Production Technician Resume Guide

Production technicians are responsible for operating and maintaining manufacturing equipment, troubleshooting technical issues, performing quality control inspections, and monitoring production processes. They also help to ensure that products meet safety standards and comply with applicable regulations.

You have the technical knowledge and experience to be an invaluable asset in any production department. But employers don’t know who you are yet, so make sure your resume stands out from the competition and shows off your best assets.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

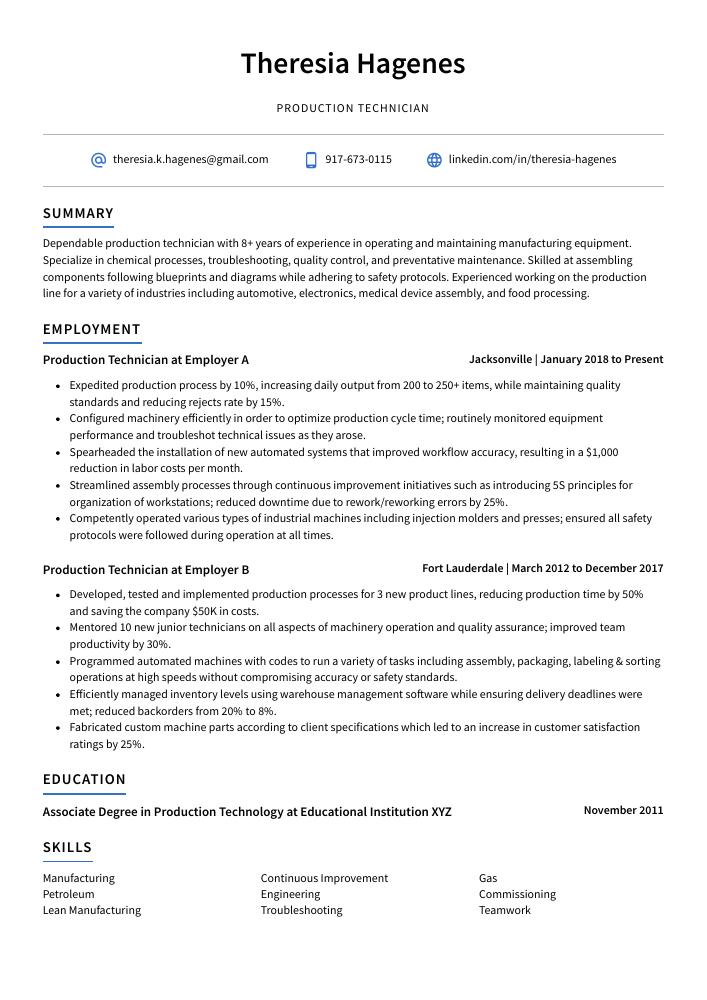

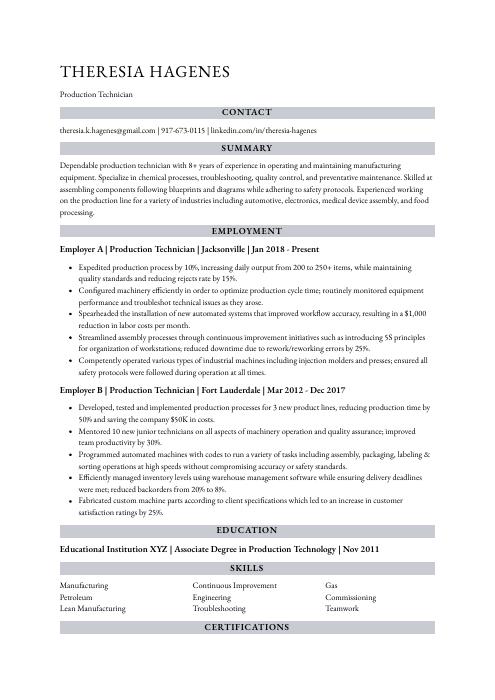

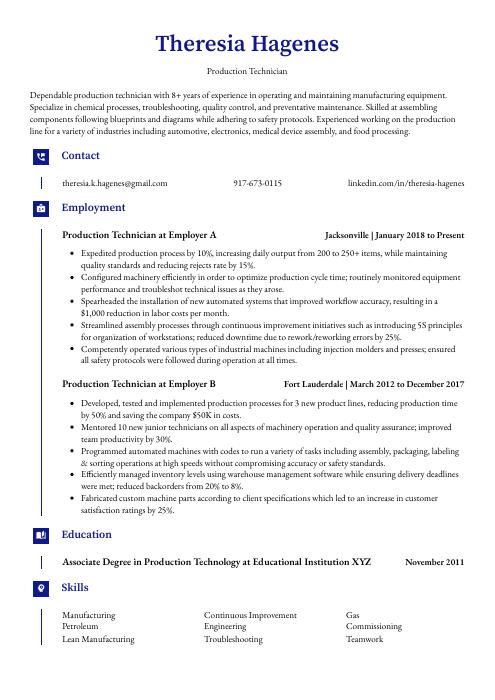

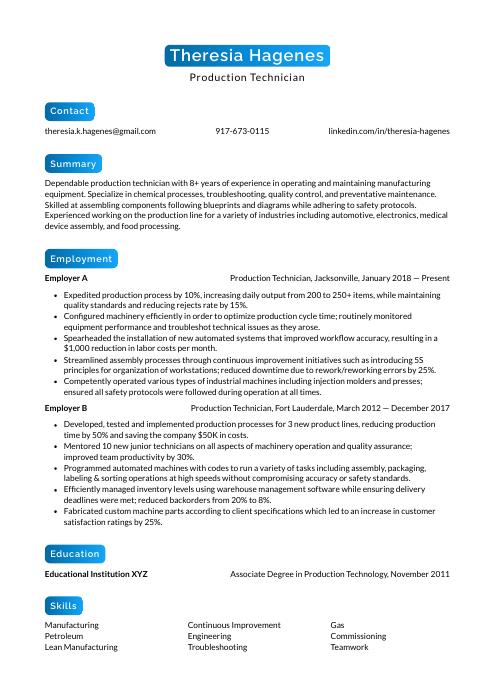

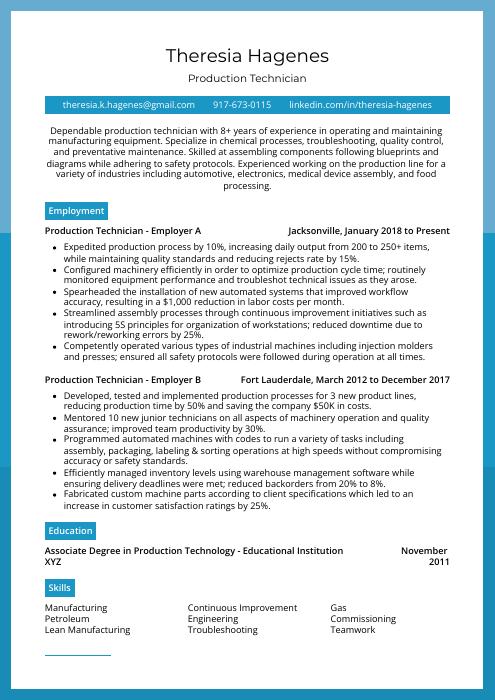

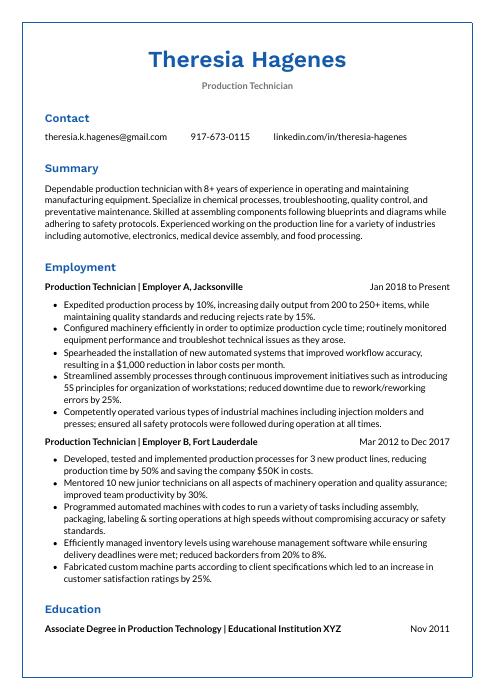

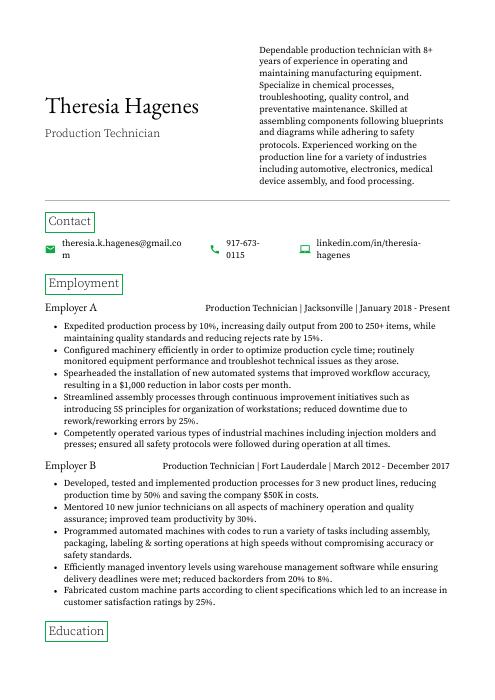

