Measurement Technician Resume Guide

Measurement Technicians are responsible for ensuring the accuracy of measurements taken from a variety of instruments, such as calipers, micrometers and other precision measuring tools. They use these instruments to measure dimensions and compare them against predetermined tolerances in order to verify product quality or identify discrepancies in production processes.

Your expertise in measuring and calibrating equipment is invaluable to any company. To get your name out there, you must write a resume that demonstrates why you are the perfect fit for the job.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

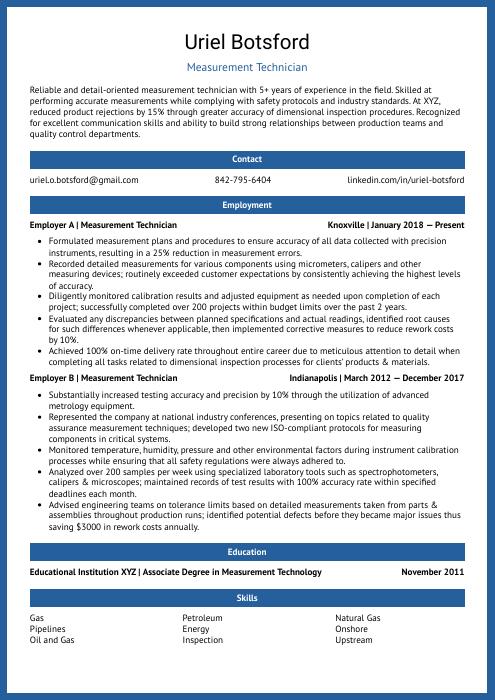

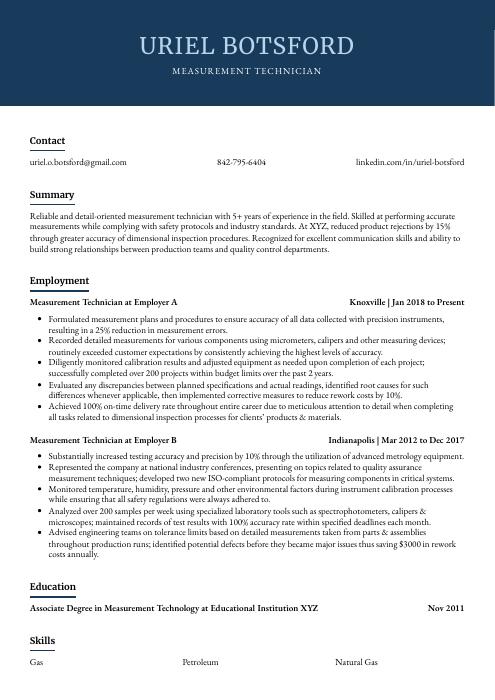

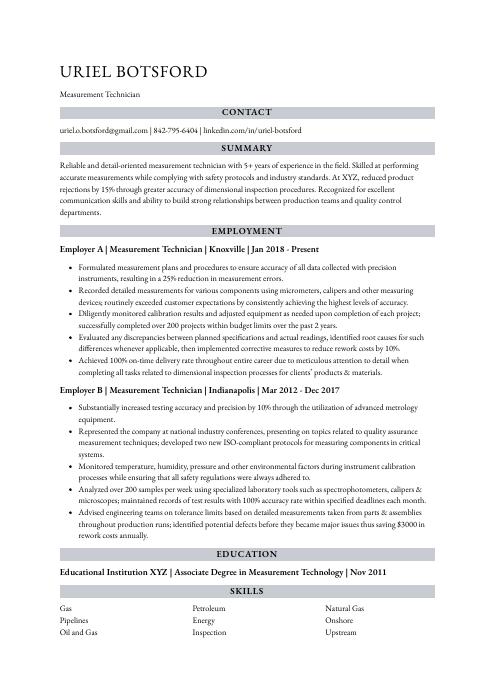

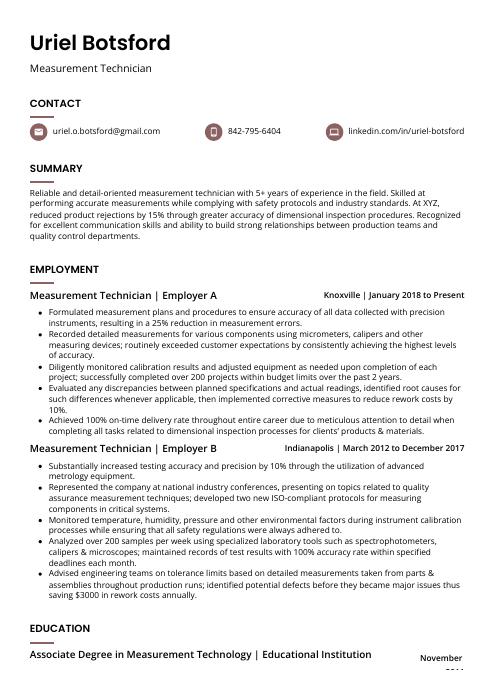

