Equipment Maintenance Technician Resume Guide

Equipment maintenance technicians are responsible for the upkeep of a variety of equipment and machinery. They inspect, repair, maintain and install new or existing systems to ensure that they are functioning correctly and safely. Additionally, these professionals diagnose problems with malfunctioning components in order to determine appropriate solutions.

Your knowledge of equipment maintenance is unparalleled. But hiring managers don’t know about your technical expertise and experience, so you must write a resume that outlines your qualifications in an eye-catching way.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

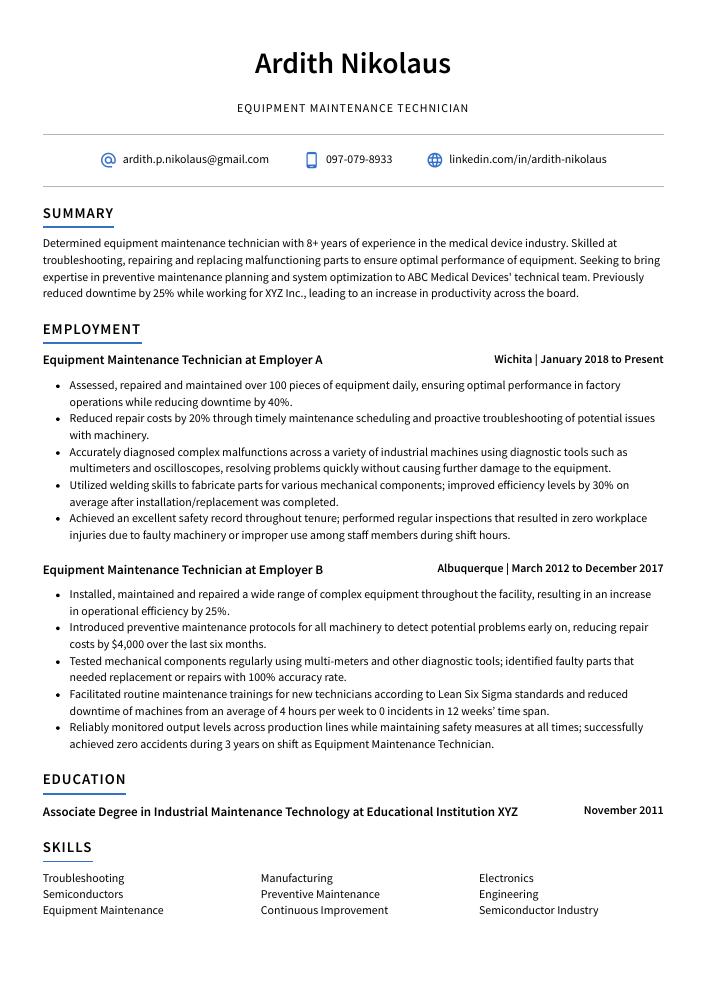

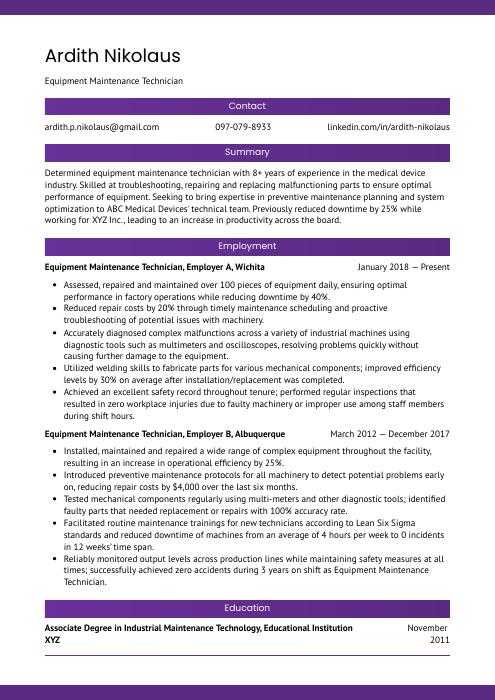

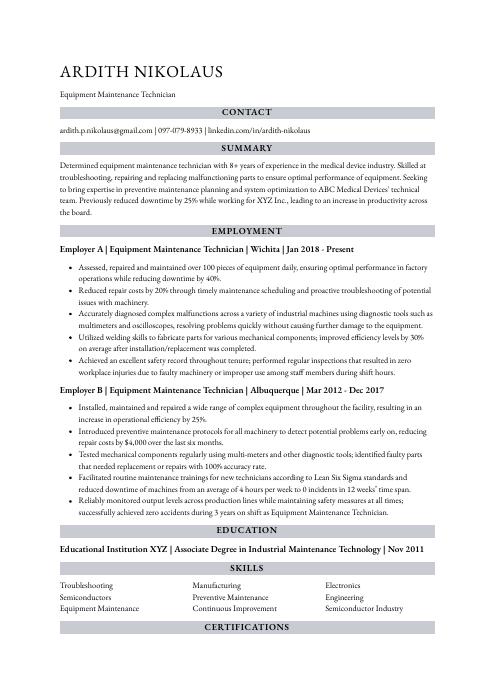

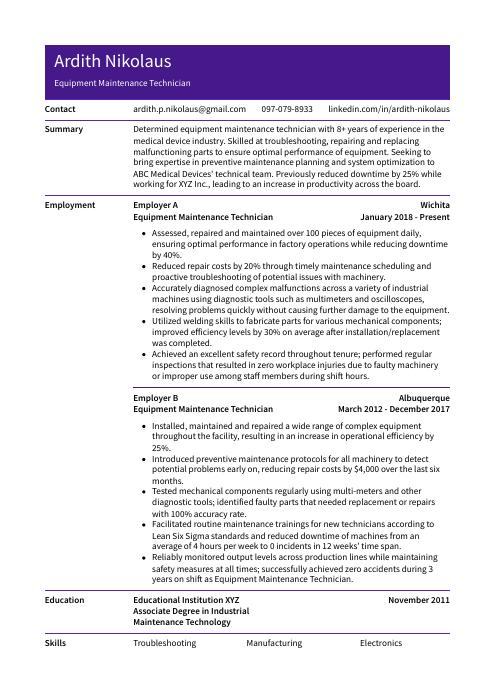

Equipment Maintenance Technician Resume Sample

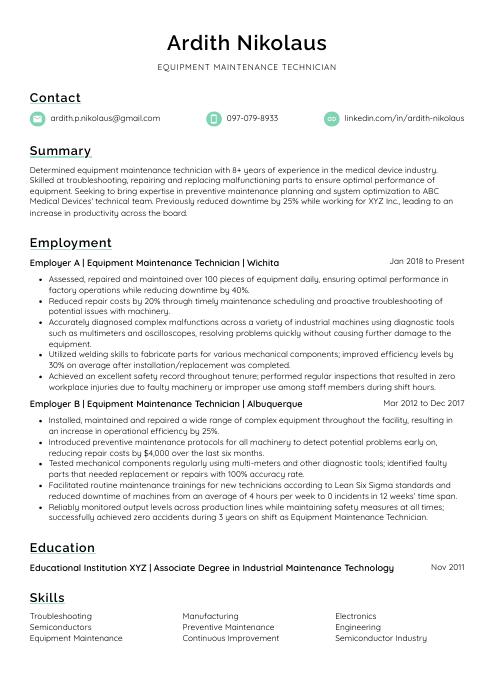

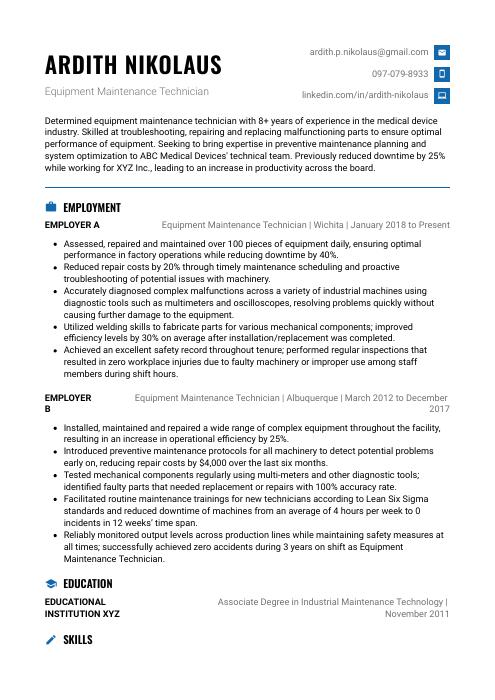

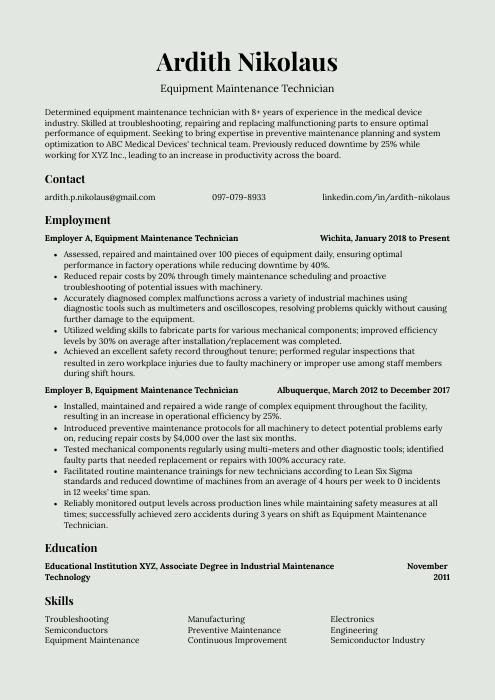

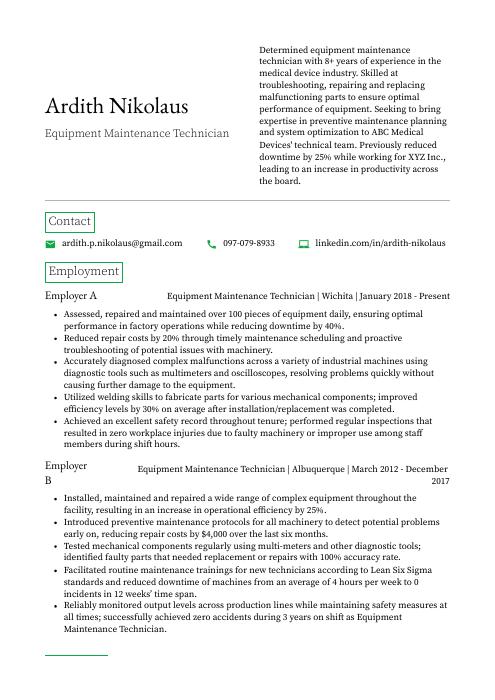

