Process Control Technician Resume Guide

Process control technicians monitor and adjust automated industrial processes, such as those in factories. They analyze data from sensors to ensure that equipment is operating correctly, troubleshoot malfunctions when they occur, and update process settings to optimize efficiency.

Your expertise in process control technology is unrivaled, but potential employers don’t know who you are. To make them aware of your experience and qualifications, you must create a resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

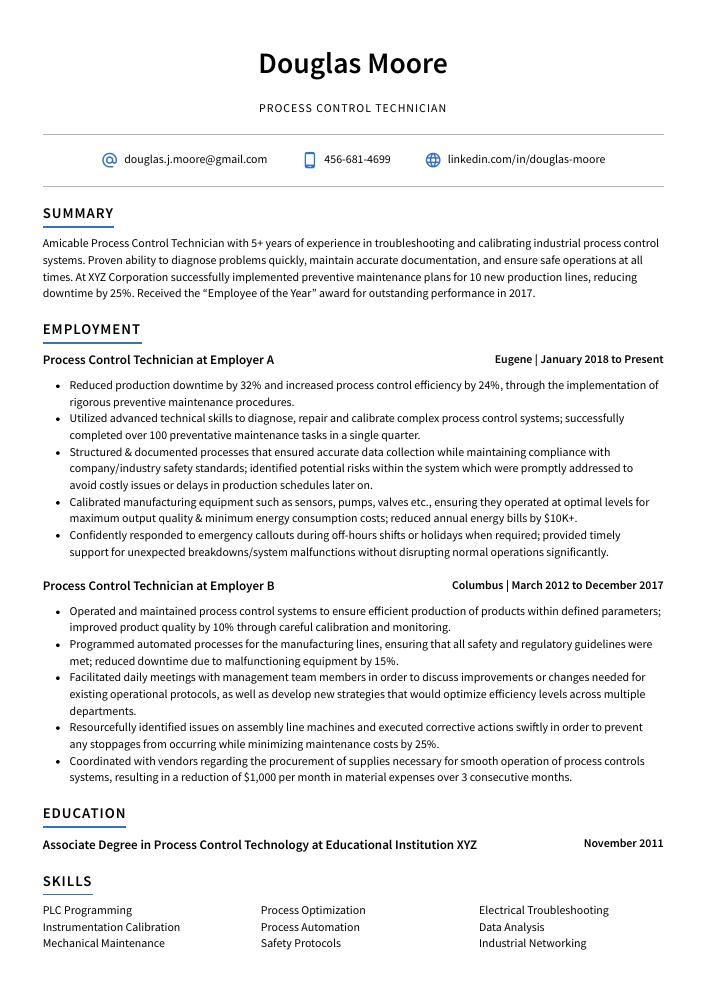

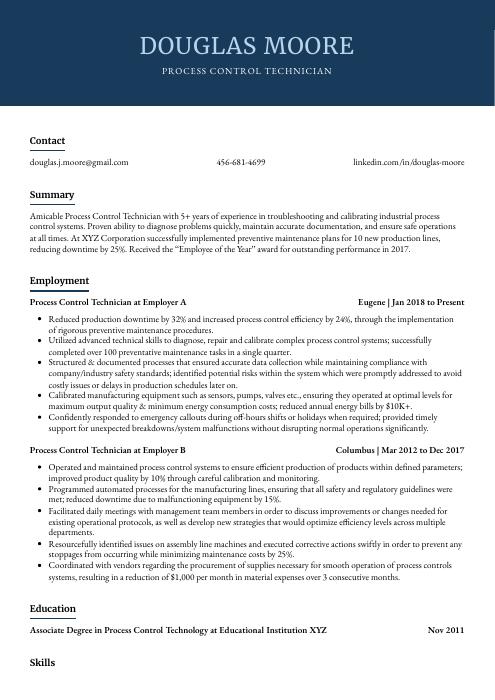

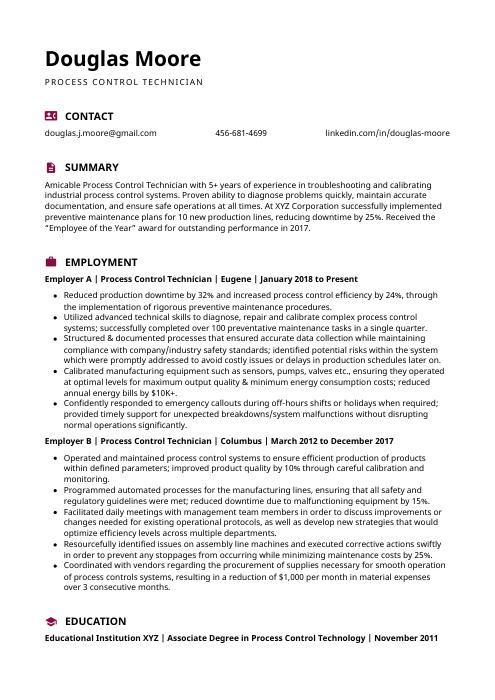

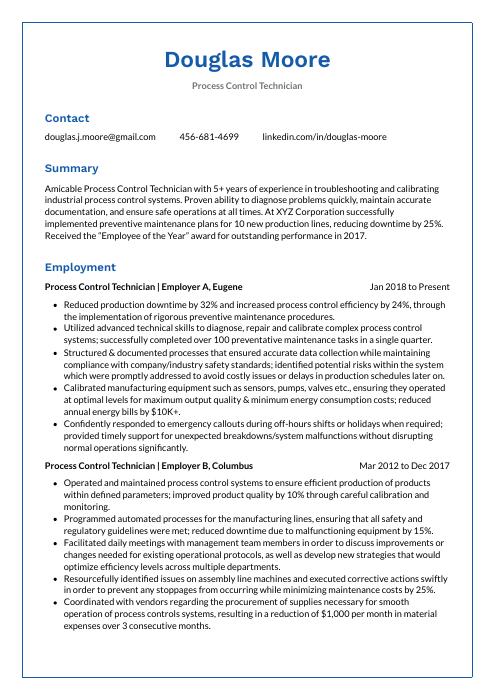

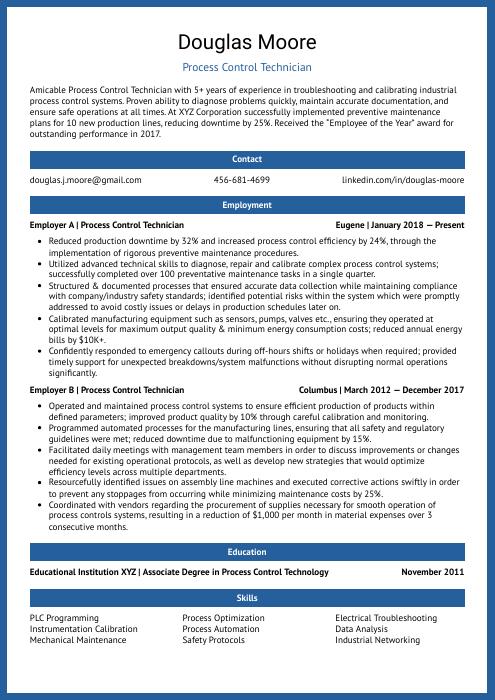

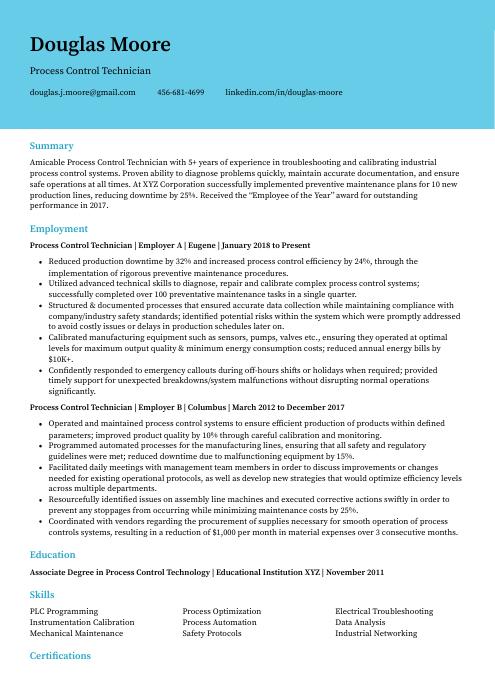

