Advanced Manufacturing Engineer Resume Guide

Advanced manufacturing engineers design, develop, and maintain production systems to ensure efficient use of materials and labor. They analyze processes to identify areas for improvement in safety, cost-effectiveness, quality control, waste reduction and energy efficiency. Additionally they troubleshoot existing equipment problems as well as develop new test procedures for products or components.

You have the know-how to make any advanced manufacturing process run like a well-oiled machine. But employers don’t yet recognize your talents; you need to write an eye-catching resume that will draw their attention and make them want to hire you.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

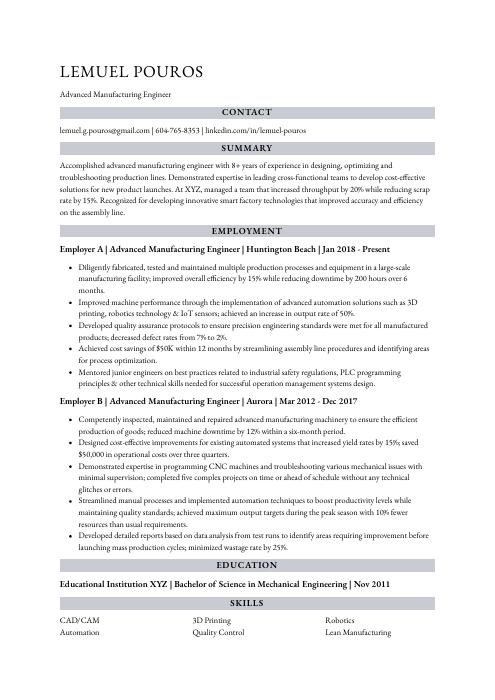

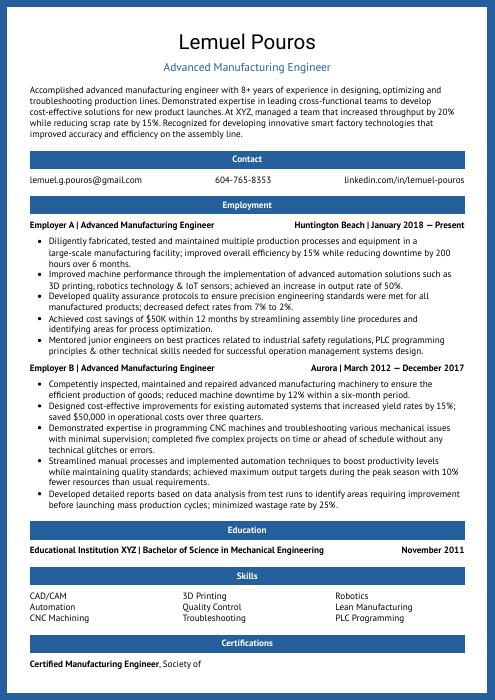

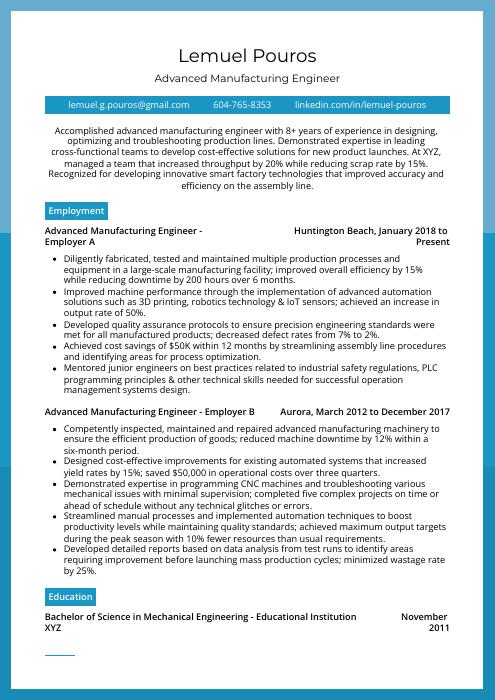

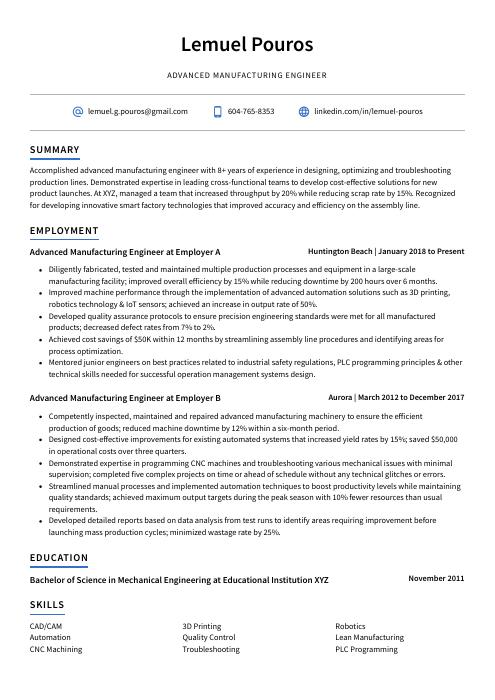

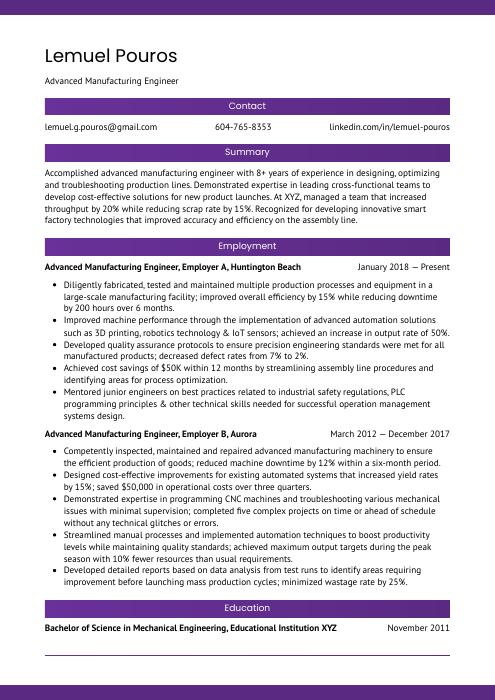

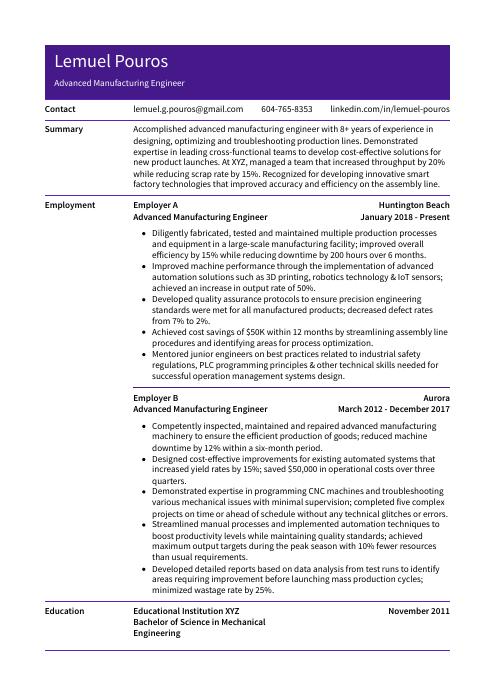

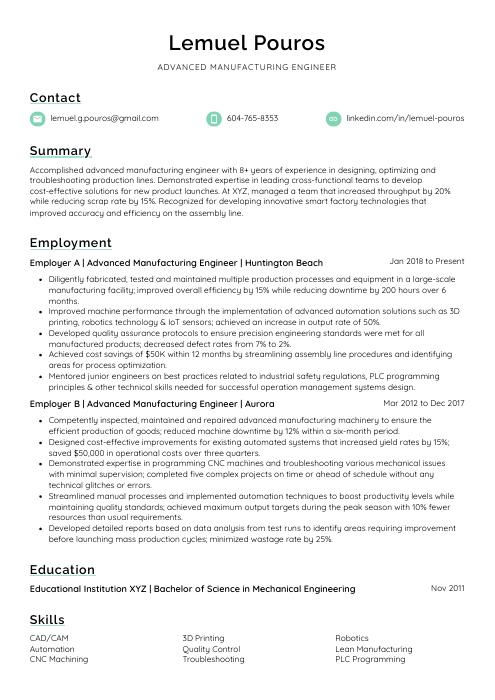

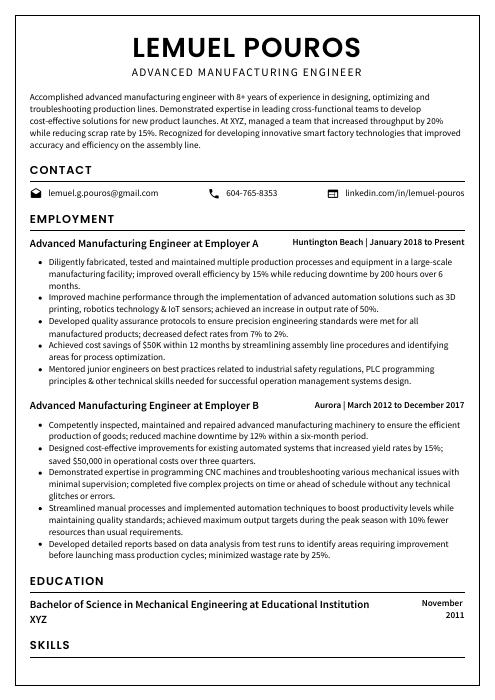

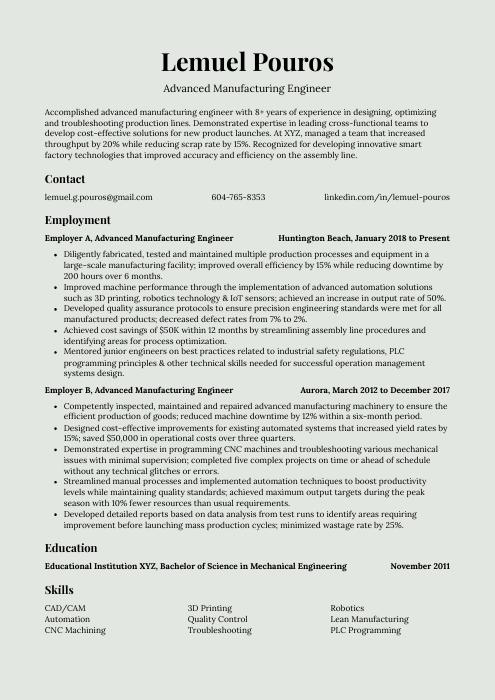

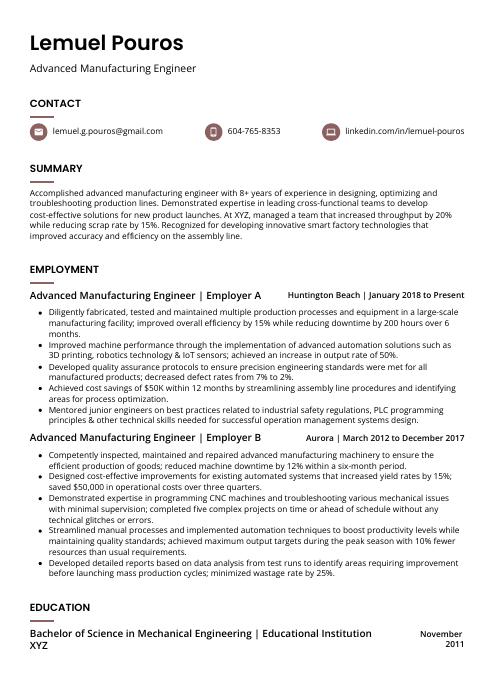

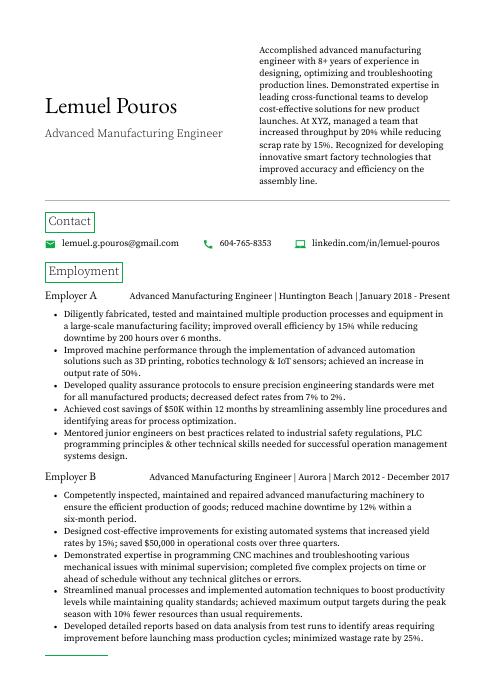

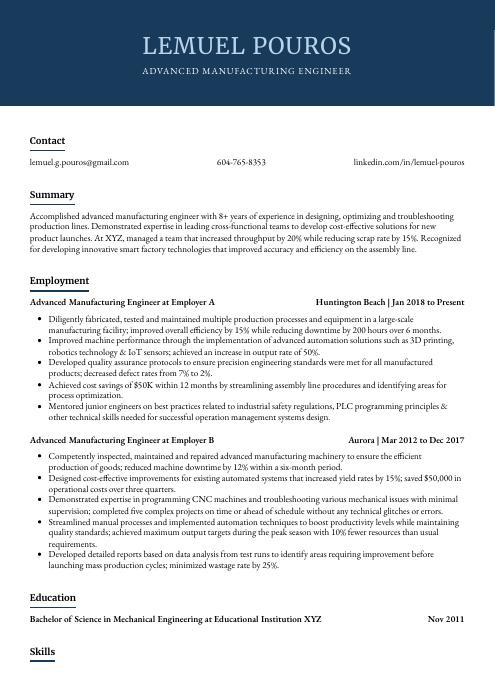

