Quality Control Manager Resume Guide

Quality Control Managers ensure that products and services meet certain standards of quality. They develop procedures to inspect and test products, as well as maintain records of findings. Additionally, Quality Control Managers are responsible for developing corrective action plans when necessary in order to improve the quality of goods or services provided by their organization.

You have the experience to manage any quality control team with ease. But potential employers don’t know you exist until they see your resume! To make sure it stands out, craft a document that will highlight your skills and accomplishments in the industry.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

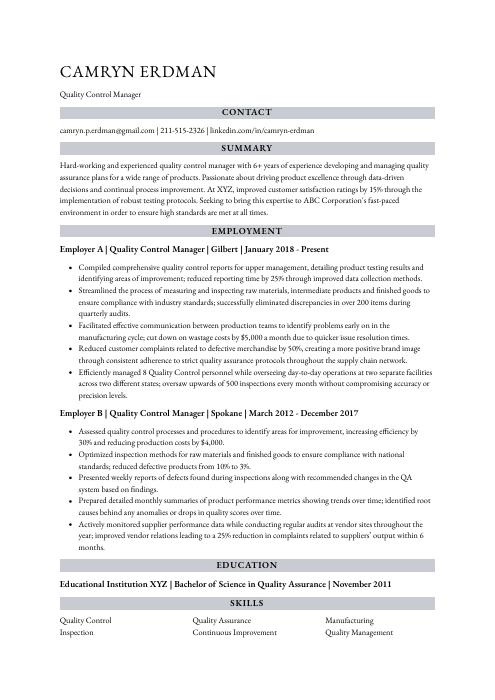

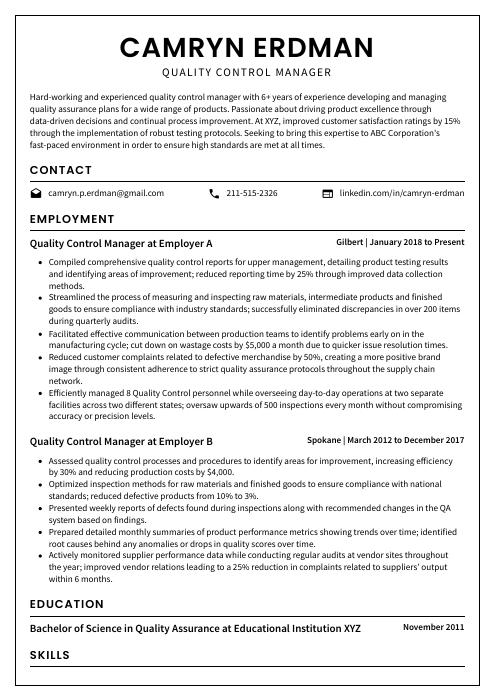

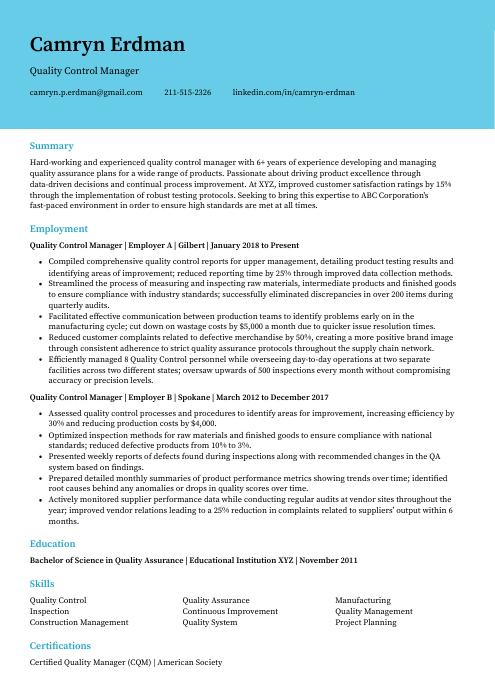

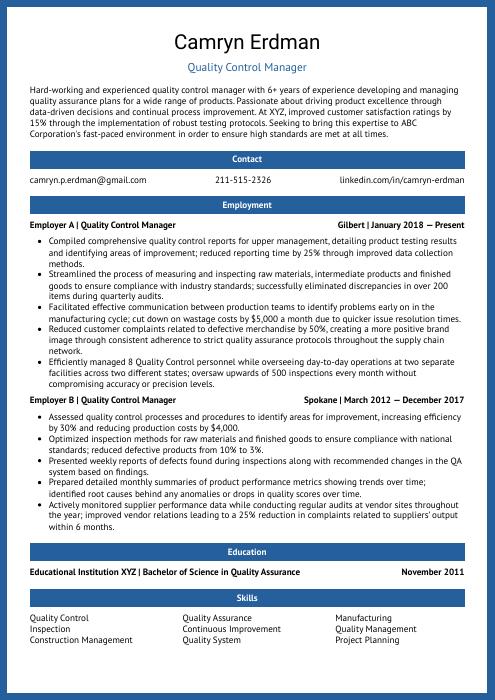

Quality Control Manager Resume Sample

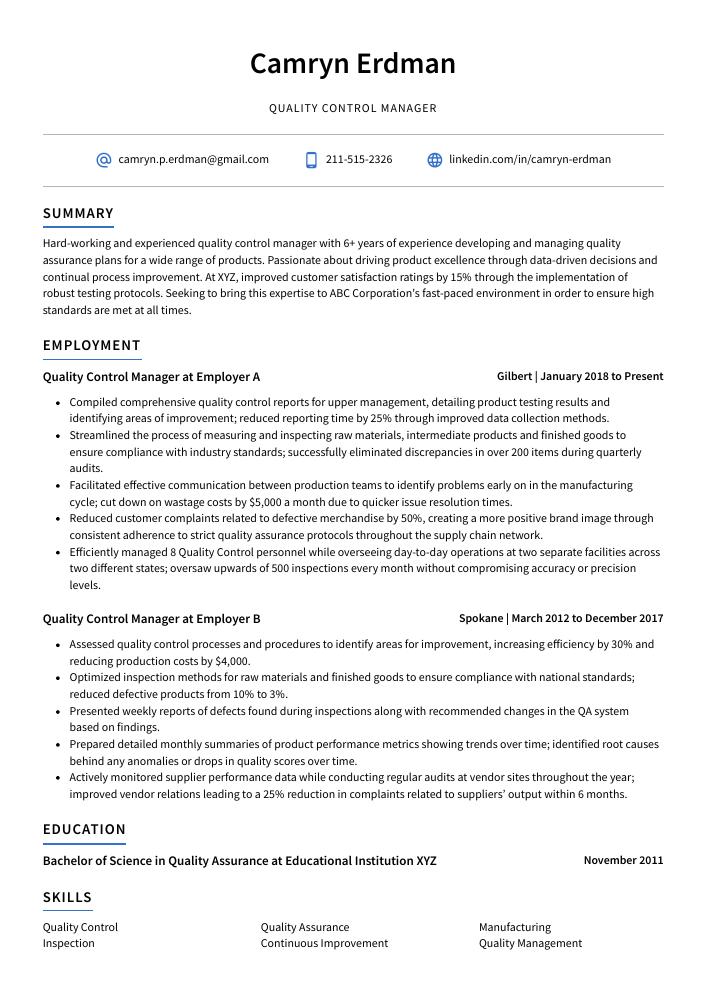

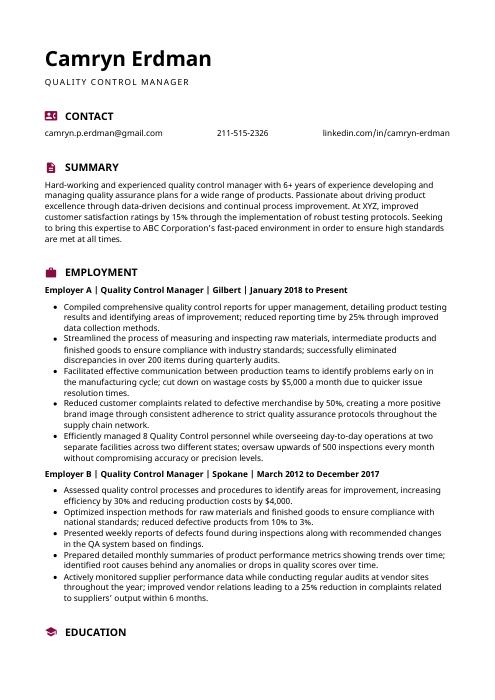

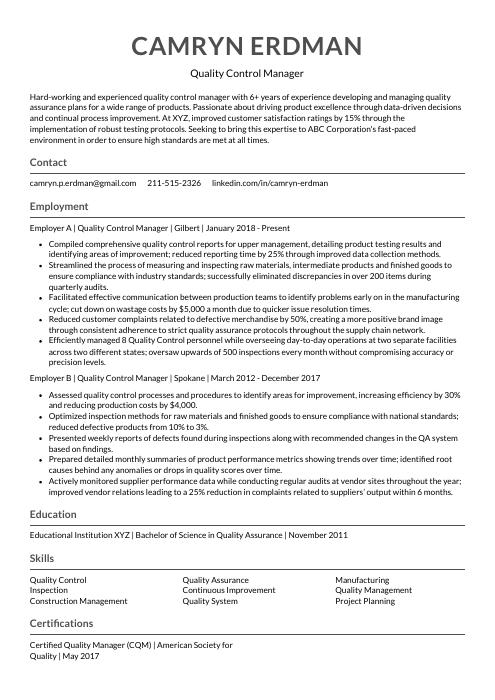

