Electrical Maintenance Technician Resume Guide

Electrical maintenance technicians are responsible for maintaining and repairing electrical systems, equipment, and components. They inspect wiring to ensure that it meets safety regulations and diagnose problems in order to determine the best course of action. Additionally, they may perform routine preventative maintenance on machines or replace defective parts as needed.

Your expertise in electrical maintenance is unparalleled. But potential employers don’t know about you yet, so to get their attention, you must write a resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

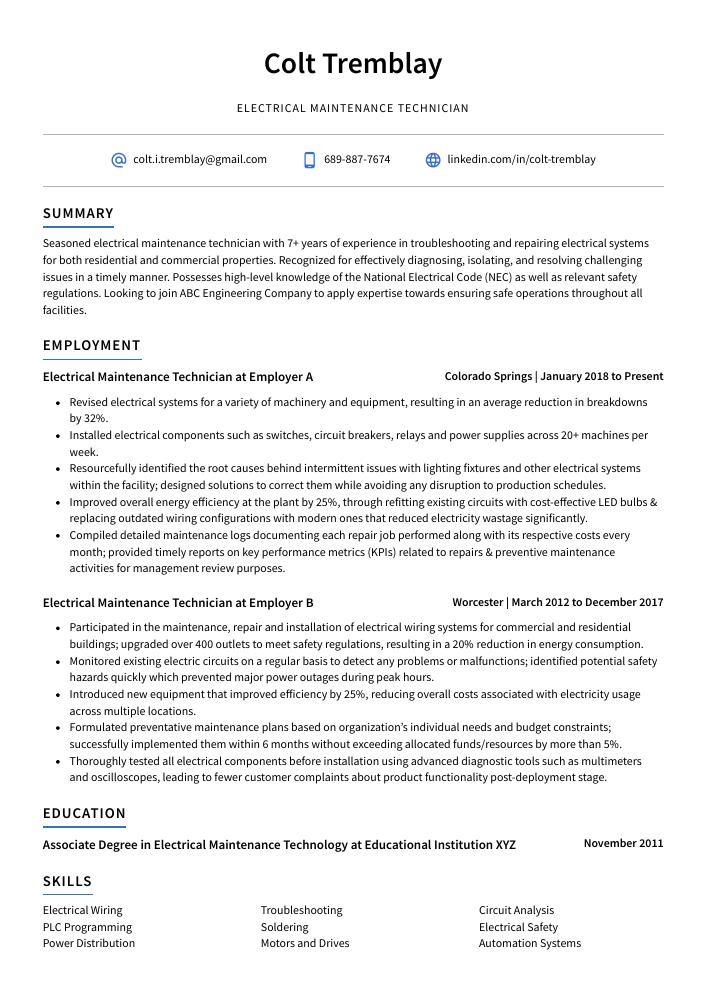

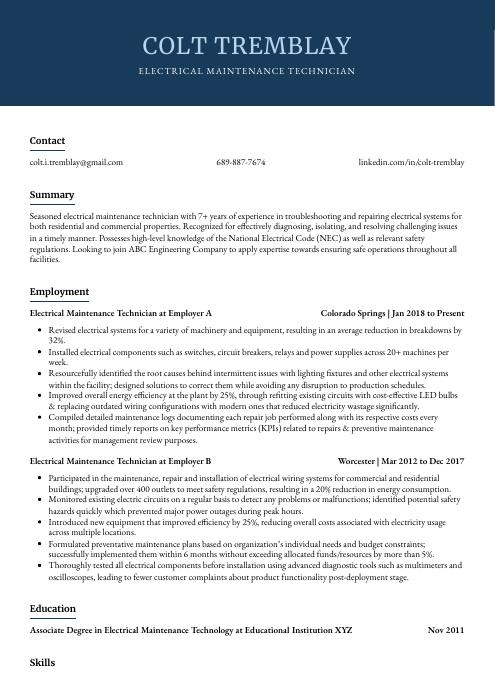

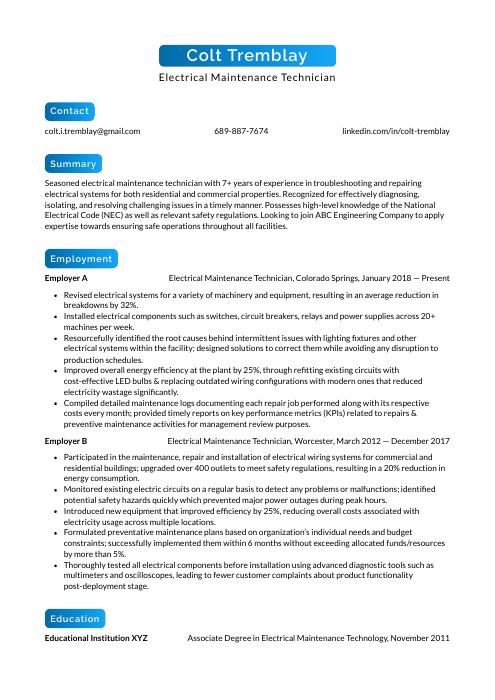

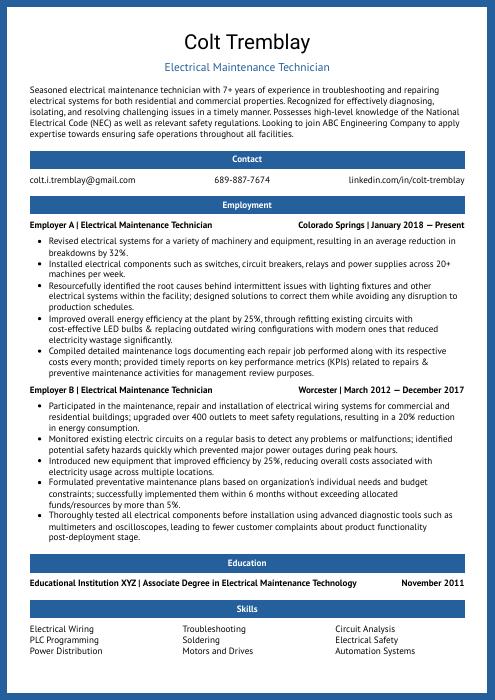

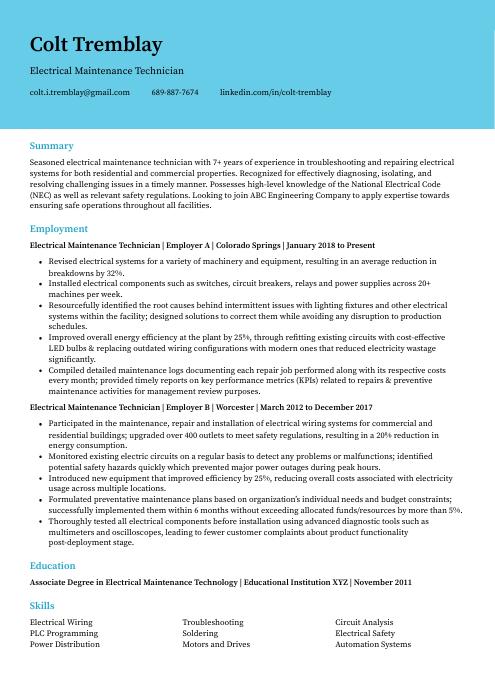

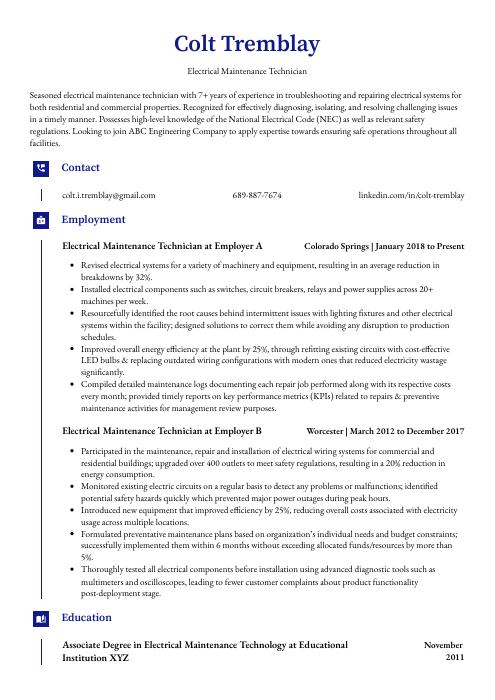

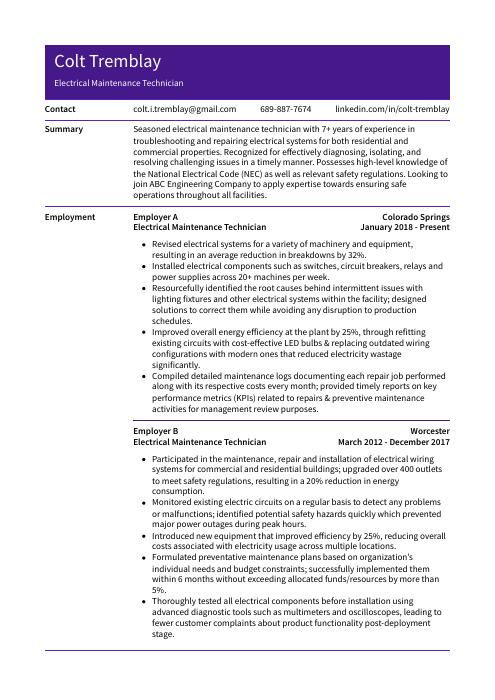

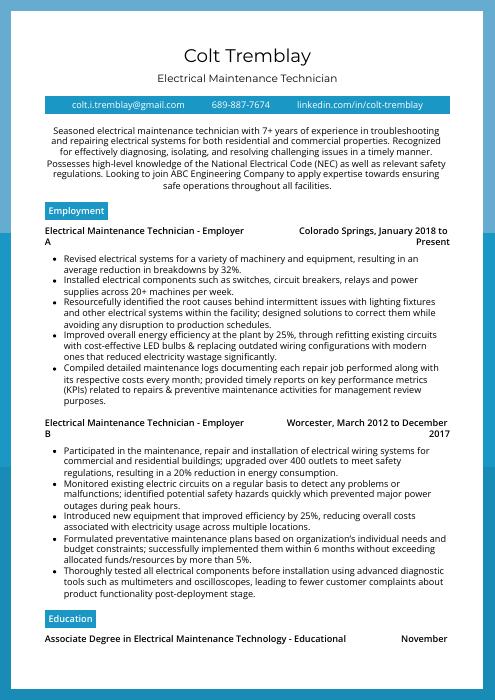

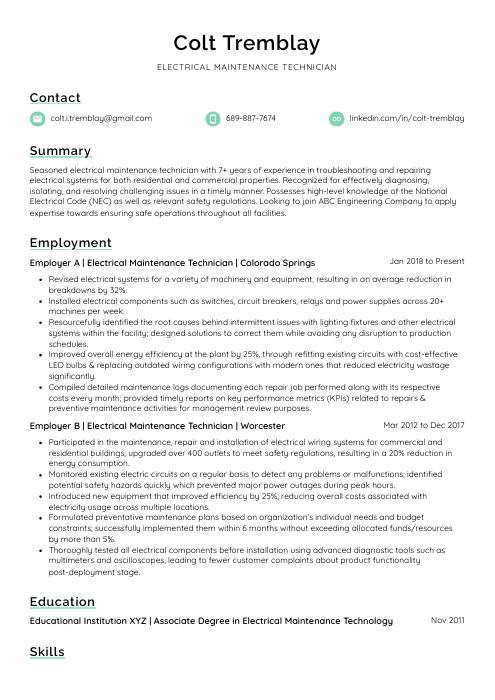

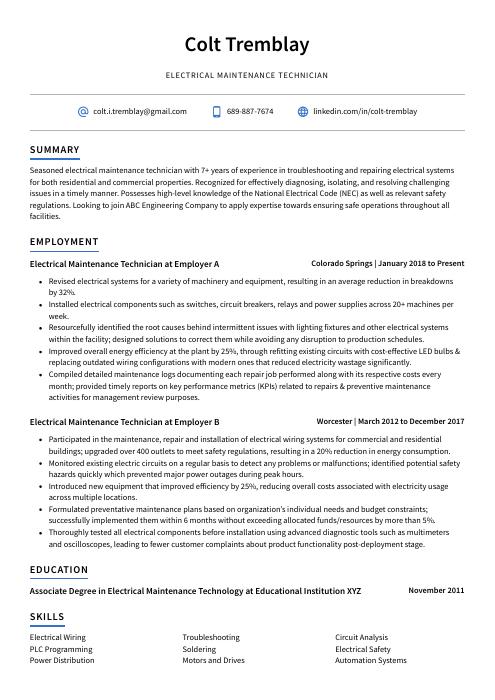

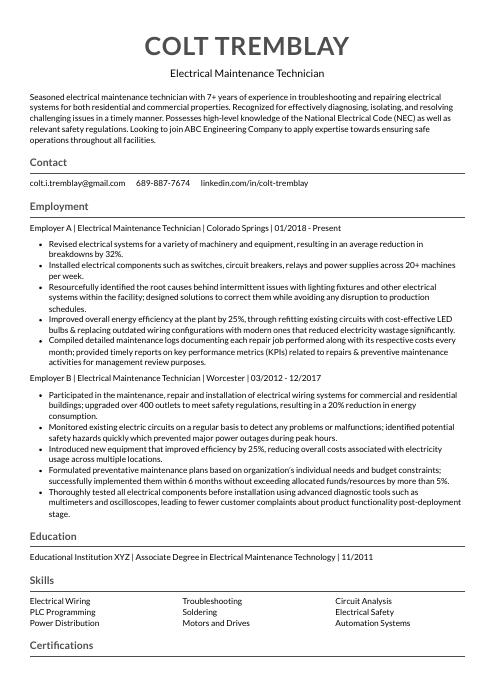

