Pipeline Technician Resume Guide

Pipeline technicians inspect, maintain and repair pipelines used to transport oil and gas. They ensure that the pipes are safe by regularly checking for corrosion or damage, testing pressure levels and recording data on their findings. Additionally, they may be responsible for installing new pipes as well as responding to any emergency situations related to pipelines.

Your experience and knowledge of pipeline systems makes you an ideal candidate for any employer. To make sure they take notice of your expertise, it’s important to create a resume that stands out from the competition.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

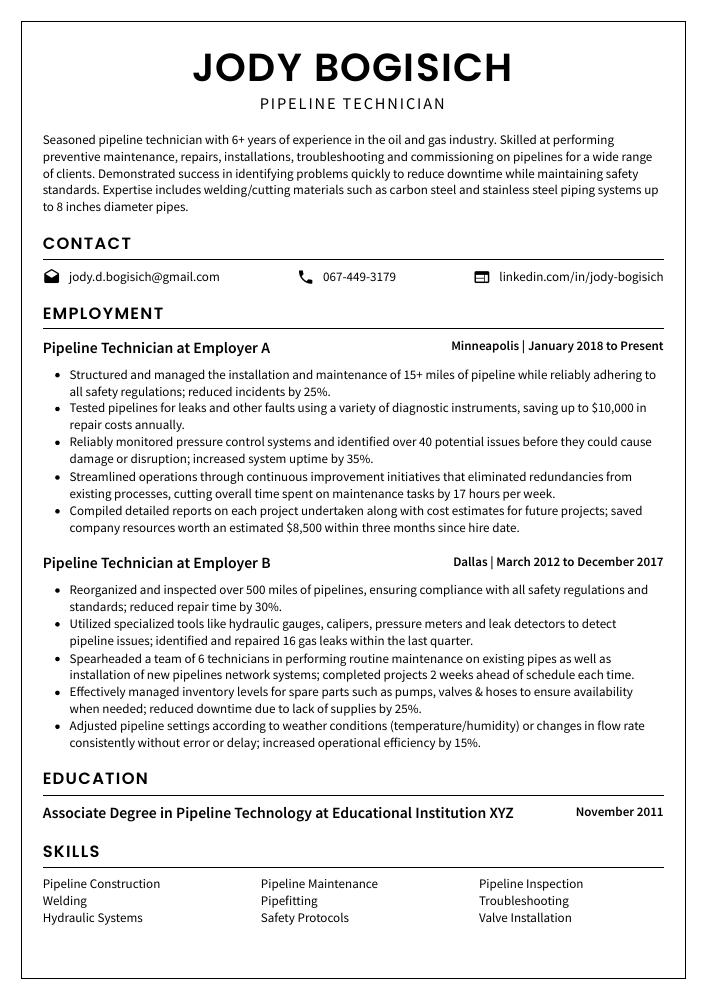

Pipeline Technician Resume Sample

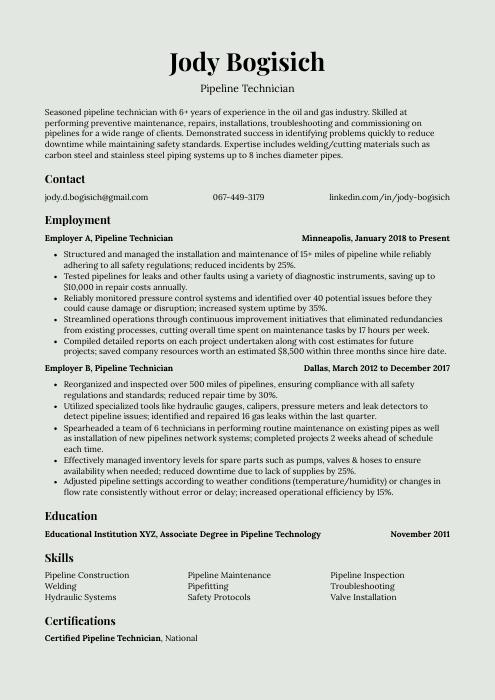

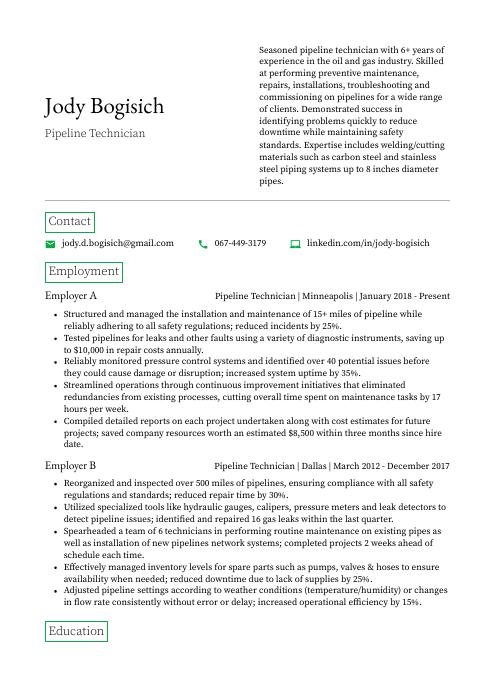

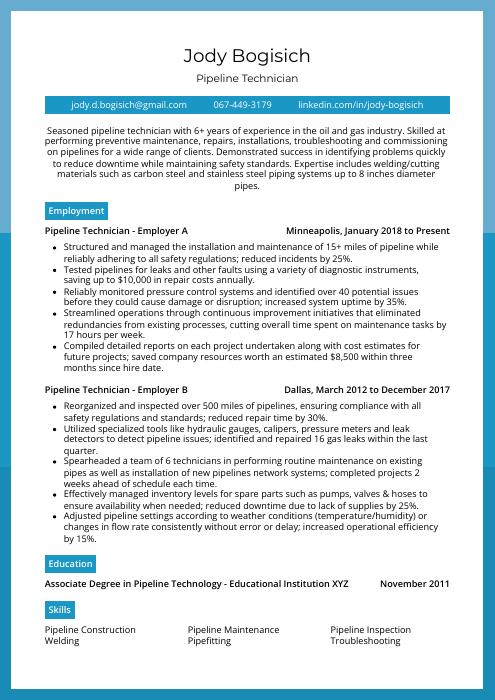