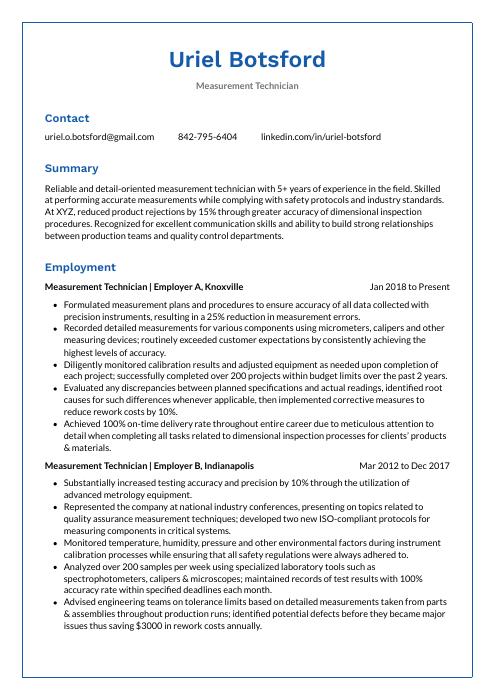

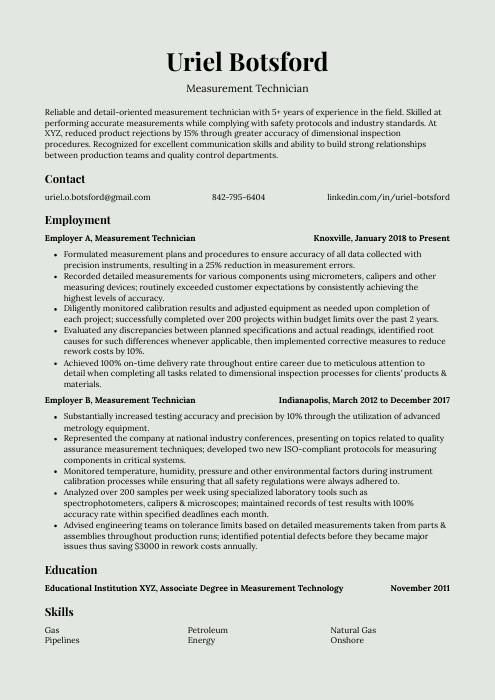

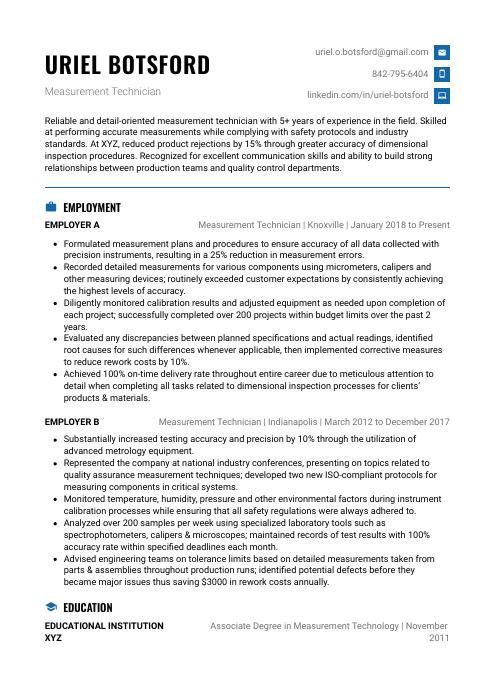

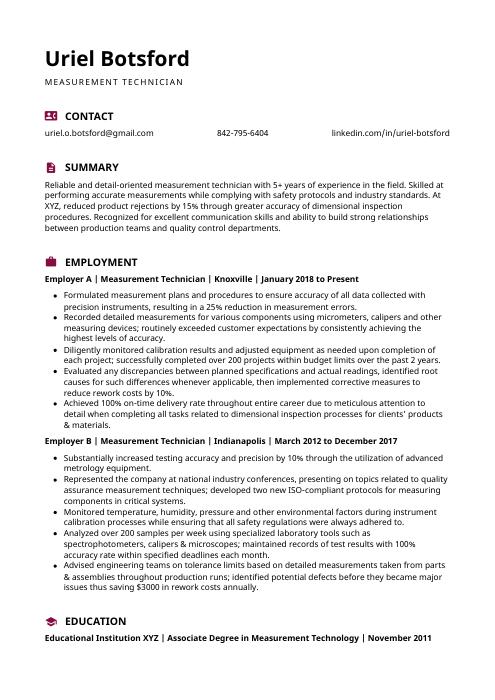

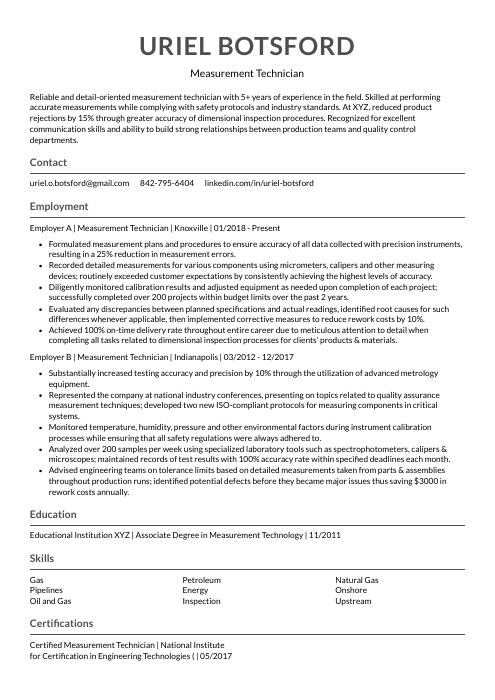

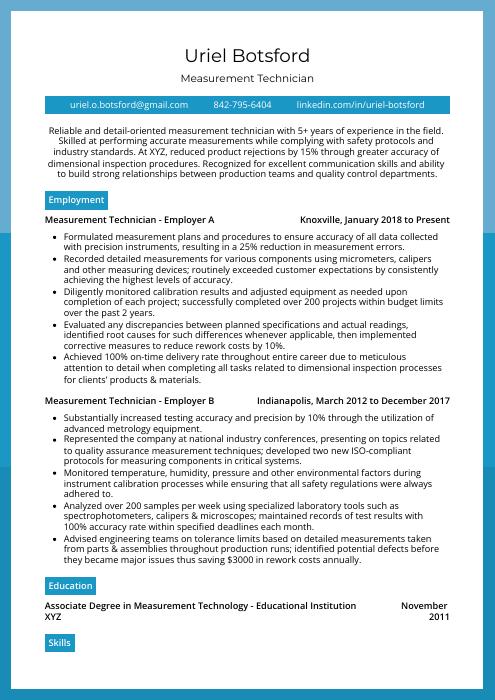

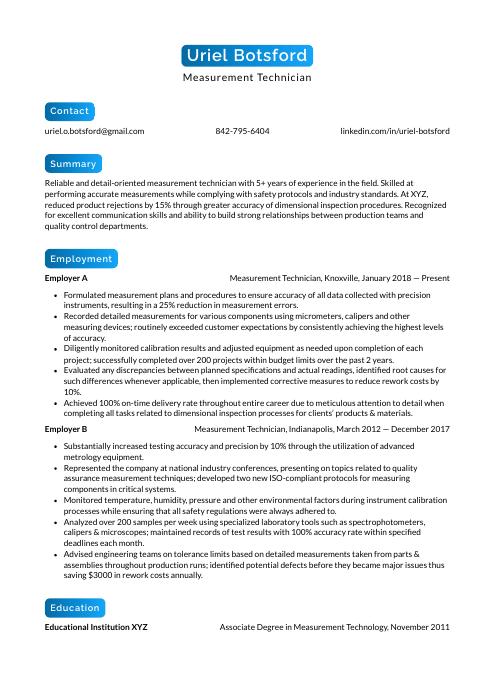

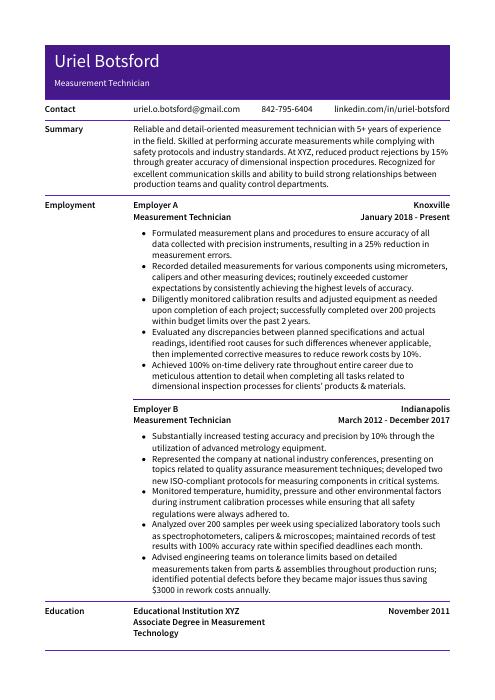

Measurement Technician Resume Sample

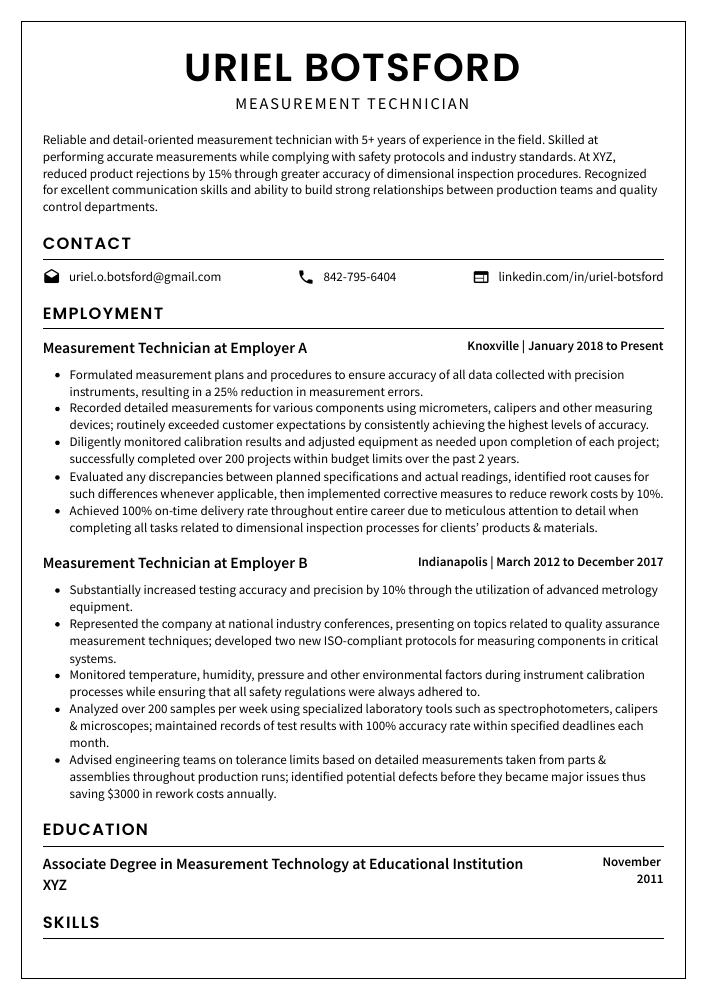

