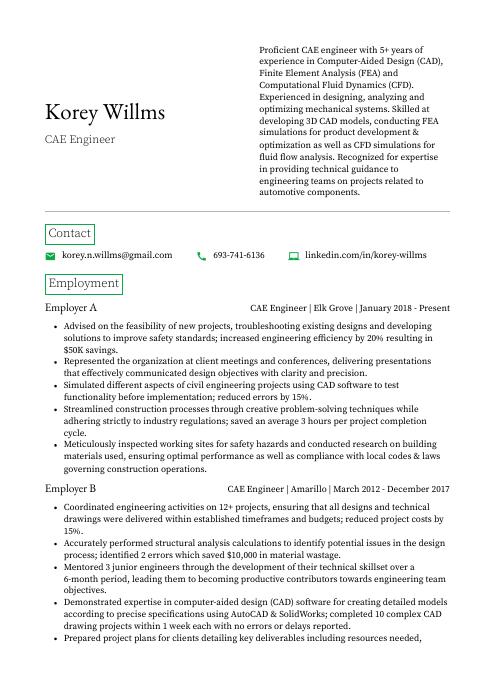

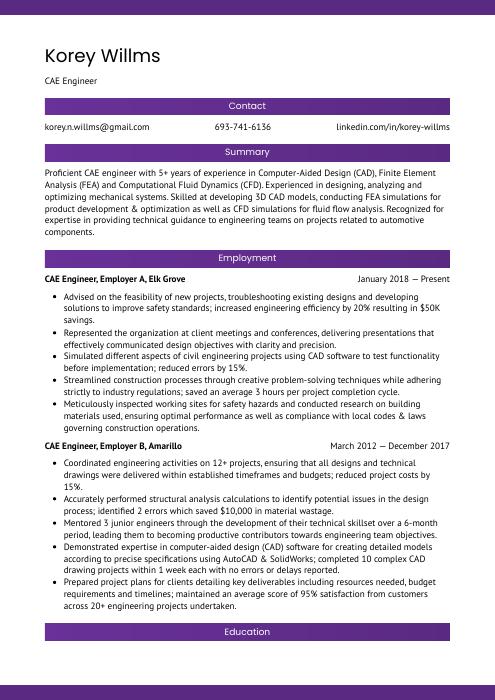

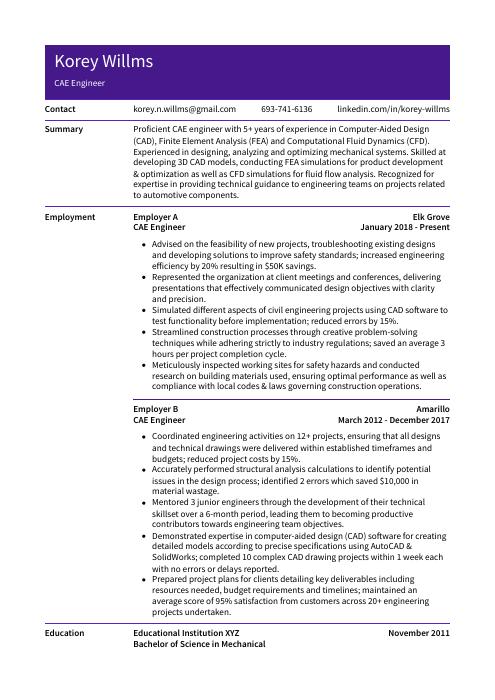

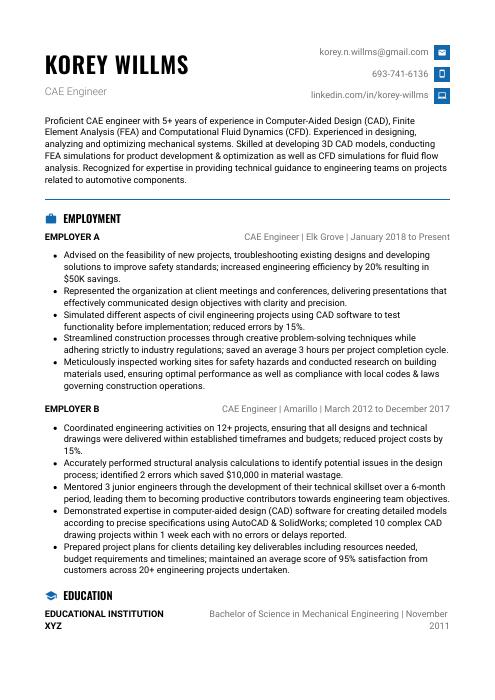

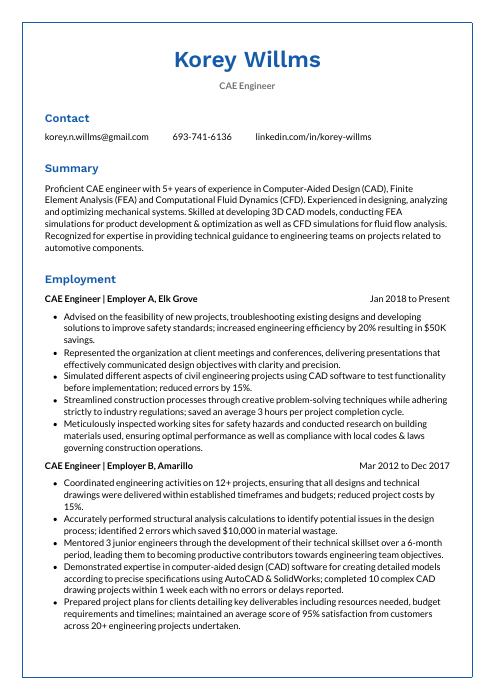

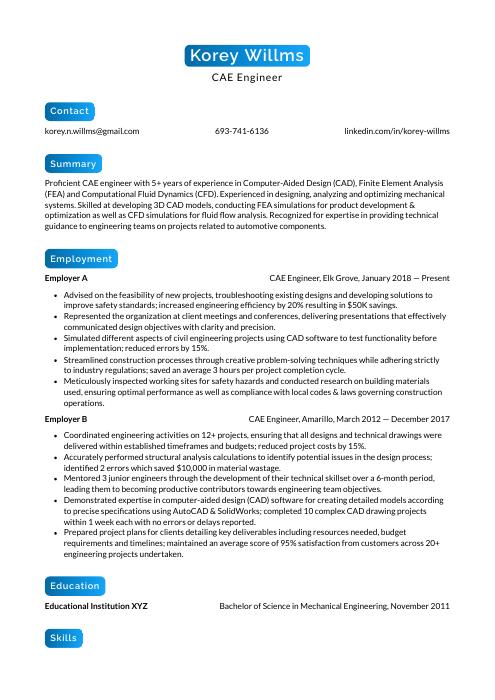

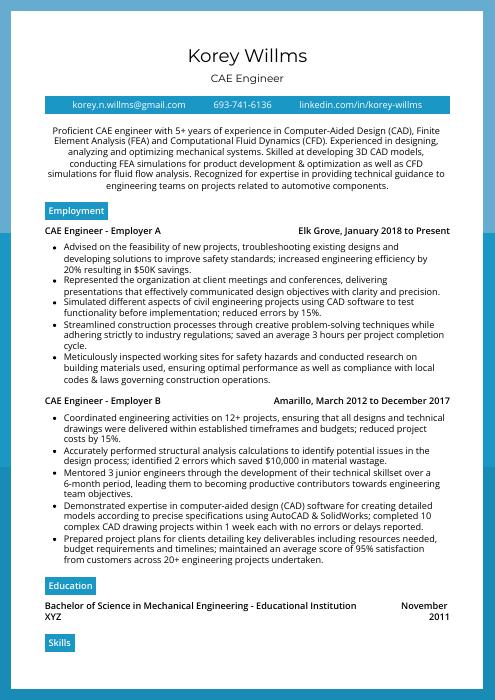

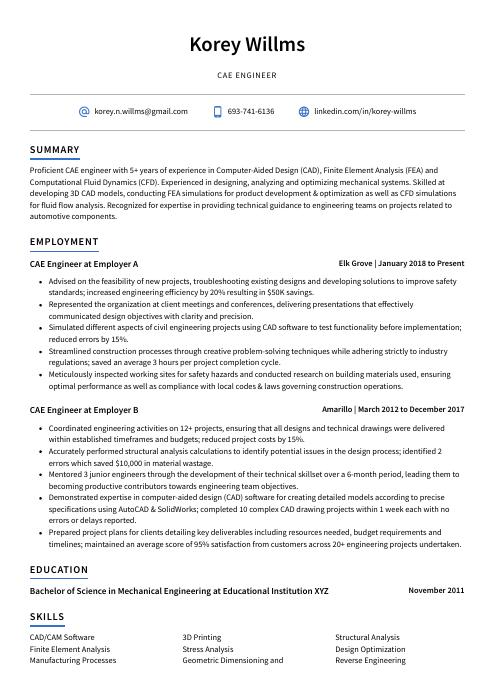

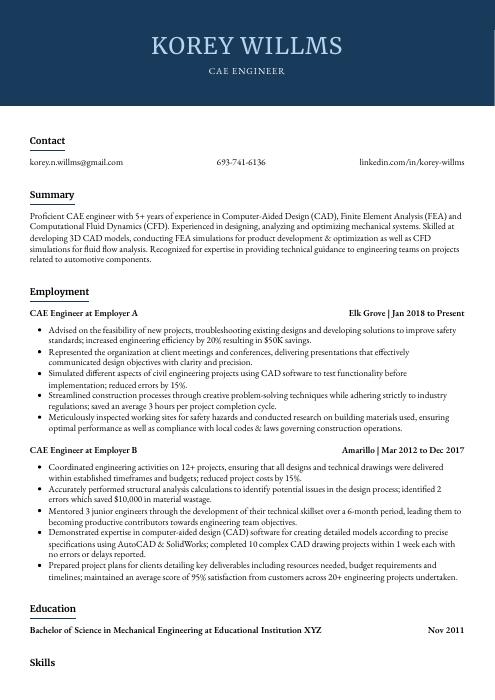

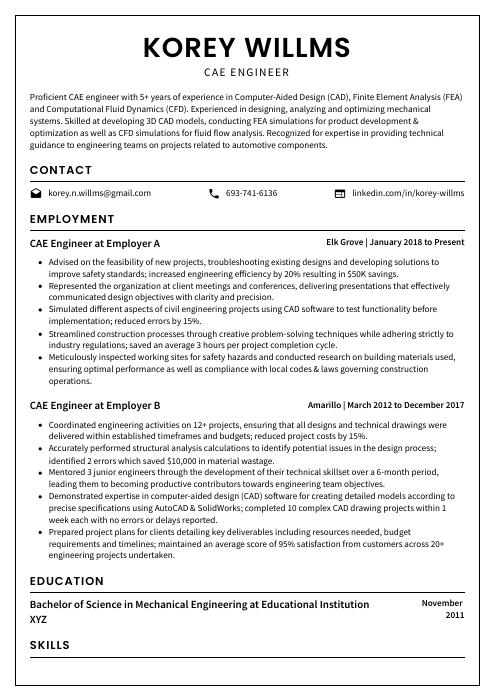

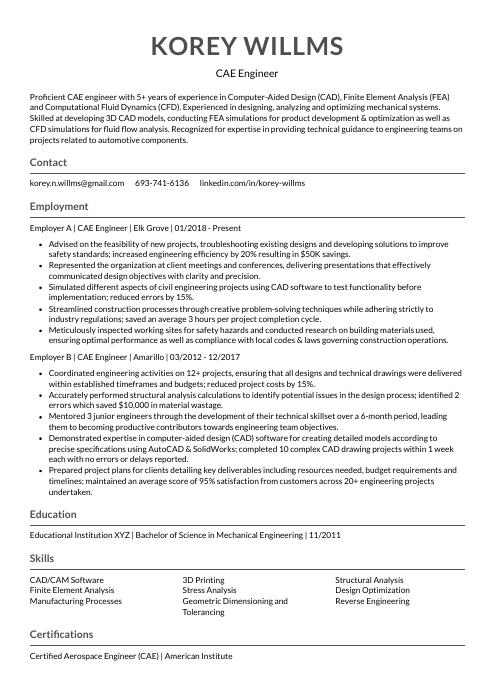

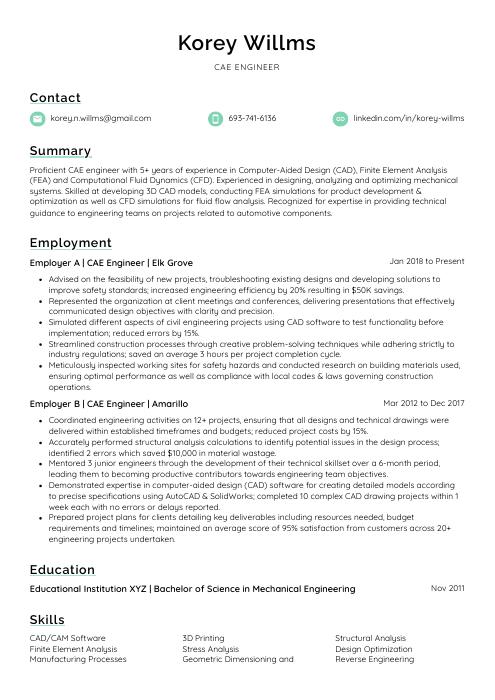

CAE Engineer Resume Sample

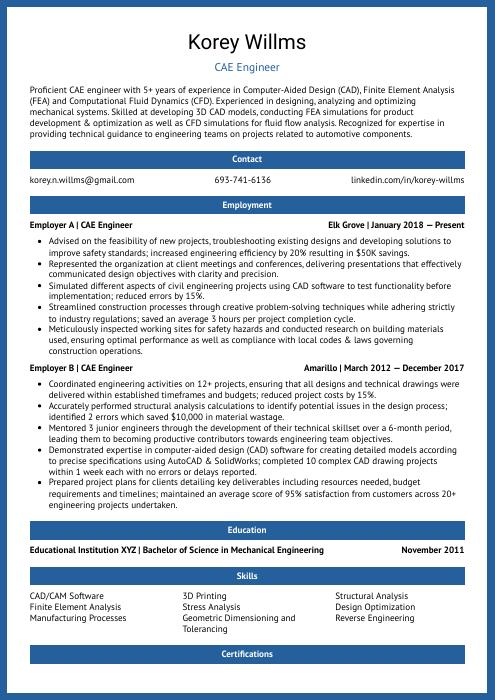

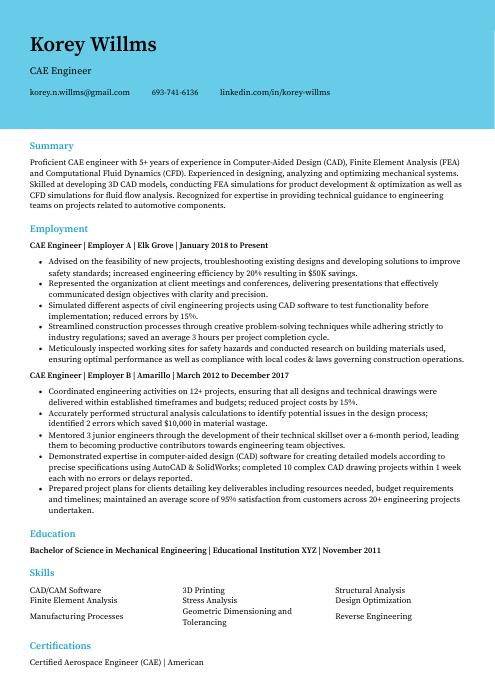

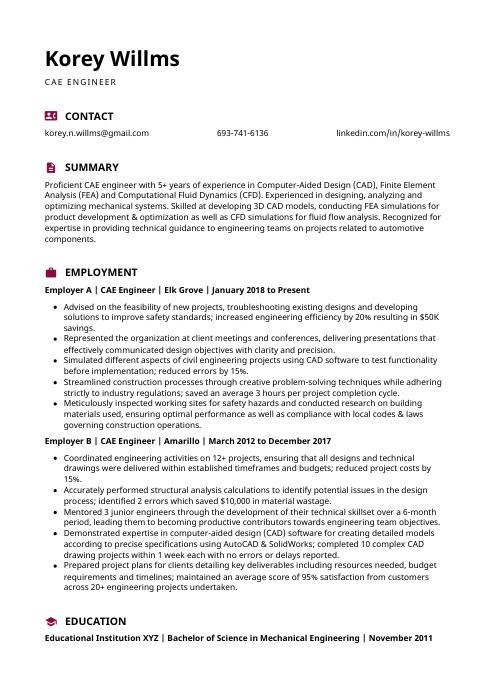

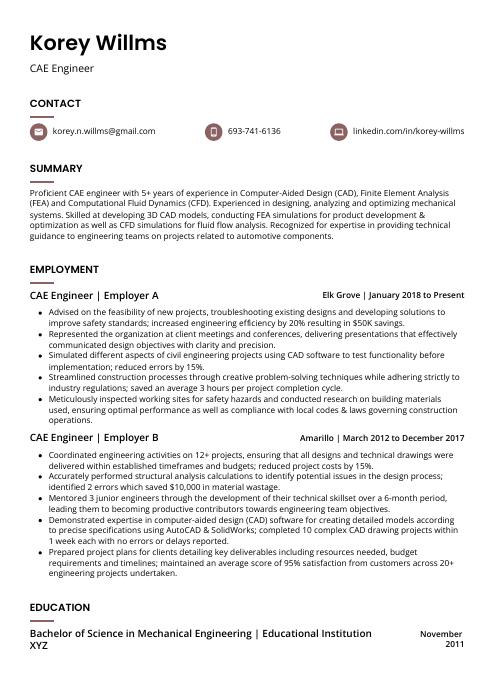

Korey Willms

CAE Engineer

[email protected]

693-741-6136

linkedin.com/in/korey-willms

Summary

