Machine Technician Resume Guide

Machine Technicians operate and maintain machinery used in the production of goods. They inspect equipment for defects, troubleshoot malfunctions, make repairs or adjustments to ensure optimal performance, and perform periodic maintenance activities such as lubrication and cleaning. Additionally, they may also install new machines or replace worn parts.

You have a knack for fixing and maintaining machines, but potential employers are still unaware of your abilities. To get them to recognize you as the top machine technician they need, it’s time to write a resume that highlights all your qualifications and experience.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

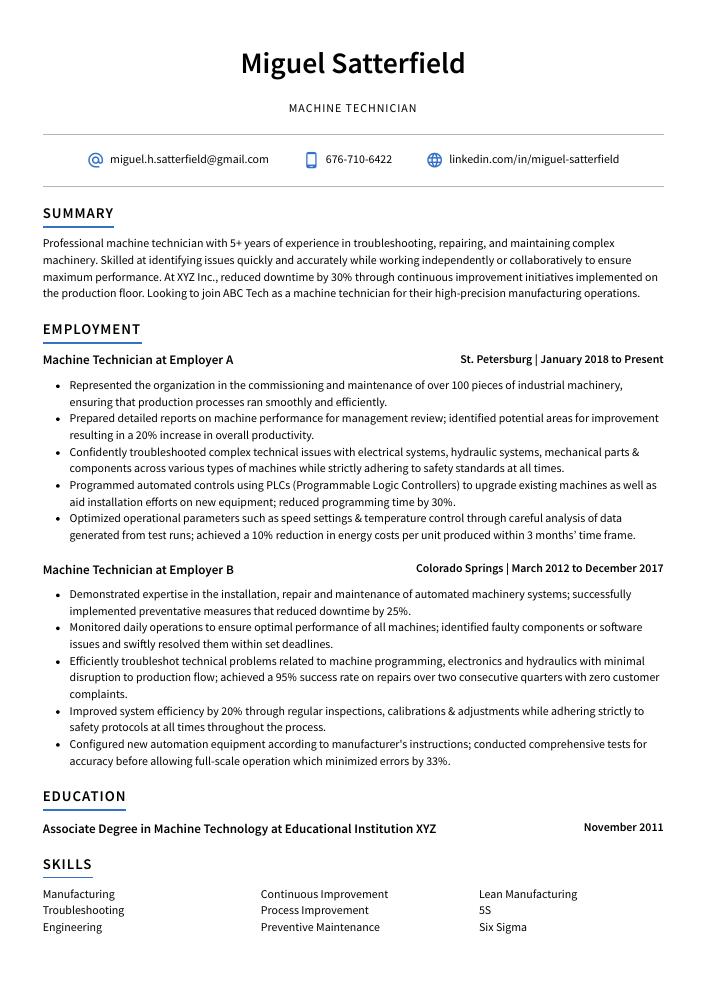