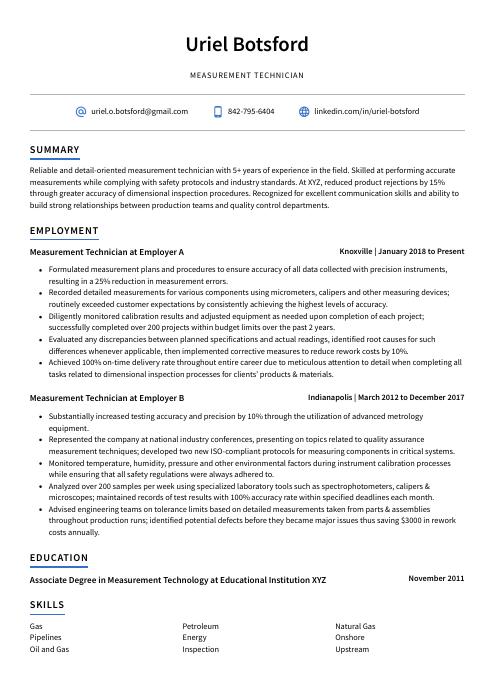

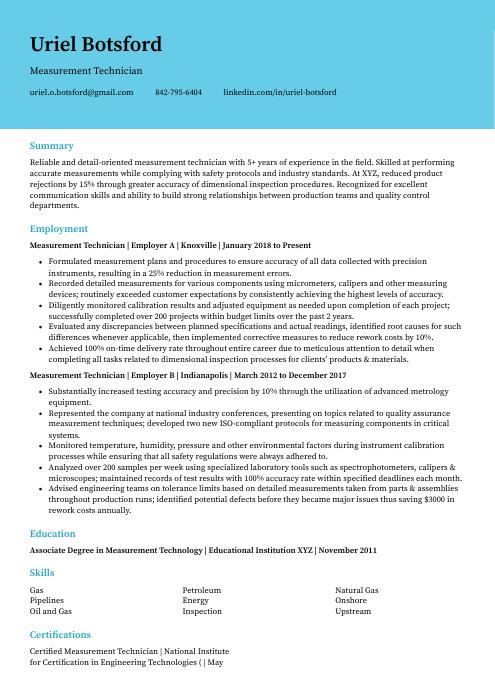

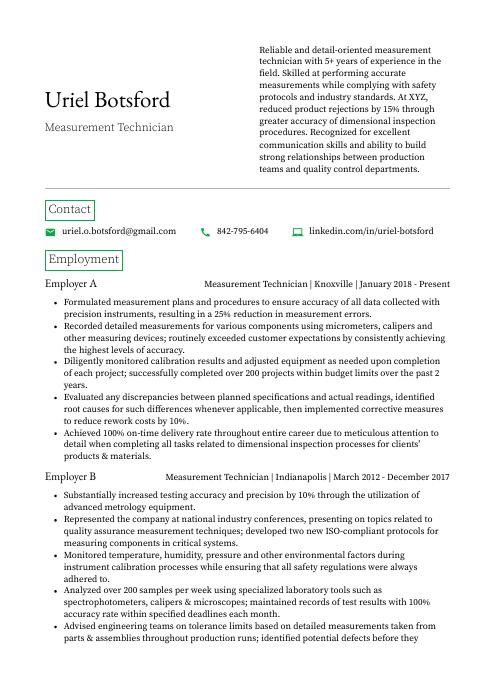

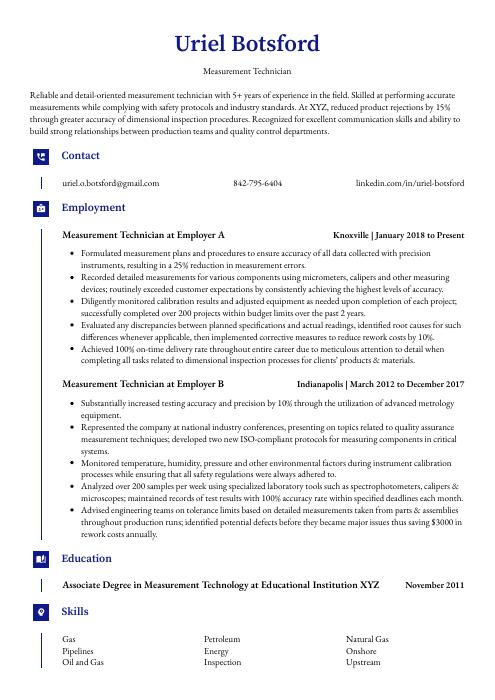

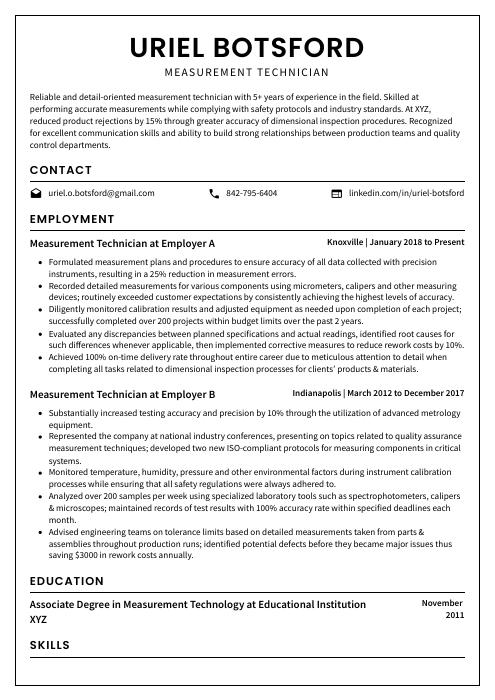

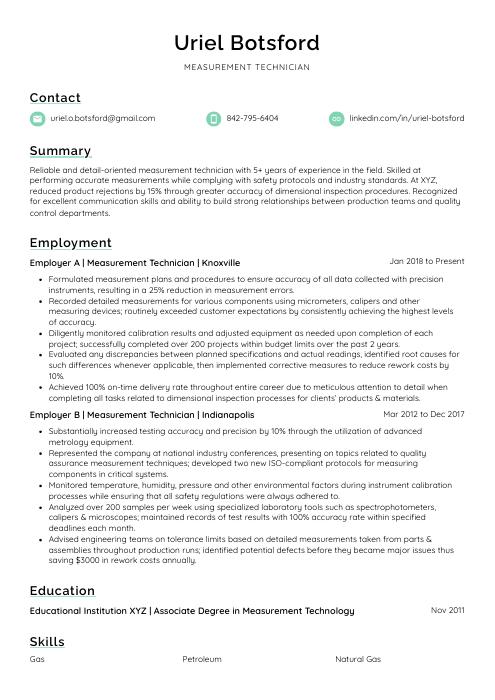

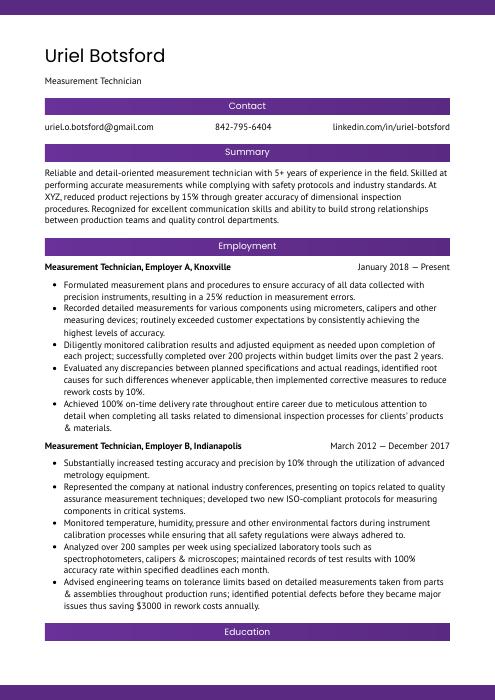

Uriel Botsford

Measurement Technician

[email protected]

842-795-6404

linkedin.com/in/uriel-botsford

Summary

Reliable and detail-oriented measurement technician with 5+ years of experience in the field. Skilled at performing accurate measurements while complying with safety protocols and industry standards. At XYZ, reduced product rejections by 15% through greater accuracy of dimensional inspection procedures. Recognized for excellent communication skills and ability to build strong relationships between production teams and quality control departments.

