Hull Maintenance Technician Resume Guide

Hull Maintenance Technicians are responsible for maintaining the exterior of a ship, including upkeep and repair. They inspect vessels to detect corrosion or other damages, clean and paint the hulls as necessary, apply sealants or coatings to protect against water damage and erosion, identify any structural flaws in need of repairs, make minor repairs onsite when possible and coordinate with contractors for larger projects.

You’re a natural when it comes to hull maintenance, and any shipyard would benefit from your expertise. To make sure employers know who you are and what you can do, you must create an eye-catching resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

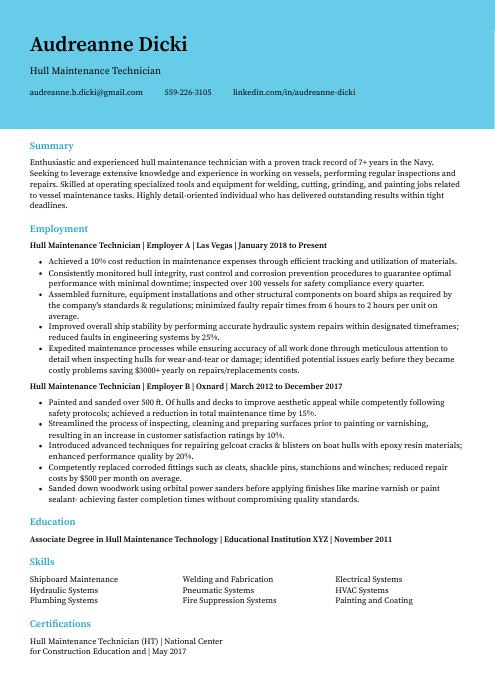

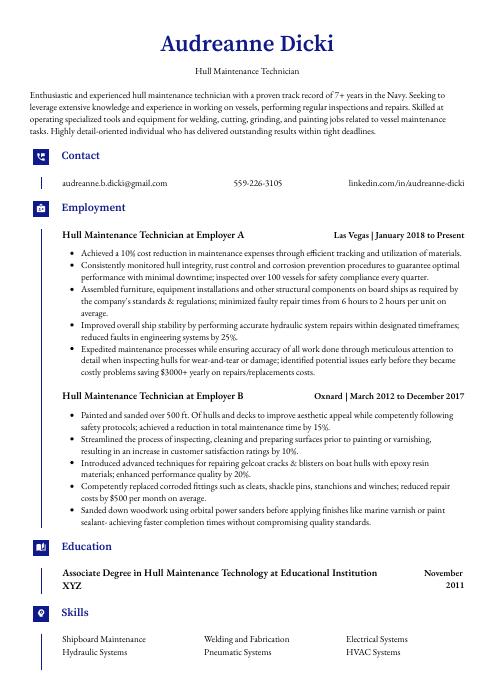

Hull Maintenance Technician Resume Sample

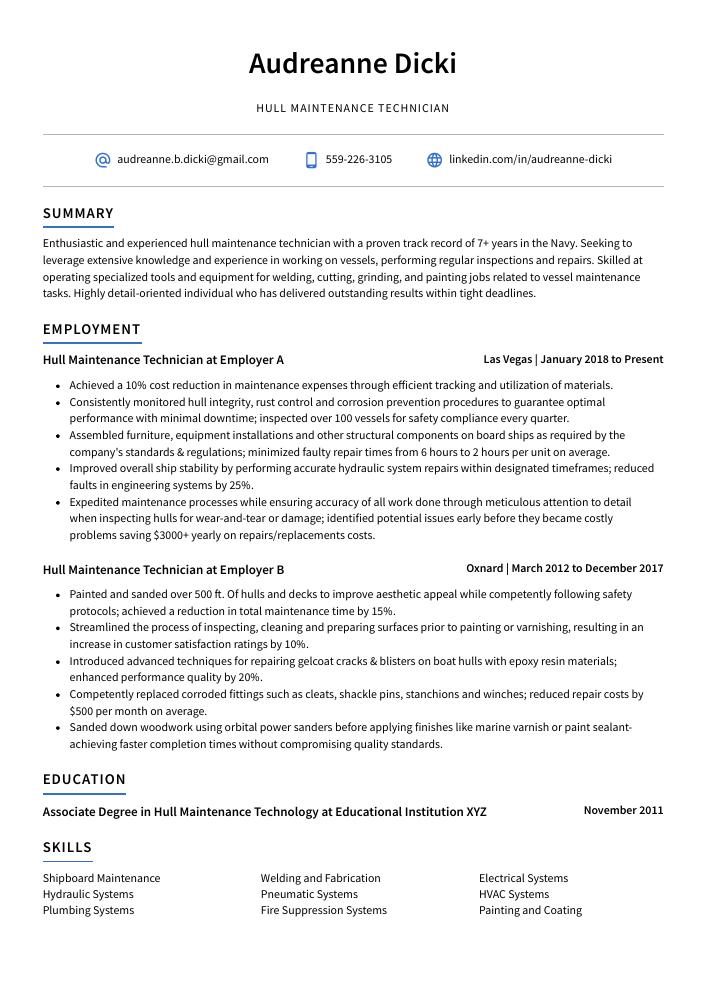

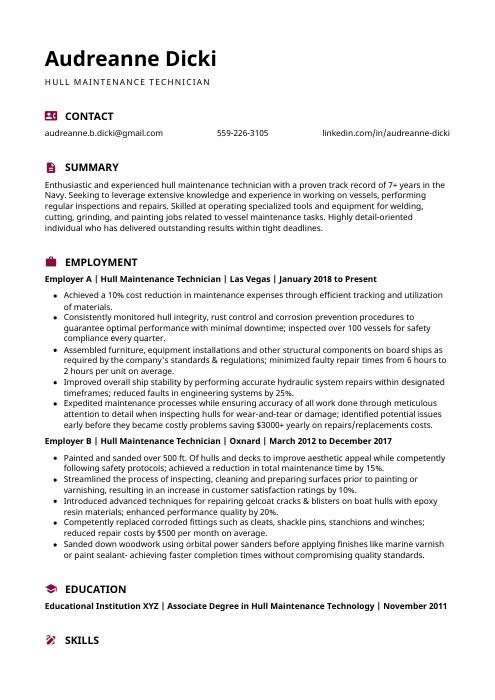

