Petroleum Technician Resume Guide

Petroleum Technicians are responsible for monitoring and maintaining the production of oil or gas wells, as well as inspecting equipment to ensure it is working properly. They also analyze data from drilling operations, maintain safety protocols and repair any malfunctioning machinery.

Your experience working with oil and gas machinery is well beyond reproach. But to get the attention of potential employers, you must write a resume that highlights your technical prowess in this field.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

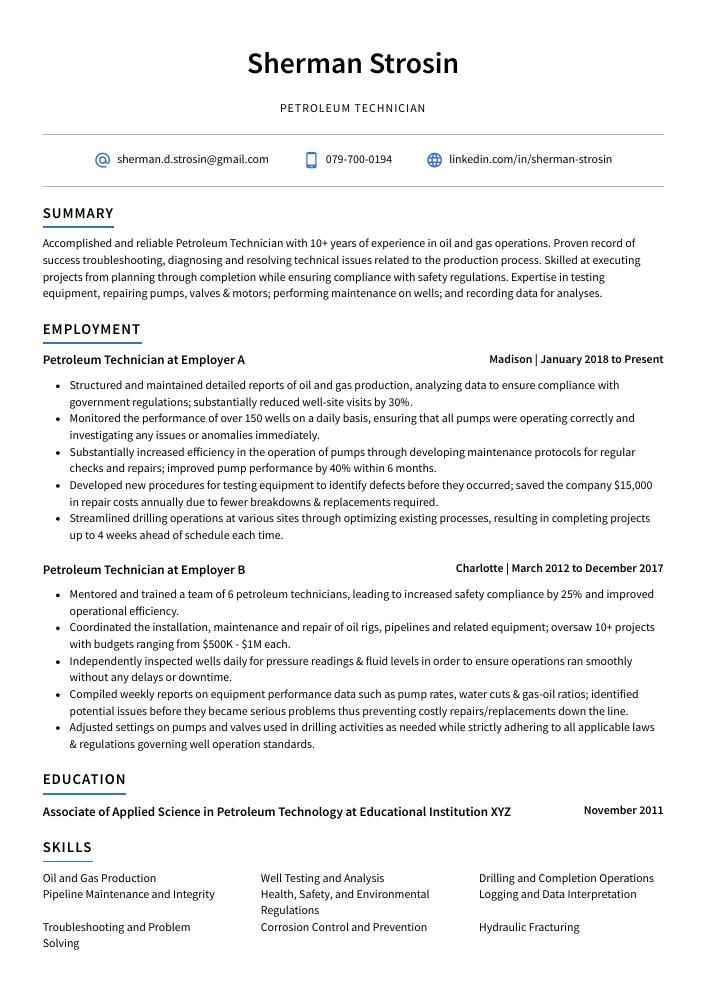

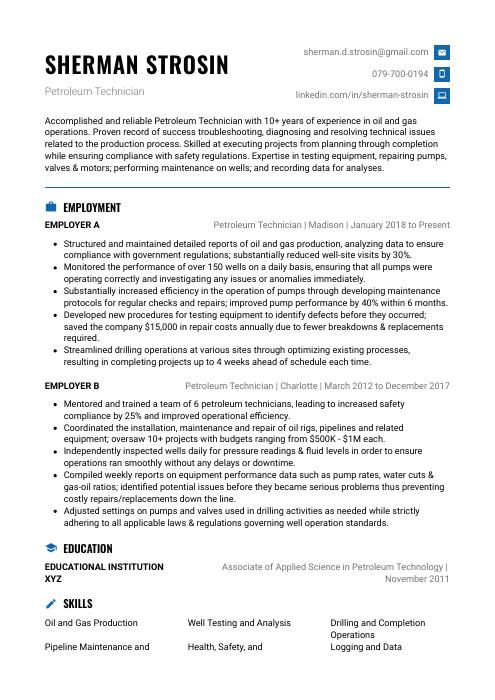