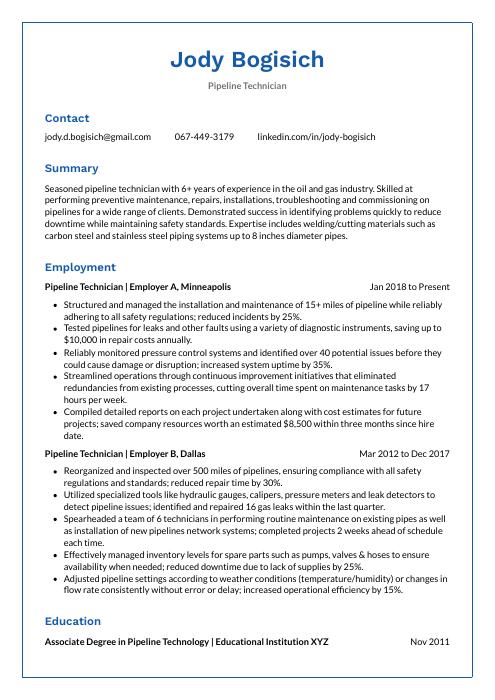

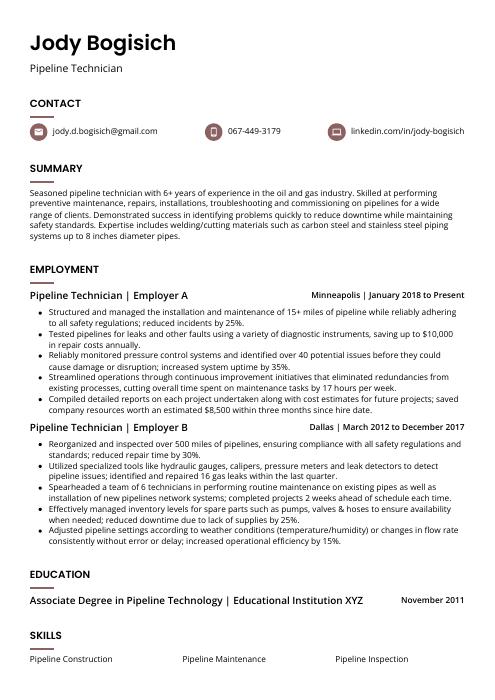

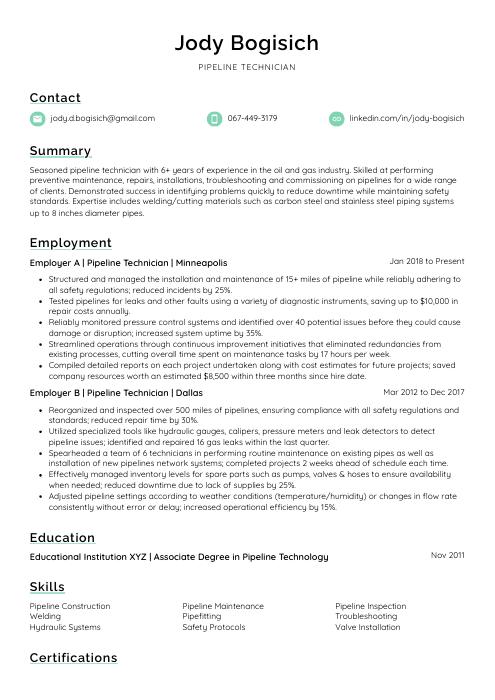

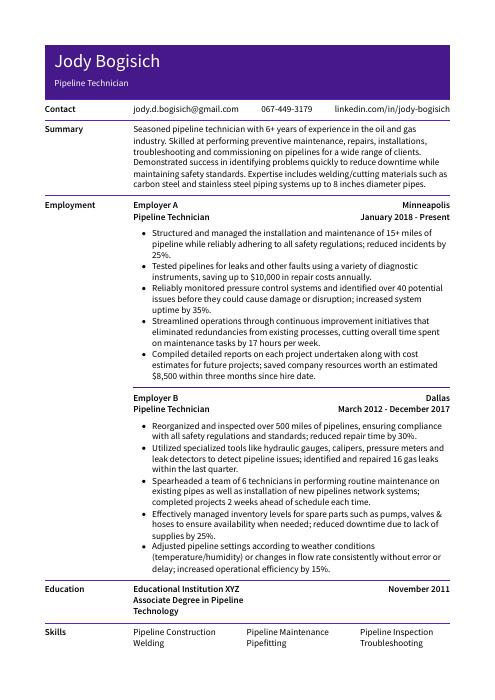

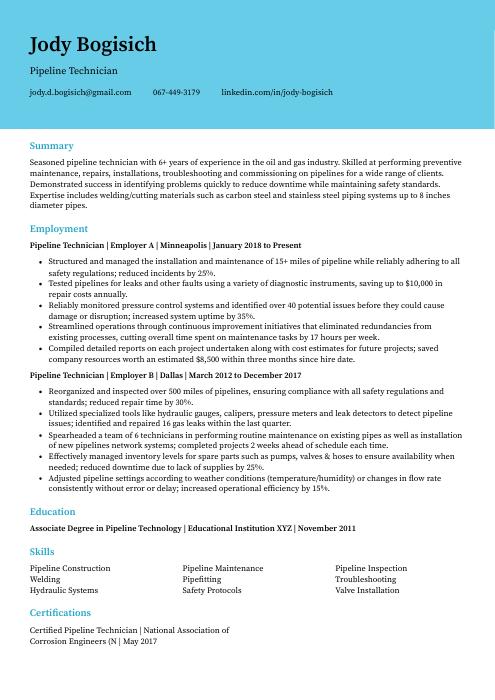

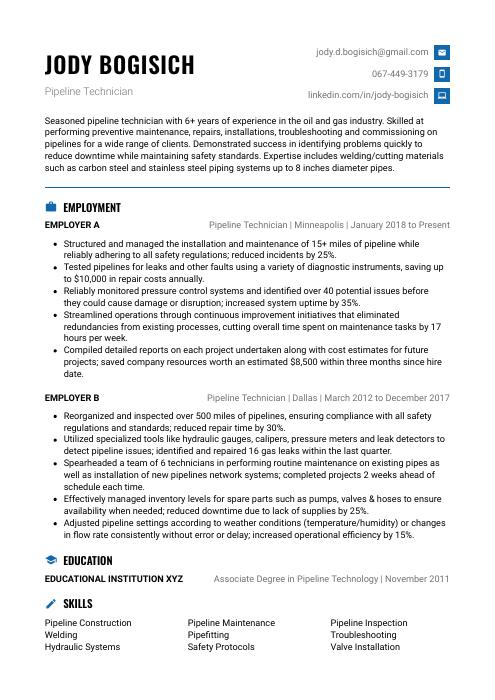

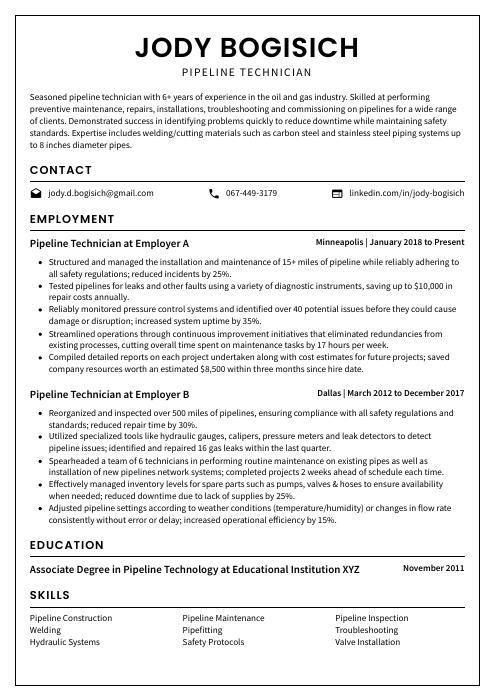

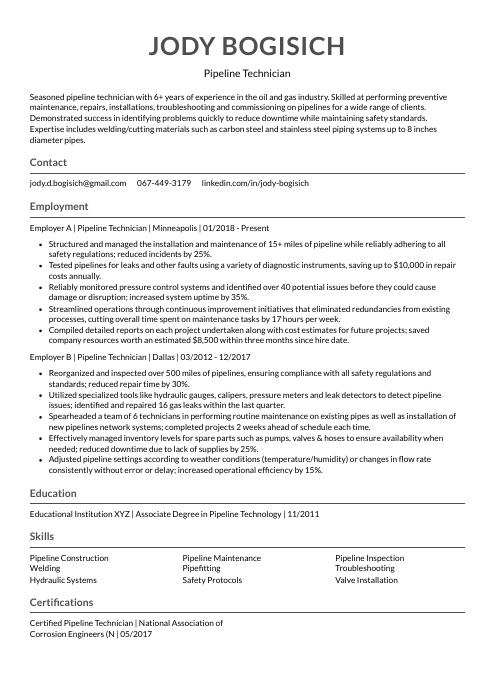

Jody Bogisich

Pipeline Technician

[email protected]

067-449-3179

linkedin.com/in/jody-bogisich

Summary

Seasoned pipeline technician with 6+ years of experience in the oil and gas industry. Skilled at performing preventive maintenance, repairs, installations, troubleshooting and commissioning on pipelines for a wide range of clients. Demonstrated success in identifying problems quickly to reduce downtime while maintaining safety standards. Expertise includes welding/cutting materials such as carbon steel and stainless steel piping systems up to 8 inches diameter pipes.