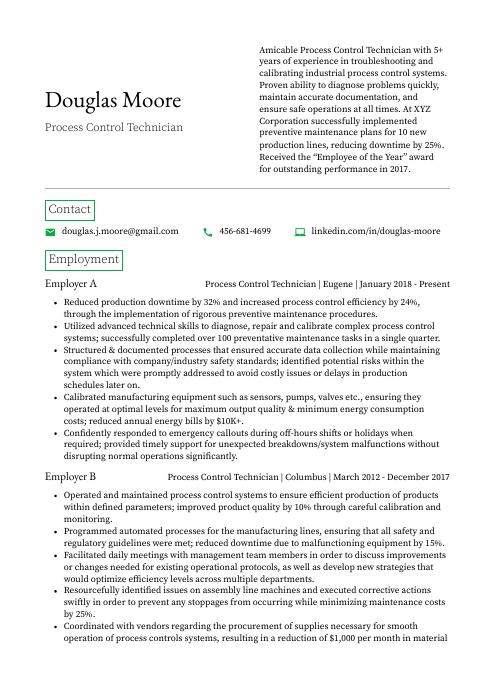

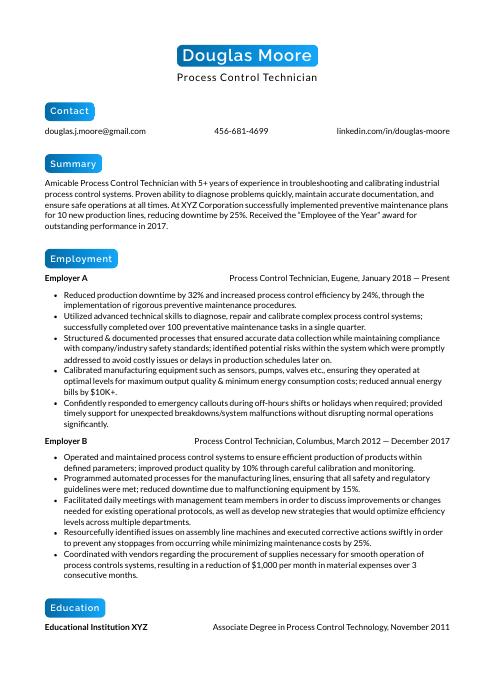

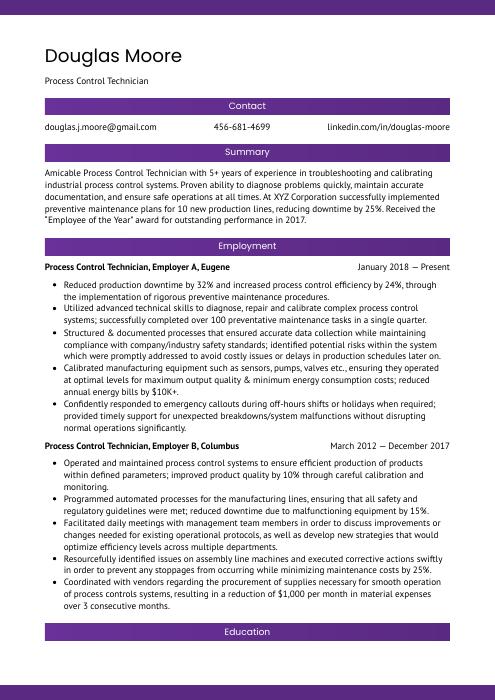

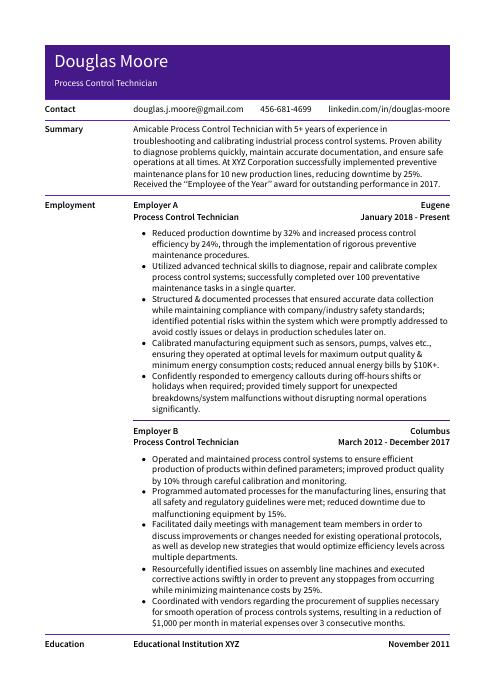

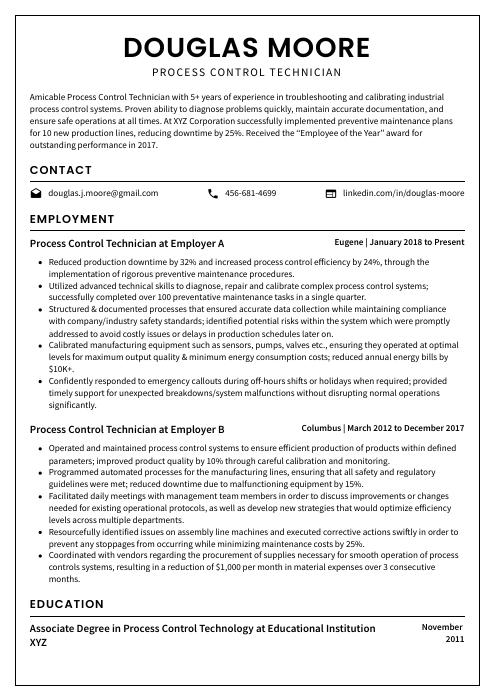

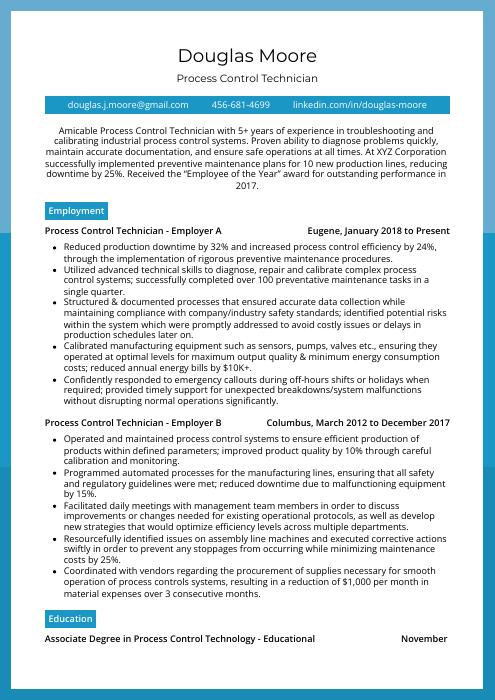

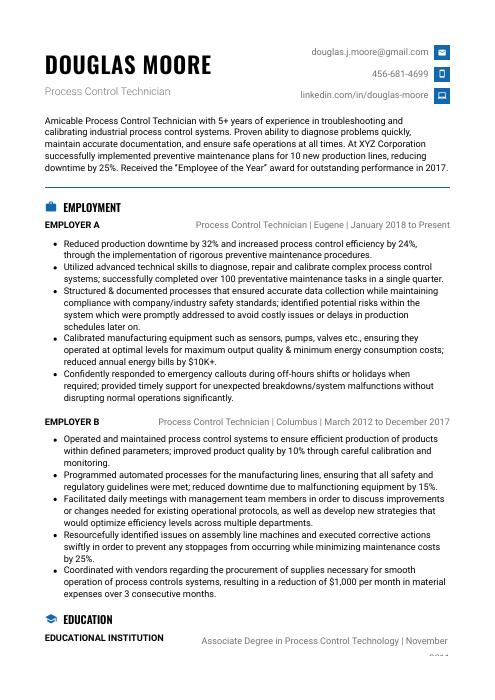

Process Control Technician Resume Sample

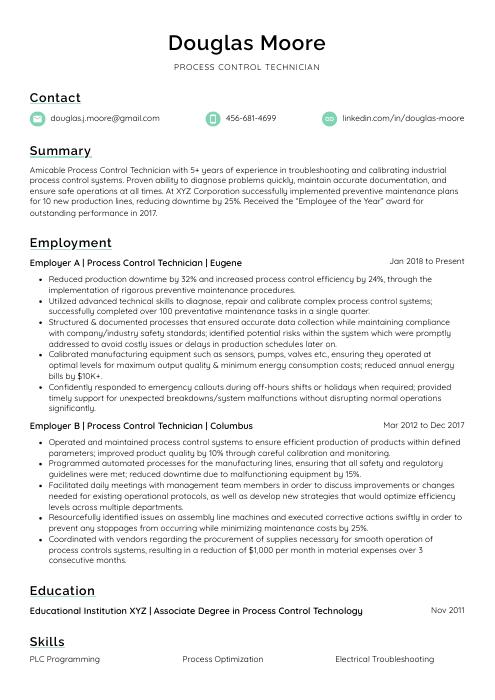

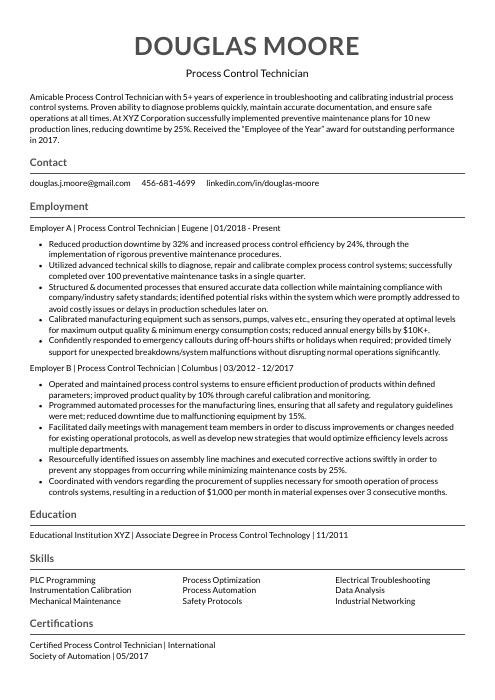

Douglas Moore

Process Control Technician

[email protected]

456-681-4699

linkedin.com/in/douglas-moore

Summary

Amicable Process Control Technician with 5+ years of experience in troubleshooting and calibrating industrial process control systems. Proven ability to diagnose problems quickly, maintain accurate documentation, and ensure safe operations at all times. At XYZ Corporation