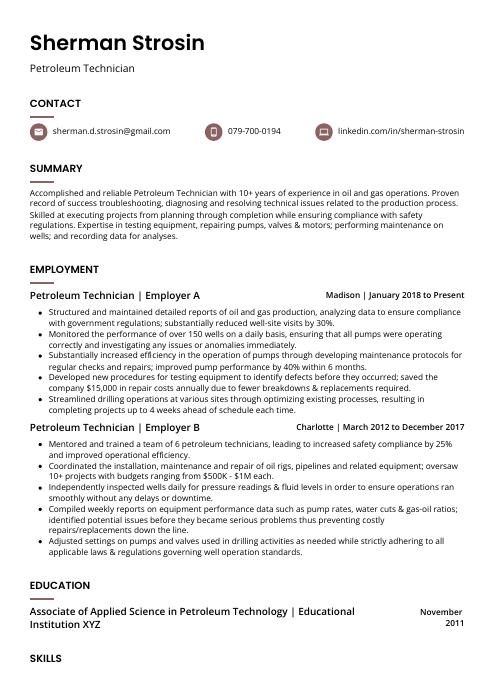

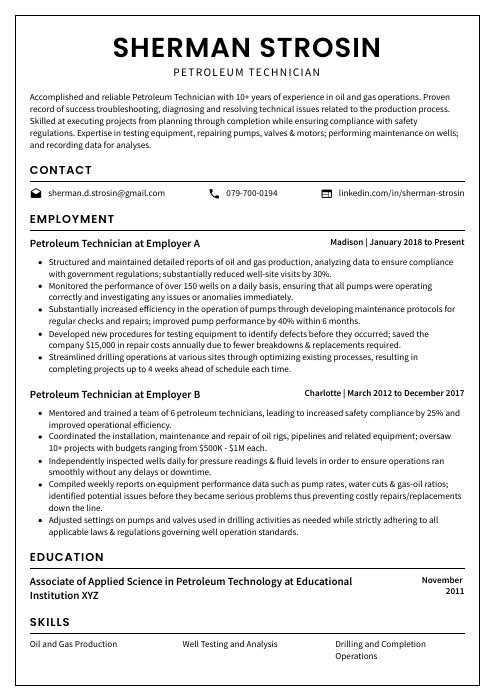

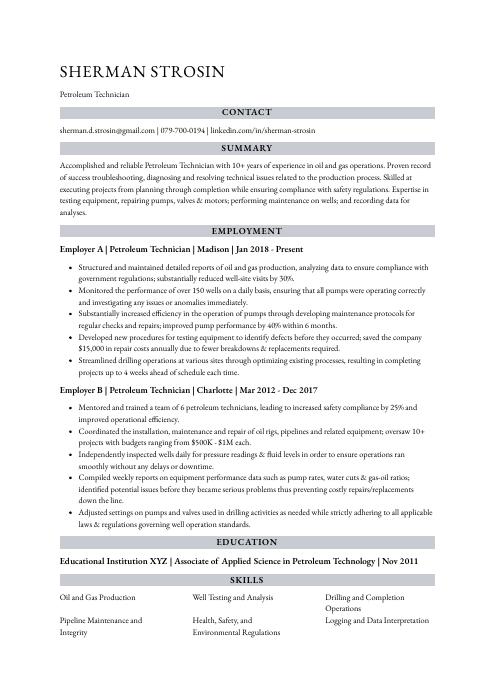

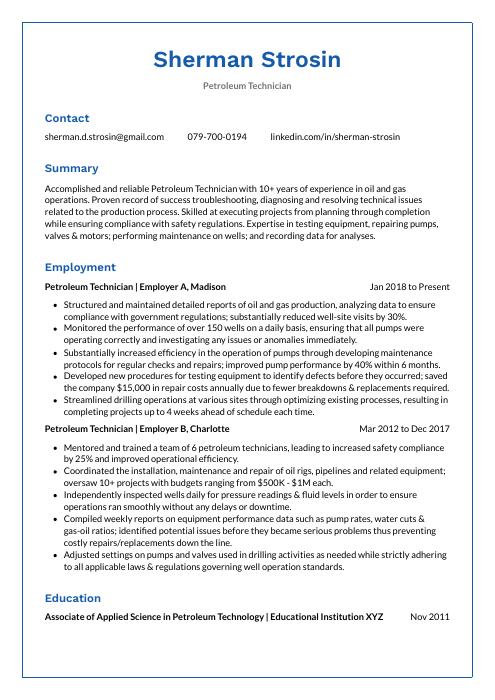

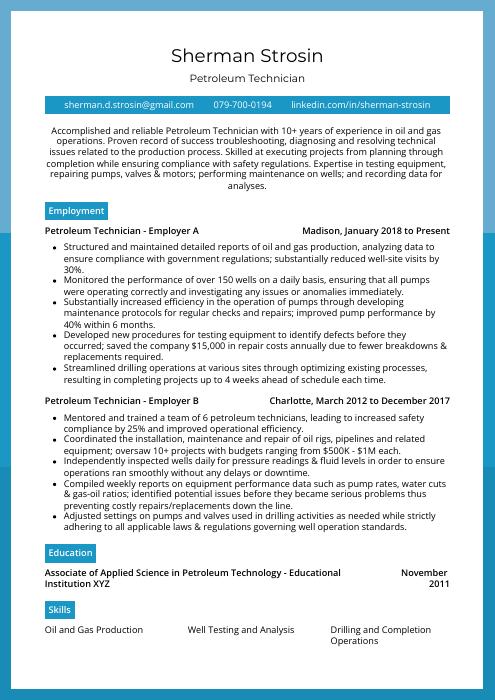

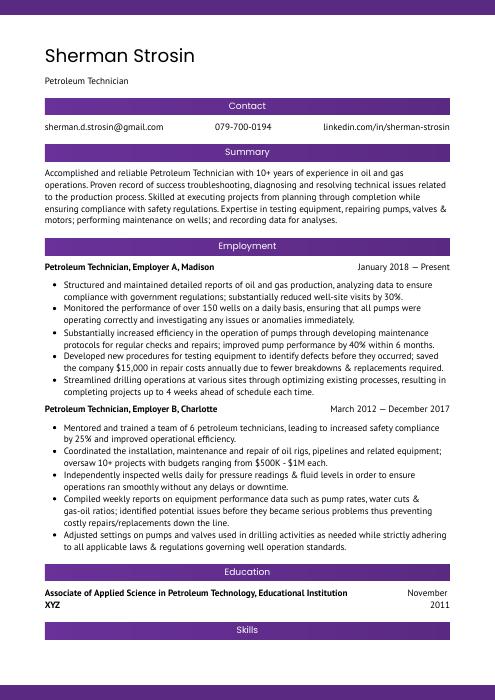

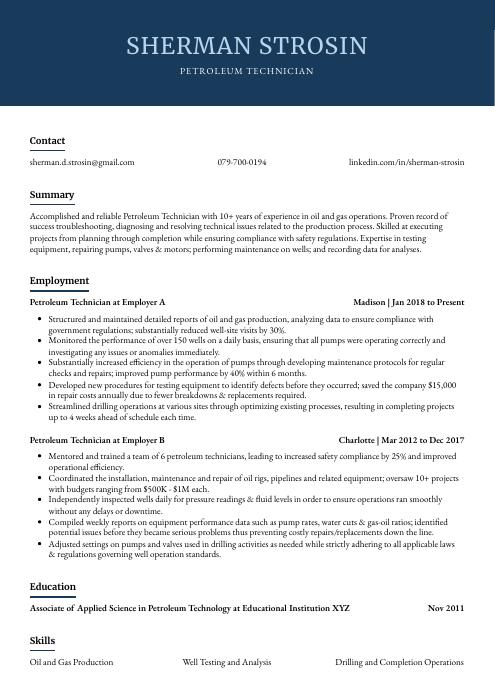

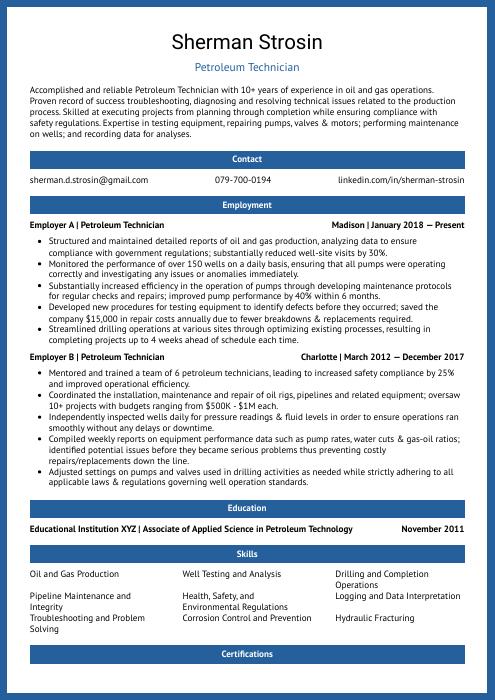

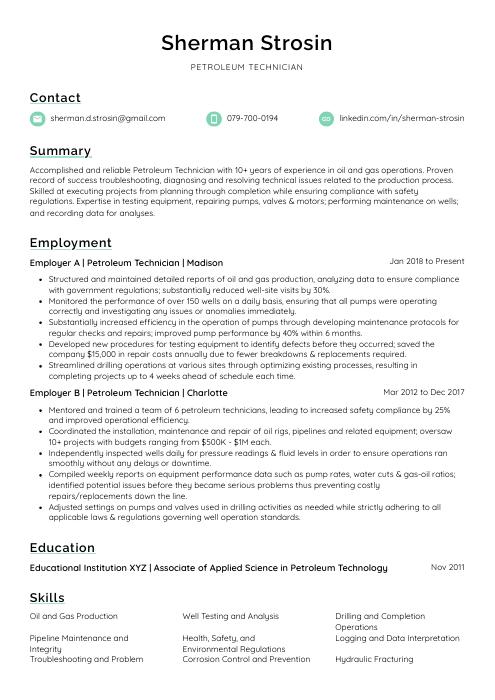

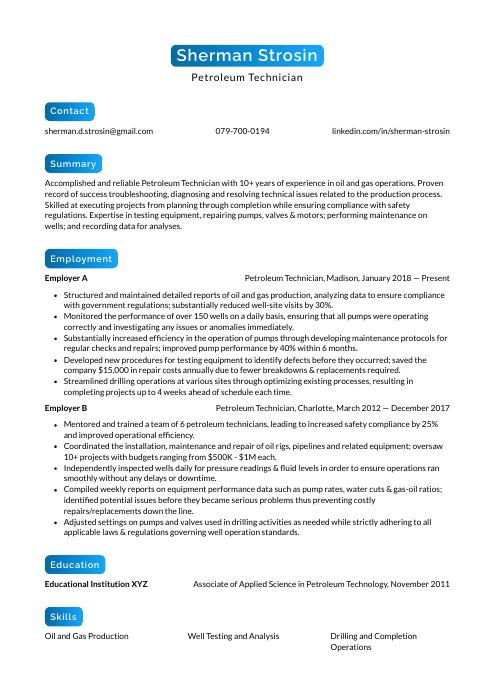

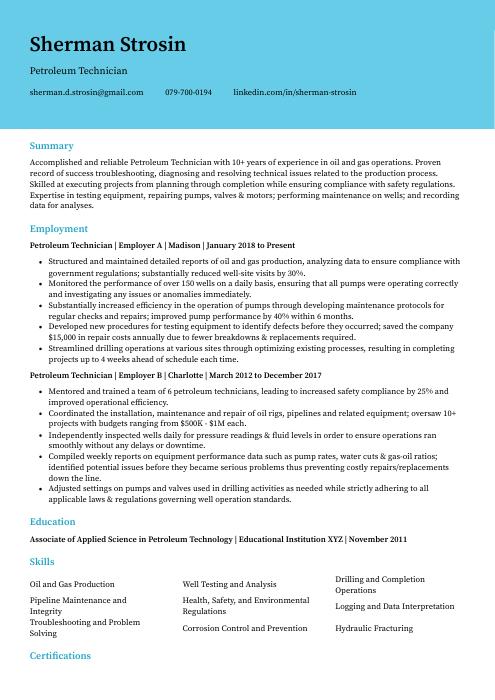

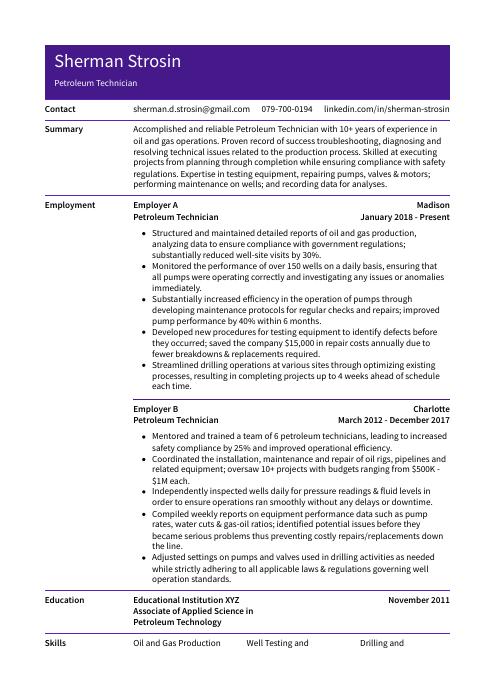

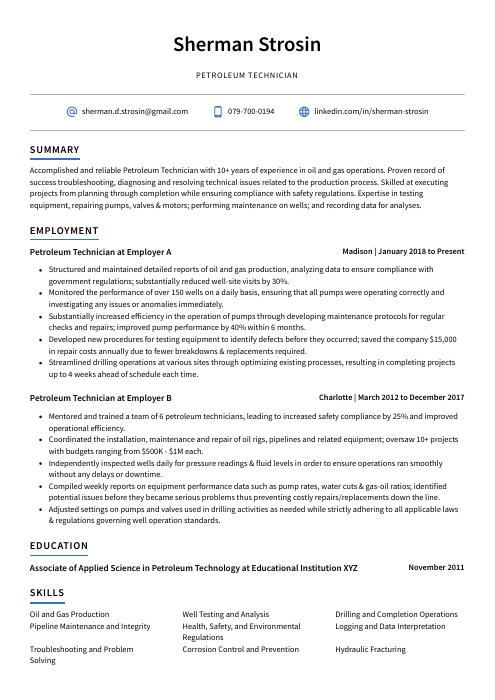

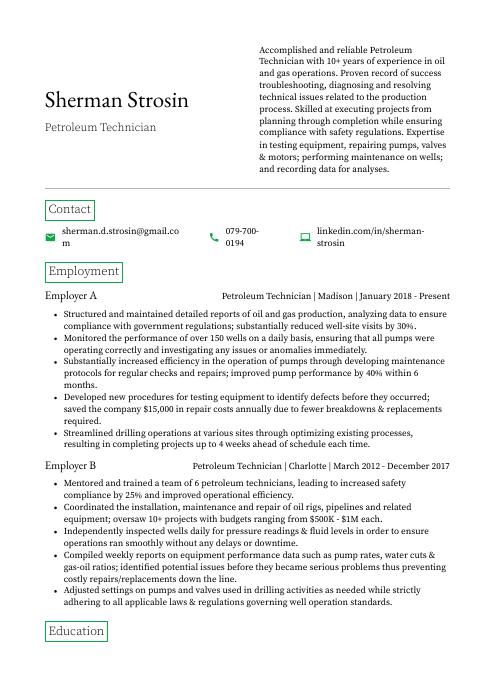

Petroleum Technician Resume Sample

Sherman Strosin

Petroleum Technician

[email protected]

