Valve Technician Resume Guide

Valve Technicians maintain, repair and inspect valves on equipment. They ensure that all components are working correctly and safely to prevent any malfunctions or accidents. They use various tools such as wrenches, screwdrivers and power drills to perform their duties.

You know your way around valves like the back of your hand, and any industrial organization would benefit from having you on their team. However, employers won’t understand what a great fit you are unless they see it in writing. To make sure that happens, write an impressive resume to showcase all of your valve technician skills.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

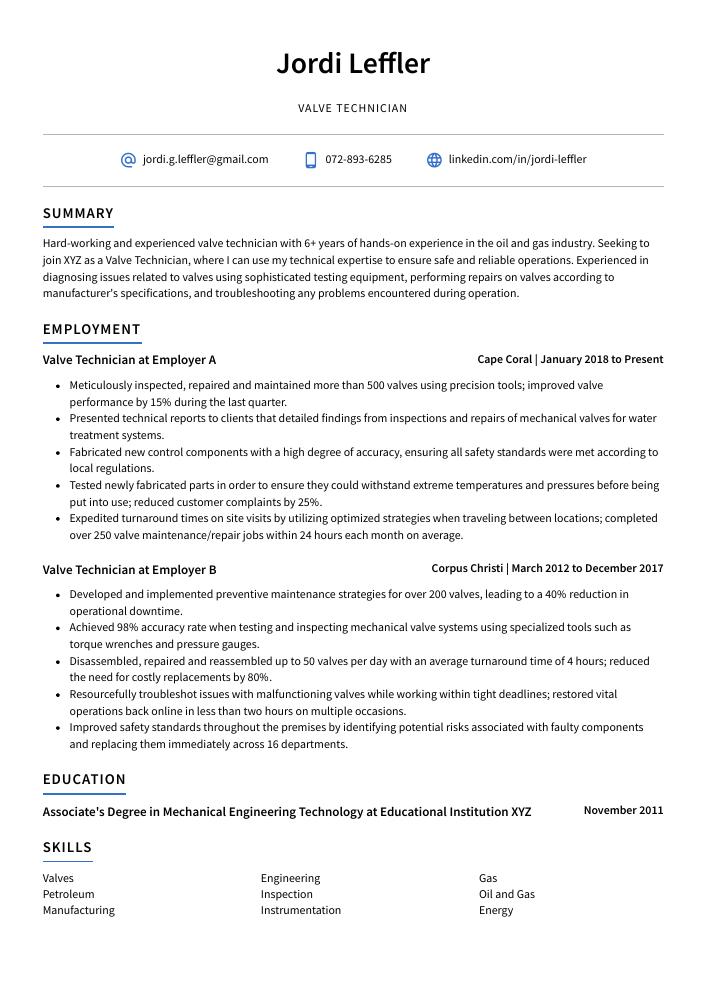

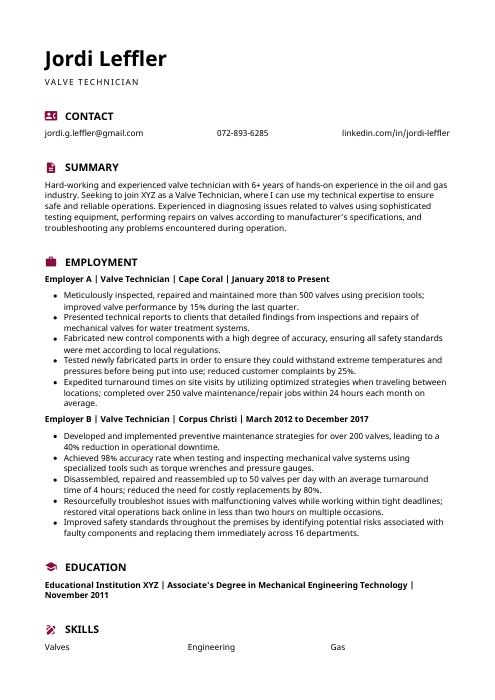

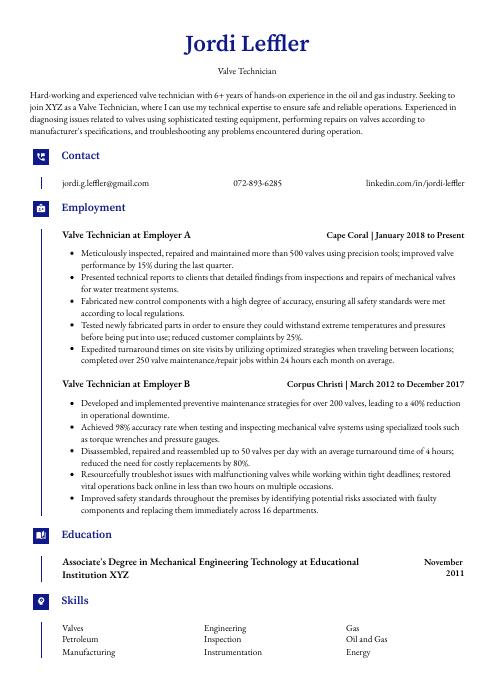

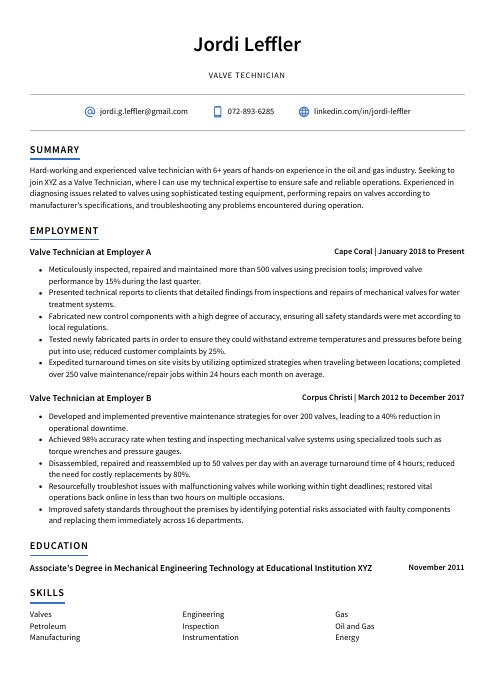

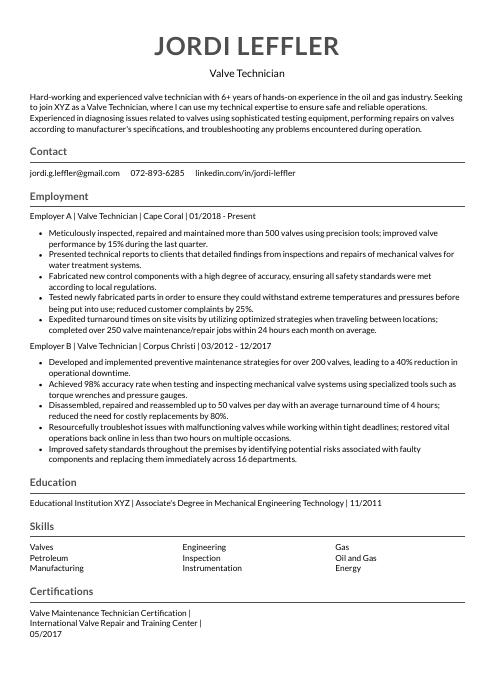

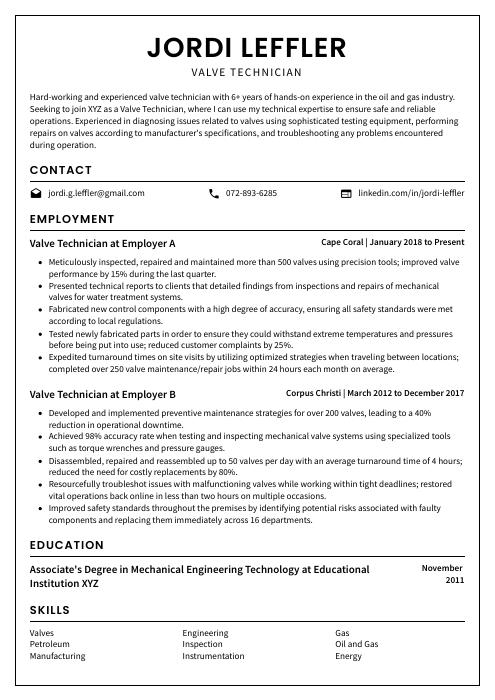

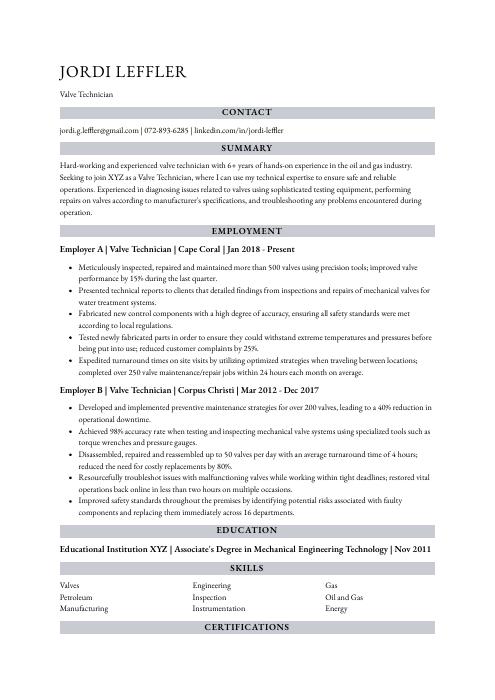

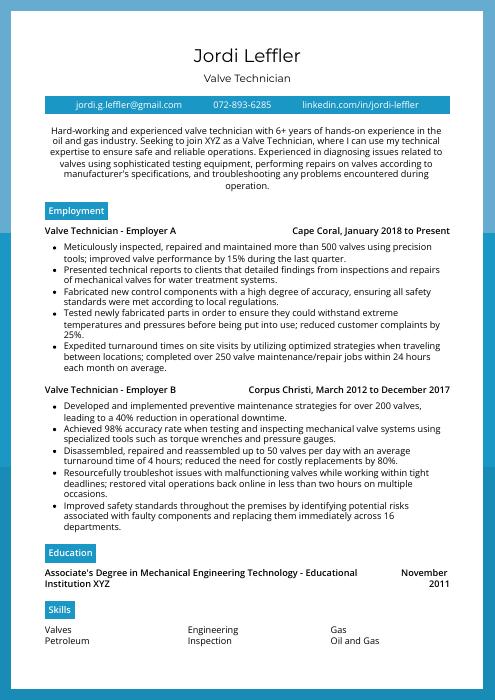

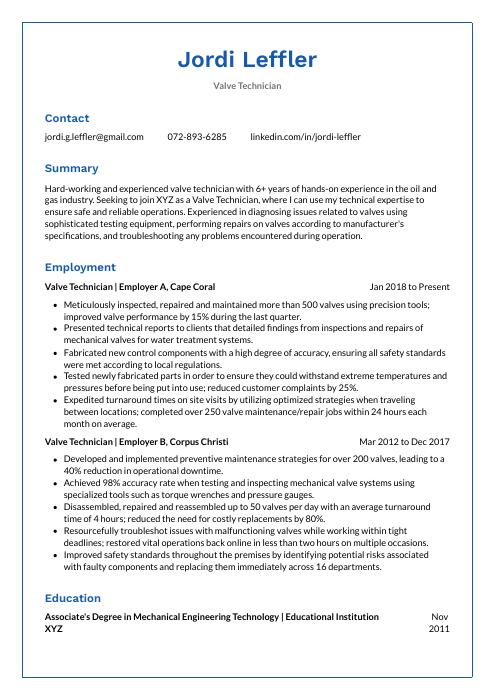