successfully implemented preventive maintenance plans for 10 new production lines, reducing downtime by 25%. Received the “Employee of the Year” award for outstanding performance in 2017.

Experience

Process Control Technician, Employer A

Eugene, Jan 2018 – Present

- Reduced production downtime by 32% and increased process control efficiency by 24%, through the implementation of rigorous preventive maintenance procedures.

- Utilized advanced technical skills to diagnose, repair and calibrate complex process control systems; successfully completed over 100 preventative maintenance tasks in a single quarter.

- Structured & documented processes that ensured accurate data collection while maintaining compliance with company/industry safety standards; identified potential risks within the system which were promptly addressed to avoid costly issues or delays in production schedules later on.

- Calibrated manufacturing equipment such as sensors, pumps, valves etc., ensuring they operated at optimal levels for maximum output quality & minimum energy consumption costs; reduced annual energy bills by $10K+.

- Confidently responded to emergency callouts during off-hours shifts or holidays when required; provided timely support for unexpected breakdowns/system malfunctions without disrupting normal operations significantly.

Process Control Technician, Employer B

Columbus, Mar 2012 – Dec 2017

- Operated and maintained process control systems to ensure efficient production of products within defined parameters; improved product quality by 10% through careful calibration and monitoring.

- Programmed automated processes for the manufacturing lines, ensuring that all safety and regulatory guidelines were met; reduced downtime due to malfunctioning equipment by 15%.

- Facilitated daily meetings with management team members in order to discuss improvements or changes needed for existing operational protocols, as well as develop new strategies that would optimize efficiency levels across multiple departments.

- Resourcefully identified issues on assembly line machines and executed corrective actions swiftly in order to prevent any stoppages from occurring while minimizing maintenance costs by 25%.

- Coordinated with vendors regarding the procurement of supplies necessary for smooth operation of process controls systems, resulting in a reduction of $1,000 per month in material expenses over 3 consecutive months.