079-700-0194

linkedin.com/in/sherman-strosin

Summary

Accomplished and reliable Petroleum Technician with 10+ years of experience in oil and gas operations. Proven record of success troubleshooting, diagnosing and resolving technical issues related to the production process. Skilled at executing projects from planning through completion while ensuring compliance with safety regulations. Expertise in testing equipment, repairing pumps, valves & motors; performing maintenance on wells; and recording data for analyses.

Experience

Petroleum Technician, Employer A

Madison, Jan 2018 – Present

- Structured and maintained detailed reports of oil and gas production, analyzing data to ensure compliance with government regulations; substantially reduced well-site visits by 30%.

- Monitored the performance of over 150 wells on a daily basis, ensuring that all pumps were operating correctly and investigating any issues or anomalies immediately.

- Substantially increased efficiency in the operation of pumps through developing maintenance protocols for regular checks and repairs; improved pump performance by 40% within 6 months.

- Developed new procedures for testing equipment to identify defects before they occurred; saved the company $15,000 in repair costs annually due to fewer breakdowns & replacements required.

- Streamlined drilling operations at various sites through optimizing existing processes, resulting in completing projects up to 4 weeks ahead of schedule each time.

Petroleum Technician, Employer B

Charlotte, Mar 2012 – Dec 2017

- Mentored and trained a team of 6 petroleum technicians, leading to increased safety compliance by 25% and improved operational efficiency.

- Coordinated the installation, maintenance and repair of oil rigs, pipelines and related equipment; oversaw 10+ projects with budgets ranging from $500K – $1M each.

- Independently inspected wells daily for pressure readings & fluid levels in order to ensure operations ran smoothly without any delays or downtime.