Experience

Pipeline Technician, Employer A

Minneapolis, Jan 2018 – Present

- Structured and managed the installation and maintenance of 15+ miles of pipeline while reliably adhering to all safety regulations; reduced incidents by 25%.

- Tested pipelines for leaks and other faults using a variety of diagnostic instruments, saving up to $10,000 in repair costs annually.

- Reliably monitored pressure control systems and identified over 40 potential issues before they could cause damage or disruption; increased system uptime by 35%.

- Streamlined operations through continuous improvement initiatives that eliminated redundancies from existing processes, cutting overall time spent on maintenance tasks by 17 hours per week.

- Compiled detailed reports on each project undertaken along with cost estimates for future projects; saved company resources worth an estimated $8,500 within three months since hire date.

Pipeline Technician, Employer B

Dallas, Mar 2012 – Dec 2017

- Reorganized and inspected over 500 miles of pipelines, ensuring compliance with all safety regulations and standards; reduced repair time by 30%.

- Utilized specialized tools like hydraulic gauges, calipers, pressure meters and leak detectors to detect pipeline issues; identified and repaired 16 gas leaks within the last quarter.

- Spearheaded a team of 6 technicians in performing routine maintenance on existing pipes as well as installation of new pipelines network systems; completed projects 2 weeks ahead of schedule each time.

- Effectively managed inventory levels for spare parts such as pumps, valves & hoses to ensure availability when needed; reduced downtime due to lack of supplies by 25%.