Valve Technician Resume Sample

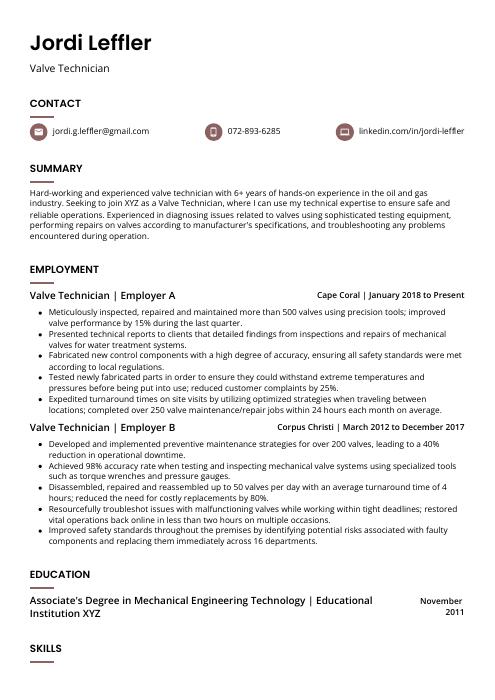

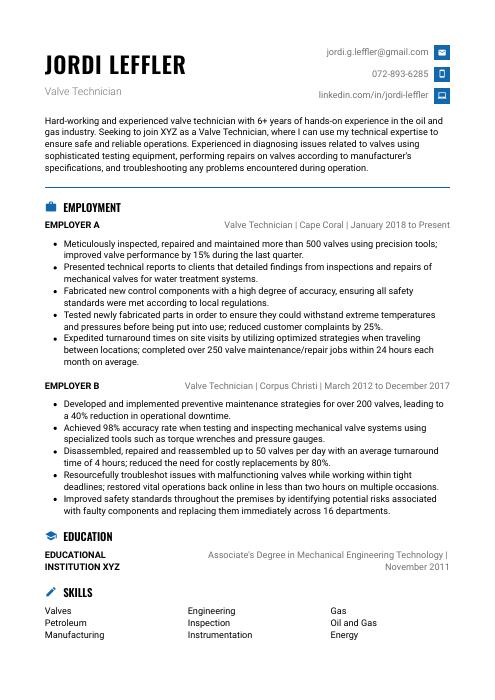

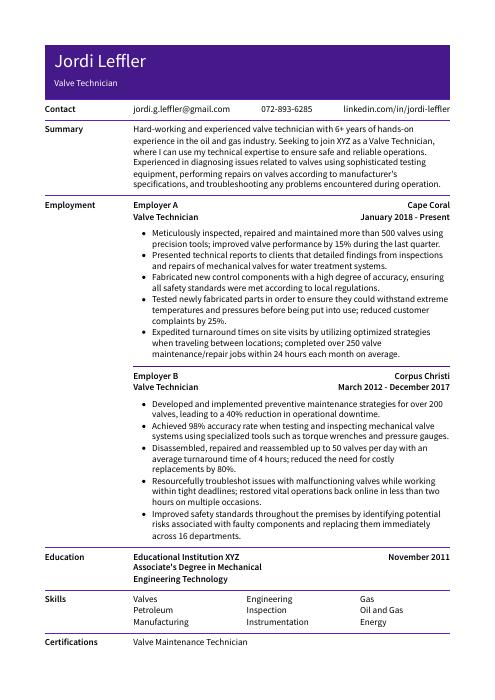

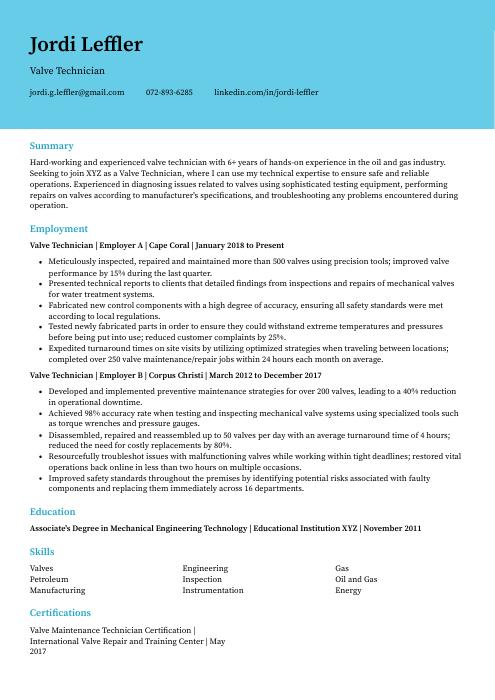

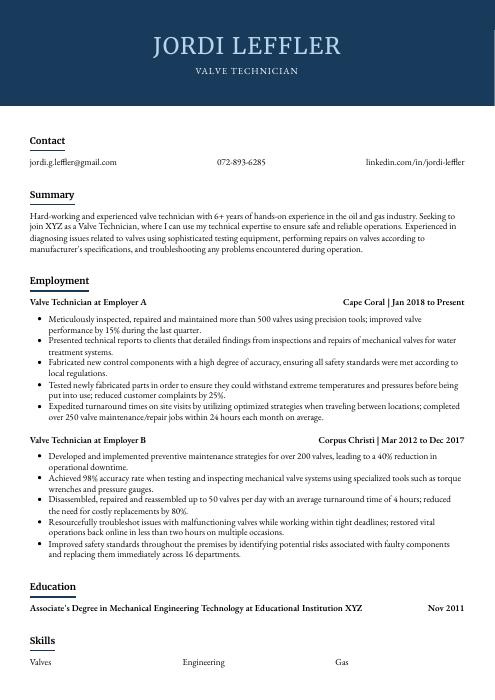

Jordi Leffler

Valve Technician

[email protected]

072-893-6285

linkedin.com/in/jordi-leffler

Summary

Hard-working and experienced valve technician with 6+ years of hands-on experience in the oil and gas industry. Seeking to join XYZ as a Valve Technician, where I can use my technical expertise to ensure safe and reliable operations. Experienced in diagnosing issues related to valves using sophisticated testing equipment, performing repairs on valves according to manufacturer’s specifications, and troubleshooting any problems encountered during operation.

Experience

Valve Technician, Employer A

Cape Coral, Jan 2018 – Present

- Meticulously inspected, repaired and maintained more than 500 valves using precision tools; improved valve performance by 15% during the last quarter.