- Compiled weekly reports on equipment performance data such as pump rates, water cuts & gas-oil ratios; identified potential issues before they became serious problems thus preventing costly repairs/replacements down the line.

- Adjusted settings on pumps and valves used in drilling activities as needed while strictly adhering to all applicable laws & regulations governing well operation standards.

Skills

- Oil and Gas Production

- Well Testing and Analysis

- Drilling and Completion Operations

- Pipeline Maintenance and Integrity

- Health, Safety, and Environmental Regulations

- Logging and Data Interpretation

- Troubleshooting and Problem Solving

- Corrosion Control and Prevention

- Hydraulic Fracturing

Education

Associate of Applied Science in Petroleum Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Petroleum Technician

American Petroleum Institute

May 2017

1. Summary / Objective

Your resume summary/objective should be an attention-grabber, giving the employer a quick overview of your qualifications as a petroleum technician. You can use this space to highlight your experience in oil and gas operations, such as well drilling or pipeline maintenance; any specialized certifications you have obtained; and how you have successfully implemented safety protocols on past projects.

Below are some resume summary examples:

Talented petroleum technician with 5+ years of experience in the oil & gas industry. Skilled at performing maintenance and repairs on drilling rigs and other equipment, as well as providing technical advice to staff. At XYZ Company, achieved a 20% increase in operational efficiency by streamlining processes for both offshore and land-based operations. Proven track record of safety compliance and promoting safe working practices within the workplace.

Professional Petroleum Technician with 5+ years of experience in the oil and gas industry. Skilled at operating complex machinery, troubleshooting technical issues, and conducting safety inspections. Adept at managing hazardous materials while adhering to strict regulations. Seeking to join ABC Energy as a Petroleum Technician where I can leverage my expertise to ensure efficient operations and safe working conditions for all personnel on-site.

Detail-oriented petroleum technician with 5+ years of experience in oil and gas operations. Experienced in the installation, maintenance and repair of a variety of petroleum production equipment. Skilled at troubleshooting complex problems quickly while staying on budget and meeting deadlines. At XYZ Oil & Gas Co., managed all safety protocols related to refining processes, resulting in no accidents or injuries reported during my tenure.

Reliable and highly skilled Petroleum Technician with 8+ years of experience in the oil and gas industry. Experienced in maintenance, repair, inspection, testing and calibration of wellhead equipment. At XYZ Energy Inc., successfully repaired pump jack systems to increase production by 10%. Recognized for efficiency in developing cost-effective solutions that meet safety regulations while improving performance standards.

Amicable and detail-oriented petroleum technician with eight years of experience in the oil and gas industry. Experienced in conducting routine maintenance on equipment, performing safety checks, monitoring operations, and troubleshooting technical issues. Seeking to join ABC Energy as a Petroleum Technician to utilize my skillset for the benefit of their team and clients.

Dependable and motivated petroleum technician with 6+ years of experience in oil and gas production. Expertise in safety protocols, wellsite operations, maintenance/repair activities, and troubleshooting equipment malfunctions. At ABC Oil & Gas Co., improved efficiency by 25% through the implementation of a new data-tracking system for all operational activities.

Driven petroleum technician with 7+ years of experience in oil and gas operations, maintenance, engineering, and construction. Skilled in operating various types of drilling rigs for exploration projects within the US Gulf Coast Region. Seeking to apply expertise to strengthen ABC’s team by providing safe and efficient operation support on upcoming projects.

Enthusiastic and reliable petroleum technician with 6 years of experience in the field. Skilled in conducting routine maintenance and repairs for oil rigs, pipelines, and other related equipment. Committed to safety protocols while delivering quality work on time. Looking to bring expertise and knowledge to ABC Company as a Petroleum Technician.

2. Experience / Employment

In the experience/employment/work history section, you want to provide details on your past jobs. This should be written in reverse chronological order, meaning the most recent job is listed first.

When writing this section, stick to bullet points and give as much detail as possible about what you did and the results obtained. For example, instead of saying “Performed maintenance checks,” say “Conducted weekly maintenance checks on oil rigs which resulted in a 10% reduction in downtime.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Monitored

- Inspected

- Operated

- Calibrated

- Troubleshot

- Analyzed

- Adjusted

- Repaired

- Tested

- Installed

- Assembled

- Maintained

- Replaced

- Serviced

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Reduced average repair time of oil rigs by 30% through the successful implementation of new safety protocols.

