Ink Technician Resume Guide

Ink Technicians are responsible for operating, maintaining and repairing specialized printing equipment. They check ink levels, monitor the quality of prints and adjust color density as needed. Additionally, they troubleshoot any issues with machines or materials in order to ensure a successful production run.

Ink technicians like you know the ins and outs of their profession, but employers don’t yet. To show them what you can do, write a resume that makes them take notice. With your experience and qualifications on paper, they’ll be sure to give you an interview.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

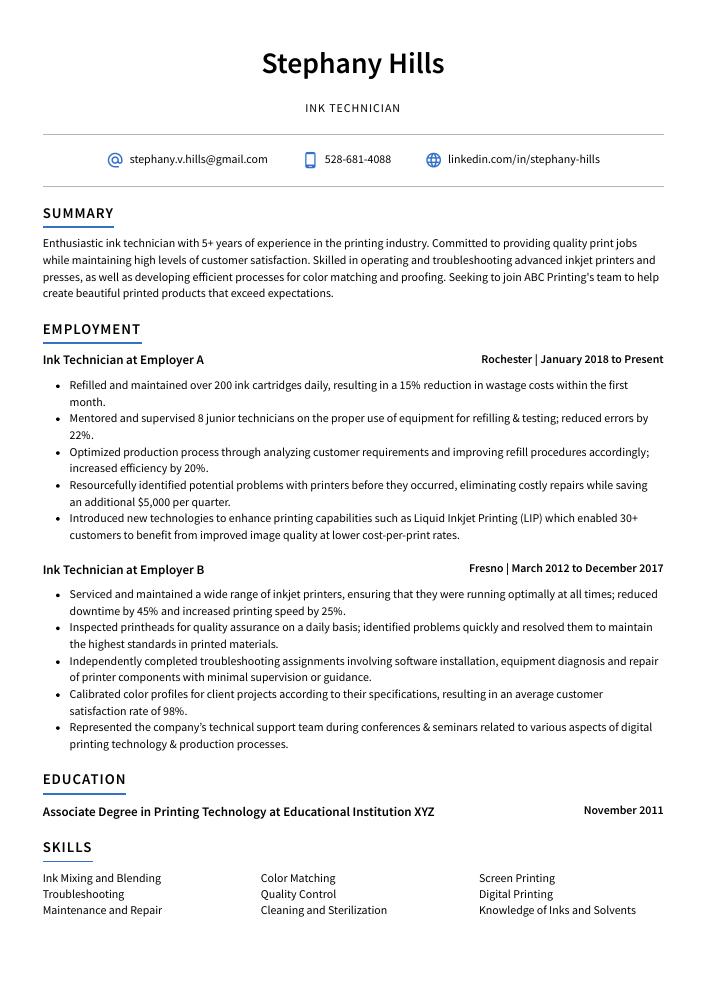

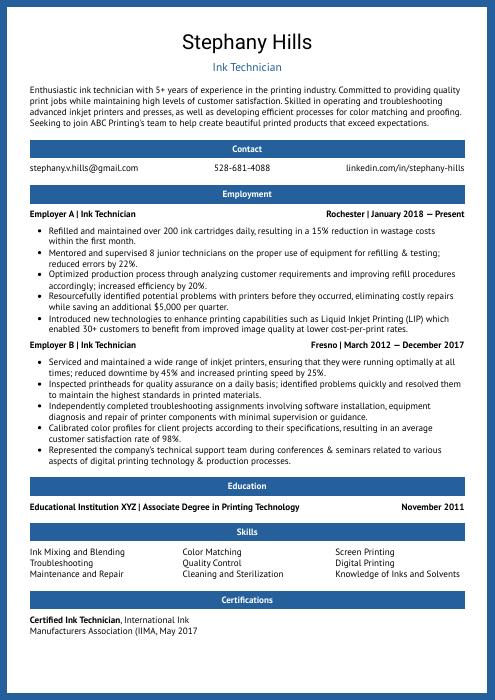

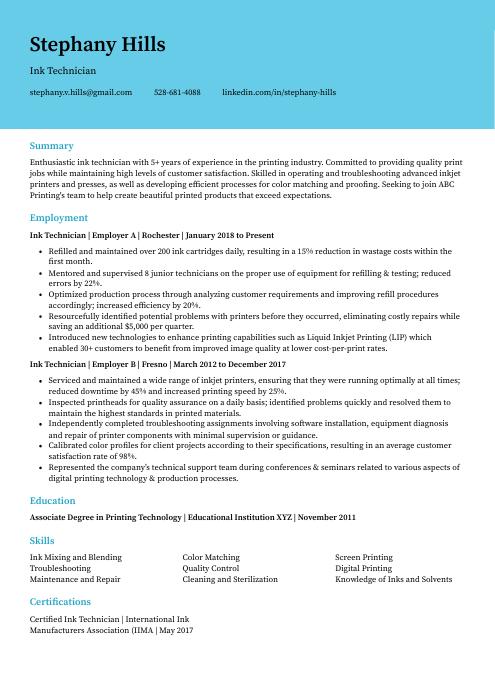

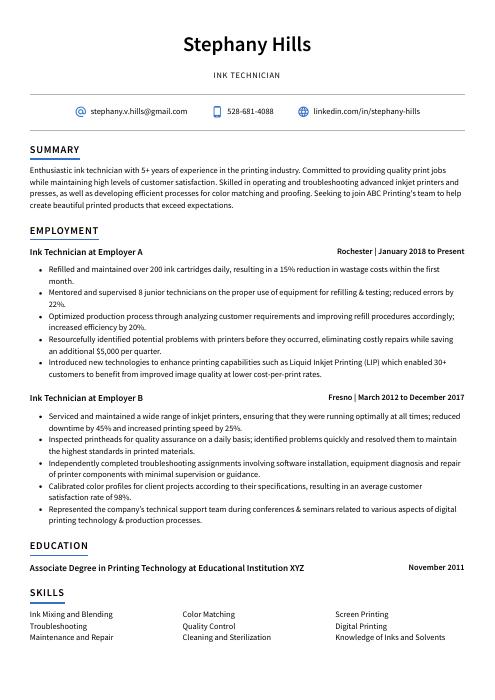

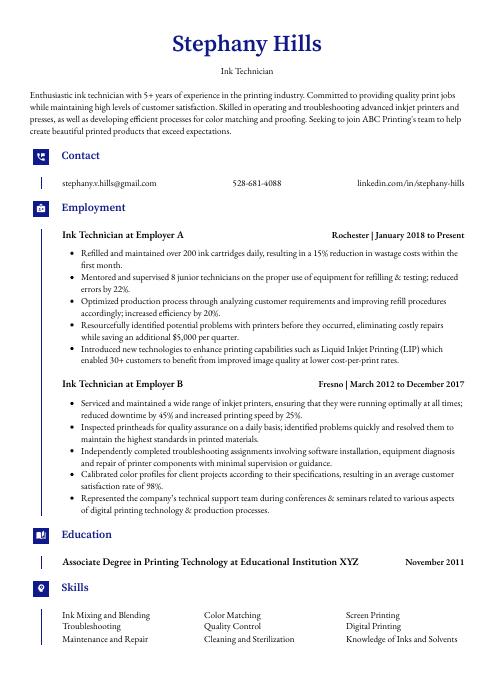

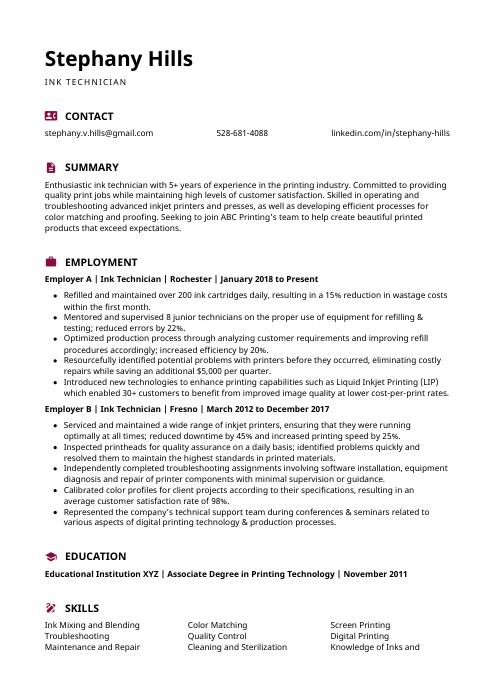

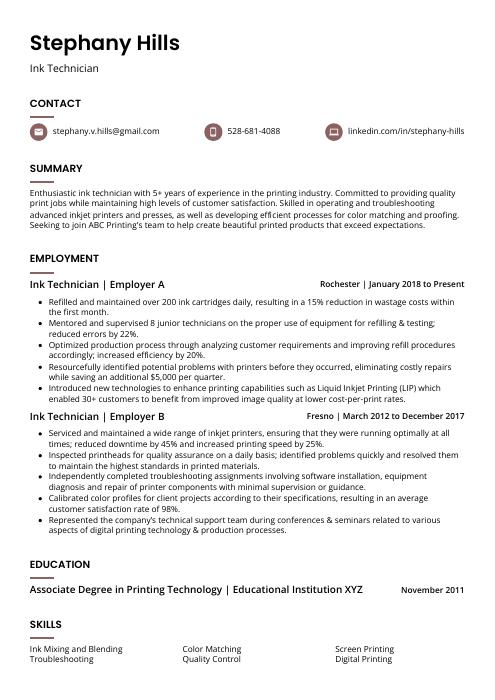

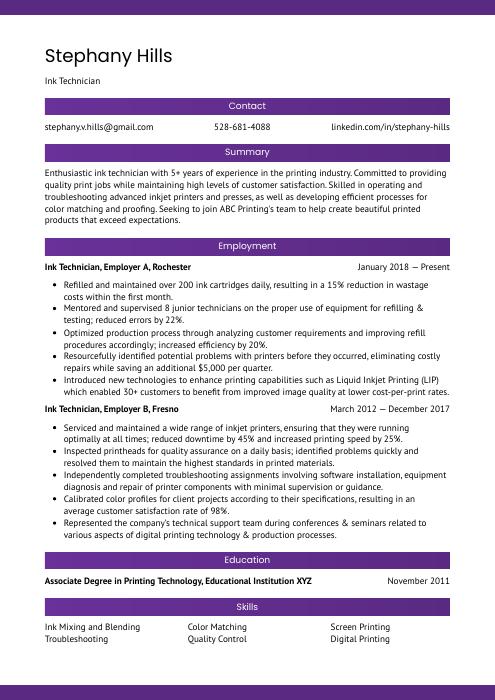

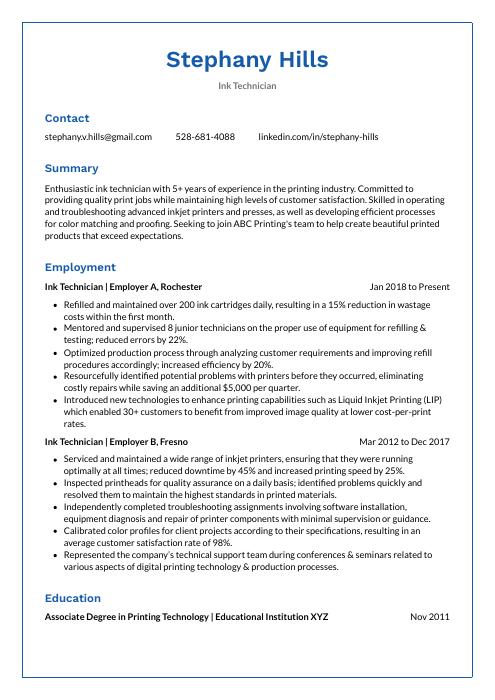

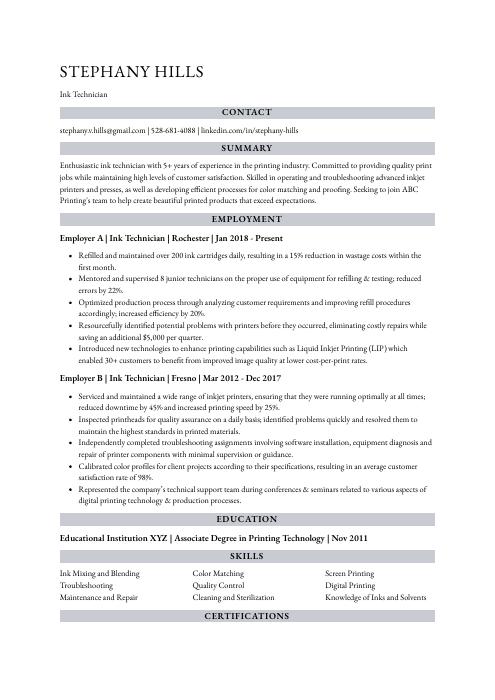

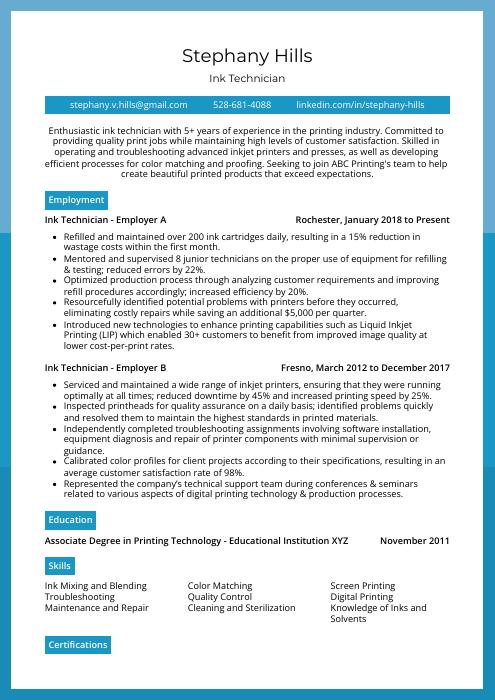

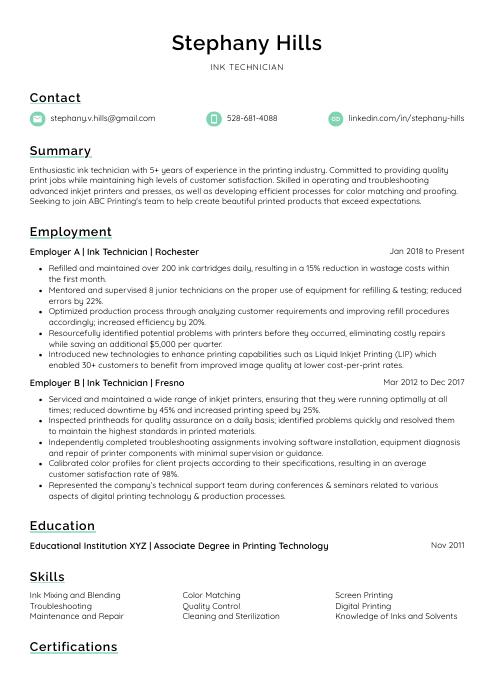