- Presented technical reports to clients that detailed findings from inspections and repairs of mechanical valves for water treatment systems.

- Fabricated new control components with a high degree of accuracy, ensuring all safety standards were met according to local regulations.

- Tested newly fabricated parts in order to ensure they could withstand extreme temperatures and pressures before being put into use; reduced customer complaints by 25%.

- Expedited turnaround times on site visits by utilizing optimized strategies when traveling between locations; completed over 250 valve maintenance/repair jobs within 24 hours each month on average.

Valve Technician, Employer B

Corpus Christi, Mar 2012 – Dec 2017

- Developed and implemented preventive maintenance strategies for over 200 valves, leading to a 40% reduction in operational downtime.

- Achieved 98% accuracy rate when testing and inspecting mechanical valve systems using specialized tools such as torque wrenches and pressure gauges.

- Disassembled, repaired and reassembled up to 50 valves per day with an average turnaround time of 4 hours; reduced the need for costly replacements by 80%.

- Resourcefully troubleshot issues with malfunctioning valves while working within tight deadlines; restored vital operations back online in less than two hours on multiple occasions.

- Improved safety standards throughout the premises by identifying potential risks associated with faulty components and replacing them immediately across 16 departments.

Skills

- Valves

- Engineering

- Gas

- Petroleum

- Inspection

- Oil and Gas

- Manufacturing

- Instrumentation

- Energy

Education

Associate’s Degree in Mechanical Engineering Technology

Educational Institution XYZ

Nov 2011

Certifications

Valve Maintenance Technician Certification

International Valve Repair and Training Center

May 2017

1. Summary / Objective

Your resume summary/objective should be an overview of your experience and qualifications as a valve technician. Include any certifications or specialized training you have, such as the Valve Maintenance Technician Certification from the American Society of Mechanical Engineers (ASME). You can also mention how many years you’ve been in this field, what types of valves you’re familiar with working on, and any special projects that demonstrate your technical expertise.

Below are some resume summary examples:

Detail-oriented valve technician with 5+ years of experience in the oil and gas industry. Skilled at troubleshooting, assembling, installing and maintaining a wide range of valves for various applications. At XYZ, successfully completed 10 valve installation projects within strict deadlines while strictly adhering to safety regulations. Recognized as an asset-oriented team player who is passionate about delivering quality results on every project.

Accomplished valve technician with 10 years of experience in the oil and gas industry. Serviced, repaired, and tested valves to ensure they meet safety standards while at XYZ Oil & Gas Company. Successfully diagnosed valve problems quickly and accurately by utilizing a variety of testing equipment including pressure gauges and flow meters. Adept at reading blueprints as well as troubleshooting issues on-site to minimize downtime for clients.

Committed valve technician with 5+ years of experience in the oil and gas industry. Skilled at troubleshooting and repairing valves, performing maintenance operations, inspecting equipment for malfunctions, and installing new parts. Achieved an average repair success rate of 98%. Seeking to join ABC Tech as a Valve Technician to provide technical expertise that will contribute towards safe operation of industrial valve systems.

Seasoned valve technician with 8+ years of experience troubleshooting and repairing valves for a variety of process systems. Seeking to join ABC Tech as their next valve tech expert, where I can leverage my expertise in high-pressure piping systems and hydraulic equipment maintenance. My past achievements include reducing downtime by 25% through an innovative solution that improved the efficiency of system operations.

Amicable and reliable valve technician with 8+ years of experience in a variety of settings. Skilled at inspecting, troubleshooting, repairing and maintaining all types of industrial valves and pumps. At XYZ Inc., improved their spare parts inventory system by 50% resulting in increased efficiency during maintenance operations. Demonstrated expertise in reading blueprints and diagrams to diagnose issues quickly.

Determined valve technician with 6+ years of experience in mechanical engineering and repair. Seeking to utilize expertise in troubleshooting, maintenance, and installation at ABC Corp. Developed an innovative system for predictive valve failure analysis that decreased downtime by 25%. Improved accuracy of measurements taken during repairs by 16%, resulting in fewer repeat visits to customer sites.

Reliable valve technician with 10+ years of experience maintaining and repairing valves in a variety of industrial settings. At XYZ, managed the maintenance program for all control valve systems, ensuring that each system was kept up to date and compliant with safety regulations. Recognized for an exceptional ability to troubleshoot complex issues quickly and effectively.

Diligent valve technician with 5+ years of experience inspecting, testing and repairing a variety of valves. Expert in troubleshooting complex systems and quickly diagnosing problems to reduce downtime. Seeking an opportunity at ABC Company that can benefit from my expertise in ensuring the highest quality standards for all components used in industrial operations.