- Reorganized inventory systems and helped to streamline supply processes, leading to a 5% increase in efficiency within 6 months.

- Spearheaded daily maintenance checks on all equipment at drilling sites; identified potentially hazardous situations before they occurred, preventing any potential disasters from occurring.

- Successfully installed over 500 meters of pipelines for two separate projects within budget and ahead of schedule; estimated savings totaled $20,000+.

- Repaired defective valves onsite using specialized tools such as torque wrenches and welding apparatus; minimized downtime by 40%.

- Presented safety instructions and procedures to a team of 25+ petroleum technicians, resulting in an improved safety record with zero reported incidents.

- Consistently monitored oil well production levels while operating pumps and valves; optimized output by 10%, increasing overall revenue by $6,000 per month.

- Optimized efficiency of drilling operations through the use of advanced analytical methods such as 3D imaging surveys and gas chromatography tests; decreased downtime costs by 20%.

- Improved accuracy when recording data from pipeline inspections using specialized software programs, reducing errors by 95%.

- Inspected pipelines for corrosion or damage on a weekly basis, ensuring that all equipment was functioning correctly at all times to avoid costly repairs/replacements.

- Calibrated and maintained various drilling and production equipment, including pumps and valves, to optimize petroleum extraction operations; successfully reduced downtime by 15%.

- Operated a variety of heavy machinery such as forklifts and cranes in an efficient manner while safely loading/unloading materials from tankers at the refinery site.

- Assembled pipelines with up-to-date welding techniques to ensure that all connections were secure; improved overall throughput by 20% over the last six months.

- Represented the company onsite when interacting with contractors or regulatory agencies regarding health & safety procedures or environmental regulations compliance issues; minimized delays due to paperwork processing time by 35%.

- Actively monitored operational data points across all stages of production, including temperature readings, pressure levels, flow rates etc., ensuring optimal conditions for high yield outputs without compromising quality standards.

- Reliably monitored, inspected and maintained oil rigs, pipelines and other petroleum-related equipment; achieved a 40% reduction in repair costs over the last year.

- Achieved an average of 3 times more production output than industry standards through innovative process improvements.

- Formulated solutions to reduce environmental impact by introducing safer drilling techniques that minimized waste disposal requirements by 50%.

- Expedited repairs on damaged pipelines using advanced welding techniques, resulting in up to 8 hours saved per incident across the network of sites managed by our company.

- Advised new technicians on safe operating procedures for hazardous materials handling during their training period; reduced incidents related to improper material storage/handling practices from 10% to 0%.

- Utilized specialized tools and equipment to inspect, repair and maintain petroleum pipelines, tanks and other associated facilities; decreased downtime by 30%.

- Introduced new safety protocols for all technicians working in hazardous areas containing various forms of combustible material; safeguarded the lives of over 40 employees.

- Facilitated regular maintenance on a variety of pumps, compressors and valves used in oil refineries; reduced operational costs by $5,000 per month.

- Prepared accurate records detailing each inspection or repair job completed according to industry standards while meeting tight deadlines without compromising quality outcomes.

- Meticulously inspected gauges regularly as part of preventative maintenance routines that resulted in fewer unplanned shutdowns from pipeline failure incidents – saving an average 8 hours/monthly.

- Effectively performed preventive maintenance, repairs and testing on petroleum refinery equipment and systems to ensure optimal performance; reduced downtime by 25%.

- Demonstrated expertise in monitoring crude oil levels, controlling production flows and troubleshooting malfunctions using advanced diagnostic tools.

- Participated in the development of safety procedures for all operations related to refining processes; implemented policy updates that increased efficiencies by 20%.

- Assessed potential risks associated with daily tasks such as inspecting pipelines, flanges or valves and took appropriate action when necessary.

- Installed new pumps, motors & tanks while adhering strictly to industry-specific regulations concerning storage capacity & design requirements; cut installation time by 40%.

- Replaced and maintained over 500 oil and gas pumps, compressors, valves and pipelines in a safe and timely manner; increased production efficiency by 13%.

- Tested equipment for any malfunctions using specialized tools such as pressure gauges & torque wrenches to diagnose problems accurately; reduced maintenance costs by $4,000 last quarter.

- Efficiently operated machinery used for drilling activities including drill rigs, directional drills and safety systems with zero incidents of downtime or accidents reported in the past two years.