Proficient CAE engineer with 5+ years of experience in Computer-Aided Design (CAD), Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). Experienced in designing, analyzing and optimizing mechanical systems. Skilled at developing 3D CAD models, conducting FEA simulations for product development & optimization as well as CFD simulations for fluid flow analysis. Recognized for expertise in providing technical guidance to engineering teams on projects related to automotive components.

Experience

CAE Engineer, Employer A

Elk Grove, Jan 2018 – Present

- Advised on the feasibility of new projects, troubleshooting existing designs and developing solutions to improve safety standards; increased engineering efficiency by 20% resulting in $50K savings.

- Represented the organization at client meetings and conferences, delivering presentations that effectively communicated design objectives with clarity and precision.

- Simulated different aspects of civil engineering projects using CAD software to test functionality before implementation; reduced errors by 15%.

- Streamlined construction processes through creative problem-solving techniques while adhering strictly to industry regulations; saved an average 3 hours per project completion cycle.

- Meticulously inspected working sites for safety hazards and conducted research on building materials used, ensuring optimal performance as well as compliance with local codes & laws governing construction operations.

CAE Engineer, Employer B

Amarillo, Mar 2012 – Dec 2017

- Coordinated engineering activities on 12+ projects, ensuring that all designs and technical drawings were delivered within established timeframes and budgets; reduced project costs by 15%.