Skills

- PLC Programming

- Process Optimization

- Electrical Troubleshooting

- Instrumentation Calibration

- Process Automation

- Data Analysis

- Mechanical Maintenance

- Safety Protocols

- Industrial Networking

Education

Associate Degree in Process Control Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Process Control Technician

International Society of Automation

May 2017

1. Summary / Objective

A resume summary for a process control technician should emphasize your technical skills and experience in the field. Include any certifications or qualifications you have, such as an Associate’s Degree in Process Control Technology or certification from the International Society of Automation (ISA). You can also mention specific automation systems you are familiar with, like Allen-Bradley PLCs or Siemens S7 controllers. Finally, highlight any successes that demonstrate your ability to troubleshoot complex problems and optimize production processes.

Below are some resume summary examples:

Well-rounded process control technician with 5+ years of experience in the oil and gas industry. Skilled in monitoring, troubleshooting, and calibrating equipment used to optimize plant operations while ensuring compliance with safety regulations. At XYZ Inc., improved production efficiency by 20%, saving an estimated $500K annually. Looking to join ABC Petrochemicals as a process control technician and use my skillset to maximize productivity.

Accomplished Process Control Technician with 10+ years of experience designing, developing and implementing process control systems. Expertise in troubleshooting complex automation problems to ensure optimal productivity and safety standards are met. Proven ability to reduce downtime by 30% while increasing production throughput rates by 17%. Seeking a Process Control Technician role at ABC Corp to further develop my problem-solving skills.

Seasoned process control technician with 5+ years of experience in the operation, maintenance and calibration of instrumentation systems. Proven success in automation process monitoring to ensure optimum efficiency. Demonstrated expertise in troubleshooting issues, repairing malfunctioning equipment and maintaining a safe work environment. Seeking an opportunity at ABC Corporation to utilize my skillset for driving operational excellence.

Passionate process control technician with 6+ years of experience in the manufacturing industry. Skilled in automation, troubleshooting, and process optimization. At XYZ Inc., managed a team of 10 technicians responsible for improving production efficiency by 30%. Received company recognition award for implementing an automated system to track equipment maintenance schedules that resulted in cost savings of $50K per month.

Dependable process control technician with 5+ years of experience in process automation and instrumentation. At XYZ, managed installation, maintenance, calibration and troubleshooting for 20 automated processes. Assisted plant engineers to optimize the performance of various systems by designing efficient process controls. Received an award for developing a cost-effective solution that improved efficiency by 25%.

Hard-working process control technician with 7+ years of experience in the manufacturing industry. Seeking to use my expertise in automation and process optimization to help ABC Company achieve its production goals. At XYZ Inc, designed a network infrastructure that allowed for remote monitoring and increased efficiency by 20%. Instrumental in streamlining quality assurance processes which saved $45K yearly.

Enthusiastic process control technician with 5+ years of experience in troubleshooting, repairing, and maintaining process control systems. At XYZ Corporation successfully implemented a new automated system to reduce manual labor by 40%, resulting in an estimated cost savings of $250K for the company. Also provided technical support on-site and remotely for clients across multiple industries.

Talented process control technician with 5+ years of experience in industrial settings. Experienced in managing complex process operations, troubleshooting and repairing automated systems, as well as monitoring production data. Looking to join ABC Technologies to leverage expertise in controlling processes for a top-tier clientele while continuing professional development and growth.

2. Experience / Employment

The employment (or experience) section is where you provide details on your work history. It should be written in reverse chronological order, meaning the most recent role is listed first.

Stick to bullet points when writing this section; doing so makes it easier for readers to quickly understand what you have done and achieved. When describing each job, try to include quantifiable results that demonstrate the impact of your work.

For example, instead of saying “Maintained process control systems,” you could say, “Monitored and adjusted process control systems daily according to safety standards and operational requirements resulting in a 10% reduction in downtime.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Monitored

- Operated

- Adjusted

- Troubleshot

- Inspected

- Calibrated

- Programmed

- Tested

- Analyzed

- Recorded

- Resolved

- Implemented

- Automated

- Optimized

- Documented

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Efficiently monitored process control systems in a manufacturing plant, ensuring that production ran as planned and met safety requirements; decreased downtime by 10%.

- Assessed operational data and identified any discrepancies or issues with the equipment, making necessary adjustments to achieve optimal performance levels while adhering to company standards.