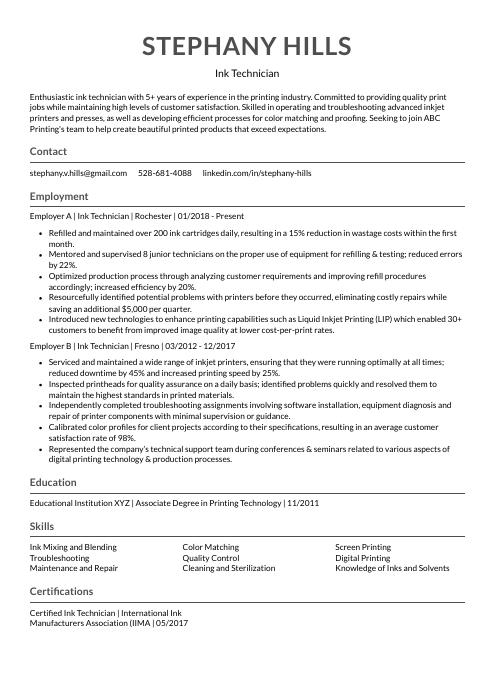

Ink Technician Resume Sample

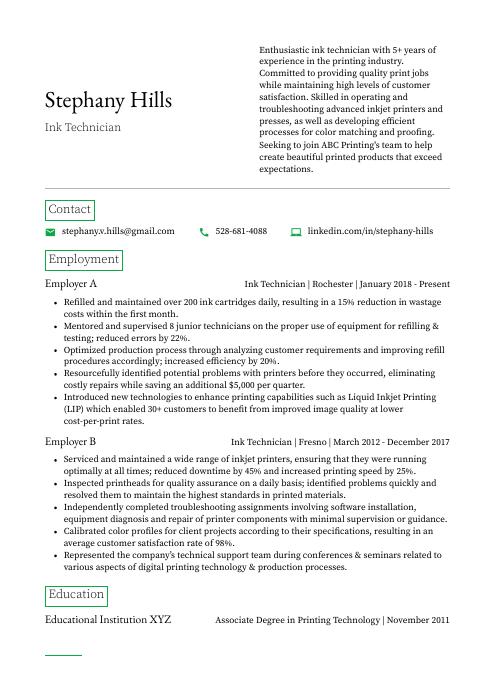

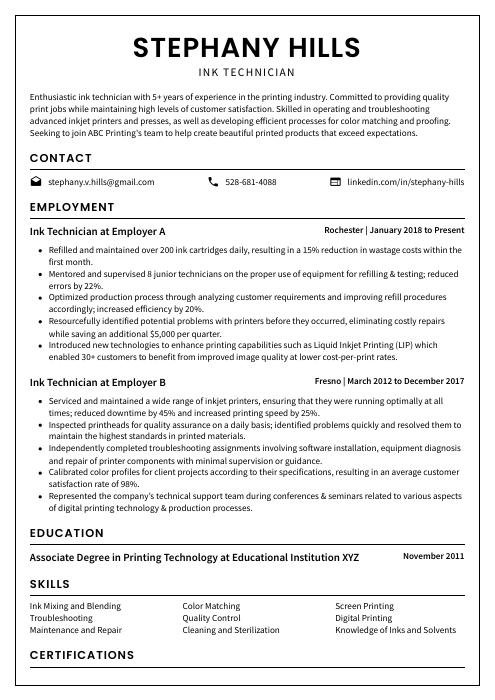

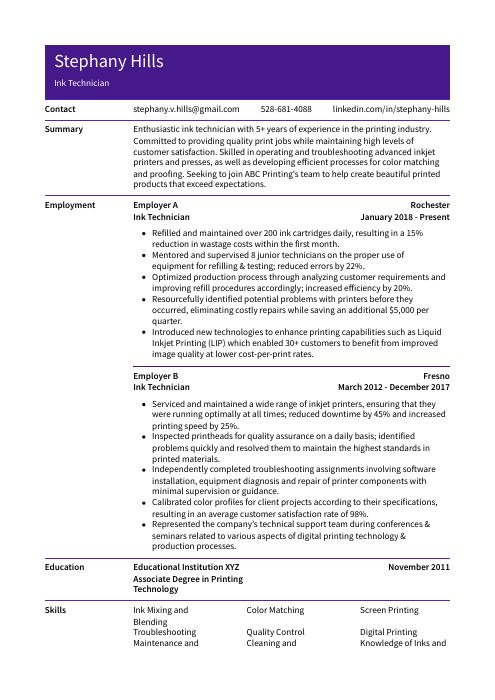

Stephany Hills

Ink Technician

[email protected]

528-681-4088

linkedin.com/in/stephany-hills

Summary

Enthusiastic ink technician with 5+ years of experience in the printing industry. Committed to providing quality print jobs while maintaining high levels of customer satisfaction. Skilled in operating and troubleshooting advanced inkjet printers and presses, as well as developing efficient processes for color matching and proofing. Seeking to join ABC Printing’s team to help create beautiful printed products that exceed expectations.

Experience

Ink Technician, Employer A

Rochester, Jan 2018 – Present

- Refilled and maintained over 200 ink cartridges daily, resulting in a 15% reduction in wastage costs within the first month.

- Mentored and supervised 8 junior technicians on the proper use of equipment for refilling & testing; reduced errors by 22%.