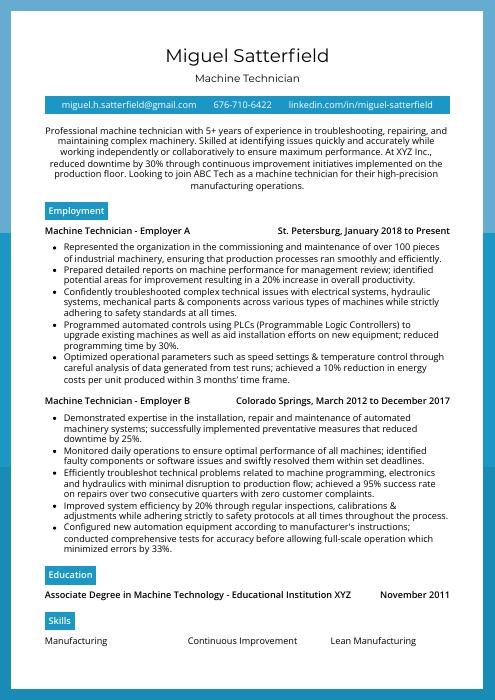

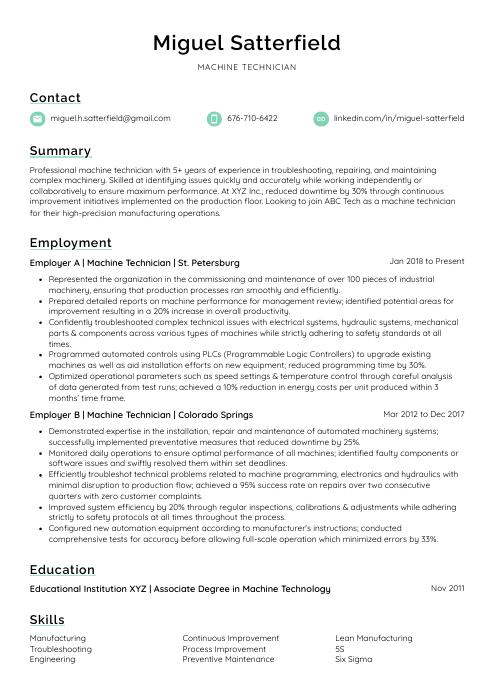

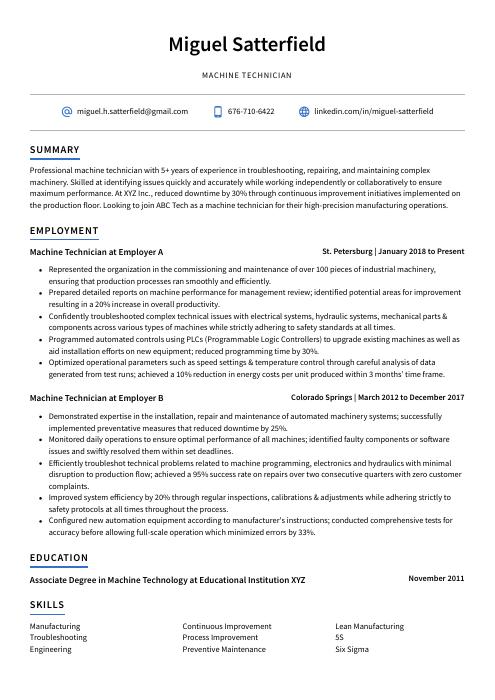

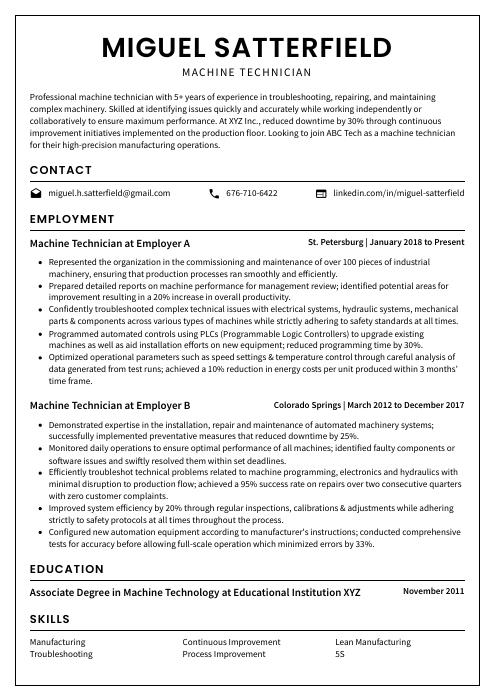

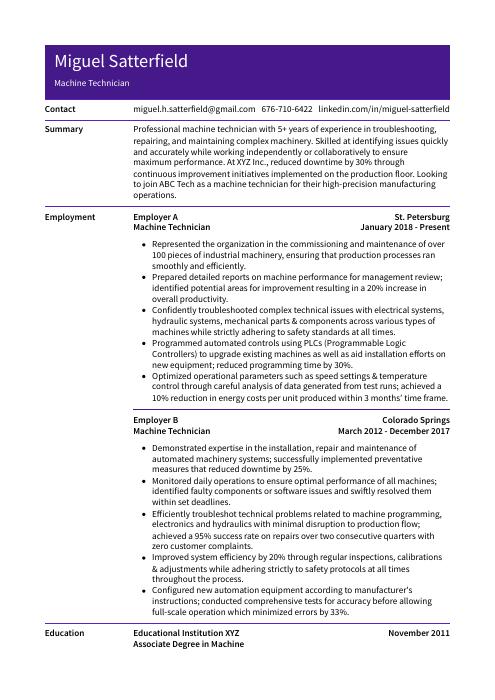

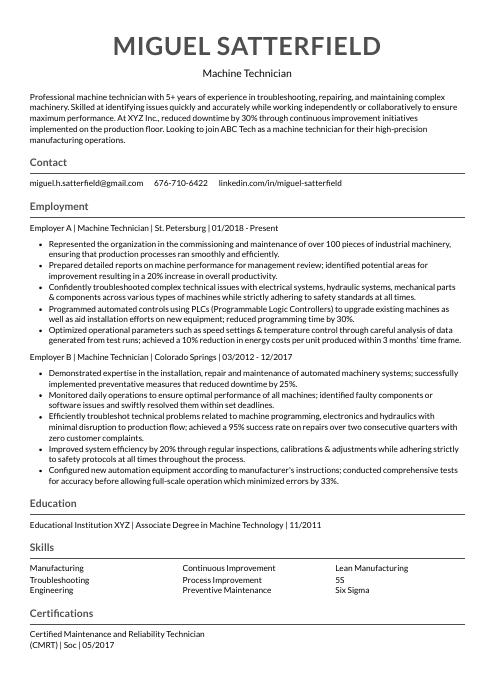

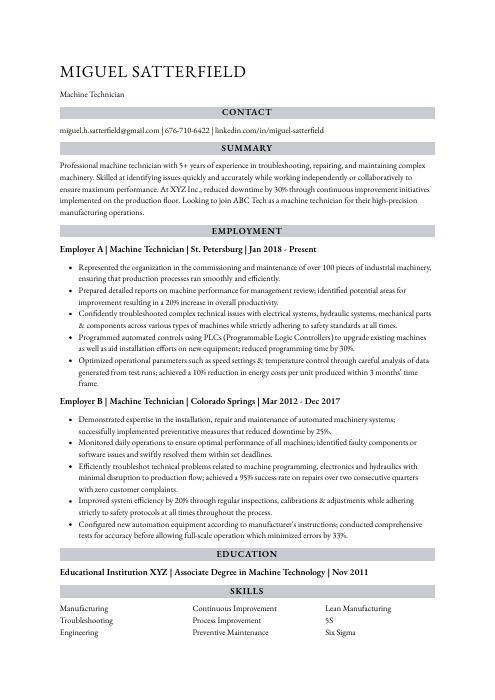

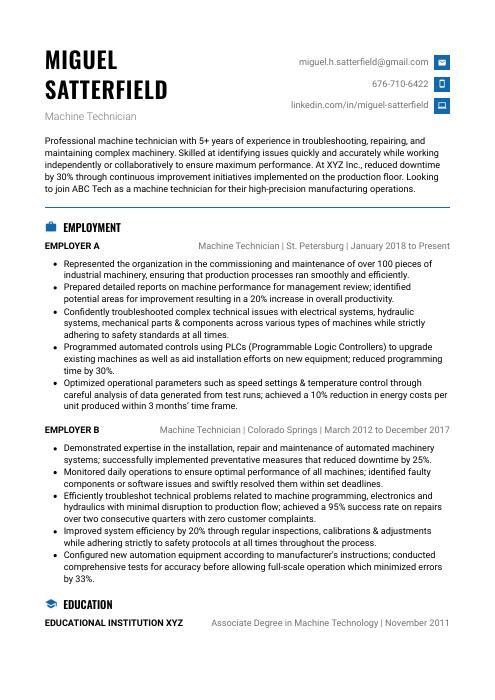

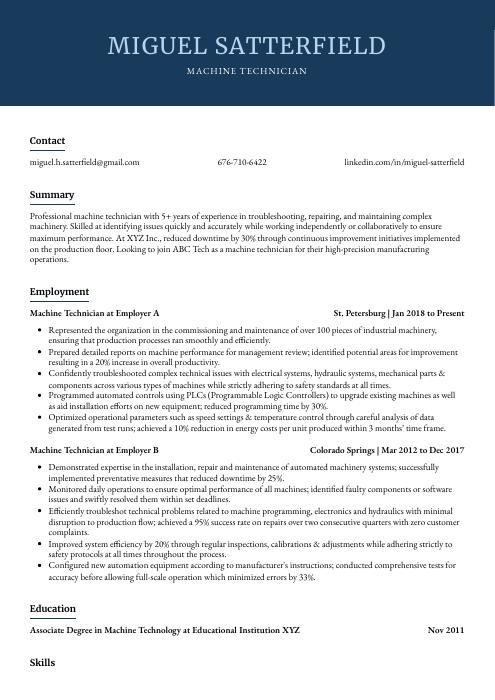

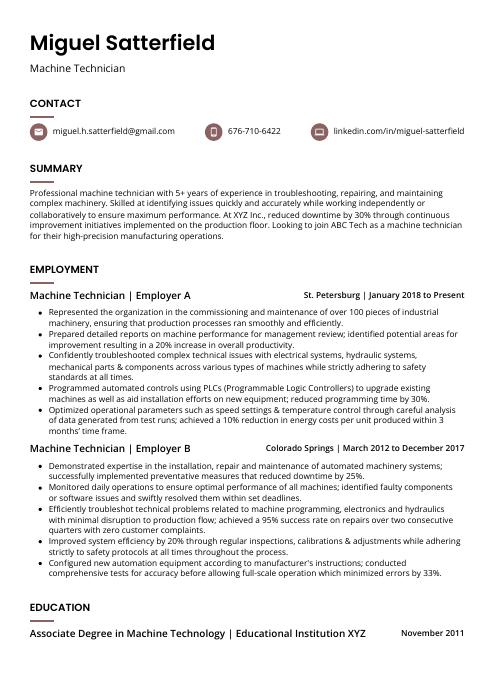

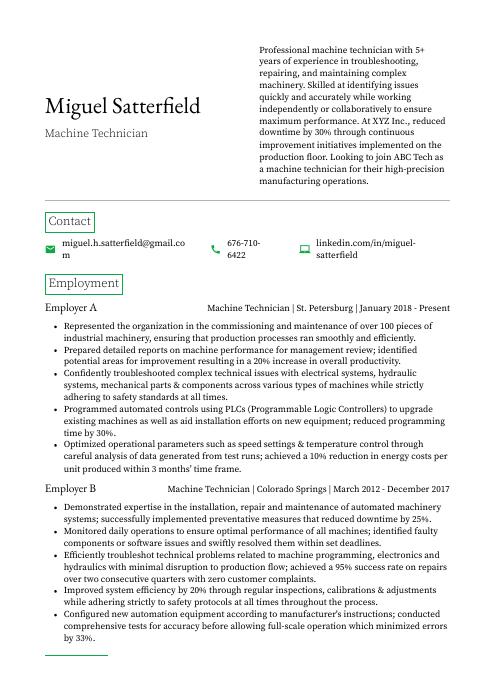

Machine Technician Resume Sample

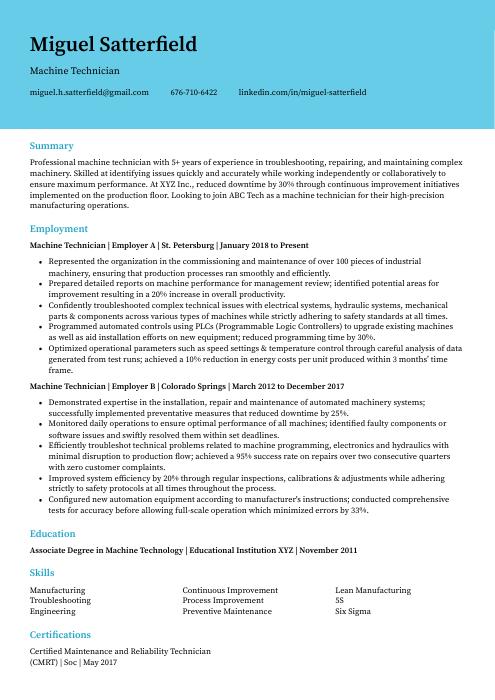

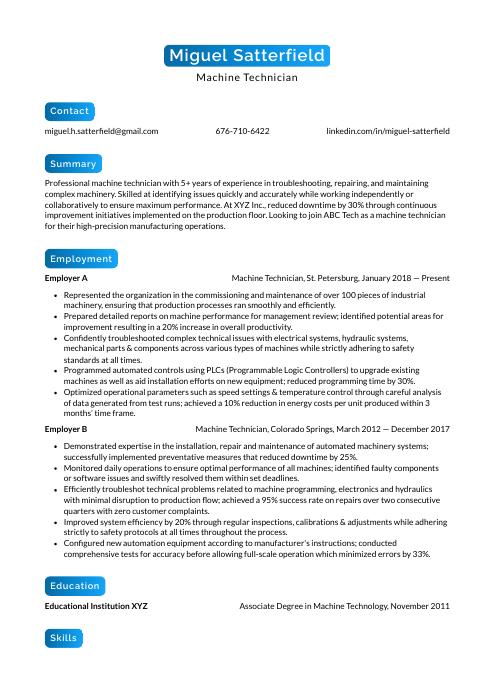

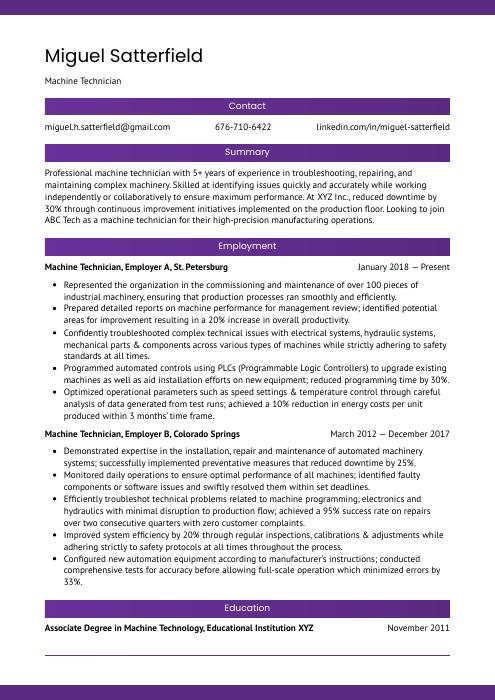

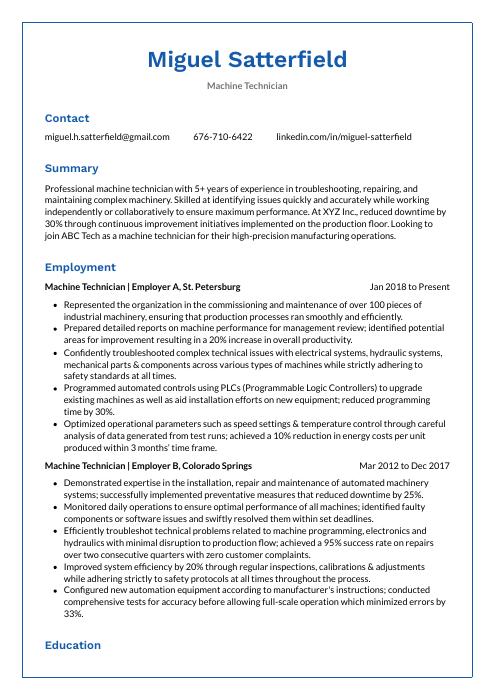

Miguel Satterfield

Machine Technician

[email protected]

676-710-6422