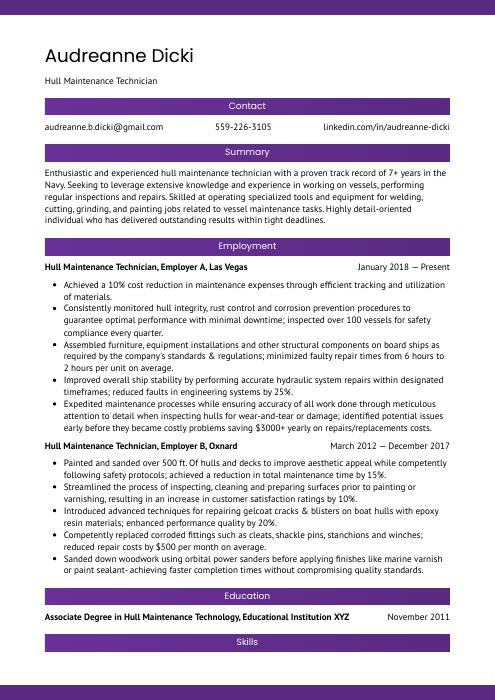

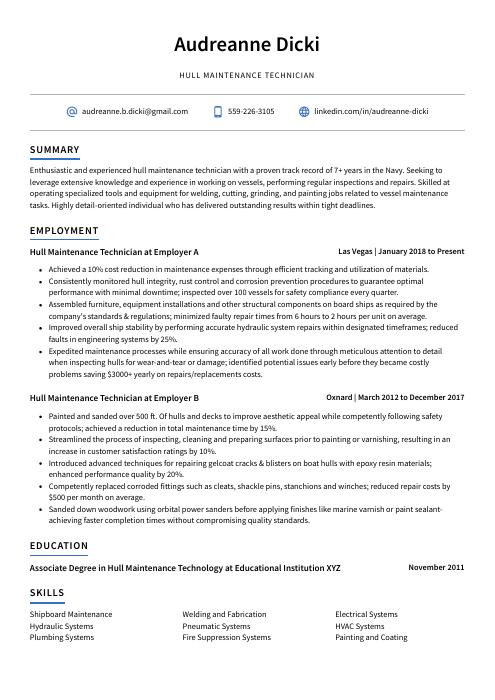

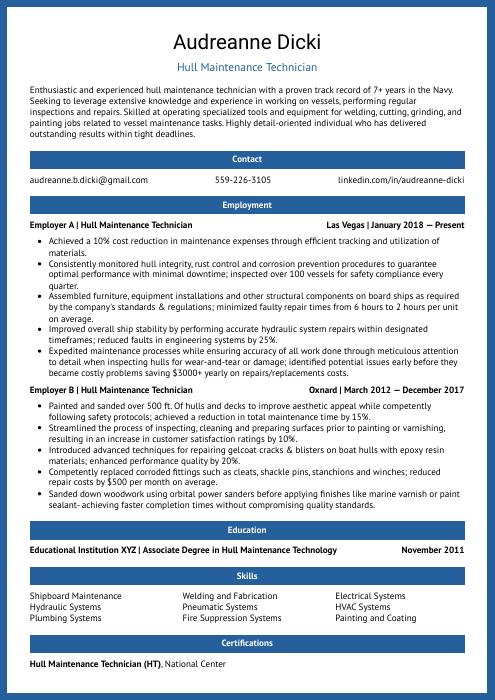

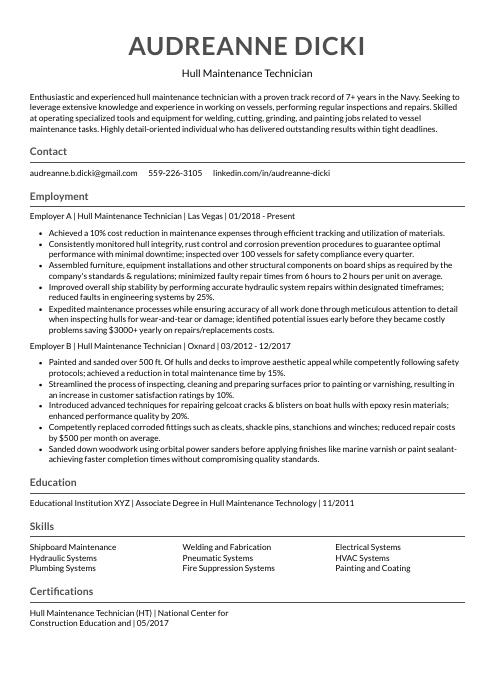

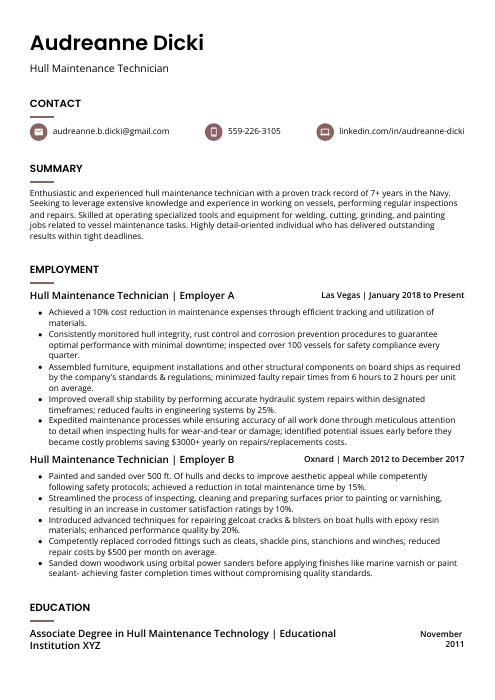

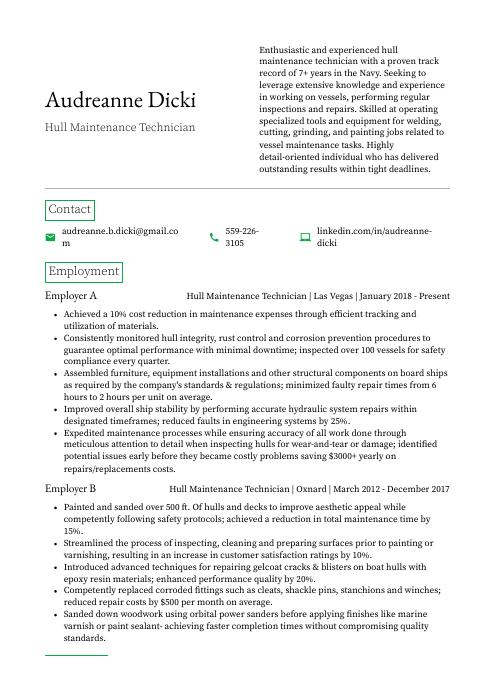

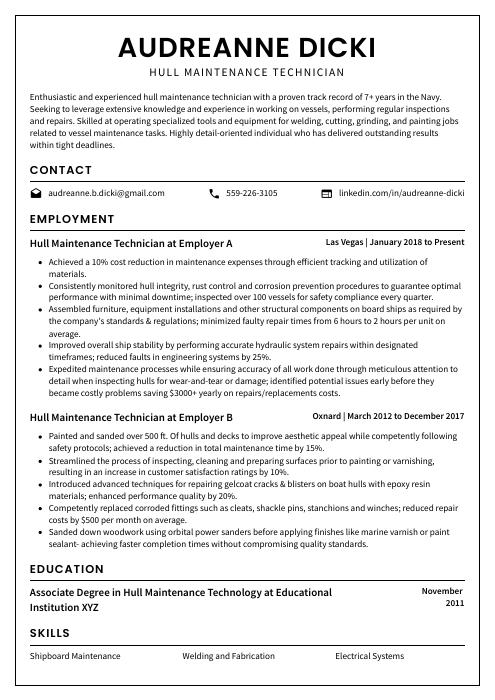

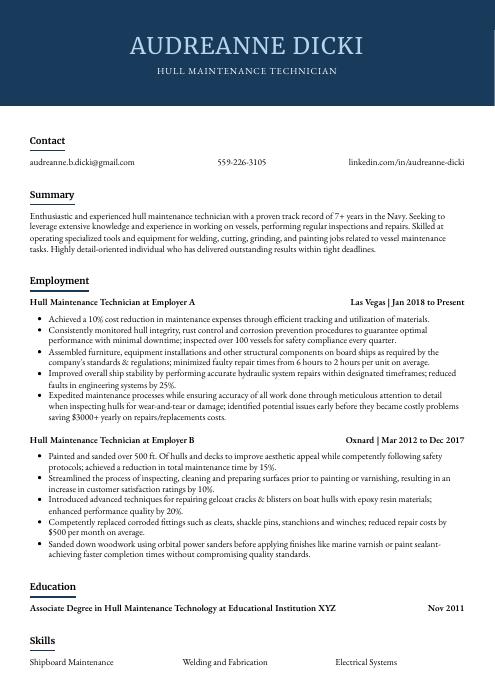

Audreanne Dicki

Hull Maintenance Technician

[email protected]

559-226-3105

linkedin.com/in/audreanne-dicki

Summary

Enthusiastic and experienced hull maintenance technician with a proven track record of 7+ years in the Navy. Seeking to leverage extensive knowledge and experience in working on vessels, performing regular inspections and repairs. Skilled at operating specialized tools and equipment for welding, cutting, grinding, and painting jobs related to vessel maintenance tasks. Highly detail-oriented individual who has delivered outstanding results within tight deadlines.