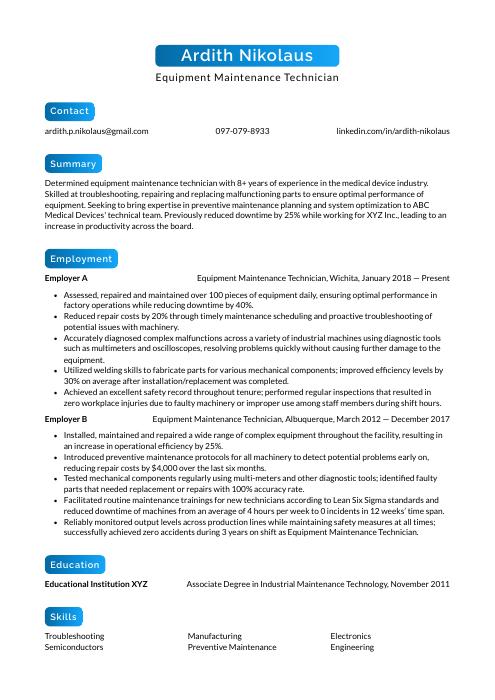

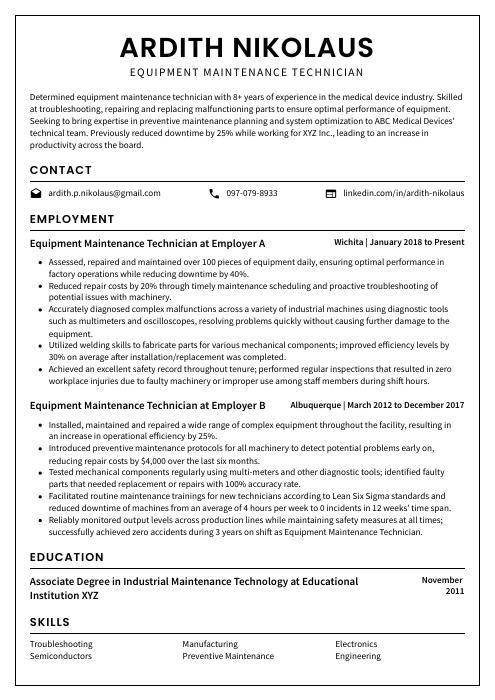

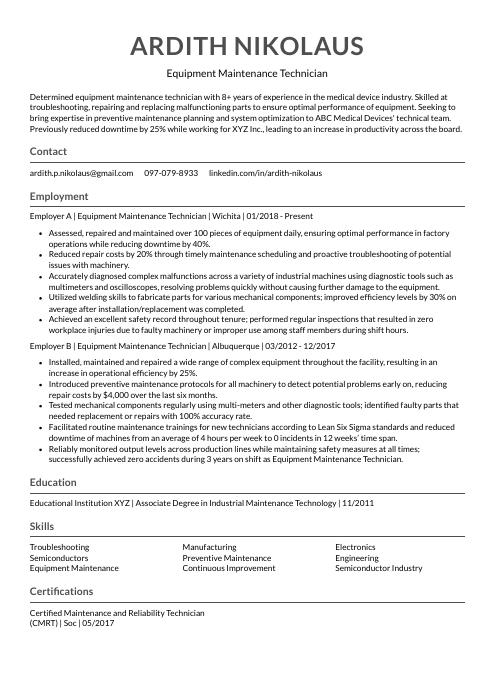

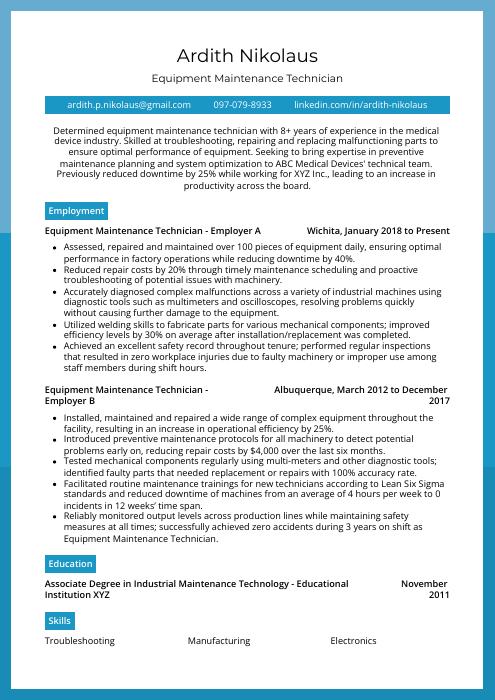

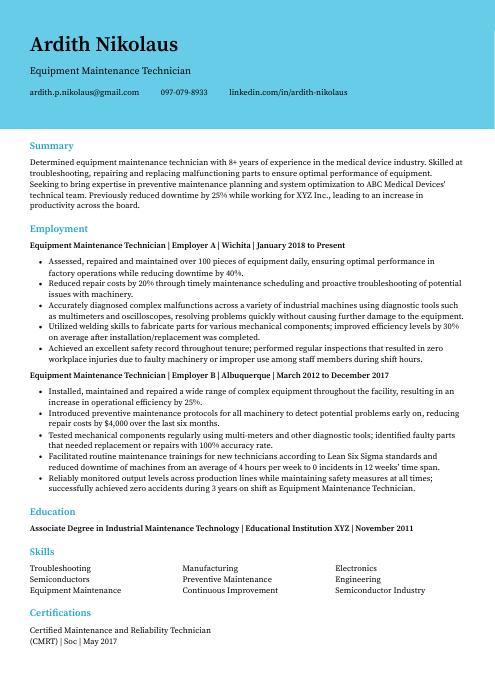

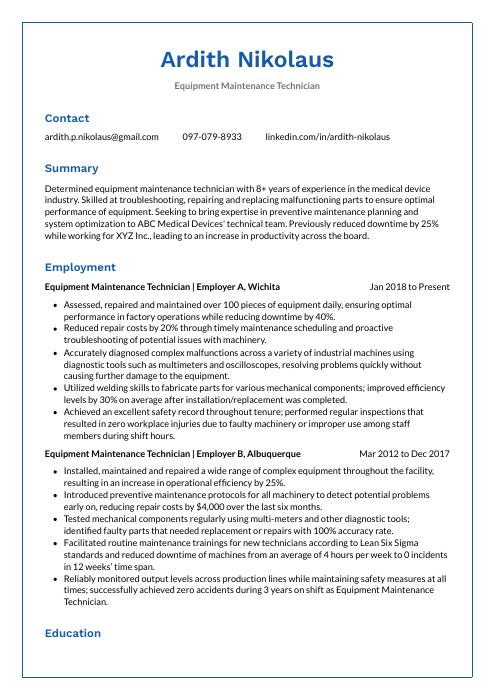

Ardith Nikolaus

Equipment Maintenance Technician

[email protected]

097-079-8933

linkedin.com/in/ardith-nikolaus

Summary

Determined equipment maintenance technician with 8+ years of experience in the medical device industry. Skilled at troubleshooting, repairing and replacing malfunctioning parts to ensure optimal performance of equipment. Seeking to bring expertise in preventive maintenance planning and system optimization to ABC Medical Devices’ technical team. Previously reduced downtime by 25% while working for XYZ Inc., leading to an increase in productivity across the board.

Experience

Equipment Maintenance Technician, Employer A

Wichita, Jan 2018 – Present

- Assessed, repaired and maintained over 100 pieces of equipment daily, ensuring optimal performance in factory operations while reducing downtime by 40%.

