Welding Engineer Resume Guide

Welding Engineers are responsible for designing and overseeing the manufacturing of welded components. They develop welding processes, select materials, analyze designs to ensure quality control, and inspect finished products. Additionally, they use their knowledge of metallurgy to identify defects in welds and recommend corrective measures.

You have a natural talent for welding and it shows in your work. But if you want to get noticed by potential employers, you must write an impressive resume that highlights your qualifications and experience.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

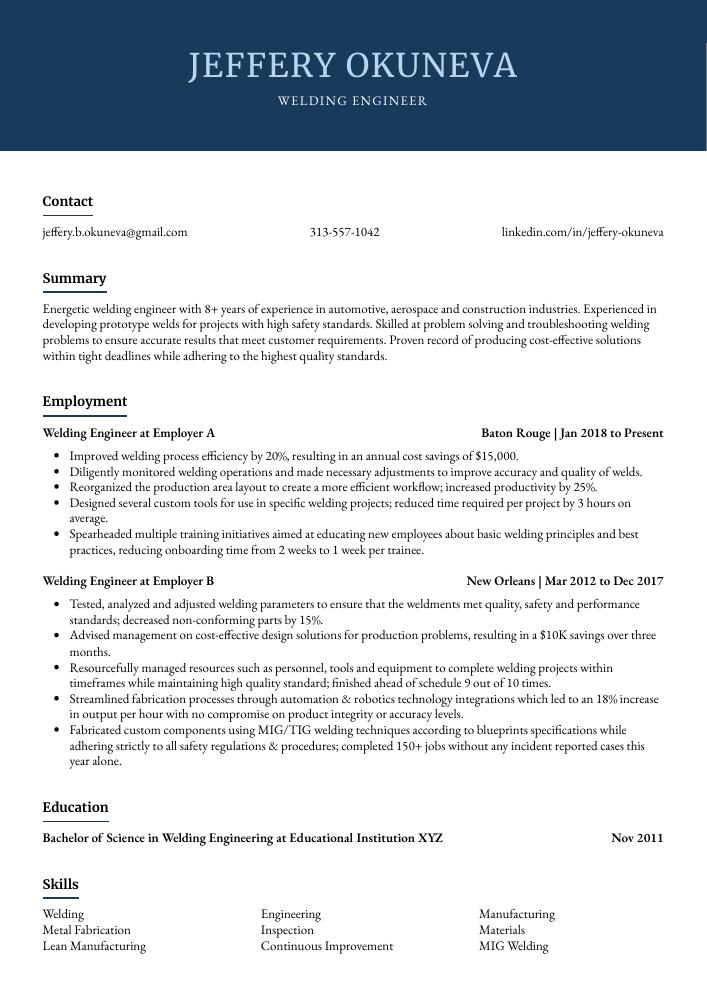

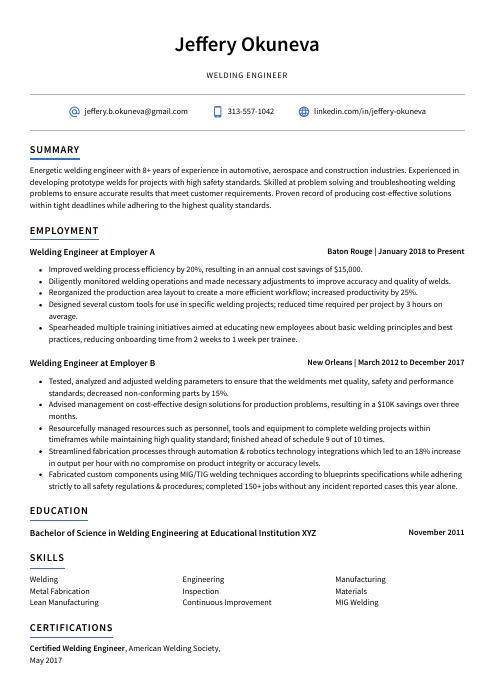