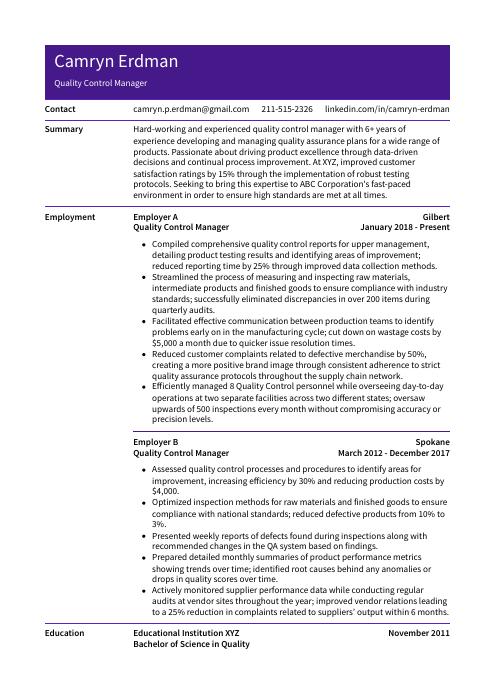

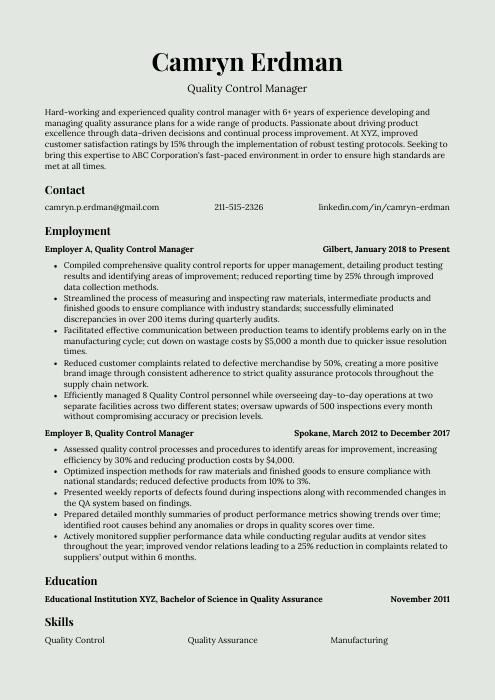

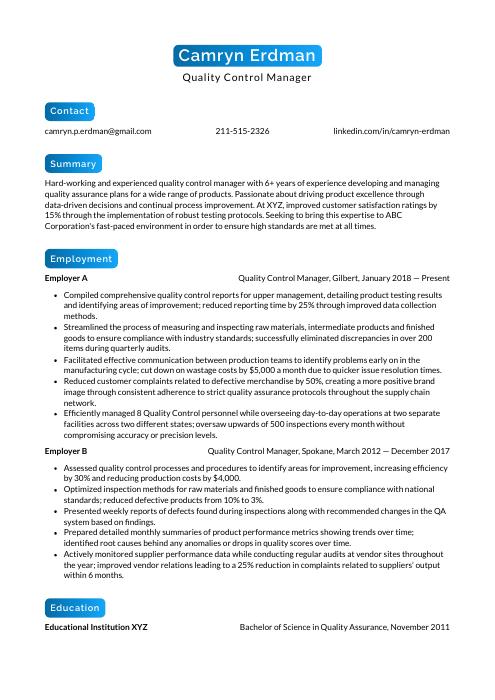

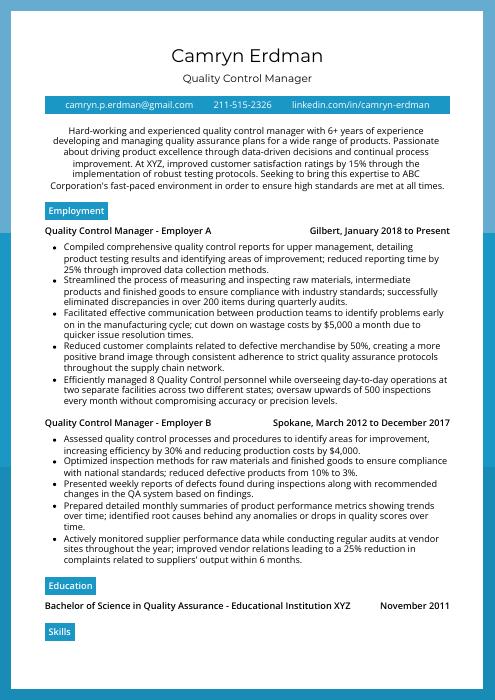

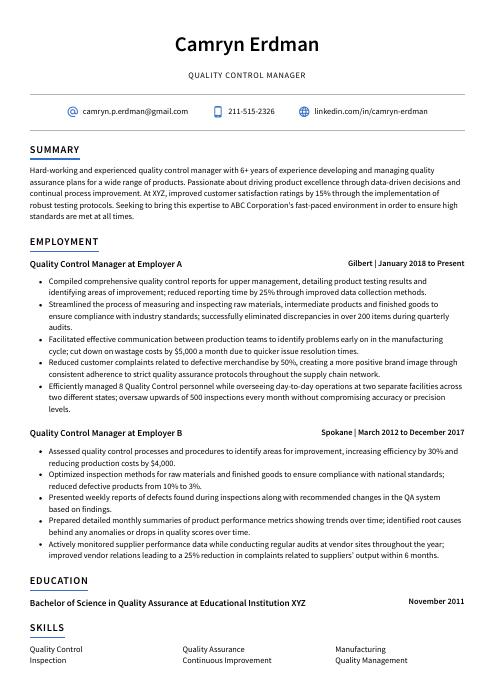

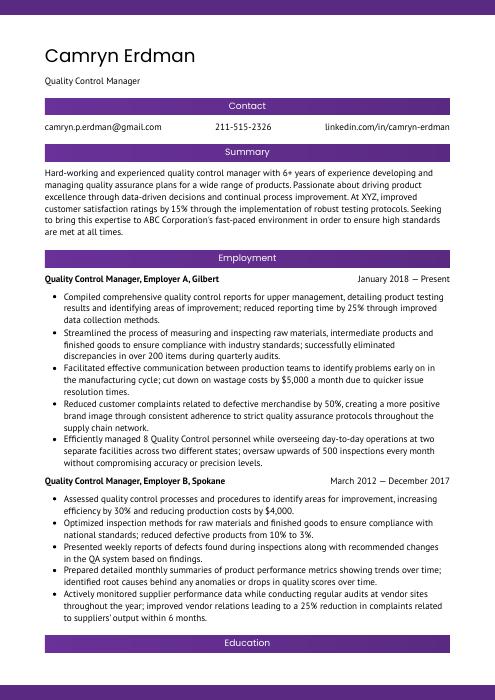

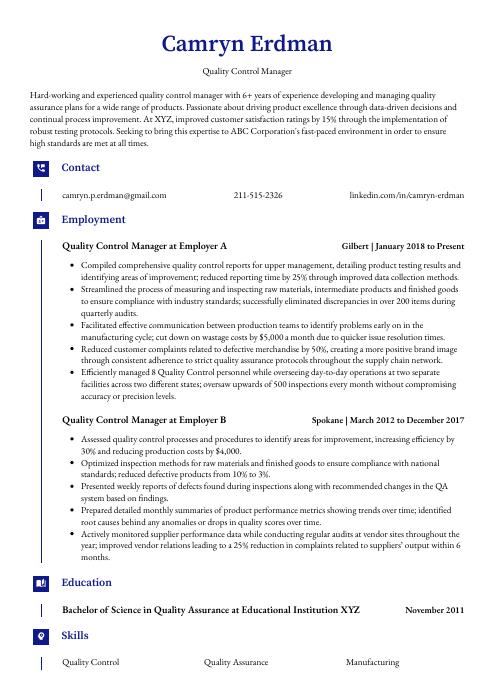

Camryn Erdman

Quality Control Manager

[email protected]