linkedin.com/in/miguel-satterfield

Summary

Professional machine technician with 5+ years of experience in troubleshooting, repairing, and maintaining complex machinery. Skilled at identifying issues quickly and accurately while working independently or collaboratively to ensure maximum performance. At XYZ Inc., reduced downtime by 30% through continuous improvement initiatives implemented on the production floor. Looking to join ABC Tech as a machine technician for their high-precision manufacturing operations.

Experience

Machine Technician, Employer A

St. Petersburg, Jan 2018 – Present

- Represented the organization in the commissioning and maintenance of over 100 pieces of industrial machinery, ensuring that production processes ran smoothly and efficiently.

- Prepared detailed reports on machine performance for management review; identified potential areas for improvement resulting in a 20% increase in overall productivity.

- Confidently troubleshooted complex technical issues with electrical systems, hydraulic systems, mechanical parts & components across various types of machines while strictly adhering to safety standards at all times.

- Programmed automated controls using PLCs (Programmable Logic Controllers) to upgrade existing machines as well as aid installation efforts on new equipment; reduced programming time by 30%.

- Optimized operational parameters such as speed settings & temperature control through careful analysis of data generated from test runs; achieved a 10% reduction in energy costs per unit produced within 3 months’ time frame.

Machine Technician, Employer B

Colorado Springs, Mar 2012 – Dec 2017

- Demonstrated expertise in the installation, repair and maintenance of automated machinery systems; successfully implemented preventative measures that reduced downtime by 25%.

- Monitored daily operations to ensure optimal performance of all machines; identified faulty components or software issues and swiftly resolved them within set deadlines.

- Efficiently troubleshot technical problems related to machine programming, electronics and hydraulics with minimal disruption to production flow; achieved a 95% success rate on repairs over two consecutive quarters with zero customer complaints.