Experience

Measurement Technician, Employer A

Knoxville, Jan 2018 – Present

- Formulated measurement plans and procedures to ensure accuracy of all data collected with precision instruments, resulting in a 25% reduction in measurement errors.

- Recorded detailed measurements for various components using micrometers, calipers and other measuring devices; routinely exceeded customer expectations by consistently achieving the highest levels of accuracy.

- Diligently monitored calibration results and adjusted equipment as needed upon completion of each project; successfully completed over 200 projects within budget limits over the past 2 years.

- Evaluated any discrepancies between planned specifications and actual readings, identified root causes for such differences whenever applicable, then implemented corrective measures to reduce rework costs by 10%.

- Achieved 100% on-time delivery rate throughout entire career due to meticulous attention to detail when completing all tasks related to dimensional inspection processes for clients’ products & materials.

Measurement Technician, Employer B

Indianapolis, Mar 2012 – Dec 2017

- Substantially increased testing accuracy and precision by 10% through the utilization of advanced metrology equipment.

- Represented the company at national industry conferences, presenting on topics related to quality assurance measurement techniques; developed two new ISO-compliant protocols for measuring components in critical systems.

- Monitored temperature, humidity, pressure and other environmental factors during instrument calibration processes while ensuring that all safety regulations were always adhered to.

- Analyzed over 200 samples per week using specialized laboratory tools such as spectrophotometers, calipers & microscopes; maintained records of test results with 100% accuracy rate within specified deadlines each month.

- Advised engineering teams on tolerance limits based on detailed measurements taken from parts & assemblies throughout production runs; identified potential defects before they became major issues thus saving $3000 in rework costs annually.

Skills

- Gas

- Petroleum

- Natural Gas

- Pipelines

- Energy

- Onshore

- Oil and Gas

- Inspection

- Upstream

Education

Associate Degree in Measurement Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Measurement Technician

National Institute for Certification in Engineering Technologies (

May 2017

1. Summary / Objective

Your resume summary or objective should be a brief yet powerful statement that gives the employer an overview of your experience and qualifications as a measurement technician. Include details such as the types of measurements you are most proficient in, any certifications or training courses you have completed, and how many years of experience you have in this field. You can also mention any awards or recognition received for excellence in your work.

Below are some resume summary examples:

Driven measurement technician with 5 years of experience in the field. Proven track record of providing accurate measurements for various projects and products, such as aircraft components, vehicle systems, and industrial equipment. Expertise includes utilizing precision instruments such as calipers, micrometers, optical comparators to ensure product accuracy within tolerance levels specified by industry standards or customer requirements.

Proficient Measurement Technician with 6+ years of experience in the field. Skilled at calibrating and troubleshooting measuring instruments, collecting data, analyzing results, and preparing reports. Managed two major projects that resulted in an average improvement of 25% on measurement accuracy across multiple facilities. Seeking to join ABC Tech as a Measurement Technician to ensure accurate measurements for their products.

Energetic measurement technician with five years of experience in the field. At XYZ, used laser trackers and other precision instruments to measure parts for aerospace applications. Skilled at working independently as well as collaborating with a team on complex projects. Recognized for excellent problem-solving skills and high accuracy rate when measuring components against blueprints or CAD models.

Well-rounded measurement technician with 10+ years of experience in the energy and utilities sector. Proven ability to analyze, inspect, calibrate, troubleshoot, and repair a wide range of instruments such as temperature controllers for industrial plants. Seeking to join ABC Energy Solutions’ team as their next measurement technician where I can bring my expertise and help them achieve their goals.

Committed measurement technician with 5+ years of experience working in the oil and gas industry. Skilled in troubleshooting, calibrating, and repairing a variety of measuring instruments. Proven track record of consistently meeting production goals while reducing downtime by 20%. At XYZ Company, developed an innovative calibration system allowing for faster testing times and fewer errors.

Dependable and detail-oriented measurement technician with 5+ years of experience in calibration, troubleshooting, and data analysis. Seeking to join ABC Technologies as an instrumentation expert to help maintain accuracy and reliability of the company’s products. In previous roles, reduced equipment downtime by 30% and improved product quality through regular maintenance checks.

Amicable measurement technician with 5+ years of experience in the engineering industry. Skilled in operating and maintaining precision tools such as calipers, micrometers, bore gauges, etc., to ensure accuracy while meeting tight deadlines. Seeking a role at ABC Company that will utilize my knowledge and expertise to contribute towards the development of quality products.