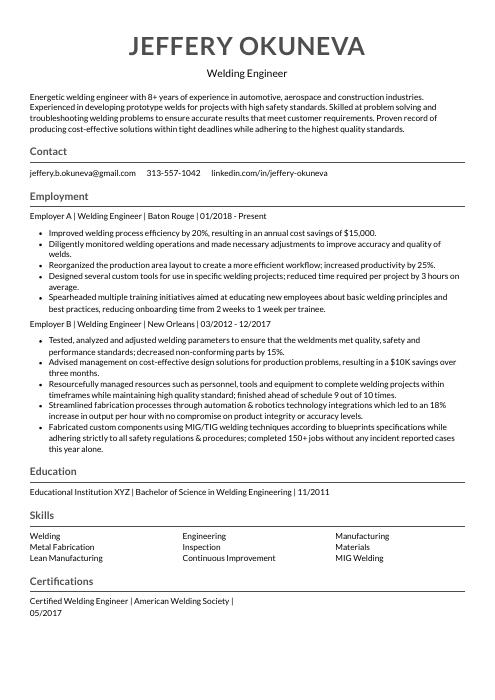

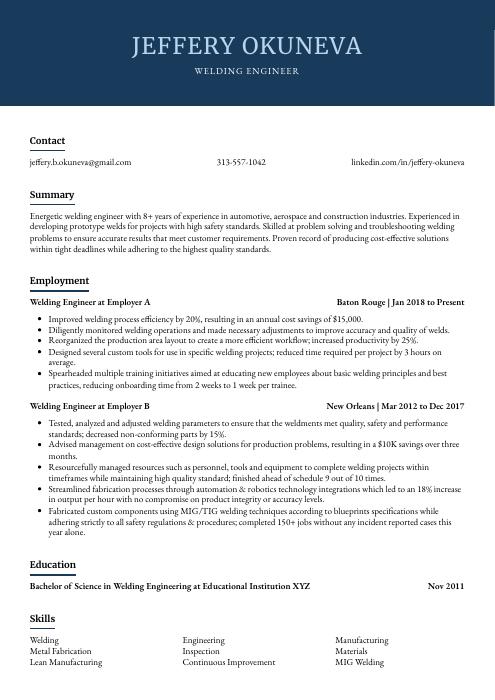

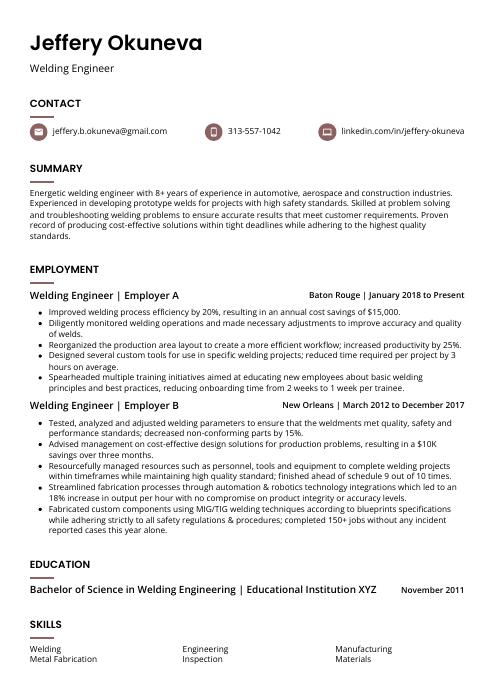

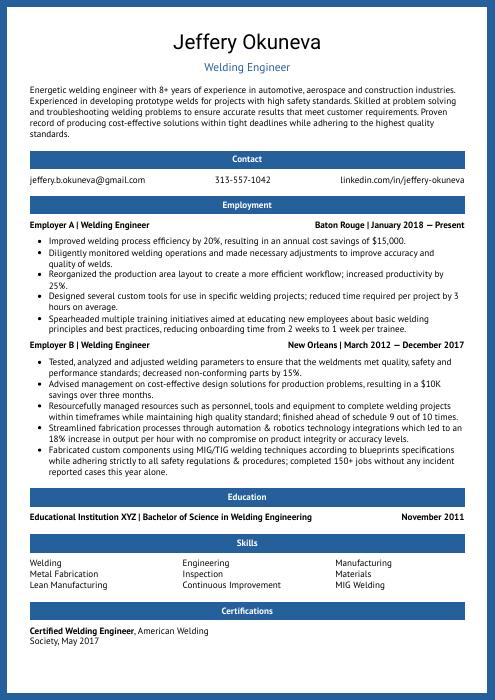

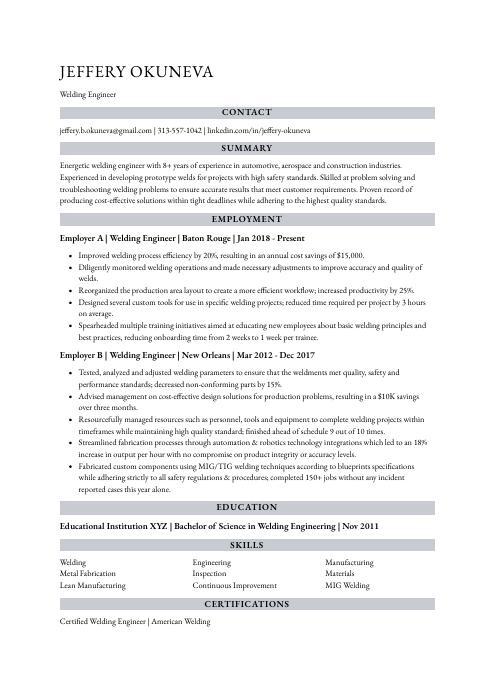

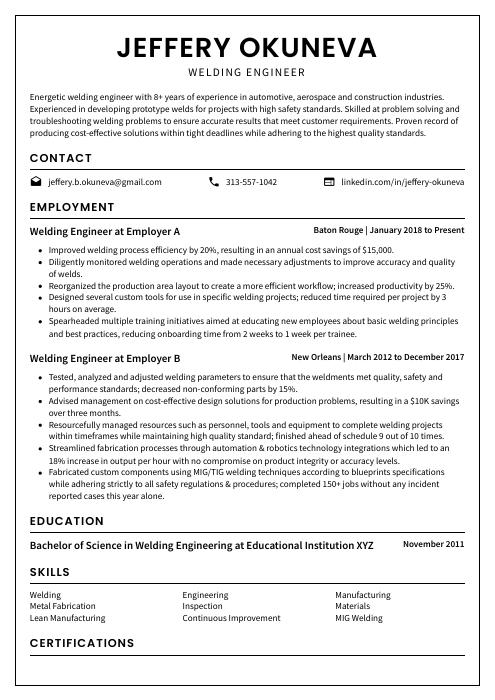

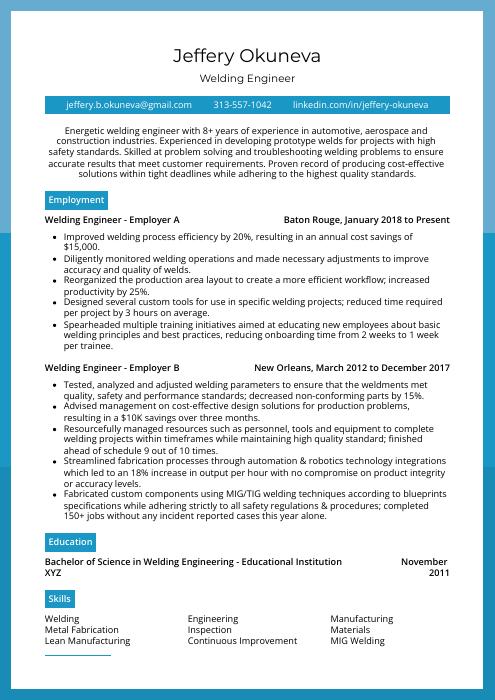

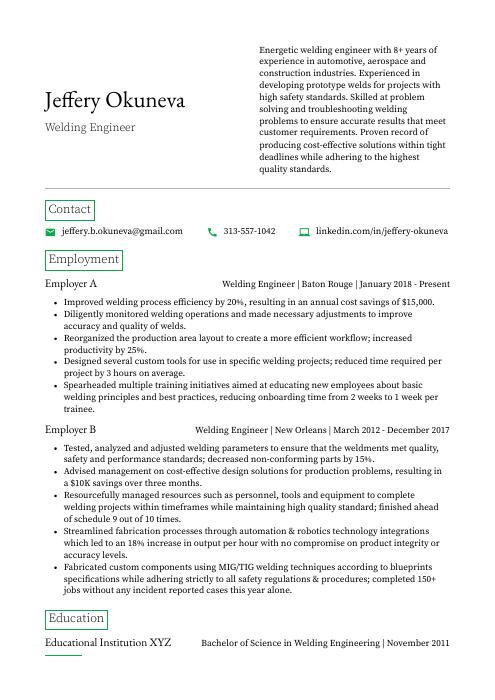

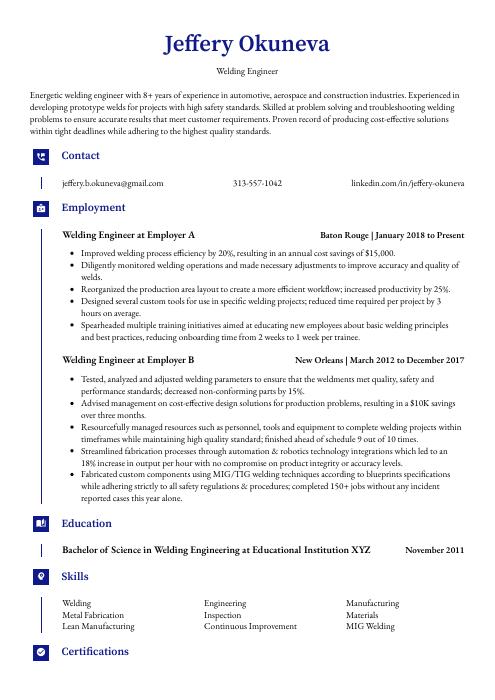

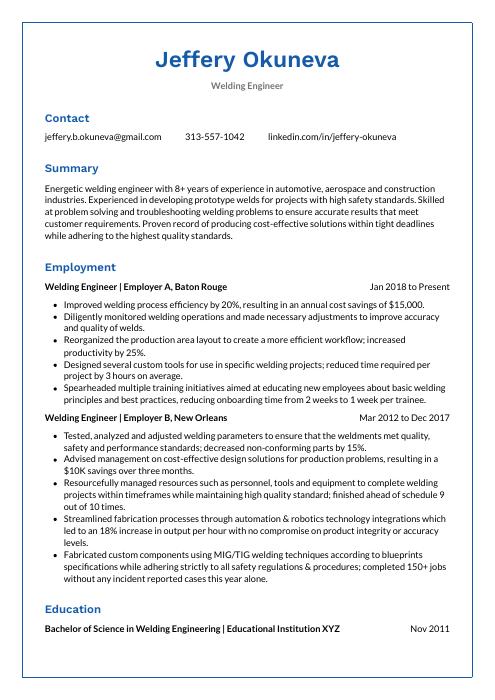

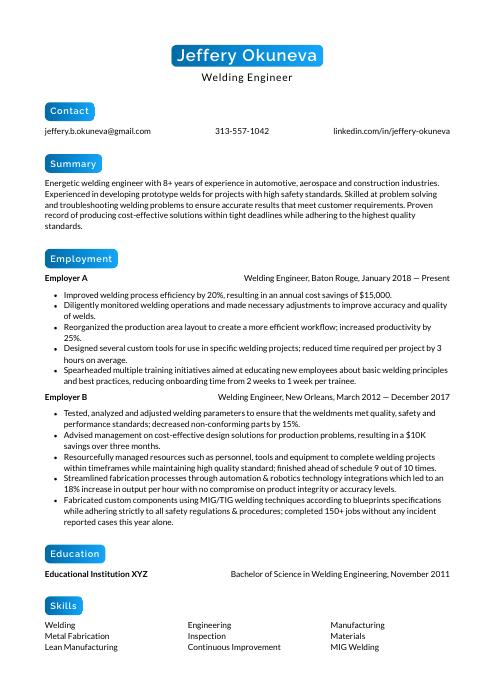

Welding Engineer Resume Sample

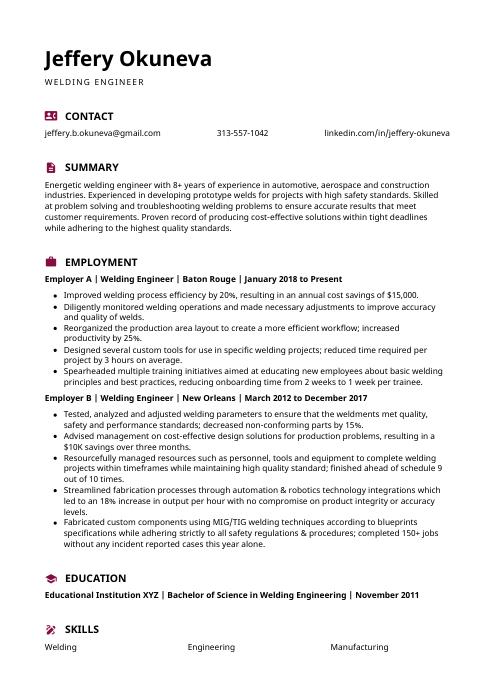

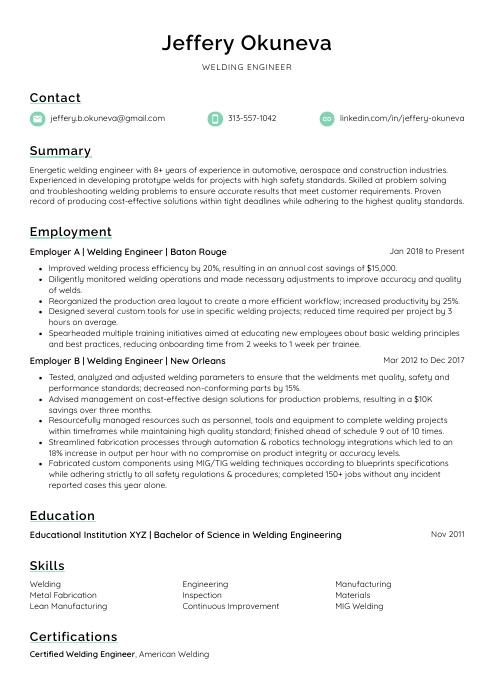

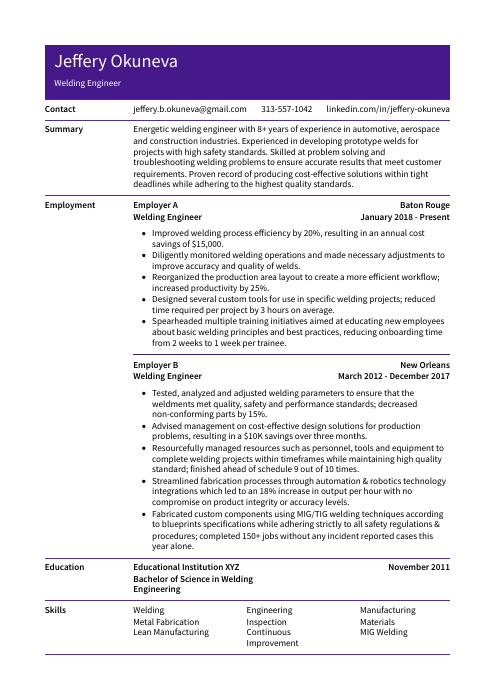

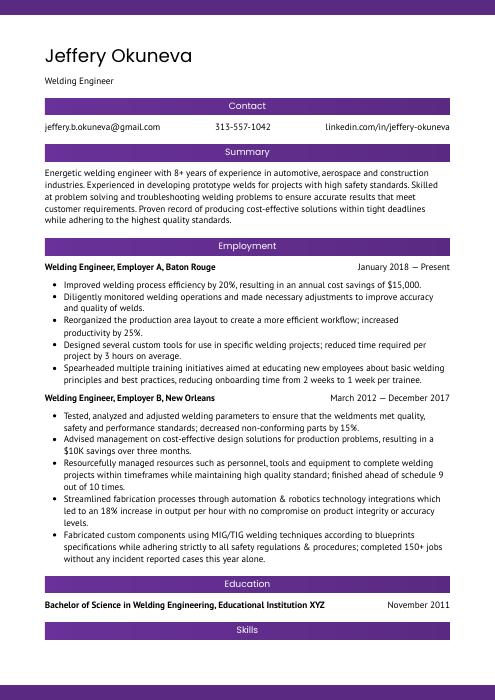

Jeffery Okuneva

Welding Engineer

[email protected]

313-557-1042