Experience

Hull Maintenance Technician, Employer A

Las Vegas, Jan 2018 – Present

- Achieved a 10% cost reduction in maintenance expenses through efficient tracking and utilization of materials.

- Consistently monitored hull integrity, rust control and corrosion prevention procedures to guarantee optimal performance with minimal downtime; inspected over 100 vessels for safety compliance every quarter.

- Assembled furniture, equipment installations and other structural components on board ships as required by the company’s standards & regulations; minimized faulty repair times from 6 hours to 2 hours per unit on average.

- Improved overall ship stability by performing accurate hydraulic system repairs within designated timeframes; reduced faults in engineering systems by 25%.

- Expedited maintenance processes while ensuring accuracy of all work done through meticulous attention to detail when inspecting hulls for wear-and-tear or damage; identified potential issues early before they became costly problems saving $3000+ yearly on repairs/replacements costs.

Hull Maintenance Technician, Employer B

Oxnard, Mar 2012 – Dec 2017

- Painted and sanded over 500 ft. Of hulls and decks to improve aesthetic appeal while competently following safety protocols; achieved a reduction in total maintenance time by 15%.

- Streamlined the process of inspecting, cleaning and preparing surfaces prior to painting or varnishing, resulting in an increase in customer satisfaction ratings by 10%.

- Introduced advanced techniques for repairing gelcoat cracks & blisters on boat hulls with epoxy resin materials; enhanced performance quality by 20%.

- Competently replaced corroded fittings such as cleats, shackle pins, stanchions and winches; reduced repair costs by $500 per month on average.

- Sanded down woodwork using orbital power sanders before applying finishes like marine varnish or paint sealant- achieving faster completion times without compromising quality standards.

Skills

- Shipboard Maintenance

- Welding and Fabrication

- Electrical Systems

- Hydraulic Systems

- Pneumatic Systems

- HVAC Systems

- Plumbing Systems

- Fire Suppression Systems

- Painting and Coating

Education

Associate Degree in Hull Maintenance Technology

Educational Institution XYZ

Nov 2011

Certifications

Hull Maintenance Technician (HT)

National Center for Construction Education and

May 2017

1. Summary / Objective

Your resume summary should be a concise overview of your experience and qualifications as a Hull Maintenance Technician. Include details such as the types of vessels you have worked on, any certifications or licenses you possess, and how many years of experience in this field you have. You can also mention any specialized training that has helped hone your skillset, such as welding or metal fabrication courses.

Below are some resume summary examples:

Talented Hull Maintenance Technician with 8+ years of experience in ship maintenance and repair. Experienced in inspecting, cleaning, maintaining and repairing parts of a ship’s hull including the decking, bottom paint coatings and welding repairs. At XYZ Shipyards established an effective preventative maintenance program that reduced downtime by 50%. Recognized for excellent problem-solving skills to identify potential issues before they become costly problems.

Professional hull maintenance technician with 5+ years of experience in the maritime industry. Skilled in inspecting, repairing and maintaining underwater structures to ensure optimal performance. Proven track record of providing on-time and cost effective services while ensuring compliance with safety regulations. Seeking to join ABC Shipyard as a Hull Maintenance Technician where I can utilize my expertise for the benefit of your organization.

Diligent and safety-conscious Hull Maintenance Technician with 5+ years of experience inspecting, repairing, and maintaining the hulls of large vessels. Looking to join ABC Marine’s team as a HMT to ensure that all ships remain in optimal condition at sea. Experienced in developing detailed reports on repairs needed or completed on ship hulls; oversaw an average turnaround time reduction from 4 days to 2 days for vessel inspections.