- Adjusted pipeline settings according to weather conditions (temperature/humidity) or changes in flow rate consistently without error or delay; increased operational efficiency by 15%.

Skills

- Pipeline Construction

- Pipeline Maintenance

- Pipeline Inspection

- Welding

- Pipefitting

- Troubleshooting

- Hydraulic Systems

- Safety Protocols

- Valve Installation

Education

Associate Degree in Pipeline Technology

Educational Institution XYZ

Nov 2011

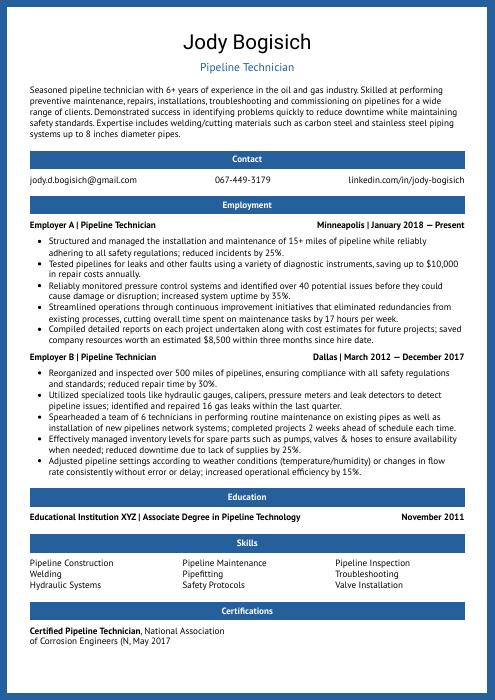

Certifications

Certified Pipeline Technician

National Association of Corrosion Engineers (N

May 2017

1. Summary / Objective

A resume summary for a pipeline technician should provide the hiring manager with an overview of your qualifications and experience. In this section, you can highlight key skills such as knowledge of industry safety standards, expertise in welding and fabrication techniques, familiarity with computer-aided design (CAD) software, and ability to troubleshoot complex mechanical problems. You could also mention any relevant certifications or awards that demonstrate your commitment to excellence in the field.

Below are some resume summary examples:

Driven and safety-minded pipeline technician with 5+ years of experience in the natural gas industry. At XYZ, responsible for monitoring and maintenance activities on a large network of pipelines spread across 8 states. Proven track record of delivering high work quality while meeting tight deadlines through efficient project management skills. Received awards from clients due to effective problem-solving and attention to detail throughout projects.

Professional pipeline technician with 5+ years of experience in oil and gas pipelines. Experienced in inspecting, maintaining, repairing and installing pipeline systems for both onshore and offshore operations. Skilled at using various tools such as leak detectors, pipe cutters/threaders/benders to ensure safety standards are met. Proven ability to quickly identify problems and provide solutions that maximize productivity while minimizing costs.

Amicable and reliable pipeline technician with 8+ years of experience in the oil and gas industry. Expertise in welding, pipefitting, and construction codes to efficiently repair leaking pipelines for a wide range of clients. Proven track record of completing projects on-time by quickly identifying issues and providing cost-effective solutions. Ready to join ABC Corp as an experienced Pipeline Technician to ensure safe operation at all times.

Talented pipeline technician with over 10 years of hands-on experience in pipeline operations and maintenance. Skilled in performing pipeline inspections, repairs, and installations to ensure safe operation of pipelines. At XYZ Energy Company, supervised the installation of new pipelines spanning 15 miles across five states. Awarded for outstanding performance during an emergency repair project that saved $2 million dollars for the company.

Accomplished pipeline technician with 8+ years of experience inspecting, maintaining, and repairing pipelines for oil and gas companies. As a lead at XYZ Oil & Gas, identified issues in pipeline systems that led to improved safety standards across the entire network. Seeking to join ABC Energy Solutions as a senior pipeline technician where I will utilize my expertise in industry best practices while working on challenging projects.

Enthusiastic pipeline technician with 5+ years of experience in oil and gas field operations. Skilled in troubleshooting, maintenance, repair, inspection and installation of pipelines. Proven success ensuring safety protocols are met while meeting production goals. Looking to join ABC Oil & Gas as a pipeline technician to contribute expertise towards improving operational efficiency and quality assurance standards.