- Accurately performed structural analysis calculations to identify potential issues in the design process; identified 2 errors which saved $10,000 in material wastage.

- Mentored 3 junior engineers through the development of their technical skillset over a 6-month period, leading them to becoming productive contributors towards engineering team objectives.

- Demonstrated expertise in computer-aided design (CAD) software for creating detailed models according to precise specifications using AutoCAD & SolidWorks; completed 10 complex CAD drawing projects within 1 week each with no errors or delays reported.

- Prepared project plans for clients detailing key deliverables including resources needed, budget requirements and timelines; maintained an average score of 95% satisfaction from customers across 20+ engineering projects undertaken.

Skills

- CAD/CAM Software

- 3D Printing

- Structural Analysis

- Finite Element Analysis

- Stress Analysis

- Design Optimization

- Manufacturing Processes

- Geometric Dimensioning and Tolerancing

- Reverse Engineering

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Aerospace Engineer (CAE)

American Institute of Aeron

May 2017

1. Summary / Objective

A resume summary/objective is your chance to make a great first impression. As a civil engineer, you can use it to highlight the projects and achievements that demonstrate your technical skills and experience in the field. For example, you could mention any certifications or degrees you have obtained, how many years of engineering experience you have under your belt, and what kind of infrastructure projects (bridges/roads etc.) you specialize in.