linkedin.com/in/jeffery-okuneva

Summary

Energetic welding engineer with 8+ years of experience in automotive, aerospace and construction industries. Experienced in developing prototype welds for projects with high safety standards. Skilled at problem solving and troubleshooting welding problems to ensure accurate results that meet customer requirements. Proven record of producing cost-effective solutions within tight deadlines while adhering to the highest quality standards.

Experience

Welding Engineer, Employer A

Baton Rouge, Jan 2018 – Present

- Improved welding process efficiency by 20%, resulting in an annual cost savings of $15,000.

- Diligently monitored welding operations and made necessary adjustments to improve accuracy and quality of welds.

- Reorganized the production area layout to create a more efficient workflow; increased productivity by 25%.

- Designed several custom tools for use in specific welding projects; reduced time required per project by 3 hours on average.

- Spearheaded multiple training initiatives aimed at educating new employees about basic welding principles and best practices, reducing onboarding time from 2 weeks to 1 week per trainee.

Welding Engineer, Employer B

New Orleans, Mar 2012 – Dec 2017

- Tested, analyzed and adjusted welding parameters to ensure that the weldments met quality, safety and performance standards; decreased non-conforming parts by 15%.

- Advised management on cost-effective design solutions for production problems, resulting in a $10K savings over three months.

- Resourcefully managed resources such as personnel, tools and equipment to complete welding projects within timeframes while maintaining high quality standard; finished ahead of schedule 9 out of 10 times.

- Streamlined fabrication processes through automation & robotics technology integrations which led to an 18% increase in output per hour with no compromise on product integrity or accuracy levels.

- Fabricated custom components using MIG/TIG welding techniques according to blueprints specifications while adhering strictly to all safety regulations & procedures; completed 150+ jobs without any incident reported cases this year alone.