- Reduced repair costs by 20% through timely maintenance scheduling and proactive troubleshooting of potential issues with machinery.

- Accurately diagnosed complex malfunctions across a variety of industrial machines using diagnostic tools such as multimeters and oscilloscopes, resolving problems quickly without causing further damage to the equipment.

- Utilized welding skills to fabricate parts for various mechanical components; improved efficiency levels by 30% on average after installation/replacement was completed.

- Achieved an excellent safety record throughout tenure; performed regular inspections that resulted in zero workplace injuries due to faulty machinery or improper use among staff members during shift hours.

Equipment Maintenance Technician, Employer B

Albuquerque, Mar 2012 – Dec 2017

- Installed, maintained and repaired a wide range of complex equipment throughout the facility, resulting in an increase in operational efficiency by 25%.

- Introduced preventive maintenance protocols for all machinery to detect potential problems early on, reducing repair costs by $4,000 over the last six months.

- Tested mechanical components regularly using multi-meters and other diagnostic tools; identified faulty parts that needed replacement or repairs with 100% accuracy rate.

- Facilitated routine maintenance trainings for new technicians according to Lean Six Sigma standards and reduced downtime of machines from an average of 4 hours per week to 0 incidents in 12 weeks’ time span.

- Reliably monitored output levels across production lines while maintaining safety measures at all times; successfully achieved zero accidents during 3 years on shift as Equipment Maintenance Technician.

Skills

- Troubleshooting

- Manufacturing

- Electronics

- Semiconductors

- Preventive Maintenance

- Engineering

- Equipment Maintenance

- Continuous Improvement

- Semiconductor Industry

Education

Associate Degree in Industrial Maintenance Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Maintenance and Reliability Technician (CMRT)

Soc

May 2017

1. Summary / Objective

Your resume summary/objective is the first thing a potential employer will read, so it’s important to make sure you get their attention. In your summary/objective, highlight your experience and qualifications as an equipment maintenance technician. For example, mention any certifications or specialized training you have received in this field; discuss how many years of experience you have working with different types of machinery; and talk about the successful repairs and preventative maintenance tasks that you completed at previous jobs.

Below are some resume summary examples:

Reliable maintenance technician with 8+ years of experience in the installation, repair and maintenance of a wide range of equipment. Looking to join ABC Facility Services as an Equipment Maintenance Technician where I can use my troubleshooting skills and knowledge of mechanical systems to ensure smooth operations for clients. Successfully reduced downtime by 45% through on-site maintenance at XYZ Company which led to improved customer satisfaction ratings.