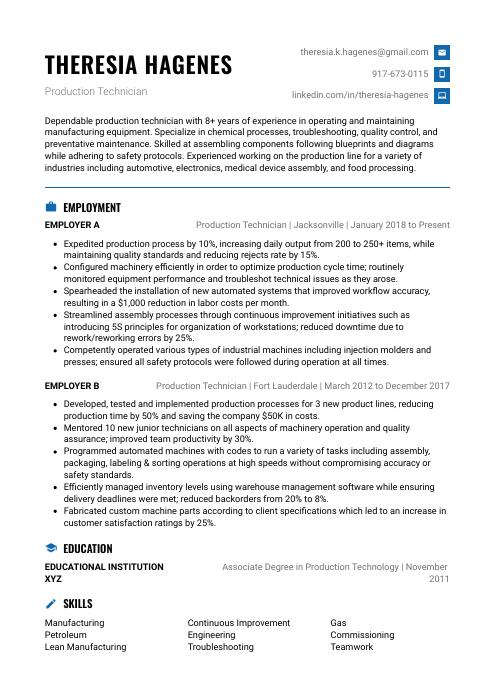

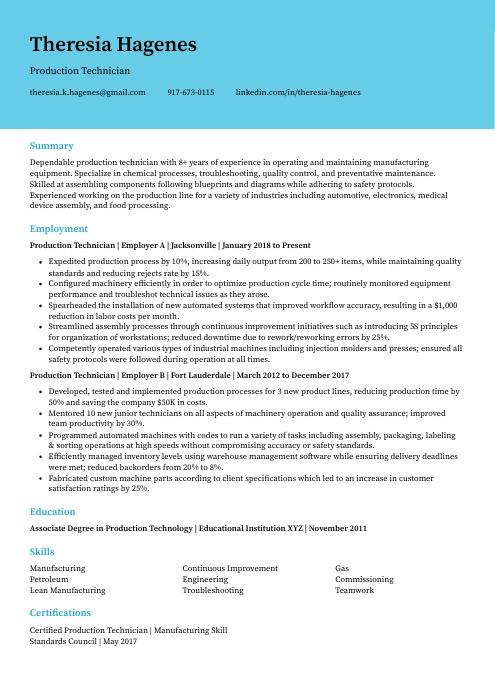

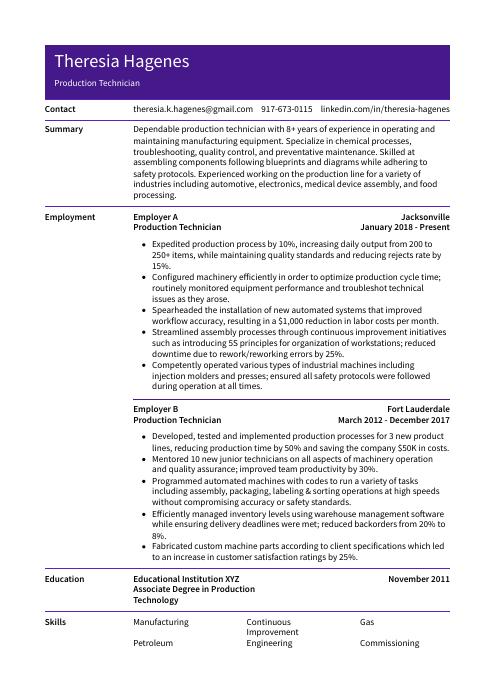

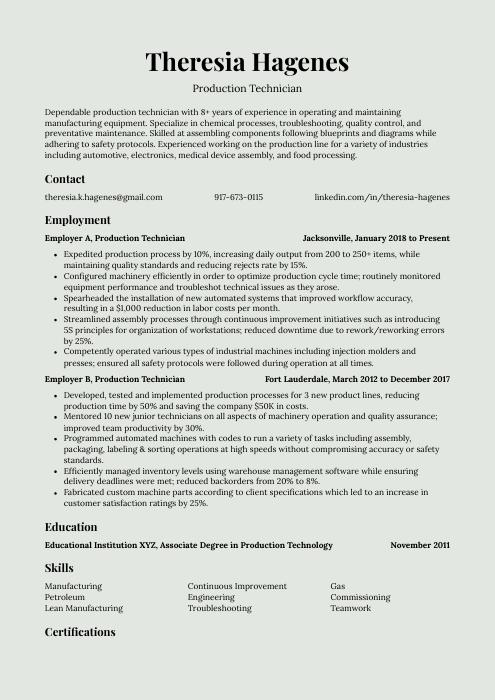

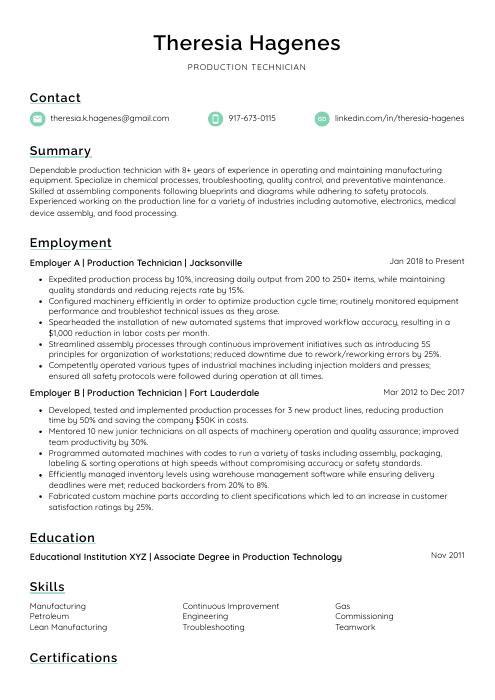

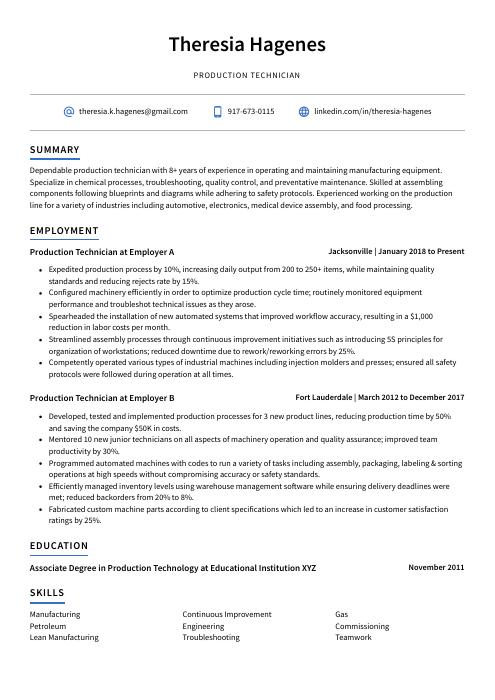

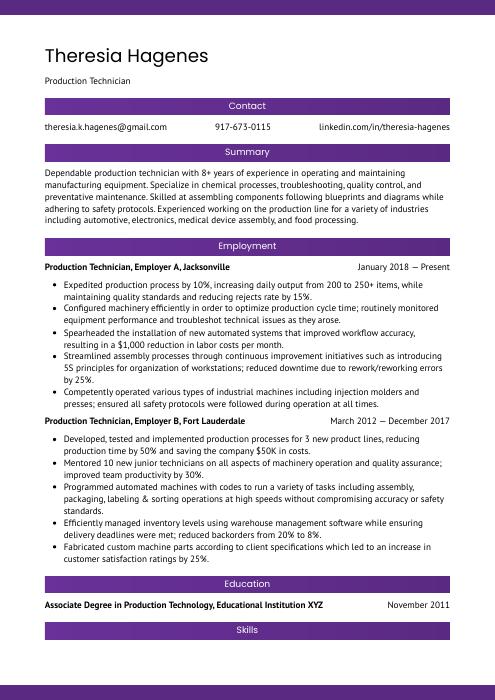

Production Technician Resume Sample

Theresia Hagenes

Production Technician

[email protected]

917-673-0115

linkedin.com/in/theresia-hagenes

Summary

Dependable production technician with 8+ years of experience in operating and maintaining manufacturing equipment. Specialize in chemical processes, troubleshooting, quality control, and preventative maintenance. Skilled at assembling components following blueprints and diagrams while adhering to safety protocols. Experienced working on the production line for a variety of industries including automotive, electronics, medical device assembly, and food processing.