Advanced Manufacturing Engineer Resume Sample

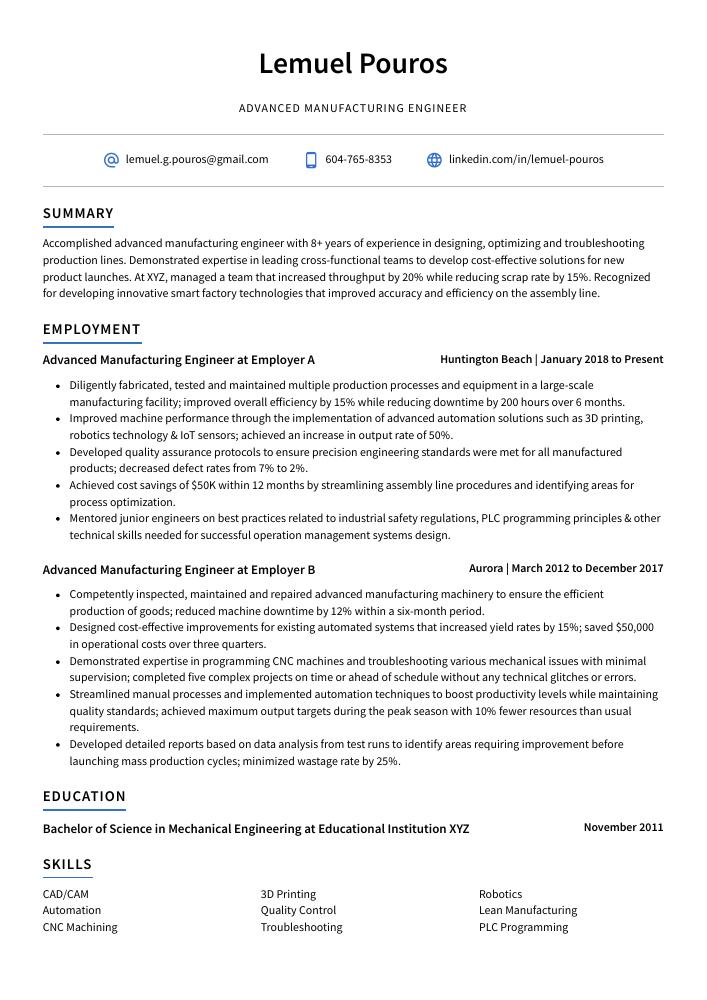

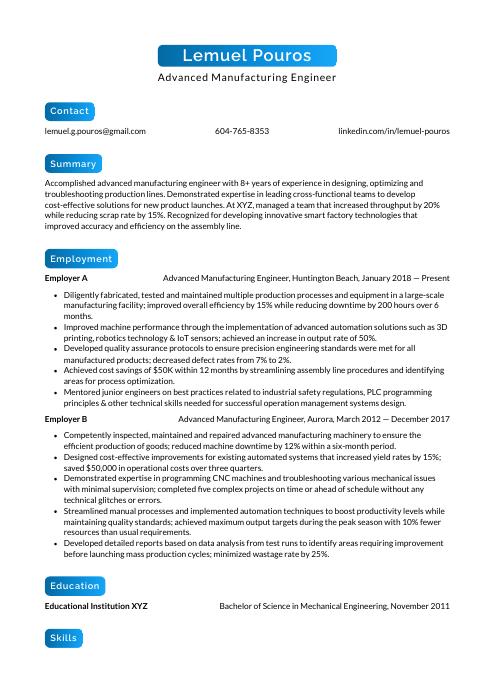

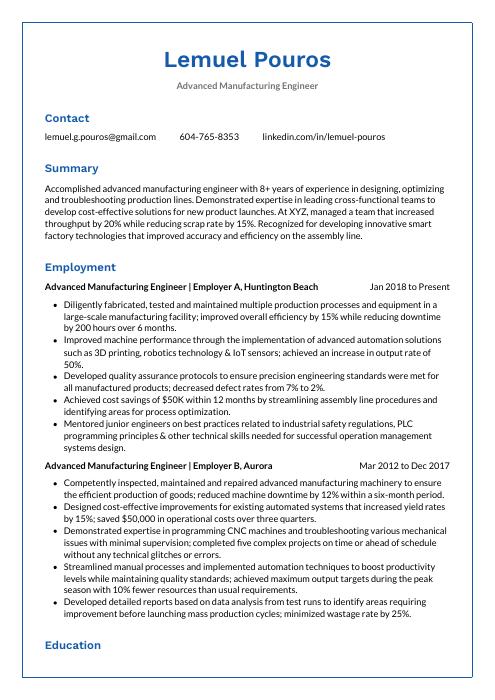

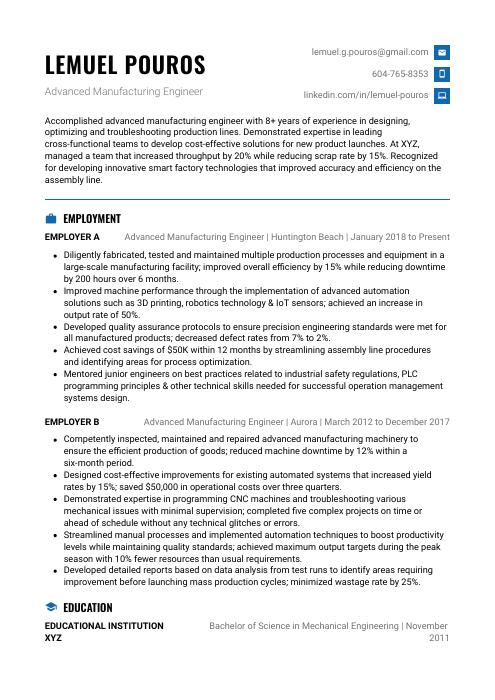

Lemuel Pouros

Advanced Manufacturing Engineer

[email protected]

604-765-8353

linkedin.com/in/lemuel-pouros

Summary

Accomplished advanced manufacturing engineer with 8+ years of experience in designing, optimizing and troubleshooting production lines. Demonstrated expertise in leading cross-functional teams to develop cost-effective solutions for new product launches. At XYZ, managed a team that increased throughput by 20% while reducing scrap rate by 15%. Recognized for developing innovative smart factory technologies that improved accuracy and efficiency on the assembly line.

Experience

Advanced Manufacturing Engineer, Employer A

Huntington Beach, Jan 2018 – Present

- Diligently fabricated, tested and maintained multiple production processes and equipment in a large-scale manufacturing facility; improved overall efficiency by 15% while reducing downtime by 200 hours over 6 months.

- Improved machine performance through the implementation of advanced automation solutions such as 3D printing, robotics technology & IoT sensors; achieved an increase in output rate of 50%.