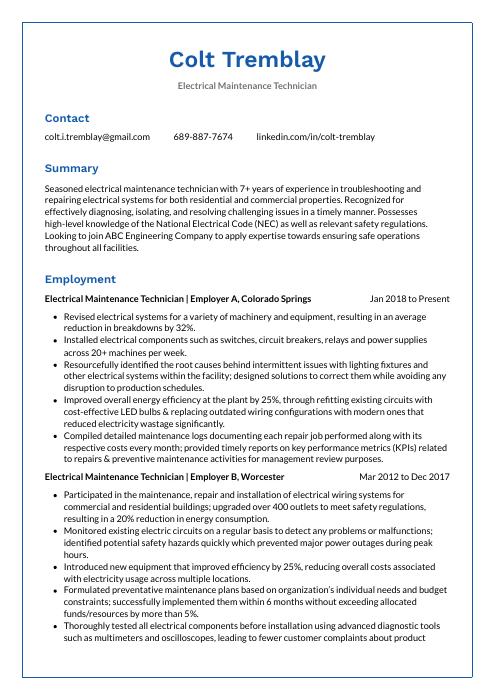

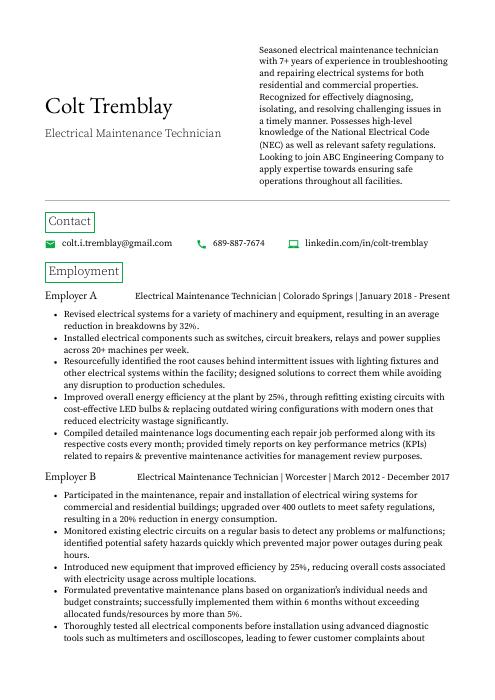

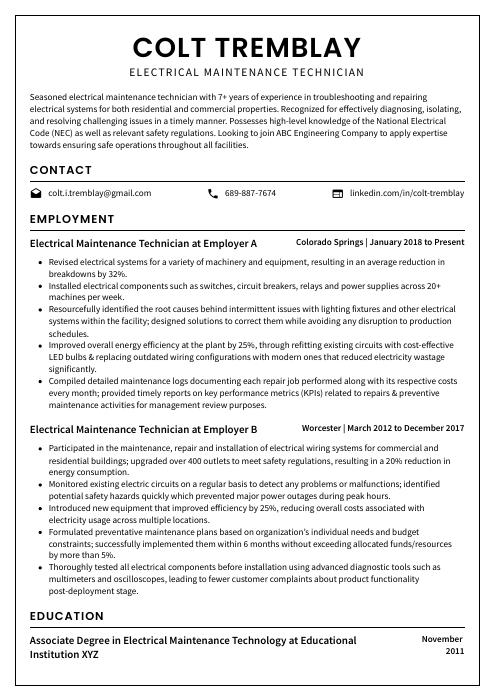

Electrical Maintenance Technician Resume Sample

Colt Tremblay

Electrical Maintenance Technician

[email protected]

689-887-7674

linkedin.com/in/colt-tremblay

Summary

Seasoned electrical maintenance technician with 7+ years of experience in troubleshooting and repairing electrical systems for both residential and commercial properties. Recognized for effectively diagnosing, isolating, and resolving challenging issues in a timely manner. Possesses high-level knowledge of the National Electrical Code (NEC) as well as relevant safety regulations. Looking to join ABC Engineering Company to apply expertise towards ensuring safe operations throughout all facilities.

Experience

Electrical Maintenance Technician, Employer A

Colorado Springs, Jan 2018 – Present

- Revised electrical systems for a variety of machinery and equipment, resulting in an average reduction in breakdowns by 32%.

- Installed electrical components such as switches, circuit breakers, relays and power supplies across 20+ machines per week.