Experience

Production Technician, Employer A

Jacksonville, Jan 2018 – Present

- Expedited production process by 10%, increasing daily output from 200 to 250+ items, while maintaining quality standards and reducing rejects rate by 15%.

- Configured machinery efficiently in order to optimize production cycle time; routinely monitored equipment performance and troubleshot technical issues as they arose.

- Spearheaded the installation of new automated systems that improved workflow accuracy, resulting in a $1,000 reduction in labor costs per month.

- Streamlined assembly processes through continuous improvement initiatives such as introducing 5S principles for organization of workstations; reduced downtime due to rework/reworking errors by 25%.

- Competently operated various types of industrial machines including injection molders and presses; ensured all safety protocols were followed during operation at all times.

Production Technician, Employer B

Fort Lauderdale, Mar 2012 – Dec 2017

- Developed, tested and implemented production processes for 3 new product lines, reducing production time by 50% and saving the company $50K in costs.

- Mentored 10 new junior technicians on all aspects of machinery operation and quality assurance; improved team productivity by 30%.

- Programmed automated machines with codes to run a variety of tasks including assembly, packaging, labeling & sorting operations at high speeds without compromising accuracy or safety standards.

- Efficiently managed inventory levels using warehouse management software while ensuring delivery deadlines were met; reduced backorders from 20% to 8%.

- Fabricated custom machine parts according to client specifications which led to an increase in customer satisfaction ratings by 25%.

Skills

- Manufacturing

- Continuous Improvement

- Gas

- Petroleum

- Engineering

- Commissioning

- Lean Manufacturing

- Troubleshooting

- Teamwork

Education

Associate Degree in Production Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Production Technician

Manufacturing Skill Standards Council

May 2017

1. Summary / Objective

Your resume summary or objective is the first thing a hiring manager will see, so you want to make sure it grabs their attention. In this section, you can highlight your experience as a production technician and any relevant certifications or qualifications that set you apart from other candidates. Additionally, mention how many years of experience in the industry you have and any successes or accomplishments that demonstrate your expertise in the field.

Below are some resume summary examples:

Energetic production technician with 5+ years of experience in a fast-paced manufacturing environment. Skilled in troubleshooting and problem solving to resolve issues quickly. Recently achieved a 10% reduction in downtime at XYZ Manufacturing by optimizing production processes and utilizing smart scheduling techniques. Looking to join ABC as the next Production Technician, where I can utilize my skills to drive even greater efficiency gains for the company.

Driven production technician with 5+ years of experience in a manufacturing environment. Skilled at troubleshooting, quality control, and inventory management. Seeking to join ABC Manufacturing as a Production Technician where I can utilize my expertise for the benefit of the company and its customers. At XYZ Inc., reduced downtime by 25% through improved maintenance procedures and optimized production processes leading to increased output efficiency.

Amicable production technician with 5+ years of experience in the manufacturing industry. Expertise in troubleshooting and resolving complex production issues while adhering to safety guidelines, company policies, and quality standards. At XYZ Corporation, managed a team of 15 technicians for efficient operations on five production lines simultaneously. Commended by supervisor for maintaining compliance on all projects within budgeted timelines.

Proficient production technician with 7+ years of experience in production and assembly operations. Proven ability to work independently or as part of a team while meeting tight deadlines. At XYZ, I was responsible for overseeing the entire production process from start to finish, ensuring quality control at each stage. Adept in troubleshooting technical issues and providing effective solutions in order to maximize productivity and efficiency.

Committed production technician with 7+ years of experience in a fast-paced environment. Strengths include troubleshooting and problem solving, as well as efficiently operating automated production systems. At XYZ, maintained 100% quality assurance standards while meeting weekly deadlines for two major product lines. Seeking to join ABC Technologies where I can leverage my skills to support their production goals.

Hard-working and knowledgeable production technician with 5+ years of experience in safety-compliant manufacturing environments. Experienced in developing and monitoring production processes, resolving technical issues, and ensuring quality assurance standards are met. Looking to join ABC Manufacturing as a Production Technician where I can apply my skillset to improve efficiency and increase productivity.

Skilled production technician with 10+ years of experience in operating and maintaining manufacturing equipment. Successfully troubleshot mechanical issues on the line, resulting in a 15% reduction of production downtime at Company X. Looking to join ABC Manufacturing as part of their team to continue utilizing my technical knowledge and problem-solving skills for successful operations.