- Revised operational procedures within the Petroleum Department based on industry trends & technological advancements resulting in improved operations performance overall.

- Serviced all types of petroleum storage tanks according to standards set forth by regulatory bodies and health codes while ensuring that proper safety protocols were followed at all times; successfully completed 10 tank cleanouts over the course of six months with no disruptions or damages incurred during processes.

- Analyzed and monitored electrical and instrumentation systems in the refinery, identified potential issues that could lead to damage of equipment or hazardous conditions; reduced downtime by 15% within 6 months.

- Troubleshot mechanical problems with heavy duty oil rigs and production machinery used for drilling operations onsite; completed repairs promptly without any safety incidents occurring in 2 years.

- Maintained records of all inspection results, service requests, machine calibration data and other relevant documents according to industry standards; improved efficiency in information retrieval by 20%.

- Confidently operated a variety of tools such as pressure gauges, electronic meters & welding machines while performing preventive maintenance tasks throughout the facility; saved up to $1,000 every month on replacement costs alone due this effort.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may be looking for a petroleum technician with experience in oil and gas production, while Organization XYZ may require the candidate to have knowledge of drilling operations.

It is essential that you tailor your skills section to each job you are applying for because many companies use applicant tracking systems these days which scan resumes for certain keywords before passing them on to a human.

Besides just listing relevant skills here, it is also important to elaborate on those same ones throughout other resume sections such as the summary or experience section.

Below is a list of common skills & terms:

- Corrosion Control and Prevention

- Drilling and Completion Operations

- Health, Safety, and Environmental Regulations

- Hydraulic Fracturing

- Logging and Data Interpretation

- Oil and Gas Production

- Pipeline Maintenance and Integrity

- Reservoir Engineering and Management

- Troubleshooting and Problem Solving

- Well Testing and Analysis

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below the resume objective. However, if you have significant work experience to showcase, it may be better to omit the education section altogether.

If an education section is included, try to highlight courses or subjects related to petroleum technology that could add value for a potential employer.

Associate of Applied Science in Petroleum Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have a certain level of expertise in the field. They can also be used as evidence of your commitment to professional development and staying up-to-date with industry trends.

If you are applying for a job which requires specific certifications, make sure they are included on your resume so that hiring managers know right away that you meet their requirements.

Certified Petroleum Technician

American Petroleum Institute

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Sherman Strosin, this would be Sherman-Strosin-resume.pdf or Sherman-Strosin-resume.docx.

7. Cover Letter

Providing a cover letter when applying for a job is an excellent way to make yourself stand out from the competition. It should include 2-4 short paragraphs which provide more detail about who you are and why you’re suited for the role.

Cover letters can also be used to fill in any gaps that may be present on your resume, giving recruiters a better understanding of your capabilities and experience as a professional. Although not always required, writing one could give you the edge over other applicants vying for the same position.

Below is an example cover letter:

Dear Rhianna,

I am writing in response to your job posting for a Petroleum Technician. With my training in oil and gas production, as well as my experience working with various types of equipment, I feel confident that I would be a valuable asset to your team.

In my current role as Petroleum Technician at [company name], I am responsible for operating and maintaining the equipment used in oil and gas production. This includes troubleshooting issues, performing repairs, and conducting regular maintenance checks. My knowledge of industry safety standards has also been beneficial in ensuring compliance with regulations.

Through my work experience, I have developed strong problem-solving skills that enable me to quickly identify and resolve issues. My ability to work independently or as part of a team makes me adaptable to any situation. I am also proficient in using computer software programs related to my field, such as Microsoft Office and AutoCAD.

I believe that my skills and qualifications make me an ideal candidate for the petroleum technician position at your company. I look forward to speaking with you soon about this opportunity.

Sincerely,

Sherman

Petroleum Technician Resume Templates

Gharial

Gharial Hoopoe

Hoopoe Indri

Indri Saola

Saola Echidna

Echidna Fossa

Fossa Cormorant

Cormorant Numbat

Numbat Markhor

Markhor Rhea

Rhea Jerboa

Jerboa Bonobo

Bonobo Ocelot

Ocelot Lorikeet

Lorikeet Kinkajou

Kinkajou Dugong

Dugong Pika

Pika Axolotl

Axolotl Quokka

Quokka Rezjumei

Rezjumei