- Improved system efficiency by 20% through regular inspections, calibrations & adjustments while adhering strictly to safety protocols at all times throughout the process.

- Configured new automation equipment according to manufacturer’s instructions; conducted comprehensive tests for accuracy before allowing full-scale operation which minimized errors by 33%.

Skills

- Manufacturing

- Continuous Improvement

- Lean Manufacturing

- Troubleshooting

- Process Improvement

- 5S

- Engineering

- Preventive Maintenance

- Six Sigma

Education

Associate Degree in Machine Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Maintenance and Reliability Technician (CMRT)

Soc

May 2017

1. Summary / Objective

A resume summary/objective is the perfect place to highlight your qualifications as a machine technician. In this section, you can mention any relevant certifications or training programs you have completed, the types of machines and systems you are most familiar with, and how your troubleshooting skills helped improve production efficiency at previous companies.

Below are some resume summary examples:

Seasoned machine technician with 5 years of experience in the installation, repair, and maintenance of various machinery. At XYZ Corporation specialized in large-scale production machines while at ABC Company worked on small-scale consumer products. Possesses expertise in diagnosing machine problems and performing repairs within a timely manner to minimize downtime. Proven record of ensuring that all tasks are completed safely according to company standards.

Well-rounded machine technician with 5+ years of experience servicing and maintaining automated machinery, including CNC plasma cutters and lathes. Skilled in troubleshooting issues to diagnose problems quickly for fast resolution. Committed to ensuring the highest level of safety standards are met at all times. Seeking a new challenge as a Machine Technician at ABC Company where I can use my expertise to maximize efficiency and productivity.

Detail-oriented machine technician with 5+ years of experience in the manufacturing industry. Proven track record of troubleshooting, repairing and maintaining heavy machinery for industrial production. Seeking to join ABC Manufacturing as their next machine technician where I can use my technical skills and expertise to ensure smooth operations. In previous roles, reduced downtime by 15% through optimized maintenance procedures.

Dependable machine technician with 10+ years of experience in troubleshooting, repairing and maintaining manufacturing equipment. Skilled at working independently or as part of a team to identify problems and develop solutions in a timely manner. Received “Technician of the Month” award for exemplary performance on multiple occasions while employed at XYZ company. Achieved an average reduction of downtime by 26%.

Amicable and detail-oriented machine technician with 8+ years of experience in the manufacturing industry. Proven track record of diagnosing and resolving mechanical problems quickly to minimize downtime for multiple production lines. Seeking to join ABC Industries as a Machine Technician, utilizing expertise in technical support, troubleshooting, preventive maintenance planning and quality assurance processes.

Skilled machine technician with 5+ years of experience in the manufacturing industry. Expertise in troubleshooting and repairing electrical, mechanical, and hydraulic components of various equipment. At XYZ Corporation, led a team to reduce downtime by 20% through preventive maintenance strategies. Passionate about leveraging my expertise to keep your machines running at peak efficiency and productivity levels.

Hard-working and reliable machine technician with over 10 years of experience in the field. Certified to maintain, repair and troubleshoot a variety of machines. Skilled at diagnosing problems quickly and efficiently. Able to work independently or as part of a team while adhering to safety standards and regulations. Committed to providing quality results that meet customer needs in an efficient manner.

Reliable and experienced machine technician with 10+ years of experience troubleshooting, maintaining and repairing CNC machinery. Highly skilled in diagnosing issues quickly and efficiently to minimize downtime. Seeking a position at ABC Company where I can utilize my expertise in mechanical systems while further developing my knowledge of modern automation technology.

2. Experience / Employment

In the experience section, you should list your employment history in reverse chronological order. This means that the most recent job is listed first.

When providing details on what you did, stick to bullet points; this makes it easier for the reader to take in all of the information quickly and efficiently. You want to provide specifics about what you did and any quantifiable results obtained from your work.

For example, instead of saying “Maintained machines,” you could say, “Performed regular maintenance checks on 10+ industrial machinery units per week resulting in a 94% reduction in downtime.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Assembled

- Calibrated

- Troubleshot

- Repaired

- Programmed

- Monitored

- Adjusted

- Tested

- Inspected

- Operated

- Replaced

- Configured

- Analyzed

- Upgraded

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Inspected and maintained all machinery components, troubleshooting and repairing complex issues with up to 80% accuracy.