Driven equipment maintenance technician with 5+ years of experience working on industrial machinery. Adept at troubleshooting and implementing preventative maintenance measures to ensure optimal performance. At XYZ, successfully maintained over 100 pieces of equipment and achieved a 95% uptime rate for all machines in the facility. Received company awards for excellence in preventive maintenance techniques, resulting in decreased downtime costs by 30%.

Committed and dependable equipment maintenance technician with 10+ years of experience in troubleshooting and repairing electrical, mechanical, hydraulic and pneumatic systems. At XYZ Corporation, successfully reduced downtime by 30% through preventive maintenance programs. Experienced in developing customized repair plans for industrial machinery to ensure optimal performance. Certified safety engineer dedicated to minimizing hazards on the job site.

Detail-oriented equipment maintenance technician with 5+ years of experience troubleshooting and repairing industrial machinery. Demonstrated expertise in diagnosing malfunctions, conducting preventative maintenance, and developing cost-effective solutions to equipment issues. Seeking to join ABC Corporation as an Equipment Maintenance Technician where my skills can be utilized to ensure optimal performance of all machinery on the production floor.

Talented equipment maintenance technician with 5+ years of experience in performing preventive, predictive and corrective maintenance on a variety of electrical and mechanical equipment. Skilled at troubleshooting complex systems to quickly identify and resolve issues. At XYZ, implemented an innovative system for tracking repairs that reduced downtime by 20%. Proven leadership skills; managed the installation team for new facility setup projects.

Accomplished equipment maintenance technician with 8+ years of experience in the field. Possesses a high level of expertise in troubleshooting, diagnosing and repairing electrical/mechanical systems on industrial equipment. At XYZ, reduced downtime by 15% through sound preventive maintenance practices while saving $18K annually on repair costs. Committed to providing an effective and efficient service for customers at all times.

Seasoned equipment maintenance technician with 8+ years of experience in the industrial sector. Proven track record of increasing equipment efficiency and reducing costly downtime through preventative maintenance measures. Seeking to join ABC Corp as an Equipment Maintenance Technician, where I can leverage my expertise in mechanical engineering to ensure optimal performance of all operational machinery.

Enthusiastic equipment maintenance technician with 5+ years of experience performing preventative, corrective and emergency repairs on a variety of industrial machinery. A certified HVAC Technician who excels at working in high-pressure environments to minimize downtime. Seeking to join ABC Manufacturing as an Equipment Maintenance Technician where I can utilize my expertise and attention to detail.

2. Experience / Employment

In the experience section, you should list your employment history in reverse chronological order. Stick to bullet points primarily; this allows the reader to take in what you have written quickly and efficiently.

When writing about your experience, be sure to include details on what you did and any quantifiable results that were achieved. For example, instead of saying “Maintained equipment,” say something like “Performed daily maintenance checks on 10 pieces of industrial machinery which resulted in a 20% reduction in downtime.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Diagnosed

- Repaired

- Installed

- Adjusted

- Calibrated

- Troubleshot

- Replaced

- Assembled

- Tested

- Operated

- Monitored

- Serviced

- Upgraded

- Maintained

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Upgraded and maintained over 100 pieces of equipment for safe operation, resulting in a 20% decrease in downtime.

- Spearheaded the implementation of preventive maintenance and repair protocols that reduced equipment breakdowns by 25%.

- Participated in monthly safety inspections to ensure adherence to OSHA regulations; identified 3 potential hazards and corrected them immediately.

- Efficiently diagnosed issues on all types of machinery, such as conveyors, pumps, motors and boilers; implemented solutions within 5 hours on average per incident.

- Improved machine performance through regular lubrication procedures which led to an increase in productivity by 30%.

- Streamlined the maintenance process for over 400 pieces of equipment, leading to a 30% reduction in downtime and an increase in productivity by $25,000.

- Reorganized the inventory system for spare parts which improved the accuracy of stock levels and reduced ordering costs by 20%.

- Serviced all machines on-site or remotely using diagnostic tools; successfully repaired 98% of issues before escalation was needed with minimal disruption to operations.