- Developed quality assurance protocols to ensure precision engineering standards were met for all manufactured products; decreased defect rates from 7% to 2%.

- Achieved cost savings of $50K within 12 months by streamlining assembly line procedures and identifying areas for process optimization.

- Mentored junior engineers on best practices related to industrial safety regulations, PLC programming principles & other technical skills needed for successful operation management systems design.

Advanced Manufacturing Engineer, Employer B

Aurora, Mar 2012 – Dec 2017

- Competently inspected, maintained and repaired advanced manufacturing machinery to ensure the efficient production of goods; reduced machine downtime by 12% within a six-month period.

- Designed cost-effective improvements for existing automated systems that increased yield rates by 15%; saved $50,000 in operational costs over three quarters.

- Demonstrated expertise in programming CNC machines and troubleshooting various mechanical issues with minimal supervision; completed five complex projects on time or ahead of schedule without any technical glitches or errors.

- Streamlined manual processes and implemented automation techniques to boost productivity levels while maintaining quality standards; achieved maximum output targets during the peak season with 10% fewer resources than usual requirements.

- Developed detailed reports based on data analysis from test runs to identify areas requiring improvement before launching mass production cycles; minimized wastage rate by 25%.

Skills

- CAD/CAM

- 3D Printing

- Robotics

- Automation

- Quality Control

- Lean Manufacturing

- CNC Machining

- Troubleshooting

- PLC Programming

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Manufacturing Engineer

Society of Manufacturing Engineers

May 2017

1. Summary / Objective

Your resume summary/objective should be a compelling introduction to your skills and experience as an advanced manufacturing engineer. In this section, you can highlight the areas of expertise that make you stand out from other applicants – such as your knowledge of CAD/CAM software, ability to develop innovative solutions for production problems, or success in streamlining processes at previous companies.

Below are some resume summary examples:

Talented advanced manufacturing engineer with 7+ years of experience developing and managing automated production lines. Adept at optimizing the design, operation, maintenance, and cost efficiency of industrial machinery systems to improve workflow productivity. Recently achieved a 23% reduction in scrap material for XYZ Co., resulting in an estimated $2M savings per year. Seeking to bring these skills to ABC Manufacturing as an Advanced Manufacturing Engineer.

Amicable and organized Advanced Manufacturing Engineer with 5+ years of experience in developing, testing and implementing advanced production processes. Skilled at analyzing process optimizations, identifying potential cost-savings opportunities and leading the implementation of lean manufacturing principles to increase efficiency. Proven track record of successful project management within tight deadlines while maintaining high quality standards.

Determined advanced manufacturing engineer with 5+ years of experience in the design and development of automated production machinery. Skilled in using advanced strategies to optimize cost, quality, safety, and efficiency for large-scale projects. At XYZ Corp., successfully implemented a new high-speed assembly line that increased production by 25%. Recognized as an innovator who can identify problems quickly and develop creative solutions.