- Optimized production process through analyzing customer requirements and improving refill procedures accordingly; increased efficiency by 20%.

- Resourcefully identified potential problems with printers before they occurred, eliminating costly repairs while saving an additional $5,000 per quarter.

- Introduced new technologies to enhance printing capabilities such as Liquid Inkjet Printing (LIP) which enabled 30+ customers to benefit from improved image quality at lower cost-per-print rates.

Ink Technician, Employer B

Fresno, Mar 2012 – Dec 2017

- Serviced and maintained a wide range of inkjet printers, ensuring that they were running optimally at all times; reduced downtime by 45% and increased printing speed by 25%.

- Inspected printheads for quality assurance on a daily basis; identified problems quickly and resolved them to maintain the highest standards in printed materials.

- Independently completed troubleshooting assignments involving software installation, equipment diagnosis and repair of printer components with minimal supervision or guidance.

- Calibrated color profiles for client projects according to their specifications, resulting in an average customer satisfaction rate of 98%.

- Represented the company’s technical support team during conferences & seminars related to various aspects of digital printing technology & production processes.

Skills

- Ink Mixing and Blending

- Color Matching

- Screen Printing

- Troubleshooting

- Quality Control

- Digital Printing

- Maintenance and Repair

- Cleaning and Sterilization

- Knowledge of Inks and Solvents

Education

Associate Degree in Printing Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Ink Technician

International Ink Manufacturers Association (IIMA

May 2017

1. Summary / Objective

Your resume summary should be a brief but compelling overview of your experience as an ink technician. Highlight the most impressive aspects of your career, such as how you have improved production efficiency or reduced costs in the past. You could also mention any certifications and awards you have received related to ink technology, as well as any special skills that make you stand out from other applicants.

Below are some resume summary examples:

Driven ink technician with a strong background in the printing industry. Possesses extensive knowledge of color, print quality and troubleshooting techniques to ensure that each job meets customer specifications. Experienced working with various types of inks and solvents on digital, offset, flexo and gravure presses. Focused on maintaining safety standards while producing high-quality products at ABC Printing Solutions.

Energetic ink technician with 5+ years of experience in the printing industry. Experienced in maintaining and troubleshooting digital and offset presses, as well as operating a wide range of ink-mixing machines. At ABC Printing Company, developed an automated system to reduce labor by 30%. Received commendation from management for streamlining processes and increasing productivity while reducing costs significantly.

Committed ink technician with 5+ years of experience in textile printing. Skilled at operating and troubleshooting equipment, mixing colors accurately to meet customer requirements, and inspecting finished products for quality assurance. Seeking to join ABC as a color specialist where I can use my technical expertise to develop new processes that will increase productivity while maintaining high-quality standards.