Well-rounded pipeline technician with 5+ years of experience in oil and gas pipeline operations. Proven track record for performing inspections, maintenance, testing and repairs to ensure safe operation and compliance with applicable regulations. Seeking a position at ABC Oil & Gas where I can utilize my skillset to improve the efficiency of their pipelines while ensuring safety standards are met.

Determined pipeline technician with 5+ years of oil and gas industry experience. Proven success in development, maintenance, repair, and inspection of pipeline systems to ensure safe operation. Seeking to leverage hands-on knowledge and expertise at ABC Energy Solutions for optimal efficiency and cost savings. At XYZ Corporation reduced unscheduled downtime by 20% through proactive inspections.

2. Experience / Employment

The work history/experience section is where you provide details on your employment history. This is best written in reverse chronological order, meaning the most recent job should be listed first.

When writing this section, use bullet points to make it easier for the reader to digest what you have said quickly and easily. When making each point, focus on providing detail about what tasks were completed and any results that were achieved as a result of your work.

For example, instead of saying “Installed pipeline equipment,” you could say “Successfully installed 10+ miles of natural gas pipelines per month with no safety incidents or environmental damage.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Inspected

- Monitored

- Operated

- Troubleshot

- Assembled

- Calibrated

- Welded

- Connected

- Measured

- Adjusted

- Fabricated

- Repaired

- Tested

- Commissioned

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Formulated plans for pipeline maintenance operations, ensuring that all activities were conducted in compliance with relevant safety regulations and industry standards; reduced incidents of equipment downtime by 16%.

- Thoroughly inspected pipelines and related components to accurately identify potential issues or areas of improvement before they developed into major problems; decreased repair costs by $1,500 over the last quarter.

- Measured pressure levels at various points along the pipeline using specialized instruments such as manometers and flowmeters; monitored parameters on a regular basis to ensure optimal performance of the system.

- Connected sections of new pipe installations according to blueprints & schematics, performing welding processes when necessary for an airtight seal between joints; completed 5+ large-scale projects within tight deadlines without compromising quality control standards set out by management team members.

- Introduced preventive maintenance measures aimed at reducing wear & tear on pipelines arising from age and/or damage due to external factors like weather conditions; increased operational life expectancy of several pipes by 10 years+.

- Welded together 2,500+ feet of pipelines and valves to connect oil & gas wellheads with processing plants utilizing TIG welding techniques; completed projects ahead of schedule by 20%.

- Demonstrated expertise in using complex tools such as hydro-jets, excavators, compressors and pumps while troubleshooting pipeline systems for optimal performance.

- Resourcefully replaced malfunctioning components on 200+ miles of pipelines while adhering to safety protocols and industry standards; decreased downtime incidents by 12%.

- Participated in a team effort that restored production capacity on 3 major offshore rigs within 6 hours after an unexpected shutdown due to technical issues.

- Troubleshot over 50 cases related to damaged or corroded pipes each quarter; identified the root cause quickly leading to 15% less maintenance costs compared with previous quarters.

- Installed and repaired over 800 gas and oil pipelines in various locations, ensuring that each system was properly tested for safety before returning to service.

- Presented technical reports detailing pipeline operations and maintenance tasks to supervisors on a monthly basis; reduced repairs necessary by 15% year-on-year due to more effective preventive measures.

- Accurately identified equipment malfunctions through rigorous troubleshooting processes and promptly resolved them within the allocated time frame of two hours or less per incident.

- Operated specialized tools such as welding machines, pressure gauges, pipe cutters etc., while following all safety protocols during every step of installation process; completed projects ahead of schedule with zero incidents reported so far this fiscal year.

- Reduced total operational costs by 12%, thanks to successful implementation of cost containment strategies like smart inventory management & energy conservation initiatives at the work sites.

- Actively monitored and maintained over 500 miles of pipeline network, troubleshooting any issues to ensure optimal performance; reduced downtime by 25%.

- Represented the company in regional meetings with local entities regarding right-of-way concerns, environmental regulations and other related matters.

- Improved safety protocols while performing routine maintenance activities on pipelines, valves, regulators and pressure control equipment; minimized risks associated with hazardous materials handling by 15%.

- Advised the team on best practices for preventative maintenance tasks such as cleaning welds & fittings, replacing gaskets or adjusting pump settings based on experience gained from 250+ service calls each year.

- Inspected all new construction projects to ensure compliance with regulatory requirements before commissioning a facility or beginning operations; completed up to 10 inspections per week within an average time frame of 4 hours/inspection rotation cycle.