Seasoned measurement technician with 10+ years of experience in the oil and gas industry. Proven ability to accurately detect, monitor, analyze, and report leaks in pipelines using advanced tools such as ultrasonic detectors. Looking to bring this expertise to ABC Corp where I can leverage my technical skillset while contributing to a safe work environment.

2. Experience / Employment

Next comes the work history section, where you provide details on your employment experience. This should be written in reverse chronological order, meaning the most recent job is listed first.

When writing out what you did for each position, stick to bullet points as much as possible; not only does this make it easier to read but also allows the reader to take in more information quickly. You want to focus on providing detail and quantifiable results when listing out your accomplishments. For example, instead of saying “Calibrated various instruments,” you could say, “Successfully calibrated over 50 pieces of measuring equipment per month using a variety of calibration techniques.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Measured

- Calibrated

- Inspected

- Analyzed

- Recorded

- Tested

- Adjusted

- Monitored

- Operated

- Troubleshot

- Programmed

- Documented

- Evaluated

- Repaired

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Optimized standard operating procedures to reduce measurement and calibration time by 25%, resulting in a 15% increase in productivity.

- Developed test plans, performed measurements and data analysis for over 200 projects using precision instruments such as multimeters, oscilloscopes and digital calipers; ensured accuracy of all calculations within 0.05%.

- Expedited the resolution of customer complaints with timely calibrations; created new standardization protocols that decreased response times from 2 days to 12 hours or less.

- Revised existing calibration records based on past results, increasing overall quality control standards by 20%.

- Confidently operated analytical equipment including spectrometers and profilometers while adhering to safety regulations at all times; maintained zero incidents during the duration of employment.

- Spearheaded the calibration of over 500 gauges, probes and other types of measuring equipment within a 12-month period; reduced downtime by 30%.

- Troubleshot complex problems related to faulty measurements and instrumentation errors, often with little or no guidance from onsite engineers.

- Reduced the cost associated with purchasing new instruments by upcycling existing tools; cut expenses by 25% in one year.

- Independently updated records for all calibrated instruments according to industry standards while keeping track of repair costs & budgets effectively; saved $1,500 in maintenance fees annually through proper documentation alone.

- Adjusted gauge settings as needed when calibrating pressure transducers and flow sensors to ensure accuracy across readings taken using various methods such as deadweight testers & comparators – results were consistently accurate within 0-0+0 range 90% of the time.

- Operated a wide range of precision measuring equipment to accurately assess components and assemblies in accordance with customer specifications, reducing defective parts by 15%.

- Measured dimensions, tolerances and angles on products using calipers, micrometers, height gauges and other instruments; quickly identified any discrepancies or irregularities prior to installation.

- Consistently monitored product quality throughout the production process while ensuring that all safety protocols were followed at all times; prevented over $10k worth of potential losses due to faulty machinery last year alone.

- Facilitated successful implementation of new ISO 9001:2015 QMS standards during a recent upgrade project; reduced measurement errors by 28% within 6 months after its completion.

- Prepared detailed reports based on collected data for review purposes; provided technical support when needed regarding measurements taken from complex designs & drawings.

- Streamlined the measurement process by implementing advanced technologies and techniques, reducing manual labor time by 50% and increasing overall accuracy of measurements.

- Structured a training program for junior technicians to ensure proper understanding of the measuring equipment while mentoring 3 new employees in calibration processes.

- Tested various components & systems against established standards, identified discrepancies quickly with an 85% success rate & provided detailed reports on findings to senior management within 24 hours.

- Mentored a team of 5 instrumentation specialists on state-of-the-art equipment as well as safety protocols; improved performance quality from 75%-95%.

- Efficiently managed inventory control systems that tracked more than 200 pieces of measuring instruments across three laboratories, resulting in cost savings up to $10K per year for the organization.

- Effectively operated and maintained precision measuring equipment in a laboratory setting, ensuring accuracy of all measurements to within 0.05% tolerance rate.

- Coordinated the calibration and repair of over 40 types of measurement instruments; reduced downtime by 25%.

- Repaired malfunctioning test equipment such as strain gages, load cells and pressure gauges with high attention to detail and technical expertise.

- Compiled comprehensive reports on testing results according to ISO 9001 standards; improved data quality assurance by 30%.

- Introduced modern methods for faster inspection process which resulted in 20% time savings per project cycle completion.

- Demonstrated technical expertise in calibrating and maintaining a wide range of precision measurement instruments, reducing calibration time by 30%.

- Documented all measurements using data acquisition systems; produced accurate records for customer audits with 95% accuracy rate.

- Participated in the design and implementation of quality assurance procedures to reduce product defects from 10% to 4%.

- Improved troubleshooting skills while inspecting equipment used in manufacturing processes, leading to quicker resolution of issues within 8 hours on average.