Reliable and experienced production technician with 5+ years of experience in the manufacturing industry. Highly skilled in troubleshooting and repairing machines, as well as producing quality products efficiently and on time. Proven track record of reducing lead times by 20% while increasing customer satisfaction ratings from 85 to 95%.

2. Experience / Employment

The work history/experience section is where you list your previous employment. It should be written in reverse chronological order, meaning the most recent job is listed first.

When writing out what you did for each role, stick to bullet points; this makes it easier for the reader to digest the information quickly and accurately. When creating these bullet points, provide detail about what tasks were completed and any quantifiable results that were achieved as a result of your work.

For example, instead of saying “Operated machines,” you could say, “Successfully operated 5+ production machines daily with an average output rate of 95%, resulting in increased efficiency across all departments.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Operated

- Monitored

- Assembled

- Inspected

- Troubleshot

- Adjusted

- Calibrated

- Programmed

- Fabricated

- Welded

- Tested

- Repaired

- Installed

- Configured

- Analyzed

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Formulated and executed production plans for manufacturing of over 1,000 parts per day with a 95% accuracy rate.

- Operated automated machinery and equipment to assemble products within quality standards; reduced defective product returns by 20%.

- Participated in the development of new production processes and techniques that increased efficiency by 15%.

- Adjusted machine settings as needed during the assembly process to ensure optimal performance and output; exceeded production targets by 25% on average each month.

- Successfully completed preventive maintenance checks on all machines every 3 months, resulting in no major breakdowns or delays throughout entire shift period (6 weeks).

- Structured and maintained production equipment, ensuring optimal performance and reliability; decreased downtime by 20% in the last quarter.

- Utilized computer-aided engineering (CAE) software to design components for new projects and modified existing designs per requirements; reduced product development time from 3 weeks to 2 weeks on average.

- Meticulously monitored all operations on the assembly line and made necessary adjustments when needed; identified potential problems before they arose and minimized defective parts yields by 25%.

- Presented technical ideas at project meetings with other engineers, managers & technicians to ensure a smooth workflow of processes across departments during product launches/updates.

- Calibrated machines used in manufacturing products daily according to safety standards, resulting in an increase of productivity by 8 hours each week without compromising quality assurance guidelines.

- Monitored and adjusted production machines daily to ensure optimal performance and output, reducing down-time by 25%.

- Introduced new production processes that increased efficiency levels across the department by 30%, saving over $10,000 in labor costs annually.

- Accurately recorded data from all stages of production process and updated records within a timely manner; eliminated inaccuracies in inventory tracking & forecasting systems resulting in more accurate forecasts for future projects.

- Advised other technicians on best practices when operating machinery and maintaining equipment, helping to reduce employee injury rates by 10%.

- Analyzed quality control reports to identify potential errors or discrepancies during product development cycle; improved accuracy of finished products with minimal adjustments based on analysis results leading to an increase in customer satisfaction ratings by 20%.

- Optimized production processes through the identification and implementation of cost-effective solutions, increasing output efficiency by 25%.

- Revised production plans to ensure that deadlines were met without compromising on product quality; reduced lead time for projects by an average of 30 hours per week.

- Repaired various machinery and equipment used in the production process with minimal disruption to operations, resulting in a 20% reduction in downtime costs over 3 months.

- Independently managed safety protocols within the work environment while supervising 8 other technicians working on large scale productions; held weekly inspections to monitor performance levels and compliance with regulations.

- Represented company at industry trade shows & conferences, sharing best practices regarding efficient manufacturing techniques as well as introducing new products developed internally which contributed $25K+ towards annual revenue growth goals.

- Inspected over 150 pieces of production machinery daily to identify operational malfunctions and defects, resulting in a 22% decrease in machine downtime.

- Improved the efficiency of 10+ automated processes by optimizing workflow, streamlining assembly lines and implementing new quality control protocols; achieved up to 20% better output with fewer resources used.

- Reliably maintained optimal performance levels during peak periods when handling multiple projects simultaneously; exceeded all production targets by an average 5%.

- Reduced waste material costs by 15%, improved energy efficiency and minimized environmental impact through regular monitoring of resource consumption rates on all machines under my supervision.

- Demonstrated strong technical aptitude while troubleshooting complex mechanical issues, providing quick solutions that allowed for faster resolution time than industry standards (18%).

- Installed and maintained over 300 pieces of machinery within a manufacturing plant, reducing downtime and increasing production efficiency by 25%.