Driven Hull Maintenance Technician with over 6 years of experience in the maritime industry. Proven ability to assist in a variety of hull maintenance and repair operations, including hull cleaning, painting and corrosion control. Highly knowledgeable on safety regulations and protocols for hazardous materials handling. Committed to maintaining excellent performance standards while working within tight deadlines at ABC Shipyard.

Well-rounded hull maintenance technician with a decade of experience ensuring the safe and reliable operation of large vessels. Experienced in welding, cutting, grinding techniques, as well as surface preparation and painting. Skilled in troubleshooting complex technical systems under pressure to identify faults or malfunctions. At XYZ have successfully maintained hulls for over 20 ships without any major incidents or accidents.

Passionate and knowledgeable Hull Maintenance Technician with 5+ years of experience in ship repair and maintenance. Skilled at performing a variety of tasks related to hull preservation, steel fabrication, welding and cutting operations. Experienced in overseeing the proper use of safety equipment while working on ships. Proven record of success in maintaining high standards for workmanship quality on board vessels.

Amicable and hardworking Hull Maintenance Technician with 7+ years of experience in the Navy. Possess comprehensive knowledge on underwater welding and repairs, as well as inspection techniques and procedures. Skilled at operating a number of power tools to complete complex tasks efficiently. Looking to join ABC Tech team to further develop skillset while maintaining quality standards for all assigned projects.

Reliable and detail-oriented Hull Maintenance Technician with 8+ years of experience in ship repair and maintenance. Experienced in performing a variety of hull maintenance tasks, including painting and coating application, sandblasting, welding, fabrication and cutting operations. Seeking to join ABC Shipyard as a Hull Maintenance Technician to contribute my expertise towards the safe operation of ships.

2. Experience / Employment

The work history/experience section is your opportunity to provide details on the roles you have held. It should be written in reverse chronological order, which means that your most recent job is listed first.

When providing information about what you did in each role, use bullet points and include as much detail as possible. This allows the reader to quickly digest what you are saying and understand how it relates to their organization’s needs.

For example, instead of saying “Performed hull maintenance,” you could say, “Inspected vessels for corrosion damage twice a week; identified areas requiring repair or replacement and submitted detailed reports outlining needed repairs.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Repaired

- Installed

- Welded

- Operated

- Tested

- Troubleshot

- Aligned

- Calibrated

- Fabricated

- Maintained

- Assembled

- Sanded

- Painted

- Replaced

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Welded structural components in steel and aluminum hulls of ships, boats, barges and other watercraft; reduced welding time by 15% over a 3-month period.

- Calibrated engines to ensure maximum efficiency when operating at full power; improved fuel consumption rate by 12%.

- Utilized advanced tools such as plasma cutters, grinders & soldering torches to repair damaged ship hulls while following safety protocols strictly; completed 11 maintenance projects within 4 months without incident or injury.

- Efficiently managed repairs on 8 sea vessels while ensuring that all defects were rectified according to industry standards and regulations; saved an average of $7000 per project in terms of labor costs.

- Demonstrated expertise in the installation of navigation systems including navigational aids (NAVAIDS), radar units & global positioning system (GPS) receivers for marine applications with minimal disruption to operations onboard shipyard crafts/vessels.

- Prepared and maintained ship hulls and related components, ensuring compliance with all regulatory requirements; reduced average repair time by 20%.

- Optimized systems performance through routine inspections of the propulsion system, steering gear and other key equipment; identified potential issues before they caused delays or operational losses.

- Tested fuel levels, lubrication oil pressure, bearing temperatures and other technical indicators to ensure optimal functioning of machinery onboard vessels.

- Reliably serviced underwater ventilation systems for engine rooms according to safety protocols; successfully completed over 500 maintenance projects in 3 years without any accidents or incidents reported.

- Coordinated a team of 10 technicians during repairs on dry docks and provided guidance when necessary; completed complex tasks within budget 4 out of 5 times while meeting customer deadlines every time.

- Facilitated the maintenance of the hulls and masts of over 100 boats, increasing their seaworthiness and overall performance by 15%.