Passionate ink technician with 8+ years of experience managing and troubleshooting printing equipment. Adept at maintaining a safe work environment while ensuring quality standards are met. At XYZ Printing, developed an ink-saving technique that reduced costs by 24% over two quarters. Seeking to leverage the same expertise to help ABC Corporation maximize efficiency and profitability in their production process.

Determined ink technician with over 8 years of experience in the production and maintenance of printing machinery. Skilled at troubleshooting, diagnosing, repairing, and maintaining offset presses to ensure smooth operation. At XYZ Company consistently achieved 100% customer satisfaction ratings by ensuring that jobs were completed on time and within budget. Successfully reduced downtime rate from 15% to 5%.

Accomplished ink technician with 5+ years of experience in the printing industry. Skilled at troubleshooting and maintaining a variety of inkjet, laser, and flexo machines for optimal performance to meet customer needs. Focused on increasing efficiency by 18% through process improvement initiatives while also reducing waste costs by 15%. Seeking to join ABC Printing Solutions as an Ink Technician.

Proficient ink technician with over 5 years of experience in ink mixing, formulation analysis, and process optimization. Demonstrated expertise in providing technical support to production operations while ensuring quality control standards are met. Seeking a role at ABC Company where I can implement my skillset and help ensure efficient production processes for the printing department.

Dependable ink technician with 5+ years of experience in the printing industry. Skilled in troubleshooting, maintenance and repair of all types of inkjet printers. At XYZ Printing Company, designed and implemented a new system for identifying printer failures quickly that enabled a 20% increase in productivity. Experienced working with various brands such as HP, Epson, Canon and Xerox.

2. Experience / Employment

In the experience/employment/work history section, you should list your job history in reverse chronological order, with the most recent role at the top.

Stick to bullet points when providing details on what you did and any results achieved. Doing so allows for easy reading by those who are reviewing your resume or CV. When writing these bullets, provide detail about what was done and the quantifiable results that were obtained.

For example, instead of saying “Mixed ink,” try something like this: “Developed new color formulations using a variety of pigments and dyes; improved consistency between batches by 20%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Operated

- Monitored

- Adjusted

- Troubleshot

- Inspected

- Calibrated

- Refilled

- Replaced

- Tested

- Cleaned

- Maintained

- Aligned

- Serviced

- Repaired

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Compiled and tested over 40 custom ink formulations and generated accurate reports, resulting in a 10% improvement of print quality.

- Formulated special printing inks using oil-based or water-soluble components; produced 500+ gallons per week while meeting stringent safety regulations and environmental standards.

- Participated actively in the development of new formulas for high performance offset lithography, flexographic and gravure printing that delivered superior colors on any type of substrate with minimal waste materials.

- Meticulously checked all raw ingredients & finished products for accuracy by measuring viscosity, color strength, pH level & other parameters to ensure maximum product consistency and replicability rate above 90%.

- Structured production schedules based on customer orders and communicated daily progress updates to supervisor; completed projects ahead of time by an average 25 hours each month without compromising quality standards.

- Operated a range of inkjet printers and associated machinery to produce high-quality printed products, resulting in a customer satisfaction increase of 25%.

- Efficiently inspected and tested printing equipment on an ongoing basis; identified defects quickly which reduced downtime by 10 hours per month.

- Repaired various types of printing machines with precision using hand tools, power tools and replacement parts; successfully restored functionality to all affected devices within 48 hours or less.

- Adjusted color density levels according to customer specifications for over 1,000 print jobs without fail over the course of a year; eliminated any need for reprints or corrections due to incorrect colors used.

- Assessed printer performance regularly utilizing specialized software programs that monitored speed, temperature & pressure levels as well as other technical parameters; optimized production processes accordingly which led to cost savings up to $500 per week in supplies needed for prints.

- Presented technical solutions to over 200 clients per quarter, increasing ink sales by 10%.

- Reorganized the inventory of inks and supplies, resulting in a 20% reduction of stockouts and improved customer service ratings.

- Diligently operated digital printing machines while ensuring that colors were accurately matched with swatch books; reduced misprints by 25%.

- Demonstrated advanced knowledge of various types of substrates used for offset and flexographic printing jobs; increased job completion rate by 15%.

- Troubleshot technical issues on production machinery such as rollers, feeder mechanisms and presses; repaired more than 75 faulty components within 4 hours each time on average.

- Streamlined ink mixture processes for 100+ jobs per day, leading to a 15% reduction in production time and saving the company $5,000 annually.

- Coordinated with other technicians to ensure that ink supplies were properly allocated and maintained; minimized shortages by 40%.

- Cleaned all equipment used for preparing the ink mixtures on a daily basis as per safety protocol, resulting in reduced risk of contamination and improved quality control standards overall.

- Proficiently operated various types of machinery related to mixing & measuring pigments/dyes within specified tolerances; generated accurate results 99% of the time which enabled smooth operations at all times.