- Achieved 94% pipeline system efficiency by monitoring pressure, flow rates and levels of oil, gas and other petroleum products.

- Assessed pipelines for potential malfunctions or leaks while performing regular maintenance; identified over 20 issues in the last 6 months before they could become a problem.

- Mentored junior technicians on safe handling procedures, equipment operation techniques and troubleshooting processes to ensure their readiness in responding to emergency situations quickly and effectively.

- Monitored up to 8 pipeline systems simultaneously at various locations using advanced diagnostic tools; reduced downtime due to technical faults by 15%.

- Proficiently prepared detailed inspection reports with diagrams including recommendations for repair or replacement components as needed; saved $1,400 in preventative repairs costs per quarter through early detection of potential problems.

- Competently inspected pipelines and other related infrastructure to ensure compliance with safety regulations, resulting in fewer incidents of leakage or damage.

- Optimized existing pipeline systems by identifying weak links and recommending appropriate solutions; successfully lowered the risk of disruption by 10%.

- Assembled valves, pumps, flanges and other components for new pipeline installations; completed projects ahead of schedule within budget constraints on 15 occasions.

- Prepared reports detailing considerations such as pressure levels, flow rates & distances between connection points following every inspection visit; compiled findings into a comprehensive summary that was shared with management weekly.

- Revised maintenance procedures based on changes in technology to maximize efficiency when performing repairs or upgrades at site locations; reduced downtime for repair activities by 20 hours per month across all sites visited annually.

- Calibrated and tested pipeline systems and equipment, maintaining up-to-date records on all maintenance activities to ensure maximum operational efficiency; successfully reduced downtime by 50%.

- Coordinated with other departments to expedite the installation of new pipelines, significantly increasing throughput and reducing costs by $4,000 over a 4 month period.

- Expedited emergency repairs on damaged pipes in high risk areas using specialized tools and techniques; completed tasks within 2 hours or less while ensuring compliance with safety regulations at all times.

- Successfully identified root causes of malfunctioning valves, pumps & compressors through detailed system analysis and implemented corrective measures that improved overall performance by 20%.

- Repaired underground gas lines following stringent environmental standards after natural disasters such as floods or earthquakes without any incidents reported due to negligence or mishandling of materials/equipment used for repair work.

- Fabricated and installed over 1,500 feet of pipeline with a team of 8 technicians in 6 months; completed project ahead of schedule and under budget.

- Consistently operated heavy machinery such as backhoes, excavators and trenchers to dig trenches for new pipelines while adhering to safety guidelines at all times.

- Commissioned 2 miles of gas pipe per day on average using the latest tools such as welding machines and pressure testing equipment; followed best practices when connecting pipes from one point to another in order to prevent leaks or contamination issues.

- Developed an efficient system for tracking inventory levels across multiple job sites which enabled accurate stock management that led to cost savings up $6K annually in supply costs due improved accuracy & visibility into materials usage trends.

- Facilitated regular maintenance activities by cleaning out blockages within lines, repairing broken valves/fittings and replacing worn-out components; increased uptime by 10% through proactive preventive measures taken before major breakdowns occurred.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in pipeline integrity and another for someone with knowledge of corrosion control.

It is therefore important to tailor the skills section of your resume according to each job you are applying for. This will ensure that employers using applicant tracking systems (which scan resumes for certain keywords) find yours relevant, thus increasing its chances of reaching a human recruiter’s desk.

In addition, it would be beneficial to provide more detail on some of your most pertinent skills by discussing them further in other sections such as summary or experience.

Below is a list of common skills & terms:

- Hydraulic Systems

- Pipefitting

- Pipeline Construction

- Pipeline Inspection

- Pipeline Maintenance

- Pressure Testing

- Safety Protocols

- Troubleshooting

- Valve Installation

- Welding

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, it’s important to mention your education below the resume objective. On the other hand, if you have significant work experience that is relevant to the pipeline technician role you are applying for, then omitting an education section may be beneficial.

If including an education section is necessary, try to focus on courses or subjects related specifically to pipelines and technology used by technicians in this field of work.

Associate Degree in Pipeline Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a certain field or skill. They can be especially beneficial when applying for jobs that require specific certifications, as they show potential employers that you have the knowledge and experience necessary to do the job well.