- Advised on safety hazards to ensure that all vessels were in compliance with maritime regulations; successfully reduced vessel damage incidents by 20%.

- Accurately conducted inspections on a variety of marine engines, propellers, steering systems & rudders for any signs of wear or corrosion within 1 hour per boat.

- Aligned shafting components as needed to reduce engine vibrations during operation; saved clients an estimated $5,000 worth in repairs due to early detection & prevention efforts.

- Installed new pumps and other equipment onboard vessels while ensuring proper connection between hoses and pipes; completed jobs 10% faster than average industry standards without compromising quality outcomes.

- Troubleshot and repaired hull-related issues on over 30 vessels, resulting in a 16% reduction of maintenance downtime.

- Mentored and trained 7 junior technicians on key elements of hull maintenance operations; improved team performance by 20%.

- Meticulously inspected the coatings and surfaces of ships’ exteriors to ensure they continued to meet safety regulations, while reducing corrosion cases by 10%.

- Represented the company at 5 international conferences & seminars as a subject matter expert on shipbuilding technology, promoting industry best practices and standards effectively.

- Developed and implemented new inspection protocols for vessel interiors that reduced repair costs by 25%, saving an estimated $20,000 annually for the organization.

- Spearheaded the maintenance and repair of hulls on 10+ vessels per week, confidently troubleshooting issues with plumbing, electrical systems and machinery to ensure optimal performance.

- Replaced faulty parts in the vessel’s engines and other mechanical components to reduce breakdown frequency by 20%.

- Confidently inspected, serviced & repaired various types of boats including yacht, sailboats and motorboats; completed all projects within allocated budget limits.

- Fabricated customized equipment for specific boat models using advanced welding techniques such as MIG/TIG welding; improved production rate by 30%.

- Participated in five successful salvage operations involving sunken ships over a 6 month period; successfully salvaged items worth $200K+.

- Structured and maintained the hull of over 150 vessels, ensuring that all surfaces were sanded and painted to industry standards; reduced repair costs by 15%.

- Proficiently used power tools such as grinders, drills and saws to perform repairs on steel or fiberglass structures including bulkheads, decks and cabins; completed projects within established timeline requirements.

- Inspected underwater ship hulls for damage using specialized equipment like sonar systems and video cameras; identified 10+ major structural issues with ships in need of immediate attention before any further damage occurred.

- Compiled detailed reports outlining each vessel’s maintenance needs after completing every inspection which enabled a quicker turnaround time between routine checks onboard ships at sea.

- Repaired damaged areas of boat hulls with epoxy resin mixtures while following safety protocols outlined by the Occupational Safety & Health Administration (OSHA).

- Actively operated a variety of power and hand tools to clean, repair, replace and upgrade hulls on boats; increased safety standards by 20% while reducing costs by $2,000 in the last year.

- Revised existing maintenance plans for over 50 vessels according to customer specifications and industry regulations; completed all tasks within agreed-upon timeframes with zero errors or complaints.

- Formulated detailed inspection reports after assessing the condition of boat hulls; identified necessary repairs/upgrades immediately before they impacted performance or became hazardous issues.

- Maintained accurate records of routine inspections & quarterly checkups on each vessel’s hull integrity as per company guidelines; helped lower total downtime due to mechanical failures significantly (by 10%).

- Performed preventative maintenance operations such as sanding down surfaces, applying epoxy coatings & paint jobs efficiently and effectively in order to extend lifespan of boat structures up to 6 months longer than previously achieved results.

- Effectively assessed and maintained the hulls of 15+ vessels per month, ensuring that all abrasion, corrosion or damage was immediately repaired to prevent further deterioration.

- Reorganized maintenance records for 100+ vessels; tracked their performance data over a two-year period and identified areas for improvement in order to reduce future repair costs by 25%.

- Presented detailed monthly reports on vessel inspections, outlining actions taken and recommending additional repair or replacement options where necessary; led team meetings with colleagues covering safety guidelines & best practices during repairs/maintenance operations.