- Improved mix consistency through analyzing color calibration records regularly while adjusting formulas accordingly; increased customer satisfaction rate by 17%.

- Replaced and maintained 10+ large-scale inkjet and laser printing machines daily, ensuring that all printer components were functioning correctly and at optimal speed.

- Expedited production time by 15%, resulting in increased output rate of over 500 printed items per hour without compromising quality.

- Reduced paper wastage by 25% through proper calibration of printers using advanced color management techniques and regularly troubleshooting errors in the system for better efficiency.

- Consistently monitored the performance of various digital presses to detect any issues with their operation; fixed mechanical problems within 2 hours on average before they could affect productivity or cause delays in delivery schedules.

- Utilized a wide range of specialized software solutions to ensure accurate reproduction and consistent results from each print job when working with high volume orders for customers across industries such as retail, advertising & publishing sectors.

- Competently monitored and adjusted ink mixing, color matching and printing processes to ensure optimal quality for all printed products; reduced product defects by 15%.

- Tested new inks on press sheets using densitometers, spectrophotometers and other measuring instruments; identified superior results with a particular brand of ink that saved $4,000 annually without compromising quality.

- Prepared charts & graphs to track print production costs as well as real-time data on overall levels of efficiency; implemented process improvements that led to an increase in productivity by 20%.

- Spearheaded the development of advanced methods for controlling moisture content throughout the entire printing process which resulted in improved adhesion rates across all substrates used at the facility.

- Developed best practices related to safe handling, disposal and storage of hazardous materials such as solvents and chemical waste generated during routine operations while maintaining strict compliance with environmental regulations at all times.

- Aligned and maintained over 100 inkjet printers and presses, ensuring that all equipment was in perfect working condition for producing high-quality prints.

- Developed innovative cost reduction strategies to improve efficiency of production; achieved savings of $5,000 per month on average through regular maintenance and repair activities.

- Achieved a 99% accuracy rate when mixing inks according to customer requirements while adhering to safety standards established by the company at all times.

- Revised existing procedures for cleaning off excess ink from printing plates between jobs which reduced changeover time by 15%.

- Actively participated in professional development sessions such as seminars related to industrial printing techniques; acquired new skills within three months period with minimal guidance or supervision required.

- Facilitated the successful operation of 10+ high-speed inkjet machines, increasing production capacity by 25% and reducing waste levels by 17%.

- Successfully trained 15 new employees in the safe use of all machinery while adhering to OSHA requirements; generated detailed reports on safety protocols for team members.

- Advised management on cost savings initiatives regarding dye & pigment usage, resulting in a $4,000 reduction in annual materials budget expenses.

- Maintained an accurate inventory record system encompassing 500 different colors and shades with weekly batch testing to ensure adherence to industry standards; reduced color variation errors by 30%.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual who is proficient in color matching, while the other may be looking for someone who has experience with a particular type of ink.

Therefore, it’s important to tailor your skills section according to each job you are applying for. This will help ensure that applicant tracking systems (which many employers use) can recognize the relevant keywords and pass on your resume accordingly.

In addition to listing these skills here, you should also discuss them further in other sections such as the summary or experience section so that recruiters know exactly what kind of expertise you possess.

Below is a list of common skills & terms:

- Cleaning and Sterilization

- Color Matching

- Digital Printing

- Ink Mixing and Blending

- Knowledge of Inks and Solvents

- Maintenance and Repair

- Quality Control

- Safety Protocols

- Screen Printing

- Troubleshooting

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, include an education section below the resume objective. However, if you have multiple years of experience as an ink technician and plenty to showcase, it’s perfectly fine to omit the education section altogether.

If including a formal education is necessary for the job role or if you choose to include one anyway, try mentioning courses related specifically to ink technology that may be relevant for this position.

Associate Degree in Printing Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They can be used to show that you have been tested and certified by an accredited organization, thus making you more qualified than other applicants.

If the job advert mentions any specific certifications or qualifications, make sure to include them on your resume as they will help prove that you are the right candidate for the position.

Certified Ink Technician

International Ink Manufacturers Association (IIMA

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Stephany Hills, this would be Stephany-Hills-resume.pdf or Stephany-Hills-resume.docx.

7. Cover Letter

Writing a cover letter is an important step in any job application process. It’s a great way to show how you can add value to the role and why your skills make you the perfect fit for it.

Cover letters are usually made up of 2 to 4 paragraphs that provide more detail about who you are, what experience and qualifications you have, as well as other relevant information such as your availability or desired salary range. Although they may not be required by all employers, writing one is highly recommended if possible.

Below is an example cover letter:

Dear Alexandrea,

I am writing to apply for the open Ink Technician position at your company. With a Bachelor’s degree in Chemistry and three years of experience working in a printing lab, I have the necessary qualifications for this role.