- Represented company at industry events such as trade shows & conventions, providing technical support when required and building relationships with key stakeholders within the sector.

- Substantially lowered customer complaints related to machine breakdowns through proactive inspections & preventative measures; achieved a 97% satisfaction rating from clients.

- Diagnosed and repaired over 500 pieces of equipment per month, ensuring that service requests were completed on time and within budget.

- Revised preventative maintenance checks to optimize performance and minimize downtime; as a result, the average lifespan of critical machinery increased by 16%.

- Actively monitored system operations and identified anomalies before they caused major malfunctions; minimized repair costs by 20% in the last quarter.

- Optimized operational processes for 8 heavy-duty industrial machines including boilers, turbines and generators; improved efficiency levels across all systems by 25%.

- Monitored inventory levels for spare parts & supplies on a weekly basis to ensure availability when needed; reduced backordering incidents from 10/month to 3/month during tenure with company.

- Competently maintained and repaired a wide range of equipment with an average repair time reduction of 25% per month; successfully completed over 150 maintenance requests in the past year.

- Formulated preventative maintenance strategies to reduce downtime, helping to extend the life span of all equipment by 20%.

- Expedited emergency repairs on-site, troubleshot 95+ mechanical systems with accuracy and efficiency while adhering to safety protocols at all times.

- Troubleshot electrical wiring malfunctions for HVAC systems, industrial machinery and other related components within 2 hours or less; identified root causes for recurring issues that led to improved operations performance overall.

- Operated hand tools such as drills, wrenches & saws in order to install new parts or replace worn ones when necessary; inspected newly installed parts regularly for quality assurance purposes.

- Developed preventive maintenance schedules for over 500 pieces of equipment, resulting in a 20% reduction in downtime and repair costs.

- Presented detailed technical reports on findings to upper management after completing routine inspections; identified and rectified minor faults before they became major problems.

- Demonstrated excellent troubleshooting skills when diagnosing issues with complex machinery components, promptly repairing or replacing faulty parts to reduce costly delays across the production line by 25%.

- Prepared comprehensive maintenance logs detailing all repairs carried out as well as any spare parts required; improved accuracy of records by streamlining data entry processes into digital database systems used throughout the facility.

- Effectively managed inventory levels within budget using MS Excel spreadsheets, ensuring that sufficient spares were available at all times without exceeding allocated expenditure limits by 10%.

- Mentored 3 junior technicians, training them on the proper use of diagnostic and repair tools while ensuring all safety protocols were adhered to.

- Compiled a detailed database containing records of equipment maintenance activities for over 200 pieces of machinery; increased system efficiency by 35%.

- Successfully overhauled 20+ machines per month according to manufacturer specifications, reducing downtime and extending the life-cycle of each asset.

- Structured preventative maintenance schedules for 10 different kinds of factory equipment in order to minimize unplanned repairs & failures, saving $5K in costs annually.

- Inspected work areas daily as partof regular maintenance duties; identified potential hazards before they caused any damage or injury with 100% accuracy rate.

- Replaced defective parts and components of various machines, tools and equipment within an industrial setting; improved operational efficiency by 35%.

- Adjusted machinery gauges in accordance with prescribed standards to ensure optimal performance; reduced downtime due to maintenance issues by 25%.

- Maintained a detailed inventory of spare parts for all mechanical systems, completing weekly checks on each piece of equipment to identify potential problems.

- Coordinated repairs among suppliers/vendors as needed, ensuring that emergency service calls were responded to promptly and efficiently; saved $1,500 on repair costs over the course of 6 months.

- Confidently diagnosed complex technical issues using diagnostic software programs & manual testing procedures and implemented practical solutions within established timelines.

- Meticulously calibrated 100+ pieces of medical equipment, including x-ray machines and MRI scanners, to ensure optimal performance and safety for staff and patients.

- Advised hospital personnel on proper use of the latest medical equipment, providing hands-on training for 20+ new hires in a year; reduced preventable errors by 32%.

- Assembled 10 complex machinery units from scratch according to manufacturer’s specifications in record time; improved productivity rate by 40%.

- Repaired over 200 malfunctioning electrical components using soldering techniques within tight deadlines; increased repair success rate from 75% to 92%.