2. Experience / Employment

In the experience section, you should provide details on your employment history. This section should be written in reverse chronological order, with the most recent job listed first.

When writing this section, use bullet points to make it easier for the reader to take in what you have to say quickly and easily. You want to include detail when describing what you did and any results or accomplishments that resulted from it.

For example, instead of saying “Repaired valves,” try something like “Successfully repaired a variety of hydraulic valve systems using specialized tools; reduced downtime by 30% through improved maintenance practices.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Inspected

- Adjusted

- Calibrated

- Repaired

- Tested

- Troubleshot

- Replaced

- Assembled

- Disassembled

- Operated

- Monitored

- Analyzed

- Fabricated

- Welded

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Advised and trained 20+ valve technicians on the installation, maintenance and repair of over 1,000 valves in industrial settings; reduced downtime by 30% and improved production efficiency.

- Facilitated regular safety inspections to ensure that all equipment was up to code; identified 50+ potential risks which were addressed through immediate corrective action plans.

- Streamlined operations by implementing an inventory management system for tracking parts and supplies used during service calls; decreased costs per job call by $500 on average.

- Accurately diagnosed problems with valves using pressure/temperature gauges, flow meters and other specialized tools before developing solutions tailored to meet specific client needs within budget requirements.

- Spearheaded a project to upgrade existing valves across five different plants throughout the city, resulting in increased reliability of automated processes while reducing energy consumption rates by 15%.

- Structured installation and maintenance plans for over 150 valves, ensuring that all safety regulations were adhered to; reduced downtime of process equipment by 30%.

- Mentored newly hired valve technicians on company policies/procedures and instructed them in the proper usage of specialized tools/equipment.

- Represented the organization at professional conferences, trade shows, supplier meetings and other industry events; generated 25+ new business contacts from these engagements.

- Consistently met or exceeded performance goals while troubleshooting any mechanical issues with valves using detailed knowledge of their function & design principles; achieved a 100% success rate in repairs within 24 hours or less across 10+ clients sites.

- Replaced defective components such as gaskets, o-rings and seals on various types of ball valves using precision hand tools to ensure optimal operation efficiency; saved 40 man-hours per month compared to prior repair methods used before implementation.

- Repaired and maintained valves and associated piping systems for industrial applications, reducing downtime by 45% through effective troubleshooting.

- Demonstrated excellent technical knowledge when inspecting valves to identify root cause of problems; implemented cost-effective solutions that increased uptime by 35%.

- Utilized advanced welding techniques such as TIG, MIG & Orbital to fix leaks in pipelines with precision while adhering strictly to safety protocols at all times.

- Welded over 500 flanged connections in accordance with industry standards within a 3 month period without compromising on quality or accuracy requirements set out by clients.

- Competently operated various types of sophisticated testing equipment including hydrostatic pressure tests, valve leakage tests & crack detection instruments with experience gained from 20+ projects across multiple industries.

- Revised and recalibrated over 250 valves and control systems, resulting in a 15% decrease of energy consumption.

- Analyzed root cause issues related to valve performance, tested various components and implemented corrective actions within established timelines; significantly reduced downtime by 40%.

- Optimized 20+ regulate-to-setpoint loops for improved accuracy and repeatability; this resulted in an increase of product yield by 10%.

- Substantially decreased the rate of failed pressure tests from 30% to 5%, leading to increased customer satisfaction levels with fewer complaints lodged against products or services provided.

- Performed regular maintenance on 150+ manual & automated valves including testing, troubleshooting and repair work utilizing specialized tools such as torque wrenches, pressure gauges etc.; completed all tasks within allotted timeframes without compromising quality standards or safety protocols.

- Installed over 500 valves, including manual and automated control systems, for various industrial plants; identified potential problems in the design to reduce installation time by 20%.

- Monitored operational performance of all valves on a daily basis, adjusting settings as needed to ensure optimal efficiency with minimal downtime.

- Adjusted valve seats and actuator positions based on pressure ratings and customer specifications; improved accuracy by 5% compared to previous levels.

- Operated diagnostic testing equipment such as flow meters, thermometers and calipers to assess system integrity and detect any malfunctions or faults; trouble-shot repairs within 2 hours on average per issue.

- Successfully completed preventative maintenance activities for up to 200 different types of valves each month; reduced rate of breakage due to wear & tear by 8%.

- Troubleshot malfunctions in valves using diagnostic equipment, resolving issues within the allotted time frame and reducing downtime by 10%.

- Effectively inspected, tested and repaired over 400 valve systems each month to ensure optimal performance; identified potential problems before they became costly repairs.