Driven advanced manufacturing engineer with 5+ years of experience in developing, implementing, and managing lean production systems. Proven success in reducing cycle times by 30% while increasing output quality. Skilled at leading cross-functional teams to implement process improvement initiatives such as Kaizen events and Six Sigma projects. Experienced in troubleshooting complex issues related to machinery performance and ergonomics.

Committed, goal-oriented advanced manufacturing engineer with 7+ years of experience in the field. Developed, installed and maintained complex production systems at ABC Corp., resulting in 25% improvement to output quality. Skilled problem solver who is adept at troubleshooting issues quickly and efficiently using root cause analysis techniques. Proven ability to work independently as well as collaboratively on cross-functional teams.

Well-rounded advanced manufacturing engineer with 5+ years of experience leading design, production, and optimization efforts for high-tech components. Seeking to join ABC Tech to apply expertise in robotics automation and software development to improve cost efficiency while ensuring the highest quality standards. In past roles, reduced costs by 24% through process optimizations while increasing throughput by 32%.

Proficient advanced manufacturing engineer with 8+ years of experience leading the design and implementation of innovative solutions to improve production efficiency. Skilled in process mapping, Lean Manufacturing principles, problem-solving and root cause analysis. Seeking a role at ABC Technologies where I can apply my expertise in advanced automation technologies towards optimizing their production processes.

Skilled advanced manufacturing engineer with 8+ years of experience in production and process optimization. Well-versed in automation, robotics, CNC machining processes and Lean methodologies. Seeking to join ABC Corp to develop innovative solutions for their advanced manufacturing needs, while utilizing my expertise to reduce costs by 15% through improved efficiency of the workflow.

2. Experience / Employment

Next comes the work history section, which should be written in reverse chronological order. This means your most recent role is listed first.

When writing this section, use bullet points to make it easier for the reader to scan through and take in what you have to say quickly. When describing what you did, provide detail and quantifiable results where possible.

For example, instead of saying “Improved production efficiency,” you could say, “Implemented a new assembly line system that reduced manufacturing time by 20%, resulting in an increase of 10% productivity.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Optimized

- Automated

- Programmed

- Fabricated

- Assembled

- Calibrated

- Troubleshot

- Monitored

- Inspected

- Tested

- Improved

- Analyzed

- Implemented

- Commissioned

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Consistently improved the efficiency of production processes by 15%, resulting in a reduction of operational costs by $45,000.

- Coordinated with engineering teams to design and develop advanced manufacturing equipment for new product lines; expedited prototype development cycle time by 25%.

- Compiled detailed reports on the performance metrics and cost effectiveness of all manufacturing systems; identified areas in need of improvement and implemented solutions that increased output rate by 30%.

- Spearheaded several projects involving troubleshooting existing problems in automated machinery, as well as designing more reliable components to reduce downtime from 8 hours to 4 hours per month.

- Formulated innovative strategies for reducing inventory expenses while increasing quality control measures across multiple production facilities – achieved an overall decrease in defective items shipped out by 20%.

- Monitored and maintained the production of advanced manufacturing equipment, resulting in a 20% improvement in output efficiency and a reduction of wastage by 50%.

- Optimized automated processes through the implementation of innovative design solutions, increasing productivity levels by up to 25%.

- Analyzed and identified areas for improvement on existing products as well as development projects; consulted with team members to devise action plans for cost-effective resolutions.

- Advised upper management on how best to utilize emerging technologies within the organization’s infrastructure; oversaw $750K worth of new investments over two years that generated an additional $1M in revenue annually.

- Successfully trained 10+ technicians on complex assembly principles & protocols, allowing them to work independently without supervision while meeting all quality assurance requirements.

- Participated in the design and development of over 15 advanced manufacturing systems, ensuring that all engineering standards were met while cost-effectively utilizing available resources.

- Developed detailed drawings and blueprints for sophisticated machinery components; reduced production time by 10% by optimizing workflow processes & procedures.

- Resourcefully troubleshot any mechanical or electrical issues in existing equipment, executing repairs quickly to minimize downtime and increase productivity levels on the shop floor.

- Commissioned new automated machines within budget constraints whilst adhering to safety regulations during assembly activities; reduced setup times from an average of 20 hours to 12 hours per machine model launch date target was achieved with 2 weeks lead time saved overall.

- Expedited quality assurance testing protocols for newly installed machinery, achieving a 98% pass rate on initial inspections as well as higher yields across product lines at lower costs per unit output.

- Structured and implemented advanced manufacturing processes to increase production efficiency by 15%, saving the company $1.5M in operational costs annually.

- Tested and validated new 3D printing technologies, robotics systems and other automated equipment to make sure they met safety regulations, quality requirements and performance standards; finalized 10+ projects within tight deadlines with zero setbacks.