211-515-2326

linkedin.com/in/camryn-erdman

Summary

Hard-working and experienced quality control manager with 6+ years of experience developing and managing quality assurance plans for a wide range of products. Passionate about driving product excellence through data-driven decisions and continual process improvement. At XYZ, improved customer satisfaction ratings by 15% through the implementation of robust testing protocols. Seeking to bring this expertise to ABC Corporation’s fast-paced environment in order to ensure high standards are met at all times.

Experience

Quality Control Manager, Employer A

Gilbert, Jan 2018 – Present

- Compiled comprehensive quality control reports for upper management, detailing product testing results and identifying areas of improvement; reduced reporting time by 25% through improved data collection methods.

- Streamlined the process of measuring and inspecting raw materials, intermediate products and finished goods to ensure compliance with industry standards; successfully eliminated discrepancies in over 200 items during quarterly audits.

- Facilitated effective communication between production teams to identify problems early on in the manufacturing cycle; cut down on wastage costs by $5,000 a month due to quicker issue resolution times.

- Reduced customer complaints related to defective merchandise by 50%, creating a more positive brand image through consistent adherence to strict quality assurance protocols throughout the supply chain network.

- Efficiently managed 8 Quality Control personnel while overseeing day-to-day operations at two separate facilities across two different states; oversaw upwards of 500 inspections every month without compromising accuracy or precision levels.

Quality Control Manager, Employer B

Spokane, Mar 2012 – Dec 2017

- Assessed quality control processes and procedures to identify areas for improvement, increasing efficiency by 30% and reducing production costs by $4,000.

- Optimized inspection methods for raw materials and finished goods to ensure compliance with national standards; reduced defective products from 10% to 3%.

- Presented weekly reports of defects found during inspections along with recommended changes in the QA system based on findings.

- Prepared detailed monthly summaries of product performance metrics showing trends over time; identified root causes behind any anomalies or drops in quality scores over time.

- Actively monitored supplier performance data while conducting regular audits at vendor sites throughout the year; improved vendor relations leading to a 25% reduction in complaints related to suppliers’ output within 6 months.

Skills

- Quality Control

- Quality Assurance

- Manufacturing

- Inspection

- Continuous Improvement

- Quality Management

- Construction Management

- Quality System

- Project Planning

Education

Bachelor of Science in Quality Assurance

Educational Institution XYZ

Nov 2011

Certifications

Certified Quality Manager (CQM)

American Society for Quality

May 2017

1. Summary / Objective

A resume summary/objective is like a trailer for a movie – it should provide the employer with an overview of your qualifications and experience as a quality control manager. In this section, you can highlight key skills such as attention to detail, problem-solving abilities, and knowledge of industry standards. You could also mention any certifications or awards you have received related to quality control management.

Below are some resume summary examples:

Proficient quality control manager with 7+ years of experience in maintaining and implementing quality management systems (QMS) for manufacturing companies. At XYZ, successfully managed the set-up of a QMS system to ensure compliance with ISO 9001 standards within 6 months. Proven track record of reducing product defects by 30% and increasing customer satisfaction ratings from 75% to 93%. Skilled at developing efficient methods to improve productivity while ensuring quality assurance goals are met.

Accomplished Quality Control Manager with a proven track record of success in leading quality assurance initiatives and ensuring compliance with industry standards. Experienced in developing, implementing, and managing QC processes for multiple departments at XYZ Company. Led the implementation of new safety protocols that resulted in zero workplace incidents over 2 years. Committed to providing exceptional customer service and delivering high-quality products on time every time.

Detail-oriented quality control manager with 10 years of experience in the manufacturing sector. Skilled at creating and implementing comprehensive plans to ensure product safety, reliability, and customer satisfaction. At XYZ Corporation I managed a team of 20 personnel responsible for inspecting all incoming raw materials as well as outgoing finished products. Developed an innovative system that improved QC accuracy by 30%, resulting in a cost savings of $150k annually.