Below are some resume summary examples:

Professional CAE engineer with 10+ years of experience in developing, testing and implementing advanced CAE simulations. Adept at utilizing CAD/CAE tools to analyze the product performance under different real-world conditions. Skilled in creating detailed reports on simulation results and providing recommendations for design improvements. Demonstrated success in delivering projects ahead of schedule while meeting customer requirements for quality assurance within budget constraints.

Committed and detail-oriented CAE engineer with 9+ years of experience developing innovative solutions and improving existing products. Highly knowledgeable in finite element analysis, CAD design, and optimization techniques. Seeking to bring expertise to ABC Tech where I can provide creative engineering solutions that exceed customer expectations. Successfully reduced product defects by 20% through improved simulations using advanced simulation tools at XYZ Corp.

Hard-working CAE engineer with 7+ years of experience in a wide array of industries. Skilled at leveraging computer-aided engineering tools and software to create innovative solutions for complex problems. Proven track record of collaborating effectively with cross-functional teams to develop, optimize, and test products efficiently. Seeking to bring my expertise in FEA/CFD simulations to ABC Company’s CAE team and deliver high quality results on time.

Determined CAE engineer with 5+ years of experience in automotive engineering and simulation. Skilled at creating comprehensive models to simulate real-world scenarios, validate designs, and analyze performance. Seeking to join ABC Tech where my expertise can be leveraged to ensure optimal safety and functionality for the company’s products. Key achievements include a 30% reduction in product design cycle time through optimization of CAE process steps.

Reliable CAE Engineer with over 5 years of experience in the automotive industry. Skilled in using advanced engineering simulations software such as ANSYS and Abaqus for component design, testing, optimization and failure analysis. Expertise includes FEA/CFD analyses to predict stress levels and fatigue life cycle performance. Proven ability to reduce product development time by 25% through efficient utilization of CAE tools.

Enthusiastic CAE engineer with 7+ years of experience in the design, development and analysis of automotive components. Proven track record for successfully developing products that meet customer requirements while adhering to strict cost and weight constraints. Adept at using simulation tools such as ANSYS, Abaqus, HyperMesh and Creo/Pro-e to analyze designs before testing them on physical prototypes.

Skilled CAE engineer with 5+ years of experience in developing and optimizing engineering designs for a wide range of industries. Seeking to join ABC Tech to utilize expertise in finite element analysis (FEA) simulations, CAD/CAE modeling, optimization techniques, and design validation processes. Achieved 15% cost reduction via optimized designs while designing an aircraft wing structure at XYZ Inc.

Passionate CAE engineer with 5+ years of experience in product design and development. Adept at using 3D printing, rapid prototyping, and numerical simulation to develop effective yet cost-efficient solutions for clients. Seeking an opportunity to join ABC Inc., where I can utilize my expertise in the automotive industry to create innovative products that meet customer needs while reducing costs.

2. Experience / Employment

The employment (or experience) section is where you provide details on your work history. This should be written in reverse chronological order, meaning the most recent job is listed first.

Stick to bullet points when writing this section; it allows for a quick and easy read of what you have done. When stating what you did, make sure to include quantifiable results whenever possible so that employers can better understand the impact of your work.

For example, instead of saying “Designed aircraft components,” you could say, “Developed CAD models for engine nacelle components using Catia V5 software which resulted in an 8% reduction in manufacturing costs.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Analyzed

- Simulated

- Fabricated

- Programmed

- Assembled

- Installed

- Calibrated

- Troubleshot

- Tested

- Documented

- Optimized

- Commissioned

- Monitored

- Upgraded

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Reduced project costs by 15% and expedited completion of 10+ projects by utilizing innovative engineering techniques.

- Substantially improved product performance, reliability and safety ratings through rigorous testing and debugging of complex systems designs.

- Compiled detailed reports on findings from tests conducted in the lab for a variety of products; identified possible solutions to issues based on results data collected over 3 years.

- Expedited production times for 5 new products by 30% through optimized assembly processes designed using CAD software programs such as AutoCAD & SolidWorks used in conjunction with other advanced toolsets/languages like MATLAB & Python programming languages.