- Resourcefully identified the root causes behind intermittent issues with lighting fixtures and other electrical systems within the facility; designed solutions to correct them while avoiding any disruption to production schedules.

- Improved overall energy efficiency at the plant by 25%, through refitting existing circuits with cost-effective LED bulbs & replacing outdated wiring configurations with modern ones that reduced electricity wastage significantly.

- Compiled detailed maintenance logs documenting each repair job performed along with its respective costs every month; provided timely reports on key performance metrics (KPIs) related to repairs & preventive maintenance activities for management review purposes.

Electrical Maintenance Technician, Employer B

Worcester, Mar 2012 – Dec 2017

- Participated in the maintenance, repair and installation of electrical wiring systems for commercial and residential buildings; upgraded over 400 outlets to meet safety regulations, resulting in a 20% reduction in energy consumption.

- Monitored existing electric circuits on a regular basis to detect any problems or malfunctions; identified potential safety hazards quickly which prevented major power outages during peak hours.

- Introduced new equipment that improved efficiency by 25%, reducing overall costs associated with electricity usage across multiple locations.

- Formulated preventative maintenance plans based on organization’s individual needs and budget constraints; successfully implemented them within 6 months without exceeding allocated funds/resources by more than 5%.

- Thoroughly tested all electrical components before installation using advanced diagnostic tools such as multimeters and oscilloscopes, leading to fewer customer complaints about product functionality post-deployment stage.

Skills

- Electrical Wiring

- Troubleshooting

- Circuit Analysis

- PLC Programming

- Soldering

- Electrical Safety

- Power Distribution

- Motors and Drives

- Automation Systems

Education

Associate Degree in Electrical Maintenance Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Electrical Maintenance Technician (CEMT)

International Society for

May 2017

1. Summary / Objective

A resume summary for an electrical maintenance technician should be a brief but powerful statement that showcases your technical skills, experience, and accomplishments. Include details such as the types of equipment you have worked on in the past, any certifications or qualifications you possess related to electrical maintenance work, and how many years of experience you have. Additionally, mention any successful projects or repairs you completed during your career so far.

Below are some resume summary examples:

Talented electrical maintenance technician with 5+ years of experience in troubleshooting and repairing complex electrical systems. Experienced working on both residential and commercial properties, specializing in industrial equipment installation and repair. Skilled at maintaining up-to-date records of all work performed while ensuring safety protocols are always followed. Committed to providing excellent customer service while adhering to the highest quality standards.