- Adjusted controller parameters such as pressure, temperature & flow rate based on pre-determined settings and customer specifications; improved product quality by 15% over 6 months of consistent monitoring.

- Tested new process control devices for accuracy using various methods including manual inspection, computer simulations & virtual models; reduced testing time per device by 30 minutes compared to previous procedures used in the facility priorly.

- Developed SOPs (Standard Operating Procedures) for system maintenance activities related to process controls which were implemented across all departments within six weeks after being approved.

- Developed and implemented process control systems that reduced energy consumption by 10% and improved overall operational efficiency.

- Inspected various production lines for any irregularities and identified potential risk factors; reported discrepancies to management team in a timely manner and proactively suggested solutions.

- Consistently monitored system performance, analyzed test data and adjusted processes as required to ensure optimal machinery operation with minimal downtime or interruption of services.

- Compiled detailed daily reports on all equipment maintenance activities including calibration results, operating conditions, safety evaluations and troubleshooting efforts to inform senior executives on the status of operations.

- Advised engineering teams on best practices related to quality assurance standards while performing routine audits of system components to guarantee adherence with pre-defined protocols & regulations at all times.

- Introduced process controls and automation systems to a manufacturing facility, achieving an 11% increase in production efficiency.

- Diligently monitored process control equipment performance metrics for accuracy; identified and addressed any discrepancies with minimal disruption of operations.

- Automated manual processes using cutting-edge software solutions, resulting in improved workflow productivity by 25%.

- Implemented quality protocols across all departments, significantly reducing product defects from 3% to 1%.

- Streamlined documentation management system according to ISO standards; reduced document indexing time by 150 hours within first 90 days on the job.

- Spearheaded the calibration, installation and maintenance of over 50 process control instruments to ensure the efficient operation of various production systems; reduced downtime hours by 15%.

- Documented all instrument readings in a timely manner for traceability and accuracy purposes; achieved an average accuracy rate of 98%.

- Optimized existing processes through continuous improvement initiatives that resulted in cost savings up to $15,000 per month.

- Substantially improved operational efficiency by identifying potential problems before they occurred and making necessary adjustments or repairs accordingly; decreased equipment failure incidents by 25%.

- Troubleshot technical issues with sophisticated automation systems using advanced diagnostic tools such as PLCs (programmable logic controllers) & SCADA (supervisory control and data acquisition).

- Resolved over 50 process control issues in the last 6 months, resulting in a 10% increase in production efficiency.

- Reorganized and updated all technical documentation related to plant processes and operations; reduced errors by 15%.

- Presented monthly reports on equipment performance to senior management, highlighting key areas for improvement and cost savings opportunities of up to $5,000 per month.

- Prepared detailed daily logs of activities performed across shift changes which resulted in improved maintenance scheduling accuracy of 85%.

- Meticulously monitored instrumentation systems using computer-aided engineering software programs; optimized system output with minimal downtime over 3 shifts each week (averaging 24 hours).

- Improved process control system accuracy by 20%, leading to improved product quality and increased efficiency.

- Effectively monitored and adjusted process parameters across 4 production lines, ensuring optimal performance at all times.

- Mentored 5 junior technicians in the proper use of process control software and troubleshooting techniques, resulting in a 50% decrease in downtime on average per line.

- Formulated detailed technical reports for management based on data collected from automated systems; tracked up to 10 different variables for each report with 100% accuracy rate over 6 months time frame.

- Recorded real-time operational data into digital logs such as temperatures, pressures & flow rates; identified issues before they impacted operations or caused delays/shortages – averting $30k in losses annually due to error correction costs & lost productivity hours.

- Competently maintained and operated process control systems, including PLCs (Programmable Logic Controllers), SCADA Systems, Automated Inspection Machines and other industrial automation equipment; reduced downtime by 10% over a six-month period.

- Revised existing procedures for controlling production processes to ensure maximum efficiency in accordance with industry standards; improved process throughput time by 15%.

- Analyzed operational data from various instruments such as pressure gauges, thermometers and flow meters to detect performance issues before they became critical problems; decreased system errors by 25%.

- Expedited the repair of malfunctioning components on machines or instrumentation via troubleshooting techniques such as root cause analysis; saved $1,000 in parts costs due to effective maintenance practices last quarter.