- Reduced downtime of fleet vehicles due to thorough maintenance checks conducted once every 6 months; implemented preventive measures such as greasing fittings/bearings which improved overall efficiency across the board by 17%.

- Installed new parts onto existing hull structures according to manufacturer’s specifications while adhering strictly to industry standards & regulatory requirements at all times; completed projects ahead of schedule consistently without compromising quality control standards in any way.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC might require a technician to be familiar with the repair of steel hulls, while Organization XYZ may need someone who is experienced in using polyurethane paints.

It’s essential to tailor your resume skills section for each job that you apply for because employers often use applicant tracking systems (ATS). These programs scan resumes for certain keywords and characteristics before passing them on to human recruiters.

In addition to simply listing relevant skills here, you should also elaborate on how they have been applied in past roles or projects. Doing this will help demonstrate why you are an ideal candidate and increase your chances of being shortlisted.

Below is a list of common skills & terms:

- Corrosion Control

- Electrical Systems

- Fire Suppression Systems

- HVAC Systems

- Hydraulic Systems

- Painting and Coating

- Plumbing Systems

- Pneumatic Systems

- Shipboard Maintenance

- Welding and Fabrication

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, it is important to include an education section below your resume objective. However, if you have significant work experience with multiple employers that demonstrate a wide range of responsibilities related to the hull maintenance technician role, omitting the education section may be acceptable.

If including an education section is necessary, try to mention courses and subjects relevant to the job you are applying for such as welding or engineering principles.

Associate Degree in Hull Maintenance Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to a potential employer that you have the knowledge and expertise necessary for the job. They also show that you are committed to staying up-to-date on industry trends and best practices.

Including certifications in your resume is an excellent way of showing employers that you are qualified for the position, as well as demonstrating your dedication to professional development. Be sure to list any relevant certifications or courses taken so hiring managers can easily see them at a glance.

Hull Maintenance Technician (HT)

National Center for Construction Education and

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Audreanne Dicki, this would be Audreanne-Dicki-resume.pdf or Audreanne-Dicki-resume.docx.

7. Cover Letter

Writing a cover letter is an opportunity to show potential employers why you are the best fit for a role. It is usually composed of 2 to 4 paragraphs and provides additional information that cannot be found in your resume.

A cover letter can be used as a way to make yourself stand out from other applicants and give recruiters more insight into who you are as a professional. Although not always required, submitting one with your job application will certainly increase your chances of success.

Below is an example cover letter:

Dear Floy,

I am writing to apply for the Hull Maintenance Technician position with your company. With over 10 years of experience in the maritime industry and a passion for working on boats, I am confident I would be a valuable asset to your team.

In my current role as Hull Maintenance Technician with ABC Maritime, I am responsible for performing all aspects of hull maintenance and repair, from painting and varnishing to gelcoat repair and fiberglass work. I have also developed strong relationships with local marinas and suppliers, which has helped me get discounts on materials and services that benefit my employer.

In addition to my hands-on experience, I also have a degree in Marine Engineering Technology from XYZ University. This education has given me a strong foundation in boat design, construction, and repairs that complements my practical skills.

I am excited about the opportunity to bring my skills and experience to your company as part of the Hull Maintenance Technician team. Thank you for your time and consideration; I look forward to hearing from you soon.

Sincerely,

Audreanne

Hull Maintenance Technician Resume Templates

Pika

Pika Lorikeet

Lorikeet Kinkajou

Kinkajou Dugong

Dugong Gharial

Gharial Saola

Saola Numbat

Numbat Hoopoe

Hoopoe Echidna

Echidna Jerboa

Jerboa Axolotl

Axolotl Markhor

Markhor Ocelot

Ocelot Indri

Indri Fossa

Fossa Quokka

Quokka Cormorant

Cormorant Bonobo

Bonobo Rhea

Rhea Rezjumei

Rezjumei