Reliable electrical maintenance technician with 8 years of hands-on experience in the power industry. Skilled at troubleshooting, repairing, and maintaining high voltage electrical systems and equipment. At XYZ Company, identified a recurring issue that saved $50K per year in energy costs. Certified by OSHA 30 for safety management protocols to ensure operational efficiency while minimizing risks associated with hazardous worksites.

Well-rounded electrical maintenance technician with 8+ years of experience in troubleshooting and repairing electrical systems. At XYZ, led a team of 3 technicians to complete successful installations on time, within budget and adhering to safety protocols. Received commendation from the supervisor for diagnosing complex issues accurately while maintaining high standards of customer service throughout all projects.

Hard-working electrical maintenance technician with 5+ years of experience troubleshooting and repairing complex electrical systems. Skilled in diagnosing and resolving issues quickly, maintaining equipment to the highest standards, and adhering to safety protocols. Seeking an opportunity at ABC Company to help implement preventive measures that reduce downtime while also improving customer satisfaction.

Skilled Electrical Maintenance Technician with 10+ years of experience carrying out preventive maintenance, repairs and troubleshooting for a variety of electrical systems. At XYZ Corporation, managed the installation and repair of complex industrial machines; improved efficiency by 20%. Proven track record in providing cost-effective solutions to reduce downtime while ensuring safety standards are met.

Diligent electrical maintenance technician with 8+ years of experience in troubleshooting, repairing and maintaining complex electrical systems. Experienced in installing, testing and inspecting all types of wiring to ensure system compliance with relevant safety standards. Seeking a position at ABC Tech to leverage expertise in resolving any mechanical or technical issues that arise during operations.

Committed and detail-oriented Electrical Maintenance Technician with 10+ years of experience in the engineering industry. Experienced in troubleshooting, repairing and maintaining complex electrical systems while adhering to safety guidelines. Seeking an opportunity at ABC Tech to use my technical knowledge and problem-solving skills to maintain optimal functionality of their electrical equipment.

Determined electrical maintenance technician with 5+ years of experience in the industrial sector. Skilled at identifying and resolving electrical malfunctions, analyzing power system problems, and providing preventative maintenance solutions for a wide range of machines and equipment. Achieved 100% success rate on all assigned projects by ensuring safe repair jobs within tight deadlines.

2. Experience / Employment

In the experience section, you should provide details on your employment history. This section should be written in reverse chronological order, meaning the most recent job is listed first.

Stick to bullet points primarily when writing this section; it makes it easier for the reader to take in what you have to say quickly and easily. Take some time to think about the specifics of what you did and any quantifiable results that were achieved as a result of your work.

For example, instead of saying “Repaired electrical equipment,” you could say, “Performed routine maintenance checks on all electrical systems within industrial facilities; identified potential issues before they became problems resulting in an 85% reduction in downtime.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Troubleshot

- Inspected

- Repaired

- Replaced

- Adjusted

- Tested

- Programmed

- Calibrated

- Monitored

- Assembled

- Connected

- Operated

- Diagnosed

- Commissioned

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Programmed and installed electrical controls, wiring and equipment in commercial spaces for lighting, HVAC systems and specialized machinery; achieved a 50% reduction in energy costs over the course of 6 months.

- Structured an effective preventive maintenance schedule that reduced breakdowns by 25%, expedited response times to customer requests by 20 minutes on average and improved employee safety standards throughout all sites.

- Expedited repair processes utilizing advanced diagnostic tools such as multimeters, circuit testers and megger meters; cut down troubleshooting time from 2 hours to 30 minutes per incident without compromising quality or accuracy of results.

- Coordinated with outside contractors to ensure timely completion of projects while maintaining cost-effectiveness at all stages; saved $10K on parts & labor expenses compared to original estimates within the first year alone.

- Confidently handled emergency repairs during off-hours shifts due to power outages/equipment failures resulting in zero downtimes across multiple locations’ operations.

- Streamlined electrical maintenance operations by troubleshooting, repairing and replacing faulty wiring on over 100 pieces of equipment monthly; reduced machine downtime by 30%.

- Diligently tested electrical systems for continuity using multimeters and other specialized testing devices to ensure safety regulations were met.

- Connected new machines to existing power sources, making sure that all connections were secure and compliant with relevant codes & standards; completed projects 10% faster than the average technician in the team.