- Introduced new technologies for maintenance operations which resulted in a 20% reduction of downtime per machine over the course of one quarter.

- Meticulously monitored equipment performance using advanced diagnostic tools such as oscilloscopes & multimeters; identified potential malfunctions before they occurred, averting costly repairs or replacements by 50%.

- Expedited emergency repair services on-site when necessary; successfully completed more than 25 urgent jobs within allocated time frames while ensuring safety standards were met at all times.

- Upgraded existing machines with modern parts and automation systems according to customer specifications; improved overall productivity by 30%.

- Proficiently operated and repaired a variety of mechanical equipment, including lathes, saws, grinders and presses; reduced downtime by 25%.

- Assembled custom machinery components for automotive clients in accordance with stringent quality standards; improved production efficiency by 10%.

- Adjusted machine settings to optimize performance and maximize output levels within established quality parameters.

- Tested machines prior to delivery or installation onsite using specialized tools such as calipers & micrometers; minimized customer complaints rate from 5% to 1%.

- Successfully diagnosed problems through visual inspections or electronics testing devices like multimeters and oscilloscopes; increased accuracy of repairs by 30%.

- Participated in the maintenance, repair and calibration of over 50 machines per week; reduced downtime by 30% through proactive troubleshooting.

- Reduced operating costs by 15% through implementation of preventive maintenance practices for all machinery and equipment in production facility.

- Utilized specialized tools to perform repairs on complex electrical systems, hydraulic mechanisms & internal combustion engines with a 95% success rate.

- Spearheaded quality control initiatives which resulted in improved product performance standards, leading to an increase in customer satisfaction rates from 65%-85%.

- Diligently followed safety protocols when conducting machine inspections and repairs; minimized risks associated with hazardous materials or dangerous work environments.

- Analyzed and troubleshot complex mechanical and electrical systems on industrial-grade machinery, quickly identifying issues and resolving them in a timely manner to minimize downtime.

- Mentored junior technicians on machine diagnostics, repair procedures, maintenance protocols and safety requirements; trained 8+ new hires over the past 3 years.

- Structured preventative maintenance plans for all machines within the facility according to company guidelines; improved overall operational efficiency by 15%.

- Actively monitored equipment performance data through computerized diagnostic tests to identify potential problems early and avoid costly repairs later down the line; reduced unexpected malfunctions by 23%.

- Diagnosed more than 200 pieces of malfunctioning equipment each month using advanced testing methods such as ultrasound scans & thermography techniques while adhering strictly to OSHA standards at all times.

- Advised maintenance team on the best practices for operating and maintaining 14 pieces of machinery, improving productivity by 20%.

- Presented automated processes to streamline workflows in 4 machine assembly areas; increased throughput from 136 parts per day to 1000+ parts daily.

- Replaced faulty components in 3 complex machines with 100% accuracy; reduced downtime hours by 30%.

- Streamlined the ordering process for spare machine parts, resulting in a cost-savings of $7000 over 6 months.

- Independently diagnosed a fault code issue on an electronic control system which was causing production delays; fixed problem within 1 hour without any external assistance or guidance.

- Calibrated and maintained over 200 machines, ensuring that all were running at maximum efficiency and accuracy; decreased downtime by 30% within the last 6 months.

- Assessed mechanical problems on machinery and used troubleshooting techniques to repair them in a timely manner; completed repairs ahead of schedule 95% of the time.

- Reorganized machine parts inventory system, resulting in an improved workflow with minimal disruptions due to missing components or tools; saved 8 hours per week in searching for parts/tools previously misfiled or lost.

- Reliably operated specialized machinery such as lathes, milling machines and CNC systems while following safety regulations and standard operating procedures (SOPs).

- Repaired various types of industrial equipment including pumps, motors & generators using hand tools, power drills & welding equipment; reduced maintenance costs by 10%.

- Competently maintained, repaired and overhauled over 100 industrial machines daily to ensure maximum production output; lowered downtime rate by 25%.

- Coordinated the purchase of parts for machine operations and ensured that all maintenance supplies were adequately stocked at all times.

- Revised technical diagrams & blueprints in order to troubleshoot mechanical problems faster, resulting in an average reduction of repair time per machine from 4 hours to 2 hours.

- Achieved a 95% success rate when repairing faulty electrical wiring systems on complex machinery components within tight deadlines without compromising safety standards or quality assurance protocols.