- Resourcefully troubleshooted equipment malfunctions when necessary, resulting in an average repair time of only 3 hours per incident.

- Welded steel components to create robust structures for the assembly line; successfully reduced scrap rates by 15%.

- Reorganized existing workflows on the shop floor and developed new ones that improved overall productivity levels by 21%.

- Achieved 95% accuracy rate while performing quality control checks during each shift; minimized defective parts count from 200/day to 10/day on average.

- Diligently prepared and assembled over 450 products per day according to technical specifications, resulting in a 12% increase in production efficiency.

- Facilitated the installation of new machinery and equipment, such as conveyor systems, pumps and electrical wiring; improved safety regulations by 60%.

- Troubleshot assembly line issues within minutes through careful diagnosis of malfunctions; reduced downtime for repairs by 25%.

- Tested quality control samples every hour to ensure that all components met standards before packaging; decreased customer complaints rate by 20%.

- Assisted with set-up of daily production goals while monitoring inventory levels on regular basis; maintained 95% accuracy when ordering supplies needed for production processes.

- Assessed production needs, identified areas of improvement and implemented cost-saving procedures that reduced production costs by 12%.

- Compiled daily production reports to track the progress of equipment maintenance, quality assurance requirements and safety standards; ensured all activities were in compliance with regulatory guidelines.

- Assembled and tested a range of electrical components for high-tech industrial machinery according to established specifications; successfully completed assembly processes on 6 machines per day (an average increase of 15%).

- Coordinated with other departments including research & development teams as well as engineering specialists when conducting preventive maintenance tasks on automated machinery across 3 shifts; lowered machine downtime by 25 hours each month.

- Actively participated in team meetings to discuss innovative ways of increasing product efficiency while ensuring minimal waste generation; enabled an overall reduction in total energy consumption by 8% over the last quarter.

3. Skills

Skill requirements will differ from one employer to the next; this can easily be ascertained from the job posting. Organization A may require experience with CNC machining, while Organization B may require familiarity with robotics.

It is essential to keep this in mind because of the applicant tracking systems utilized by many companies. Their role is to analyze resumes for certain characteristics (such as specific keywords), filtering out the ones they deem not to be a high-quality match for that particular job.

Once listed here, you can further elaborate on your skillset by discussing it in more detail in other areas, such as the summary or experience section.

Below is a list of common skills & terms:

- 5S

- Commissioning

- Continuous Improvement

- Electronics

- Energy

- Engineering

- Factory

- GMP

- Gas

- Inspection

- Lean Manufacturing

- Manufacturing

- Oil and Gas

- Oil and Gas Industry

- Onshore

- Petrochemical

- Petroleum

- Pipelines

- Preventive Maintenance

- Process Improvement

- Process Safety

- Project Planning

- Pumps

- Quality Assurance

- Refinery

- Supervisory Skills

- Team Leadership

- Teamwork

- Time Management

- Troubleshooting

- Upstream

4. Education

Mentioning your education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, it is best to include an education section below your resume objective. However, if you have significant work experience that should be showcased instead of focusing on educational qualifications, leaving out the education section altogether might be a better option.

If including an education section, try to mention courses related to the production technician role such as engineering or industrial technology classes that may demonstrate additional skillsets for this position.

Associate Degree in Production Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They can also be used to show that you have kept up with the latest industry trends and advancements, as certifications are often updated regularly.

Include any relevant certifications on your resume when applying for jobs, as this will help employers determine if you possess the necessary skillset for the job.

Certified Production Technician

Manufacturing Skill Standards Council

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Theresia Hagenes, this would be Theresia-Hagenes-resume.pdf or Theresia-Hagenes-resume.docx.

7. Cover Letter

Including a cover letter with your job application is an important step in the recruitment process. This document provides recruiters with a better understanding of who you are, what makes you unique and why you would be a great fit for the role.

Cover letters should typically include 2 to 4 paragraphs that supplement and enhance information provided on your resume. It allows applicants to express their personality, explain any gaps or inconsistencies in their work history, and show they have done research into the company they’re applying to.

Below is an example cover letter:

Dear Layne,

I am writing to apply for the Production Technician position at your company. With experience in a wide range of production settings and a proven ability to troubleshoot issues and optimize processes, I am confident I would make an excellent addition to your team.

In my current role as Production Technician at [company name], I oversee all aspects of the production process, from raw materials procurement to finished product shipping. In addition to managing day-to-day operations, I also implement process improvements and lead teams of up to 20 workers during busy periods. My efforts have resulted in increased efficiency and productivity across the board.