- Developed preventative maintenance programs for industrial automation systems including motors, switches, relays and circuit breakers; identified potential problems before they occurred resulting in less disruption of service delivery & costs savings up to $8K a month.

- Repaired damaged switchboards according to manufacturer’s instructions, utilizing hand tools such as pliers or wrenches as well as computerized diagnostic equipment when necessary; successfully fixed 90% of issues within 2 hours or less per repair task.

- Mentored a team of electrical maintenance technicians and successfully completed 16 complex projects in a timely manner.

- Reorganized the existing wiring & electronics systems to optimize performance, resulting in an 18% reduction in energy consumption costs over 6 months.

- Tested all incoming equipment for safety standards compliance; identified and resolved potential hazards before they caused operational disruptions or malfunctions.

- Reduced downtime on critical machines by 25%, through preventive maintenance checks, troubleshooting activities and repairs of associated components onsite or offsite as needed.

- Meticulously documented work progress using established procedures while ensuring accuracy & completeness at every step; maintained complete records to ensure regulatory compliance with local/state laws/codes etc..

- Facilitated efficient maintenance of all electrical systems, diagnosing and resolving malfunctions in a timely manner at an industrial plant with 500+ machines; increased overall productivity by 25%.

- Diagnosed and repaired over 1000 faults within the electrical system during two years of service, reducing downtime incidents by 30%.

- Consistently conducted preventive maintenance checks on all wiring systems to ensure compliance with safety regulations; detected 10 potential hazards that were quickly rectified before any harm was caused.

- Achieved cost savings of $9000 through successful installation & troubleshooting efforts for motor control centers and other functional parts related to the power supply system.

- Replaced faulty wiring components such as transformers, capacitors & relays more than 800 times in accordance with industry standards while ensuring optimal performance levels throughout each project’s duration.

- Optimized the electrical system’s performance by performing regular maintenance and repair tasks on over 250 pieces of equipment, resulting in a 20% reduction in downtime.

- Troubleshot complex electrodes, wiring systems and circuit boards to identify problems and restore functionality; completed all repairs within 24 hours on average.

- Represented the company at industry-related conferences to showcase new technologies for maintaining electrical systems; increased customer inquiries by 40%.

- Actively monitored power grid conditions through daily inspections of meters & other measuring devices; identified risks ahead of time which prevented any potentially costly outages or damages from occurring.

- Assessed existing electrical installations for safety hazards every month, providing detailed reports that were used to make corrective adjustments where necessary; raised standards compliance rating from 70% to 90%.

- Reliably maintained electrical systems and equipment, troubleshooting malfunctions to ensure minimal downtime in operations; reduced maintenance costs by 10%.

- Calibrated controls, tested power outlets and replaced faulty parts on a regular basis to guarantee safety regulations were met at all times.

- Presented weekly reports of preventive maintenance activities for up to 40 machines, highlighting any mechanical issues found during inspections and providing recommendations for repair solutions that saved the company an average of $800 per month in repairs.

- Spearheaded numerous projects related to electrical system upgrades and improvements; successfully completed 4 large-scale installations within budget & deadline constraints while adhering strictly to applicable codes, standards & safety protocols throughout the process.

- Demonstrated excellent teamwork when training junior technicians on proper use of tools & diagnostic devices as well as safe practices when working with electricity.

- Competently maintained, repaired and tested electrical systems in a factory setting; improved operational efficiency by 10% through timely maintenance services.

- Operated sophisticated diagnostic equipment to identify defects in the wiring system, replaced faulty components with new ones and restored power supply within 2 hours per incident.

- Advised plant management team on the installation of new electrical devices such as switchboards, lighting fixtures & motors while adhering to safety guidelines at all times; reduced risk of electric shocks by 16%.

- Utilized hand tools such as pliers, screwdrivers & wrenches for disassembly/reassembly tasks during maintenance activities; completed preventative repairs across 35 machines every day without any downtime or delays in production schedules.

- Assembled electronic control circuits for motor-driven equipments including pumps, circuit breakers and compressors under minimum supervision from senior technicians; increased assembly accuracy rate by 20%.

- Adjusted and repaired electrical components, wiring and systems to ensure proper functioning of all equipment; reduced downtime by 15% through preventive maintenance.