- Assembled prototype components according to specifications provided; implemented timely modifications following customer feedback reviews before finalizing design plans within expected deadlines each time without fail or delay.

- Reorganized engineering and design processes to increase efficiency by 20%, reducing project completion times from 8 weeks to 6.

- Tested, validated and documented engineering changes on 10+ aircraft models; improved operational reliability of all planes by 15%.

- Diligently monitored production line operations for compliance with safety regulations while ensuring quality standards were met or exceeded.

- Developed innovative solutions to complex technical issues in collaboration with other engineers, resulting in a cost reduction of $15,000 per month across the company’s fleet of aircrafts.

- Troubleshot mechanical problems on 3 different types of engines using advanced diagnostic tools; reduced downtime hours spent repairing engine defects by 30%.

- Facilitated the development of 15+ CAE models to simulate product performance, resulting in a 5% decrease in design cycle time and $3,000 reduction in prototyping costs.

- Utilized the Finite Element Method (FEM) and Computational Fluid Dynamics (CFD) software packages such as ANSYS Workbench and Fluent to analyze structural integrity, fluid flow patterns and heat transfer issues.

- Improved designs by detecting potential areas of failure through linear/nonlinear static stress analysis; successfully reduced manufacturing defects by 10%.

- Reliably coordinated with cross-functional teams including Mechanical Designers & CAD Engineers for model validation purposes; completed projects ahead of schedule on 8 occasions last year.

- Structured tests using NVH tools like LabVIEW for validating noise & vibration levels within mechanical systems; achieved 50 dB rating without compromising quality or reliability standards set forth by industry regulations.

- Achieved a 25% reduction in product development time by implementing an improved system for tracking design changes.

- Competently designed, tested and implemented over 15 new components for a complex aircraft engine control system, resulting in increased efficiency and reliability of the unit.

- Presented plans to upper management on multiple occasions regarding proposed engineering projects; successfully negotiated cost savings of $90K+ per project while meeting deadlines consistently.

- Monitored test flight data from 10+ aircrafts on daily basis to identify potential safety issues and assess performance areas that needed improvement or enhancement; updated software accordingly with zero downtime incidents reported during any testing period.

- Assessed materials used in production process against specified requirements set out by FAA regulations and industry standards; identified discrepancies within 5 minutes of review 90% of the time saving considerable resources & costs for organization overall.

- Participated in the design, development and optimization of 10+ innovative CAE systems; ensured that projects were completed on schedule with zero errors.

- Consistently monitored system performance to ensure reliability at all times; reduced downtime incidents by 25% over a six month period.

- Optimized existing software algorithms for better accuracy and precision within budget parameters; improved processing speed by 45%.

- Fabricated complex CAD models from raw data sets in order to predict product behavior under varying conditions, enabling engineers to make informed decisions quickly without compromising quality standards or safety regulations.

- Calibrated mechanical components according to rigorous industry specifications while documenting test results accurately and completely; saved $16,000 worth of repairs due to timely maintenance checks over one year span.

- Independently designed and implemented innovative solutions to upgrade existing software systems, resulting in a 15% decrease in system downtime.

- Upgraded network infrastructure by installing new hardware components and deploying latest OS versions, increasing overall system performance efficiency by 20%.

- Commissioned five complex IT projects from start to finish on time and within budget; saved the organization $5k annually in labor costs due to streamlined processes.

- Programmed customized algorithms for data analysis tasks using Python, Java & JavaScript languages; increased accuracy of predictions by 22%.

- Formulated comprehensive test plans for quality assurance purposes that included regression testing along with manual/automated scenarios; reduced bug count rate per release cycle by 50%.

- Revised blueprints and technical specifications for over 15 construction projects, resulting in a 12% reduction in material costs.

- Documented engineering designs using AutoCAD software to produce detailed diagrams of mechanical assemblies; improved accuracy by 20%.

- Efficiently managed the fabrication of multiple prototypes within tight timelines and budget limitations; completed all tasks 2 weeks ahead of schedule.

- Designed innovative solutions for diverse structural problems encountered during the engineering process; saved an average $5,000 per project due to creative problem-solving techniques.