- Introduced a new maintenance system that enabled more efficient tracking of regular inspections, ultimately resulting in an 8% decrease in repair costs.

- Formulated innovative solutions for complex technical problems related to valve control units and automation processes, saving up to 25 hours per week on manual labor tasks alone.

- Coordinated with other technicians on-site when servicing larger projects such as oil pipelines or gas plants; completed assignments quickly while adhering to safety protocols at all times.

- Prepared and installed over 200 valves and associated piping systems for industrial operations, ensuring that safety regulations were strictly followed at all times.

- Participated in team-based projects to troubleshoot valve units with up to 50% efficiency increase achieved on average; identified multiple hazardous conditions throughout the process and corrected them promptly.

- Inspected existing pipelines, valves and actuators for corrosion or wear using advanced tools such as ultrasonic thickness gauges while adhering to industry standards; detected a 40% decrease in performance rate of faulty parts due to improper maintenance practices before corrective action was taken.

- Assembled new pieces of equipment including pressure relief valves, checkvalves, ball shut offs and other components based on production requirements within an 8 hours period on average per job order with no quality control issues reported upon completion of assignments.

- Diligently monitored fluid flow rates through pipeline networks utilizing sophisticated software programs; documented readings from various points along the system resulting in 30+ optimized configurations implemented successfully across different sites each month.

- Compiled detailed reports on valve inspection and testing results of over 150 valves per month, resulting in a 10% reduction in valve repair time.

- Reduced the need for emergency repairs by 25%, ensuring that all valves were properly serviced and tested as part of preventative maintenance protocols.

- Reorganized warehouse inventory to improve efficiency; organized parts into labeled bins, allowing technicians to locate necessary components more quickly with less downtime spent searching through boxes or shelves.

- Efficiently repaired up to 50 valves each shift while adhering strictly to safety regulations; completed jobs 8 hours ahead of schedule during peak times due to fast workmanship rates and accuracy rate of 97%.

- Assessed customer needs accurately when troubleshooting their issues, recommending cost effective solutions whenever possible which allowed them to save an average of $400 in unnecessary costs per job order every week.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization might be seeking someone with experience in valve repair and maintenance, while another might want a technician who is knowledgeable about the latest safety regulations.

It’s important to tailor your skills section to each job you are applying for because many employers today use applicant tracking systems (ATS). These software programs scan resumes for certain keywords before passing them on to human recruiters.

You should also mention any relevant certifications or qualifications here as well as elaborate more on some of the most important ones in other sections such as the summary or work history.

Below is a list of common skills & terms:

- Commissioning

- Continuous Improvement

- Control Valves

- Energy

- Engineering

- Gas

- Inspection

- Instrumentation

- Maintenance

- Maintenance and Repair

- Manufacturing

- Mechanical Engineering

- Offshore Drilling

- Oil

- Oil and Gas

- Oilfield

- Onshore

- Petroleum

- Pressure

- Preventive Maintenance

- Project Engineering

- Pumps

- Supervisory Skills

- Teamwork

- Testing

- Troubleshooting

- Valves

4. Education

Adding an education section to your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, list your education below the resume objective. However, if you have many years of work experience as a valve technician to showcase, it might be best to omit an education section altogether.

If an education section is included, make sure to mention courses related specifically to valve technicians such as fluid mechanics or thermodynamics that demonstrate relevant knowledge for the job position.

Associate’s Degree in Mechanical Engineering Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to a potential employer that you have the necessary knowledge and skills for a particular job. Having certifications is an indication of your commitment to professional development, as well as your dedication to staying up-to-date with industry trends.

Including any relevant certifications in this section of your resume can be beneficial when applying for positions where specific qualifications are required or preferred.

Valve Maintenance Technician Certification

International Valve Repair and Training Center

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Jordi Leffler, this would be Jordi-Leffler-resume.pdf or Jordi-Leffler-resume.docx.

7. Cover Letter

Including a cover letter in your job application package is a great way to make sure your skills and experience stand out. A cover letter should be made up of 2-4 paragraphs that explain why you are the perfect fit for the role, in addition to what’s already mentioned on your resume.

Cover letters are not always mandatory but they can go a long way towards helping you land an interview with a potential employer. They provide more detail about who you are as an individual and how well suited you would be for the position at hand.

Below is an example cover letter:

Dear Melissa,

I am writing to apply for the Valve Technician position at XYZ Company. As a certified valve technician with more than 10 years of experience, I am confident that I can be an asset to your team.