- Prepared detailed reports on the status of installations, repairs and modifications carried out for better tracking purposes; updated records with progress notes every two weeks.

- Commissioned new switchboards and circuit breakers per the Australian Standards (AS3000); completed projects within budget constraints in record time (+20%).

- Independently managed a team of 10 electricians during peak construction season to efficiently install lighting fixtures, power outlets & cabling systems at 3 newly-built sites across Sydney metropolitan area.

- Inspected existing wiring connections in industrial buildings as part of safety checks before customers moved into premises; identified any potential hazards or risks due to poor electrical design/execution and remedied same without delay.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in repairing and troubleshooting electrical circuits, while another may be looking for someone who is knowledgeable about the installation of new systems.

As such, it’s important to tailor the skills section of your resume to each job that you are applying for. This will help ensure that your application gets past applicant tracking systems (which scan resumes for certain keywords) and into the hands of a human recruiter or hiring manager.

In addition to listing relevant skills here, you should also discuss them further in other sections like summary or work history; this will give recruiters a better understanding as to why you would make an excellent fit for their organization.

Below is a list of common skills & terms:

- Automation Systems

- Circuit Analysis

- Electrical Safety

- Electrical Wiring

- Instrumentation and Calibration

- Motors and Drives

- PLC Programming

- Power Distribution

- Soldering

- Troubleshooting

4. Education

Including an education section on your resume will depend upon how far along you are in your career. If you just graduated and have no prior experience, list your educational qualifications below the objective statement. However, if you have been working as an electrical maintenance technician for years with plenty of work to showcase, omitting this section is perfectly fine.

If including an education section, try mentioning courses and subjects that relate to the job role of an electrical maintenance technician.

Associate Degree in Electrical Maintenance Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise and knowledge in a particular field. They can be used to show potential employers that you have the necessary skills for the job, as well as prove that you have kept up with industry trends and developments.

Including certifications on your resume is an excellent way to make yourself stand out from other applicants, so don’t forget to include any relevant ones when applying for jobs!

Certified Electrical Maintenance Technician (CEMT)

International Society for

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Colt Tremblay, this would be Colt-Tremblay-resume.pdf or Colt-Tremblay-resume.docx.

7. Cover Letter

Attaching a cover letter to your resume is a great way to make yourself stand out from the competition. It’s an opportunity for you to explain why you’re well-suited for the role, and give recruiters more insight into who you are as a professional.

A cover letter typically contains 2-4 paragraphs focusing on relevant skills, experience and accomplishments that demonstrate how they match up with the job requirements outlined in the advertisement or listing. They should also include some information about your personality or unique traits which can help employers get to know you better.

Below is an example cover letter:

Dear Noah,

I am writing to apply for the Electrical Maintenance Technician position at ABC Corporation. As a highly skilled and experienced electrical technician with more than 10 years of experience in the field, I am confident that I can be a valuable asset to your team.

In my current role as an electrical maintenance technician at XYZ Inc., I am responsible for maintaining and repairing all electrical equipment and systems in our facility. My duties include troubleshooting problems, performing preventative maintenance, and making repairs as needed. In addition, I often work with outside contractors to coordinate larger projects.

Through my experience, I have developed strong problem-solving skills that allow me to quickly identify and resolve issues. My attention to detail ensures that all repairs are made correctly the first time, minimizing downtime and maximizing efficiency. My excellent communication skills also allow me to effectively communicate with other members of the maintenance team as well as management when necessary.

I am confident that I can be a valuable asset to your organization and would welcome the opportunity to discuss how my skills could benefit your company further. Thank you for your time and consideration; I look forward to hearing from you soon!

Sincerely,

Colt

Electrical Maintenance Technician Resume Templates

Bonobo

Bonobo Kinkajou

Kinkajou Ocelot

Ocelot Dugong

Dugong Fossa

Fossa Hoopoe

Hoopoe Echidna

Echidna Gharial

Gharial Pika

Pika Rhea

Rhea Lorikeet

Lorikeet Axolotl

Axolotl Numbat

Numbat Saola

Saola Jerboa

Jerboa Indri

Indri Markhor

Markhor Quokka

Quokka Cormorant

Cormorant Rezjumei

Rezjumei