- Spearheaded 4 successful bridge renovation initiatives that have been recognized with national awards from industry leaders such as ABC Engineering Corporation and XYZ Associates Ltd.

- Installed and tested over 150 computer systems, components and peripherals for clients in the last 12 months; reduced debugging time by 40%.

- Successfully launched 5 new software applications with a team of 4 engineers; improved user experience for all users by 25% within 3 months.

- Introduced automated testing procedures to improve product quality and reduce delivery deadlines by 22%; managed 10+ projects simultaneously on schedule without any delays.

- Analyzed system requirements and developed detailed technical specifications documentations that led to successful project completion with 50% fewer resources than expected.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC might require experience with MATLAB while Organization XYZ might be looking for someone who is proficient in AutoCAD.

It is essential to tailor the skills section of your resume to each job that you are applying for because many employers use applicant tracking systems these days, which scan resumes for certain keywords before passing them on to a human.

Once listed here, it can also be beneficial to discuss your most important skillset in more detail elsewhere – such as the summary or experience sections – so that they stand out from other applicants and demonstrate why you would make an ideal candidate.

Below is a list of common skills & terms:

- 3D Printing

- CAD/CAM Software

- Design Optimization

- Finite Element Analysis

- Geometric Dimensioning and Tolerancing

- Manufacturing Processes

- Reverse Engineering

- Stress Analysis

- Structural Analysis

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below the resume objective. However, if you have significant work experience to showcase, omitting the education section is perfectly fine.

If an education section is included, try to list courses and subjects relevant to the role of a CAE engineer that may give employers more insight into why they should hire you for this position.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to a potential employer that you have the knowledge and skills necessary for the job. Employers are always looking for candidates who can demonstrate their expertise in a certain area, so including certifications on your resume is an excellent way to show them what you bring to the table.

If you have any relevant certifications related to the position, make sure they are included prominently in this section of your resume. This will help employers quickly identify how qualified you are and may give them more confidence when considering hiring you.

Certified Aerospace Engineer (CAE)

American Institute of Aeron

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Korey Willms, this would be Korey-Willms-resume.pdf or Korey-Willms-resume.docx.

7. Cover Letter

Including a cover letter with your job application is a great way to demonstrate your enthusiasm and interest in the position. It’s usually made up of 2 to 4 paragraphs that explain why you’re an ideal fit for the role and how your skills and experience will be beneficial.

Cover letters are not mandatory but they do give recruiters a better idea of who you are as a professional, so it’s always worth taking the time to write one if possible. They provide insight into what makes you stand out from other candidates which could make all the difference when it comes to getting hired!

Below is an example cover letter:

Dear Dannie,

I am writing in response to your posting for a CAE Engineer. With my experience in developing and managing CAE processes, as well as my hands-on experience with various CAE tools, I am confident I can be an asset to your organization.

In my previous role at [company name], I was responsible for developing and managing the CAE process for the development of new products. This involved working with cross-functional teams to ensure that all relevant disciplines were considered during the design process. I also developed and maintained relationships with vendors to ensure that we had access to the latest CAE tools and technologies. In addition, I led a team of engineers in the use of these tools to carry out analyses on new designs.

Through this experience, I have gained a strong understanding of how to develop and manage effective CAE processes. My hands-on experience with various CAE tools has also given me a good understanding of how they can be used effectively to carry out analyses on product designs. These skills would enable me to contribute positively to your organization’s bottom line by ensuring that new products are designed efficiently and effectively using state-of-the artCAE techniques.

I have attached a copy of my resume detailing my projects and engineering experience. I can be reached anytime via phone or email should you wish to discuss my application further.

Sincerely,

Korey

CAE Engineer Resume Templates

Quokka

Quokka Jerboa

Jerboa Pika

Pika Echidna

Echidna Markhor

Markhor Kinkajou

Kinkajou Saola

Saola Rhea

Rhea Ocelot

Ocelot Dugong

Dugong Hoopoe

Hoopoe Fossa

Fossa Axolotl

Axolotl Bonobo

Bonobo Gharial

Gharial Numbat

Numbat Cormorant

Cormorant Indri

Indri Lorikeet

Lorikeet Rezjumei

Rezjumei