Determined Quality Control Manager with 7+ years of experience in developing, implementing, and managing quality control systems. Experienced leader who is adept at leading teams to ensure that products meet high standards for safety and performance. Successfully implemented a zero-defects policy resulting in improved customer satisfaction ratings by 25%. Proven track record of reducing product defects from 30% to 5%, saving the company $500K annually.

Reliable Quality Control Manager with 10+ years of experience driving the implementation and maintenance of quality assurance processes. Skilled in developing and executing test plans, monitoring production output standards, troubleshooting malfunctions, and ensuring compliance to industry regulations. Achieved 99% on-time delivery success rate while reducing product defects by 20%. Looking to join ABC Company as their next Quality Assurance Manager.

Amicable quality control manager with 8+ years of experience in the manufacturing industry. Achieved a 10% reduction in defect rates and improved product consistency by 40%. Skilled at leading teams of 5 to 20 employees and implementing process improvements that have resulted in cost savings totaling $50,000 per year. Seeking to bring this expertise to ABC Manufacturing as its next Quality Control Manager.

Passionate Quality Control Manager with 8+ years of experience leading teams in the successful implementation of quality control processes. Proven track record of reducing product defects by 25%, while increasing customer satisfaction rates to 95%. Seeking an opportunity to join ABC Inc., and bring my knowledge, leadership skills, and dedication for improving production efficiency.

Seasoned Quality Control Manager with 10+ years of experience in leading and directing teams to ensure quality standards are met. Track record of developing process improvements that resulted in a 15% reduction in defective products and improved customer satisfaction by 24%. Seeking to leverage expertise at ABC, Inc. to drive operational performance and maintain product excellence.

2. Experience / Employment

In the experience section, you should provide details on your employment history. This section should be written in reverse chronological order, with your most recent role listed first.

When stating what you did for each job, use bullet points to make it easier for the reader to digest the information quickly. You want to take some time when writing these bullets and think about the specifics of what you did and any quantifiable results that were achieved because of your work.

For example, instead of saying “Ensured product quality,” you could say “Conducted daily inspections on products prior to shipping out; identified issues which resulted in a 15% decrease in customer complaints.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Developed and implemented strict quality control procedures, boosting product reliability by 20% and reducing customer complaints by 60%.

- Substantially improved the company’s quality assurance system through data analysis of consumer feedback; reduced defect rate to 0.1%.

- Formulated effective strategies for detecting potential defects in products before shipment, resulting in a 75% decrease in returned goods within the first year of implementation.

- Introduced new testing processes and standards which enabled faster inspection times without compromising accuracy or safety; decreased production time per unit by 30 minutes on average.

- Demonstrated exceptional problem-solving skills when diagnosing issues with prototypes prior to launching them into the market, saving $15K+ from being lost due to defective units each quarter.

- Reliably maintained quality control standards for hundreds of products, resulting in a 20% decrease in customer complaints and over $10,000 saved from product rework costs.

- Spearheaded the implementation of new processes that improved inspection accuracy by 30%, reducing defect rates to below industry standard levels.

- Advised production teams on best practices for achieving product consistency while meeting stringent quality requirements; successfully lowered scrap rate by 25%.

- Expedited resolution of any issues identified during inspections or testing, ensuring all non-compliant items were corrected or removed promptly with minimal disruption to operations; achieved zero defects within two weeks on multiple occasions.

- Participated actively in internal audits and supplier evaluations to ensure compliance with safety regulations and customer expectations; contributed towards successful certification renewals three years running without incident.

- Mentored and trained 10+ quality inspectors on the use of QA/QC procedures and tools; increased accuracy in product inspections by 11% within 6 months.

- Coordinated with production staff to ensure that all manufactured items met internal standards, specifications and customer requirements before releasing them for shipment.

- Utilized a variety of precision measurement instruments such as micrometers, calipers, gauges etc., to evaluate dimensions against established criteria and identified defects or inconsistencies accurately every time.

- Structured regular audits at 3 manufacturing sites per month to review process controls & compliance levels; decreased average defect rate from 8% to 4%.

- Resourcefully developed improved methods for maintaining high-quality products while reducing costs associated with incoming materials – saved $25K annually in raw material expenses over 5 years’ tenure.

- Revised quality control policies and procedures to ensure compliance with safety regulations, resulting in a 20% reduction of product defects.