Skills

- Welding

- Engineering

- Manufacturing

- Metal Fabrication

- Inspection

- Materials

- Lean Manufacturing

- Continuous Improvement

- MIG Welding

Education

Bachelor of Science in Welding Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Welding Engineer

American Welding Society

May 2017

1. Summary / Objective

Your resume summary should provide the employer with a snapshot of your welding engineering skills and experience. In this section, you can mention the certifications or qualifications you have obtained, such as AWS D1.1 certification or ASME IX qualification; any relevant projects you’ve worked on in the past; and how many years of experience you have in welding engineering. This will give employers an idea of what kind of value they could get from hiring you.

Below are some resume summary examples:

Skilled welding engineer with 5+ years of experience in the automotive industry. Seeking to leverage extensive knowledge and expertise in welding engineering, metallurgy, and design processes at XYZ company. At ABC Automotive, designed a production line for aluminum welding that resulted in 20% cost savings over traditional methods. Experience includes developing high quality welds utilizing MIG/TIG techniques on various metals.

Passionate welding engineer with 7+ years of experience in the field. Skilled at developing welding procedures, performing quality control inspections, and troubleshooting weld defects. Seeking to leverage expertise in metallurgy to become a part of ABC’s team and help drive innovation for its clients’ projects. Previous roles include increasing production efficiency by 17% via improved processes and materials selection.

Amicable welding engineer with 5+ years of experience in designing and implementing welding processes for a variety of industries. At XYZ, developed over 25 successful projects to improve productivity while reducing costs by 20%. Excellent ability to collaborate cross-functionally and create innovative solutions that exceed customer expectations. Seeking an opportunity to utilize my expertise at ABC Corporation.

Seasoned welding engineer with 10+ years of experience in the industry. Expertise in developing and implementing welding procedures, ensuring weld quality standards are met and troubleshooting welding problems. At XYZ Company, led a team of five engineers to design new process lines which reduced production cost by 25%. Proven success in meeting project deadlines while maintaining high safety protocols.

Driven welding engineer with 7+ years of experience in the automotive industry. Skilled at developing and implementing welding processes to efficiently produce high-quality products that meet customer expectations. At XYZ, reduced scrap rate by 38% while improving production speed by 45%. Seeking a new challenge as Welding Engineer at ABC where I can further develop my skills and contribute to success.

Professional welding engineer with 8+ years of experience in welding fabrication and metallurgy. Expertise in design, development, implementation, and testing of welding processes for a variety of materials including aluminum, steel, stainless steel. Seeking to leverage expertise at ABC Technologies to develop innovative solutions that meet customer requirements while adhering to safety standards.

Dependable welding engineer with 5 years of experience in the engineering sector. At XYZ, developed and managed welding techniques for a number of products across various industries. Led numerous projects to improve weld strength, quality, and consistency while reducing costs by 15%. Possesses excellent problem-solving skills that have enabled successful completion of complex engineering tasks.

Hard-working welding engineer with 10+ years of experience developing efficient welding processes and systems. Proven track record of achieving high-quality results in both industrial and laboratory settings. Seeking to utilize expertise in metallurgy, robotics, and manufacturing principles at ABC Corporation to meet production goals while maintaining safety standards.

2. Experience / Employment

The employment (or experience) section is where you can talk about your work history. This should be written in reverse chronological order, which means that the most recent job is listed first.

When writing this section, stick to bullet points primarily; doing so allows the reader to quickly digest what you have said. You want to provide detail when writing these bullets and explain what you did and any results achieved from it.

For example, instead of saying “Performed welding tasks,” you could say, “Successfully welded a variety of metals using MIG/TIG processes while adhering to strict safety protocols.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Fabricated

- Welded

- Inspected

- Assembled

- Operated

- Calibrated

- Troubleshot

- Programmed

- Monitored

- Repaired

- Tested

- Analyzed

- Designed

- Installed

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Programmed robotic welding systems to produce high-precision welds with 30% greater accuracy than manual operations, resulting in a 20% decrease in production costs.

- Meticulously monitored and inspected metalworking processes to ensure that all finished products met industry standards; identified and rectified any defects before they were shipped out, reducing wastage by 5%.

- Reduced the number of rejected parts due to incorrect welds from 10 per day down to 1 per week through meticulous project planning and spot checks on quality control procedures.

- Mentored junior welding engineers on advanced techniques such as Gas Tungsten Arc Welding (GTAW) & Shielded Metal Arc Welding (SMAW), allowing them to become certified professionals within 6 months under my guidance.