- Substantially reduced cycle times on assembly lines through process automation, resulting in a 25% improvement of overall product throughput capacity per hour across all shifts.

- Utilized data analytics tools such as MATLAB & Mathematica to identify areas for further optimization while also troubleshooting existing issues related to machinery malfunctions or incomplete orders; monitored over 20 machines simultaneously at any given time with minimal supervision required from management staffs.

- Facilitated daily meetings between operations personnel and engineering teams to discuss ways of improving production output while minimizing waste levels; successfully identified over 50 improvements which led towards an additional 7% cost savings each month without compromising on quality control measures.

- Assembled and tested complex manufacturing parts and systems to ensure quality control, reducing defects by 25% over a six-month period.

- Revised existing production processes for greater efficiency, minimizing labor costs by $4,500 per month while meeting all safety standards.

- Represented the company in regional trade shows and conferences, successfully demonstrating new technologies to potential customers via hands-on demonstrations of products and services.

- Programmed automated machinery components with advanced software programs; reduced downtime on machines due to errors or malfunctions by 45%.

- Confidently troubleshot technical problems within short turnaround times using critical thinking skills honed through years of experience in advanced manufacturing engineering roles.

- Troubleshot complex production issues on the assembly line and redesigned components to increase efficiency by 24%.

- Reduced downtime in advanced manufacturing processes by 25%, allowing for an extra 10,000 units of product to be produced each month.

- Assessed potential design modifications that would improve robotics systems; successfully implemented new designs that reduced labor costs by $4,500 per week.

- Reorganized the factory layout which improved workflow and increased output levels from 6,000 items/day to 8,500 items/day in three months’ time period.

- Efficiently operated various pieces of computer-controlled machinery such as robotic arms and 3D printers with minimal errors or delays; completed projects ahead of schedule 75% of the time.

- Presented complex engineering solutions to production teams, resulting in a 10% increase in efficiency and reduction of assembly time by 30 minutes.

- Meticulously developed advanced manufacturing processes using CAD/CAM systems, improving the quality of products while reducing labor costs by 15%.

- Automated production line operations with PLC programming and robotics; increased throughput rates by 20% while simultaneously lowering energy consumption levels.

- Implemented safety protocols for all automated machines according to industry standards; reduced workplace accidents related to machinery use by 25%.

- Calibrated automated equipment on a regular basis; conducted preventive maintenance checks that enabled machines to run consistently at peak performance levels without any downtime or delays in delivery schedules.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one may be looking for someone with experience in 3D printing, while the other is seeking an individual who has expertise in robotics.

It’s important to tailor your skills section of your resume to each job you are applying for so that it matches what employers are searching for. This will help ensure that applicant tracking systems can identify the keywords they’re scanning resumes for and pass them on to a human reviewer.

In addition, if certain skills have been mentioned more than once throughout the job posting, make sure you emphasize those as well by elaborating on them elsewhere in your resume (such as within the summary or experiences sections).

Below is a list of common skills & terms:

- 3D Printing

- Automation

- CAD/CAM

- CNC Machining

- Lean Manufacturing

- PLC Programming

- Quality Control

- Robotics

- Troubleshooting

- Welding

4. Education

Adding an education section to your resume will depend on how far along you are in your career. If you just graduated and have no work experience, include the education section below your resume objective. However, if you have extensive relevant work experience that is more important to showcase than any educational qualifications, then omitting an education section altogether is perfectly acceptable.

If adding an education section to your advanced manufacturing engineer resume, try to mention courses and subjects related specifically to this role or industry such as engineering design principles or materials science fundamentals.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and proficiency in a certain field. They are also an excellent way of showing potential employers that you have taken the initiative to stay up-to-date with industry standards and best practices.

Including certifications on your resume can be extremely beneficial, especially if they are relevant to the job you’re applying for. Doing so will help make sure that hiring managers take notice of your qualifications and skillset when reviewing applications.

Certified Manufacturing Engineer

Society of Manufacturing Engineers

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Lemuel Pouros, this would be Lemuel-Pouros-resume.pdf or Lemuel-Pouros-resume.docx.

7. Cover Letter

Cover letters are a great way to supplement your resume and add more detail about who you are as a professional. Writing one is not always necessary, but it can be an effective tool for getting noticed by recruiters or hiring managers.

A cover letter should contain 2 to 4 paragraphs that explain why you’re the best person for the job. It’s important to keep in mind that this document should provide new insights about yourself beyond what’s already stated on your resume.

Below is an example cover letter:

Dear Julie,

I am writing to apply for the position of Advanced Manufacturing Engineer at XYZ Corporation. With over 10 years of experience in advanced manufacturing engineering and a strong background in lean manufacturing principles, I am confident that I can be an asset to your team.