- Achieved zero safety incidents while maintaining strict adherence to workplace health & safety policies at all times during shift operations; increased employee morale within the team significantly over 6 months’ duration.

- Represented the facility in an international conference, successfully demonstrating the company’s advanced process control technologies and increasing awareness of the brand by 25%.

- Demonstrated expertise in setting up automated monitoring systems for a variety of processes; reduced production downtime and wastage by 20% while ensuring compliance with safety regulations.

- Successfully implemented changes to process control procedures that improved efficiency and accuracy across multiple operations, resulting in an increase of $5,000 per month on average.

- Participated in projects to develop new automation tools for factory machines, reducing manual labor costs by 10 hours every week and enabling faster completion times for large orders.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require the candidate to be proficient with Siemens PLCs, while Organization XYZ may prefer someone who is familiar with Rockwell Automation.

It is important to tailor the skills section of your resume for each job you are applying for because many employers use applicant tracking systems these days – computer programs that scan resumes for certain keywords before passing them on to a human.

Once listed here, it’s also beneficial to discuss some of your most pertinent qualifications in other areas such as the summary or experience section.

Below is a list of common skills & terms:

- Data Analysis

- Electrical Troubleshooting

- Industrial Networking

- Instrumentation Calibration

- Mechanical Maintenance

- PLC Programming

- Process Automation

- Process Optimization

- Robotics Programming

- Safety Protocols

4. Education

Mentioning your education on your resume will depend on how far along you are in your career. If you just graduated and have no prior work experience, include an education section below your resume objective. However, if you have significant professional experience to showcase, omitting the education section is perfectly fine.

If including an education section is necessary, try to mention courses and subjects related to process control technician roles that demonstrate technical skills or knowledge relevant for the position.

Associate Degree in Process Control Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and proficiency in a certain field. They are especially useful if the job you are applying for requires specific certifications or qualifications.

Including any relevant certifications on your resume will help to show potential employers that you have taken the time and effort to stay up-to-date with industry standards, as well as having been tested by an accredited organization.

Certified Process Control Technician

International Society of Automation

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Douglas Moore, this would be Douglas-Moore-resume.pdf or Douglas-Moore-resume.docx.

7. Cover Letter

A cover letter is a unique way to introduce yourself to prospective employers and make it easier for them to get an idea of who you are. It is typically made up of 2-4 paragraphs that explain why you’re the perfect fit for the role and provide additional information about your background, skills, and experience.

Cover letters aren’t always necessary when applying for jobs but they can be very beneficial in helping you stand out from other applicants. They allow hiring managers to gain more insight into who you are as a professional beyond what’s on your resume, giving them better context about why they should consider you for the job.

Below is an example cover letter:

Dear Shakira,

I am writing to apply for the position of Process Control Technician at ABC Corporation. I am a highly skilled and experienced process control technician with over 10 years of experience in the field. I have a strong knowledge of process control systems and instrumentation, and I am capable of troubleshooting and repairing process control equipment.

I have experience working in both manufacturing and processing plants, and I have gained valuable experience in a variety of industries including food & beverage, pharmaceuticals, chemicals, oil & gas, and power generation. In my previous role as a Process Control Technician at XYZ Corporation, I was responsible for maintaining and repairing process control equipment such as controllers, sensors, valves, pumps, motors, etc. I also provided support to the production team by ensuring that the process control system is operating correctly and efficiently.

I am a motivated individual who is always looking for new challenges. I am confident that I can make a positive contribution to your organization if given the opportunity. Please find attached my resume for your review. If you have any questions or would like to discuss my qualifications further, please do not hesitate to contact me at [phone number] or [email address]. Thank you for your time and consideration; I look forward to hearing from you soon!

Sincerely,

Douglas

Process Control Technician Resume Templates

Bonobo

Bonobo Hoopoe

Hoopoe Markhor

Markhor Ocelot

Ocelot Saola

Saola Dugong

Dugong Quokka

Quokka Kinkajou

Kinkajou Jerboa

Jerboa Pika

Pika Gharial

Gharial Axolotl

Axolotl Lorikeet

Lorikeet Indri

Indri Numbat

Numbat Fossa

Fossa Cormorant

Cormorant Rhea

Rhea Echidna

Echidna Rezjumei

Rezjumei