- Troubleshot complex technical issues relating to equipment malfunctions or process breakdowns quickly and accurately; averted costly downtime incidents while cutting repair times by 40%.

- Effectively managed the welding process of large-scale steel structures, ensuring that all welds met safety and quality standards while completing projects ahead of schedule.

- Prepared detailed drawings to specify type of weld required; completed 120+ plans on time with an average accuracy rate exceeding 95%.

- Introduced new processes using specialized welding equipment, resulting in a 15% reduction in raw material costs for two consecutive years.

- Optimized existing production processes by installing state-of-the art robotic welders and cutters; improved productivity levels by up to 20%.

- Utilized advanced test equipment such as x-ray detectors and ultrasonic instruments to inspect finished products; reduced rejections due to defects from 8% down 2%.

- Expedited welding projects and reduced project completion time by 20% while meeting all safety requirements.

- Inspected welds to ensure high-quality standards of workmanship; conducted on-site inspections for over 100 jobsites, resulting in a 98% customer satisfaction rating.

- Represented the company at industry conferences and trade shows as an expert in welding engineering; developed positive relationships with key customers through active networking opportunities.

- Structured comprehensive training programs for new welding engineers, covering topics such as metallurgy, joint design & fabrication techniques, steam piping systems & layout plans – enabling their successful onboarding within months rather than years.

- Successfully led the development and implementation of automated robotic welder machines which increased productivity by 25%.

- Installed, tested and maintained over 200 welding machines across 10 sites, ensuring optimal performance of all equipment with minimal downtime.

- Presented ideas for innovative improvement to production processes at bi-annual engineering meetings; achieved an 11% increase in productivity within 6 months.

- Coordinated the activities of a team of 8 welders, monitoring progress on projects while troubleshooting any issues that arose during fabrication process; reduced average completion time by 28%.

- Efficiently developed new welding methods & procedures to meet customer specifications, resulting in zero rejected items over a 4 month period on all orders processed through my department.

- Formulated safety protocols and oversaw their implementation among junior engineers in order to guarantee compliance with industry standards; lowered work-related incidents by 25%.

- Revised welding procedures and drawings for manufacturing processes, resulting in a 10% reduction in production time.

- Operated welding equipment such as MIG, TIG, arc welders and plasma cutters to assemble structural steel components with high accuracy (+/- 0.02 mm).

- Compiled detailed reports on welding projects that included graphs & charts of quality control data; identified areas needing improvement which increased safety by 30%.

- Consistently monitored parts throughout the assembly process to ensure they met required design specifications; resolved any errors within 5 hours or less per incident.

- Participated in multiple training sessions regarding new advancements in welding technology to stay abreast of industry trends; improved efficiency by 15%.

- Monitored welding processes to ensure welding operations are in compliance with applicable codes and standards; reduced welding defects by 20% over a period of 6 months.

- Assembled, set-up and operated various types of manual & automated welding equipment for fabrication jobs, including MIG welders, TIG torches and plasma cutters; completed projects 60% faster than the industry average.

- Achieved cost savings worth $4,000 through increased efficiency in material purchasing for all welding projects; identified sources that provided bulk discounts on materials used frequently.

- Developed new techniques for arc cutting & gouging metals using different amperage settings which resulted in improved quality control during inspections while reducing project completion time by 12%.

- Actively participated in safety training sessions related to confined space entry protocols as well as gas shielding requirements when operating robotic welders or performing hot works near flammable environments.

- Calibrated and monitored welding equipment to ensure accuracy and efficiency, resulting in a 25% decrease in production costs.

- Repaired broken or damaged welding machines on site with minimal downtime; reduced instances of machine malfunction by 45%.

- Welded components together for various projects using MIG/TIG welders and other related tools; completed over 150 tasks within budget and on time.

- Analyzed blueprints, specifications and customer requests to determine the most suitable method of joining materials together; created detailed drawings outlining these procedures successfully 99% of the time.

- Competently operated automated robotic machinery used for welding large-scale projects while ensuring that safety protocols were followed at all times.

- Demonstrated advanced welding techniques and methods to design, fabricate and assemble metal structures while meeting safety standards; successfully completed over 25 projects with a zero-accident record.

- Facilitated training sessions for new welders on various processes such as MIG & TIG welding, plasma arc cutting, oxyacetylene brazing/welding and soldering; improved efficiency by 10% within 4 months of implementation.

- Assessed components from incoming materials to ensure that they meet precise specifications before beginning any type of fabrication or assembly process; reduced scrap rates by 14%.