Some key accomplishments that demonstrate my suitability for this role include:

– Streamlining the material handling process by implementing a just-in-time delivery system, which reduced inventory costs by 10%.

– Developing a new quality control protocol that caught defects earlier in the production process, resulting in a 25% reduction in scrap and rework expenses.

– Implementing lean manufacturing principles throughout the plant, which led to a 15% increase in output while reducing waste by 30%.

Sincerely,

Theresia

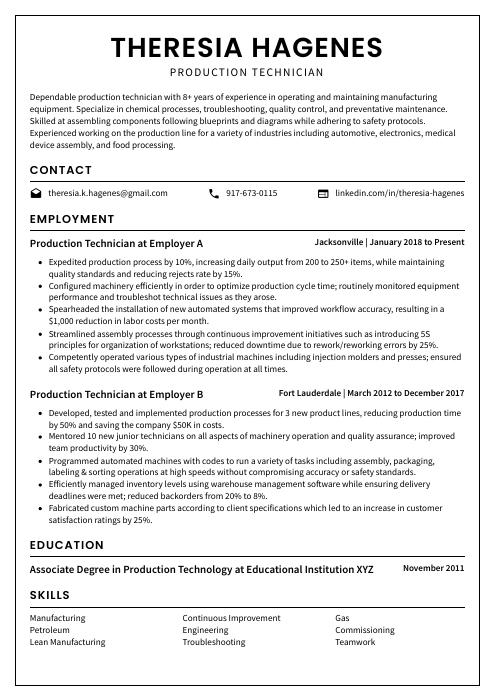

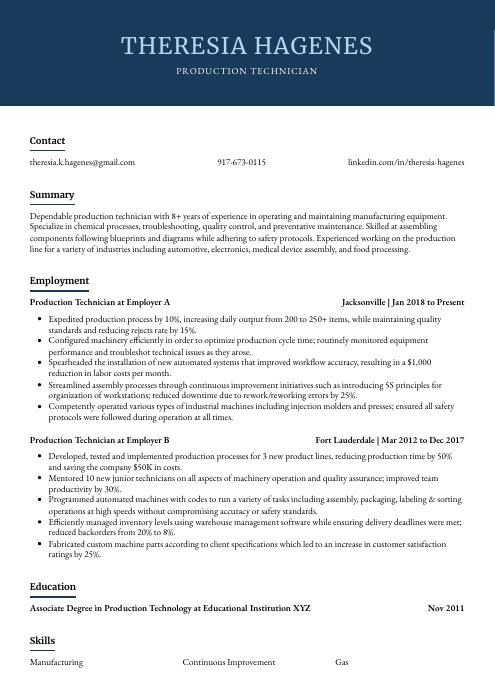

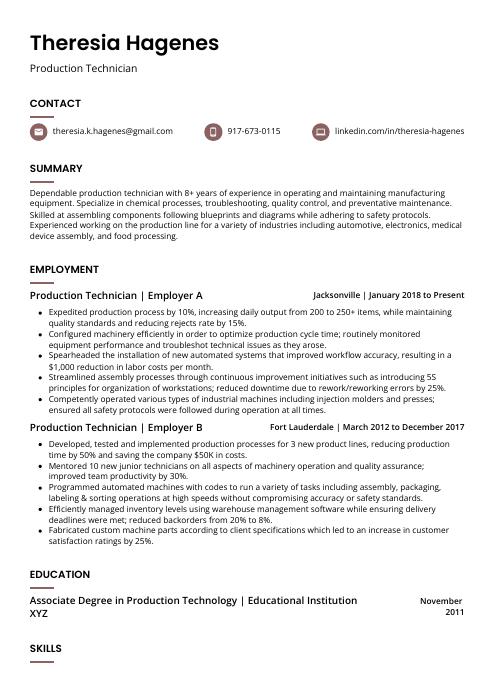

Production Technician Resume Templates

Indri

Indri Ocelot

Ocelot Hoopoe

Hoopoe Numbat

Numbat Gharial

Gharial Kinkajou

Kinkajou Rhea

Rhea Markhor

Markhor Cormorant

Cormorant Bonobo

Bonobo Fossa

Fossa Quokka

Quokka Echidna

Echidna Dugong

Dugong Pika

Pika Saola

Saola Lorikeet

Lorikeet Axolotl

Axolotl Jerboa

Jerboa Rezjumei

Rezjumei