In my previous job, I was responsible for mixing ink colors according to customer specifications and ensuring that the color matched what was requested. I also worked closely with the press operators to ensure that the ink was applied correctly and troubleshoot any issues that arose. In addition, I kept detailed records of all ink batches mixed and maintained inventory levels of supplies.

I am confident that I can be an asset to your team and contribute to your bottom line. My attention to detail, knowledge of color theory, and ability to work well under pressure are just some of the skills that would enable me to excel in this role. Additionally, my experience with both offset and digital printing presses makes me uniquely qualified for this position.

I look forward to speaking with you about this opportunity soon. Thank you for your time and consideration!

Sincerely,

Stephany

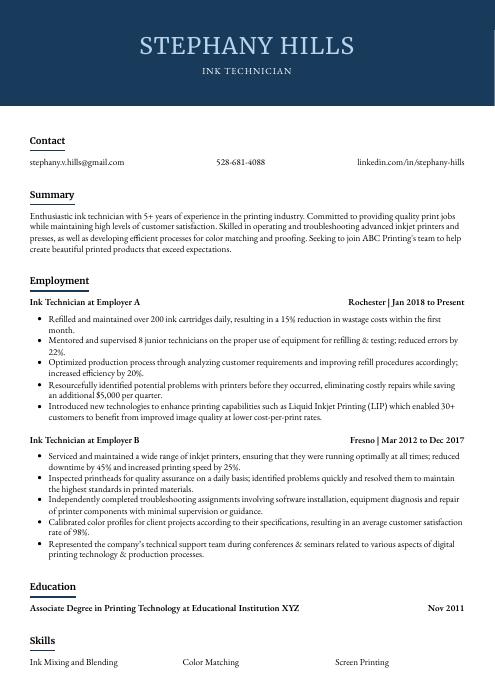

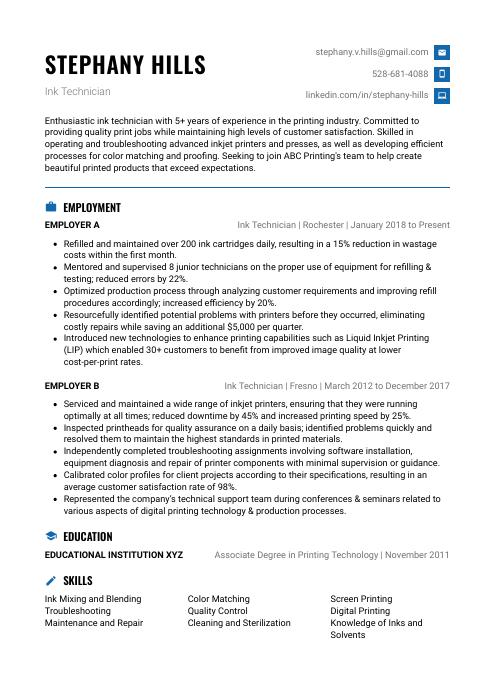

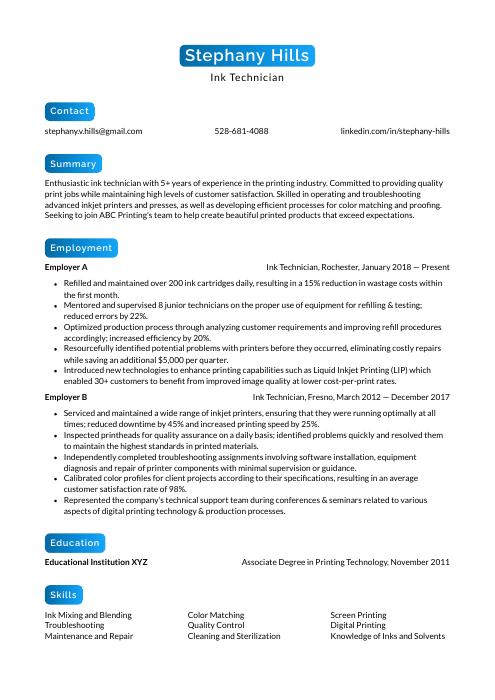

Ink Technician Resume Templates

Ocelot

Ocelot Dugong

Dugong Axolotl

Axolotl Gharial

Gharial Hoopoe

Hoopoe Fossa

Fossa Jerboa

Jerboa Markhor

Markhor Bonobo

Bonobo Echidna

Echidna Kinkajou

Kinkajou Numbat

Numbat Rhea

Rhea Lorikeet

Lorikeet Indri

Indri Quokka

Quokka Saola

Saola Cormorant

Cormorant Pika

Pika Rezjumei

Rezjumei