- Independently managed the maintenance of all equipment related to welding operations including torches, regulators, hoses and power sources in order to minimize downtime due to malfunction or wear-and-tear issues by 20%.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require experience with TIG welding, while Organization XYZ may prefer MIG.

When crafting your resume skills section, you want to tailor it to the job that you are applying for in order to ensure maximum visibility by applicant tracking systems (ATS). ATSs are computer programs used by employers which scan resumes looking for certain keywords before passing them on to a human recruiter.

In addition, make sure not only list these skills but also explain how they will benefit the company further down in other sections of your resume such as the summary or work experience area.

Below is a list of common skills & terms:

- 5S

- ASME

- American Welding Society

- Arc Welding

- AutoCAD

- Automation

- Automotive

- CAD

- Certified Welding Inspector

- Commissioning

- Continuous Improvement

- Corrosion

- EPC

- Energy

- Engineering

- FMEA

- Factory

- Failure Analysis

- Gas

- ISO

- Inspection

- Kaizen

- Lean Manufacturing

- MATLAB

- MIG Welding

- Machine Tools

- Machining

- Manufacturing

- Manufacturing Engineering

- Materials

- Materials Science

- Mechanical Engineering

- Metal Fabrication

- Metallurgy

- NDT

- Nuclear

- Oil and Gas

- Onshore

- Petrochemical

- Petroleum

- Pipelines

- Piping

- Power Plants

- Pressure Vessels

- Process Engineering

- Product Development

- Project Engineering

- Project Planning

- Quality Assurance

- Quality Control

- Refinery

- Robotics

- Root Cause Analysis

- SOLIDWORKS

- Six Sigma

- Steel

- Supervisory Skills

- TIG Welding

- Teamwork

- Testing

- Troubleshooting

- Weld

- Welding

- Welding Inspection

4. Education

Mentioning an education section on your resume will depend on how far into your career you are. If you just graduated and have no prior experience, include an education section below your resume objective. However, if you have a few years of welding engineering experience to showcase in the work history section, omitting the education part might be better suited for this role.

If including an education section is necessary, try to mention courses or subjects related to welding engineering that could help demonstrate your knowledge and skills relevant for this job position.

Bachelor of Science in Welding Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the knowledge and skills required for a given field. They are also proof of your commitment to professional development, as they require dedication and hard work in order to obtain them.

Including certifications on your resume can be an excellent way to show hiring managers that you are serious about the job and have taken steps towards becoming more qualified for it.

Certified Welding Engineer

American Welding Society

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Jeffery Okuneva, this would be Jeffery-Okuneva-resume.pdf or Jeffery-Okuneva-resume.docx.

7. Cover Letter

Including a cover letter with your resume is a great way to introduce yourself and demonstrate why you’re the best person for the job. It should be made up of 2-4 paragraphs that provide more information about who you are, what makes you an ideal candidate and how hiring you will benefit the employer.

Cover letters aren’t always required when applying for a position, but they can help give recruiters or employers a better understanding of your skillset, experience and qualifications. Writing one can also set you apart from other applicants as it shows initiative and dedication in wanting to secure the role.

Below is an example cover letter:

Dear Tressie,

I am writing in response to your ad for a Welding Engineer. With more than 10 years of experience as a welder and welding engineer, I am confident I can be an asset to your team.

In my current role, I oversee all welding operations for a manufacturing company that produces metal products. I develop welding procedures and specifications, train welders, and troubleshoot welding problems. I have also performed failure analysis on welds to determine the cause of failures.

I am knowledgeable about various welding processes, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and shielded metal arc welding (SMAW). I am also familiar with different types of metals, such as carbon steel, stainless steel, aluminum, and titanium. In addition, I have experience using computer-aided design (CAD) software to create 3D models of welded structures.

My strong communication skills have helped me build good relationships with other engineers, managers, and workers in the factory. My ability to work well under pressure has enabled me to meet deadlines even when there are last-minute changes or unexpected problems.

I believe my skills and experience make me an ideal candidate for the Welding Engineer position at your company. I look forward to speaking with you soon about this opportunity.

Sincerely,

Jeffery

Welding Engineer Resume Templates

Saola

Saola Dugong

Dugong Echidna

Echidna Axolotl

Axolotl Indri

Indri Bonobo

Bonobo Fossa

Fossa Hoopoe

Hoopoe Lorikeet

Lorikeet Pika

Pika Jerboa

Jerboa Ocelot

Ocelot Numbat

Numbat Cormorant

Cormorant Rhea

Rhea Quokka

Quokka Gharial

Gharial Markhor

Markhor Kinkajou

Kinkajou Rezjumei

Rezjumei