In my previous role as a Valve Technician at ABC Company, I was responsible for maintaining and repairing all types of valves used in the company’s operations. I have experience working with both manual and automated valves, and I am familiar with a variety of brands and models. In addition to my technical skills, I have also developed strong problem-solving and troubleshooting abilities.

I am knowledgeable about OSHA regulations related to valve maintenance and repair, and I always follow safe work practices when performing these tasks. My attention to detail ensures that all repairs are carried out correctly the first time, which minimizes downtime for your operations.

I would welcome the opportunity to put my skills and experience to work for XYZ Company as your next Valve Technician. Thank you for your time and consideration; please do not hesitate to contact me if you have any questions or need additional information.

Sincerely,

Jordi

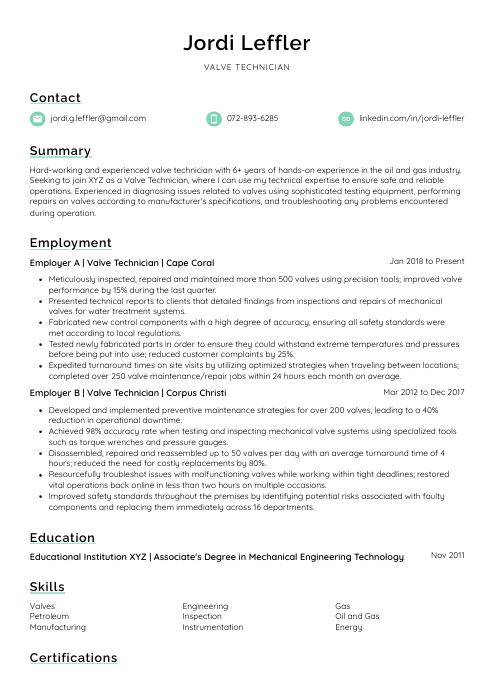

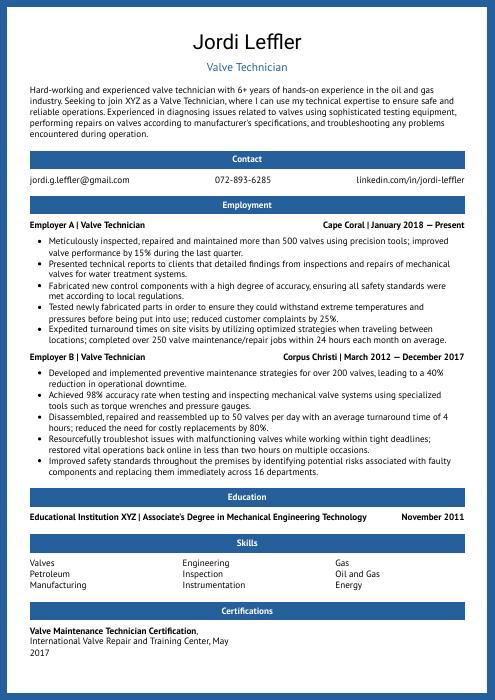

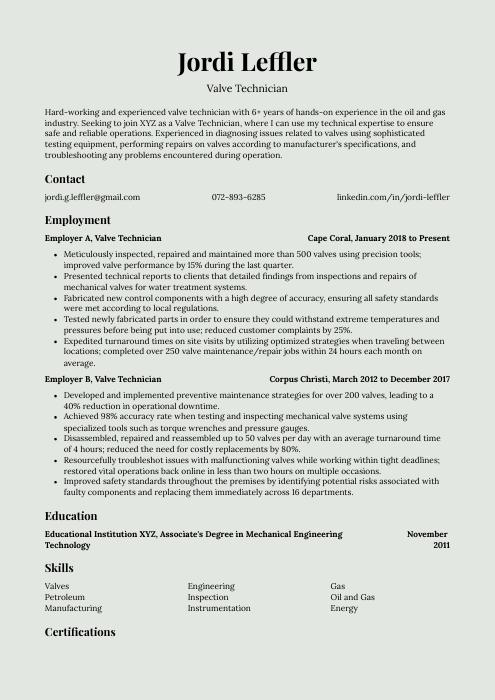

Valve Technician Resume Templates

Kinkajou

Kinkajou Jerboa

Jerboa Quokka

Quokka Hoopoe

Hoopoe Gharial

Gharial Axolotl

Axolotl Indri

Indri Fossa

Fossa Echidna

Echidna Pika

Pika Dugong

Dugong Cormorant

Cormorant Numbat

Numbat Rhea

Rhea Markhor

Markhor Bonobo

Bonobo Lorikeet

Lorikeet Ocelot

Ocelot Saola

Saola Rezjumei

Rezjumei