- Replaced faulty parts such as circuit boards or motors with original spare parts ordered online at 50% cost savings compared to market prices.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization might be seeking someone with experience in electrical maintenance, while another might require expertise in hydraulic systems.

It is essential to tailor the skills section of your resume for each job you apply for; this is because many employers use applicant tracking systems these days that scan resumes for certain keywords before passing them on to a human.

In addition to listing key qualifications here, it can also help if you elaborate further on some of the most important ones elsewhere within your resume – such as the summary or work experience sections.

Below is a list of common skills & terms:

- 5S

- Automation

- Automotive

- CVD

- Calibration

- Computer Hardware

- Continuous Improvement

- Cross Functional Team Leadership

- Design of Experiments

- Electrical Troubleshooting

- Electricians

- Electro Mechanical

- Electronics

- Engineering

- Equipment Maintenance

- Failure Analysis

- IC

- Lean Manufacturing

- Maintenance

- Maintenance Management

- Maintenance and Repair

- Manufacturing

- Metrology

- PLC

- Pneumatics

- Preventive Maintenance

- Process Improvement

- Robotics

- Root Cause Analysis

- SPC

- Semiconductor Industry

- Semiconductors

- Six Sigma

- Team Leadership

- Teamwork

- Test Equipment

- Testing

- Thin Films

- Time Management

- Troubleshooting

4. Education

Adding an education section on your resume will depend on how much work experience you have. If you are just starting out and don’t have any relevant job history, then include your education below your resume objective. However, if you already have years of experience in the equipment maintenance technician field, it might not be necessary to add an education section at all.

If including an education section is important for the role or company you are applying to, try mentioning courses taken that relate directly to being a successful equipment maintenance technician.

Associate Degree in Industrial Maintenance Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and proficiency in a certain field. They are especially important when applying for jobs that require specific skills or certifications, as they prove you have the necessary qualifications to do the job.

When listing certifications on your resume, make sure to include any relevant details such as where you obtained it from and what year it was awarded. This will help employers understand how up-to-date your certification is and if it’s still valid.

Certified Maintenance and Reliability Technician (CMRT)

Soc

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Ardith Nikolaus, this would be Ardith-Nikolaus-resume.pdf or Ardith-Nikolaus-resume.docx.

7. Cover Letter

Writing a cover letter is an opportunity to express yourself and demonstrate your enthusiasm for the role. It should include 2-4 paragraphs that are separate from your resume, allowing you to share more information about who you are as a professional.

Cover letters may not be mandatory for most job applications but it can give employers greater insights into why you would be a great fit for the position. They provide an ideal platform to explain why they should hire you over other applicants, making them invaluable when applying for jobs!

Below is an example cover letter:

Dear Retta,

I am interested in applying for the Equipment Maintenance Technician position at your company. I have experience with a wide range of equipment, from small tools to large machines, and have been responsible for their upkeep and repair. My skills include troubleshooting and repairing electrical and mechanical issues, as well as performing preventative maintenance.

In my current role, I am responsible for maintaining a fleet of vehicles. I perform regularly scheduled maintenance, such as oil changes and tire rotations, as well as repairs when necessary. When a vehicle is in need of major repairs, I consult with the mechanic on staff to determine the best course of action. I also keep records of all maintenance and repair work that is performed on each vehicle.

I am confident that I can be an asset to your team by keeping your equipment in good working order and minimizing downtime due to repairs. My ability to work independently or as part of a team makes me adaptable to any situation. Please find attached my resume for your review; I look forward to speaking with you soon about this opportunity.

Sincerely,

Ardith

Equipment Maintenance Technician Resume Templates

Jerboa

Jerboa Numbat

Numbat Pika

Pika Bonobo

Bonobo Axolotl

Axolotl Fossa

Fossa Gharial

Gharial Lorikeet

Lorikeet Echidna

Echidna Saola

Saola Quokka

Quokka Kinkajou

Kinkajou Cormorant

Cormorant Indri

Indri Rhea

Rhea Dugong

Dugong Markhor

Markhor Ocelot

Ocelot Hoopoe

Hoopoe Rezjumei

Rezjumei