- Actively monitored test results against established standards and provided recommendations for adjustments when needed; improved overall system efficiency by 17%.

- Programmed data-logging equipment to accurately measure and record temperature, pressure, flow rate and other parameters for over 200 projects in the last year; reduced troubleshooting time by 15%.

- Meticulously monitored instrument readings to detect any irregularities or unexpected changes within a 10 microsecond window of accuracy.

- Presented comprehensive project reports detailing results from measurements taken on various systems at monthly team meetings; saved $5,000 on measurement costs annually through cost effective solutions.

- Utilized advanced measuring tools such as digital multimeters & oscilloscopes to inspect circuit boards and perform calibration tests with precision across all stages of production process.

- Reorganized spare parts inventory system with improved labeling methods that enabled faster access times while reducing misplacement errors by 25%.

- Competently inspected, calibrated and assessed over 200 measuring instruments for accuracy each month; improved the test result reliability by 10%.

- Utilized a variety of precision tools such as calipers, micrometers, rulers and gauges to measure parts according to specified standards.

- Identified issues with faulty equipment during inspections and recalibrated them using advanced diagnostic systems; reduced downtime costs by $1,000 in the last quarter.

- Assisted senior engineers in developing testing protocols that ensured accurate measurements were taken against industry benchmarks; completed projects within allotted timeframes on average 8 hours ahead of schedule.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require familiarity with a certain type of measuring equipment, while Organization XYZ may need someone who is an expert in data analysis.

You want to tailor the skills section of your resume to each job that you are applying for – this will help ensure that applicant tracking systems (computer programs used by many employers) pick up on all relevant keywords and pass your application along to a human recruiter.

In addition, it is also important to elaborate further on these skills in other sections such as the summary or experience section. This will give recruiters more insight into how well-suited you are for the position at hand.

Below is a list of common skills & terms:

- Automation

- Calibration

- Commissioning

- Drilling

- Energy

- Energy Industry

- Engineering

- Gas

- Inspection

- Instrumentation

- Natural Gas

- Oil

- Oil and Gas

- Oil and Gas Industry

- Oilfield

- Onshore

- PLC

- Petrochemical

- Petroleum

- Pipelines

- Piping

- Pressure

- Preventive Maintenance

- Process Control

- Project Planning

- Pumps

- SCADA

- Supervisory Skills

- Troubleshooting

- Upstream

- Valves

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, it is important to mention the courses or subjects related to measurement technician roles that you studied. However, if you have significant work experience with plenty of responsibilities to showcase, omitting the education section might be a better choice.

If an education section is included, try mentioning any relevant coursework or certifications that could demonstrate your knowledge and expertise as a measurement technician.

Associate Degree in Measurement Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a certain field. They show that you have taken the time and effort to become certified by an authoritative body, which can be highly beneficial when applying for jobs.

When writing your resume, make sure to include any certifications relevant to the job you are applying for. This will help hiring managers recognize that you possess the necessary skills and qualifications they are looking for in their ideal candidate.

Certified Measurement Technician

National Institute for Certification in Engineering Technologies (

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Uriel Botsford, this would be Uriel-Botsford-resume.pdf or Uriel-Botsford-resume.docx.

7. Cover Letter

Writing a cover letter is an important part of the job application process. It serves as a way to introduce yourself and highlight your key skills, qualifications and experiences that make you suitable for the role in question.

A cover letter should be composed of 2 to 4 paragraphs which build upon what is already mentioned in your resume. They are not mandatory but can give recruiters valuable insight into who you are as a professional and why they should consider hiring you over other applicants.

Below is an example cover letter:

Dear Francesco,

I am writing to apply for the Measurement Technician position with Brown Industries. As a Measurement Technician with three years of experience in the field, I have the skills and knowledge needed to excel in this role.

In my current position as a Measurement Technician at ABC Corporation, I am responsible for performing calibration and maintenance on all measurement devices in use by the company. My responsibilities also include conducting investigations into potential sources of measurement error, developing new methods for more accurate measurements, and training other technicians on proper measurement techniques. In addition to my technical skills, I have excellent problem-solving and interpersonal skills that allow me to effectively communicate with colleagues from other departments.

I am confident that I can be an asset to your team and contribute to the success of your organization. I would welcome the opportunity to discuss my qualifications further during an interview at your earliest convenience. Thank you for your time and consideration.

Sincerely,

Uriel

Measurement Technician Resume Templates

Axolotl

Axolotl Dugong

Dugong Quokka

Quokka Gharial

Gharial Cormorant

Cormorant Lorikeet

Lorikeet Jerboa

Jerboa Ocelot

Ocelot Bonobo

Bonobo Numbat

Numbat Fossa

Fossa Markhor

Markhor Saola

Saola Echidna

Echidna Hoopoe

Hoopoe Indri

Indri Rhea

Rhea Kinkajou

Kinkajou Pika

Pika Rezjumei

Rezjumei