In my current role as an advanced manufacturing engineer at ABC Corporation, I manage a team of 12 engineers and technicians responsible for developing and implementing new production processes. In addition to overseeing day-to-day operations, I also lead projects to improve process efficiency and reduce costs. To date, we have successfully implemented several cost-saving initiatives that have resulted in millions of dollars in savings for the company.

I am also well-versed in Six Sigma methodology and have led numerous successful Lean/Six Sigma improvement projects. My experience with data analysis and root cause problem solving has allowed me to identify opportunities for process improvements that have had a positive impact on quality and productivity.

I believe my skills and experience would benefit XYZ Corporation as you continue to grow and expand your operations. I am eager to utilize my expertise to contribute to the success of your organization, and I look forward to speaking with you about this opportunity soon. Thank you for your time!

Sincerely,

Lemuel

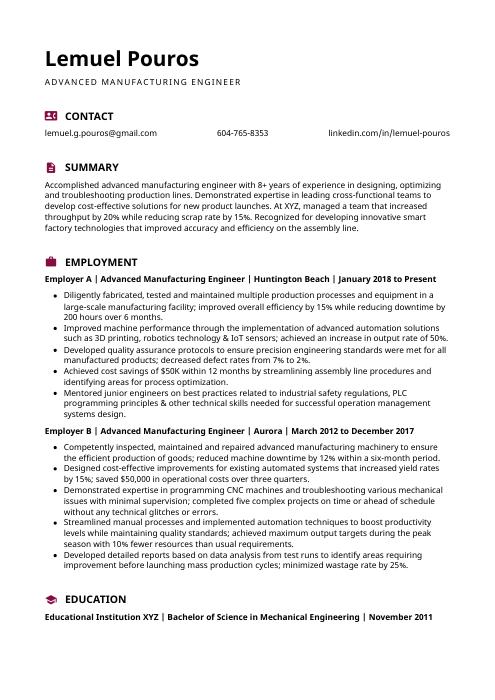

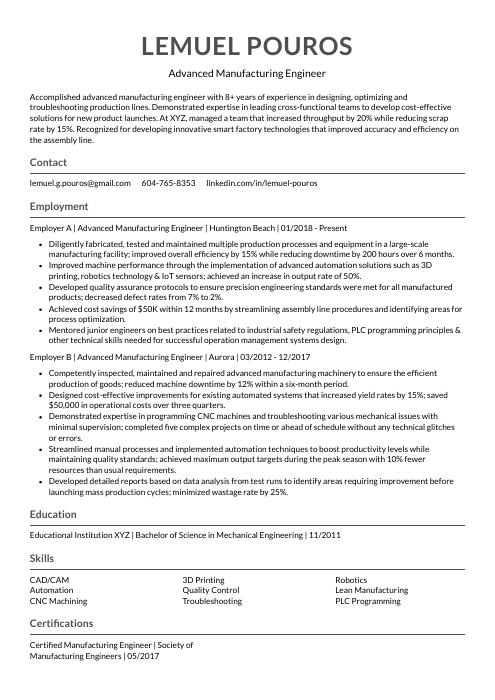

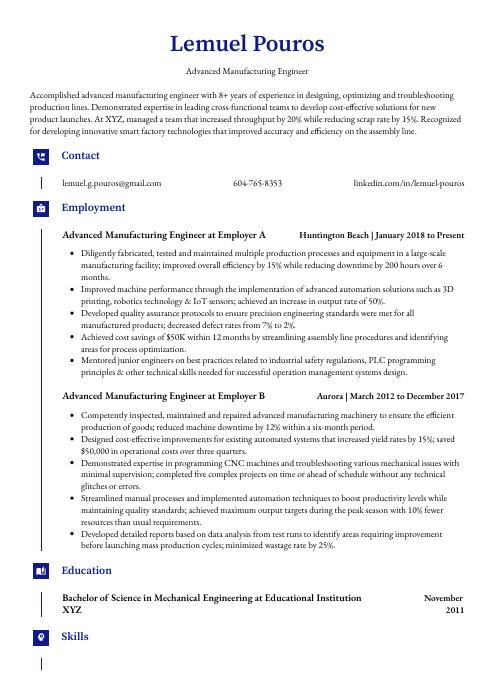

Advanced Manufacturing Engineer Resume Templates

Kinkajou

Kinkajou Markhor

Markhor Echidna

Echidna Numbat

Numbat Ocelot

Ocelot Rhea

Rhea Axolotl

Axolotl Jerboa

Jerboa Pika

Pika Lorikeet

Lorikeet Cormorant

Cormorant Saola

Saola Hoopoe

Hoopoe Dugong

Dugong Indri

Indri Gharial

Gharial Fossa

Fossa Quokka

Quokka Bonobo

Bonobo Rezjumei

Rezjumei