- Achieved ISO 9001 certification by successfully implementing quality management systems that met or exceeded industry standards.

- Represented the company at various trade shows and events as an expert on quality assurance techniques; increased sales leads by 50%.

- Consistently monitored production process for accuracy and effectiveness, ensuring all products were defect-free before release into market place.

- Reorganized team operations to improve efficiency while maintaining high levels of customer satisfaction; reduced operating costs by 10%.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may be looking for someone with experience in ISO 9001, while organization XYZ may require expertise in Six Sigma.

The skills section of your resume should therefore be tailored to the job you are applying for; this is especially important given that many employers use applicant tracking systems which scan resumes for certain keywords before passing them on to a human.

It’s also wise to mention any relevant certifications or qualifications (e.g., Lean Manufacturing) here as well as elaborating further on the most important ones elsewhere in your resume – such as within the summary and work experience sections.

Below is a list of common skills & terms:

- 5S

- AutoCAD

- Concrete

- Construction Management

- Construction Safety

- Continuous Improvement

- Contract Management

- Contract Negotiation

- Contractors

- Engineering

- GMP

- ISO

- Inspection

- Lean Manufacturing

- Manufacturing

- Materials

- Operations Management

- Process Improvement

- Process Scheduler

- Product Development

- Project Estimation

- Project Planning

- Quality Assurance

- Quality Auditing

- Quality Control

- Quality Management

- Quality System

- Root Cause Analysis

- Six Sigma

- Subcontracting

- Supervisory Skills

- Team Leadership

- Time Management

- Validation

- Value Engineering

4. Education

Including an education section on your resume will depend on how much experience you have. If you are just starting out in the field and don’t have a lot of work history, mention your education below your resume objective. However, if you’ve been working as a quality control manager for some time and want to showcase those accomplishments first, omitting an education section is perfectly acceptable.

If including an education section, try to list courses related to the job you’re applying for such as management or engineering principles that could be beneficial in this role.

Bachelor of Science in Quality Assurance

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your proficiency in a particular field and can give you an edge over other applicants. They show that you have taken the time to learn about the subject matter, as well as prove that you have been tested by a reputable organization.

Including certifications on your resume is especially important if they relate directly to the job for which you are applying. Doing so will help employers see how qualified and knowledgeable of the industry you truly are.

Certified Quality Manager (CQM)

American Society for Quality

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Camryn Erdman, this would be Camryn-Erdman-resume.pdf or Camryn-Erdman-resume.docx.

7. Cover Letter

Submitting a cover letter is an excellent way to make a good impression on potential employers. Unlike resumes, cover letters are more personal and provide recruiters with better insights about who you are as a professional.

A typical cover letter usually consists of 2 to 4 paragraphs that explain why you’re the right person for the job and how your skills and experiences can be beneficial for the company. Having one in hand increases your chances of success significantly, so it’s always recommended to include one when applying for jobs.

Below is an example cover letter:

Dear Daniella,

I am writing to apply for the Quality Control Manager position at ABC Corporation. As a quality control professional with more than 10 years of experience in the manufacturing industry, I have a proven track record of reducing defects and ensuring compliance with quality standards. In my current role as Quality Control Manager at XYZ Corporation, I oversee all aspects of quality control for our production line, including incoming inspection, in-process inspection, and final product inspection. I also develop and implement quality improvement initiatives that have resulted in significant reductions in scrap rates and customer complaints.

In addition to my experience managing a team of quality inspectors, I also have strong analytical skills and experience using statistical methods for process improvement. I am confident that I can use my knowledge and skills to help ABC Corporation improve its overall performance and competitiveness.

I would welcome the opportunity to discuss how I can contribute to your organization’s success. Please contact me at [your phone number] or [your email address] to arrange a meeting. Thank you for your time and consideration.

Sincerely,

Camryn

Quality Control Manager Resume Templates

Hoopoe

Hoopoe Fossa

Fossa Quokka

Quokka Numbat

Numbat Cormorant

Cormorant Dugong

Dugong Ocelot

Ocelot Indri

Indri Pika

Pika Saola

Saola Kinkajou

Kinkajou Lorikeet

Lorikeet Echidna

Echidna Bonobo

Bonobo Markhor

Markhor Rhea

Rhea Axolotl

Axolotl Jerboa

Jerboa Gharial

Gharial Rezjumei

Rezjumei