- Developed new preventive maintenance procedures which improved overall equipment reliability by 20%, while reducing energy costs by $6,000 annually across 3 production lines simultaneously.

- Formulated and implemented preventative maintenance plans for 8 mechanical systems, increasing the uptime of machines by 25%.

- Facilitated repairs and replacements on electrical systems with minimal disruption to production schedules; decreased downtime from 4 hours per repair to 1 hour or less.

- Effectively diagnosed complex issues in automated machinery using high-level diagnostic tools, reducing equipment malfunctions by 17% within 2 months.

- Installed new components such as motors and control panels onto existing machine models while maintaining safety protocol standards; improved overall performance efficiency by 15%.

- Compiled detailed reports regarding system operations and preventive maintenance activities that were used to keep clients up-to-date on their machinery status; saved an average of 6 hours per month in customer service time spent addressing inquiries due to this initiative.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one may be looking for someone who is experienced in operating CNC machines while another might require experience with robotics.

Therefore, it is important to tailor the skills section of your resume to each job that you are applying for. This will help ensure that applicant tracking systems (which many companies use these days) recognize the relevant keywords and pass your resume on to a human being.

In addition, you should also discuss some of the most pertinent skills in other sections such as summary or experience so they can get more attention from recruiters.

Below is a list of common skills & terms:

- 5S

- Automotive

- Continuous Improvement

- Cross Functional Team Leadership

- Engineering

- Forklift Operation

- Kaizen

- Lean Manufacturing

- Machining

- Maintenance

- Maintenance and Repair

- Manufacturing

- Operations Management

- Preventive Maintenance

- Process Improvement

- Product Development

- Root Cause Analysis

- Six Sigma

- Supervisory Skills

- Team Leadership

- Teamwork

- Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, mention your education below your resume objective. However, if you have years of work experience with plenty to showcase, omitting the education section is perfectly fine.

If an education section is included, try to include courses or subjects related to machine technician roles that demonstrate a strong understanding of the field such as electrical engineering or mechanical engineering technology.

Associate Degree in Machine Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a given field. They show potential employers that you have taken the time and effort to gain knowledge and skills related to the job you are applying for, which can help set you apart from other applicants.

Include any certifications relevant to the position on your resume so hiring managers know what qualifications you possess. This will give them an idea of how well-suited you are for the role and increase your chances of being selected as a candidate.

Certified Maintenance and Reliability Technician (CMRT)

Soc

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Miguel Satterfield, this would be Miguel-Satterfield-resume.pdf or Miguel-Satterfield-resume.docx.

7. Cover Letter

Including a cover letter with your job application is an excellent way to make a good first impression. Cover letters are typically made up of 2 to 4 paragraphs and provide recruiters with more information about you and why you’re the perfect fit for the role.

Not all jobs require a cover letter, but if one does it’s important that you take the time to write an effective one. It can be used as an opportunity for you to showcase your skills, knowledge and personality in greater detail than what is presented on your resume alone.

Below is an example cover letter:

Dear Camilla,

I am writing to apply for the machine technician position at your company. As a qualified and experienced machine technician, I am confident that I can be a valuable asset to your organization.

In my current role as machine technician at [company name], I maintain and repair a wide variety of machines used in the manufacturing process. My experience has given me a deep understanding of how these machines work, and I have developed strong troubleshooting and problem-solving skills. In addition, I have excellent mechanical aptitude and manual dexterity, which allows me to perform repairs quickly and efficiently.

I am also familiar with all relevant safety regulations, and I always take care to follow safe working practices when carrying out repairs or maintenance tasks. My goal is always to get the job done right the first time, so that production can resume as soon as possible.

If you are looking for an experienced machine technician who will keep your machines running smoothly and safely, then please contact me to arrange an interview at your earliest convenience. Thank you for your time & consideration.

Sincerely,

Miguel

Machine Technician Resume Templates

Gharial

Gharial Ocelot

Ocelot Hoopoe

Hoopoe Rhea

Rhea Lorikeet

Lorikeet Axolotl

Axolotl Cormorant

Cormorant Dugong

Dugong Kinkajou

Kinkajou Jerboa

Jerboa Markhor

Markhor Saola

Saola Pika

Pika Indri

Indri Numbat

Numbat Echidna

Echidna Bonobo

Bonobo Fossa

Fossa Quokka

Quokka Rezjumei

Rezjumei