Include any relevant certifications on your resume so hiring managers can quickly see what qualifications you possess. This will help them determine if you are qualified for the position and give them more confidence in making their decision about whether to hire you or not.

Certified Pipeline Technician

National Association of Corrosion Engineers (N

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Jody Bogisich, this would be Jody-Bogisich-resume.pdf or Jody-Bogisich-resume.docx.

7. Cover Letter

Writing a cover letter is an important part of the job application process. It helps you to explain why you are a great fit for the role, and allows recruiters to get a better understanding of your professional background.

Cover letters should generally be between 2 – 4 paragraphs long and provide additional detail about yourself that may not already be mentioned in your resume. They also give employers more insight into who you are as a person, beyond just what’s on paper.

Below is an example cover letter:

Dear Lauretta,

I am writing in response to your ad for a Pipeline Technician. With over 5 years of experience working with pipelines, I am confident I would make a great addition to your team.

In my current role as a Pipeline Technician for ABC Corporation, I am responsible for maintaining and repairing pipelines. My duties include inspecting pipelines for leaks, testing pipeline pressure, and making repairs as needed. I have also been involved in several projects to install new pipelines. My experience has taught me how to work safely around high-pressure lines and how to troubleshoot problems quickly and efficiently.

I believe my skills and experience would be an asset to your company. I am knowledgeable about various types of pipeline systems and have the ability to work independently or as part of a team. In addition, my strong communication skills allow me to effectively communicate with other technicians, engineers, and managers.

I look forward to speaking with you about this opportunity and thank you for your time.

Sincerely,

Jody

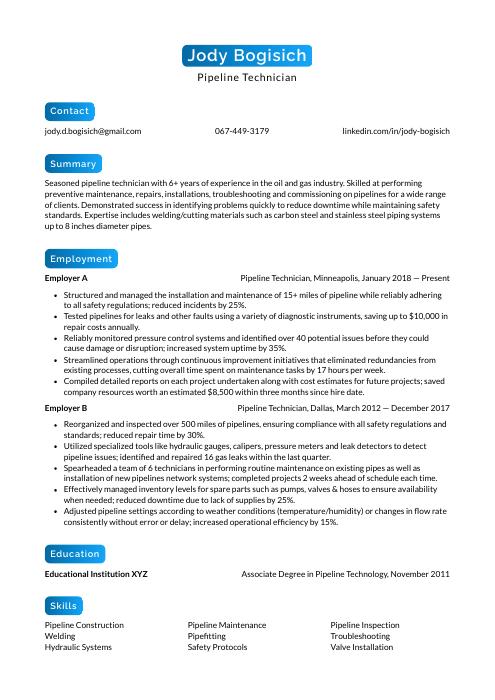

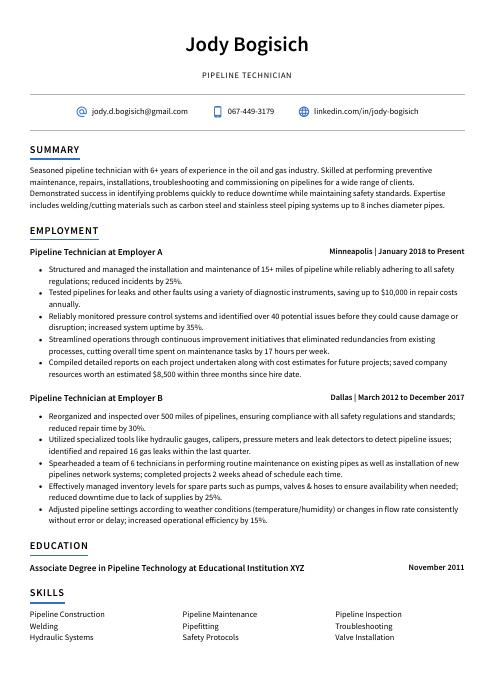

Pipeline Technician Resume Templates

Kinkajou

Kinkajou Axolotl

Axolotl Ocelot

Ocelot Hoopoe

Hoopoe Saola

Saola Quokka

Quokka Gharial

Gharial Numbat

Numbat Rhea

Rhea Markhor

Markhor Fossa

Fossa Lorikeet

Lorikeet Pika

Pika Dugong

Dugong Bonobo

Bonobo Jerboa

Jerboa Echidna

Echidna Cormorant

Cormorant Indri

Indri Rezjumei

Rezjumei