Concrete Technician Resume Guide

Concrete Technicians are responsible for testing, inspecting and evaluating the strength of concrete used in construction projects. They analyze samples to determine if a structure is safe or needs repairs and make recommendations based on their findings. Additionally, they also ensure that all materials meet industry standards before being used in a project.

You’ve got an eye for detail and a knack for working with concrete. To get your foot in the door of any construction company, you must write a resume that highlights your qualifications as a concrete technician.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

Concrete Technician Resume Sample

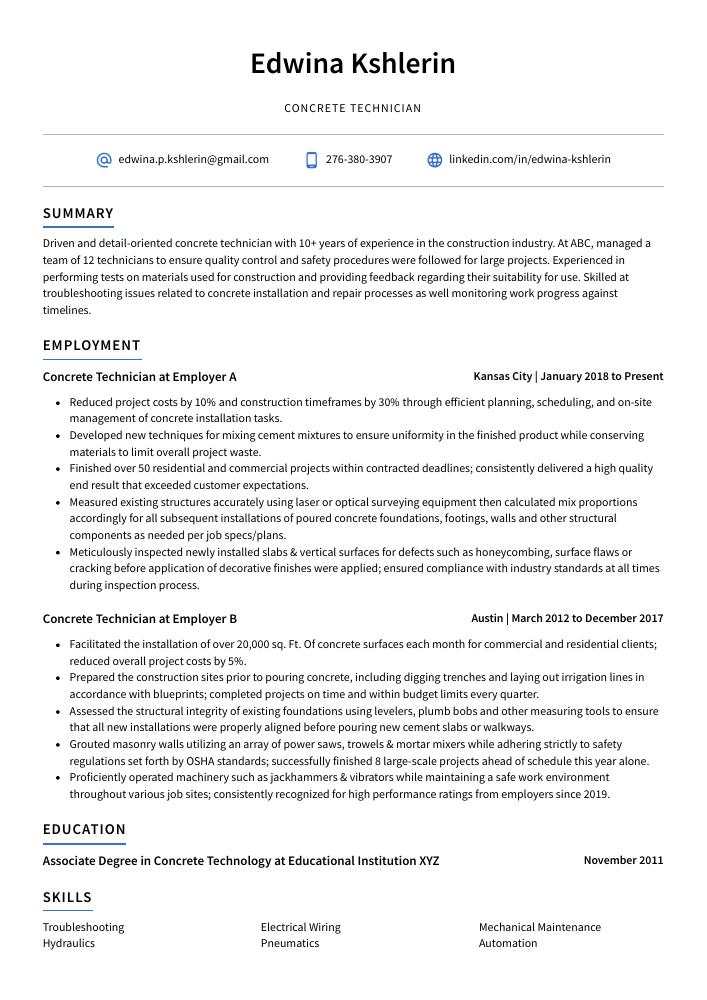

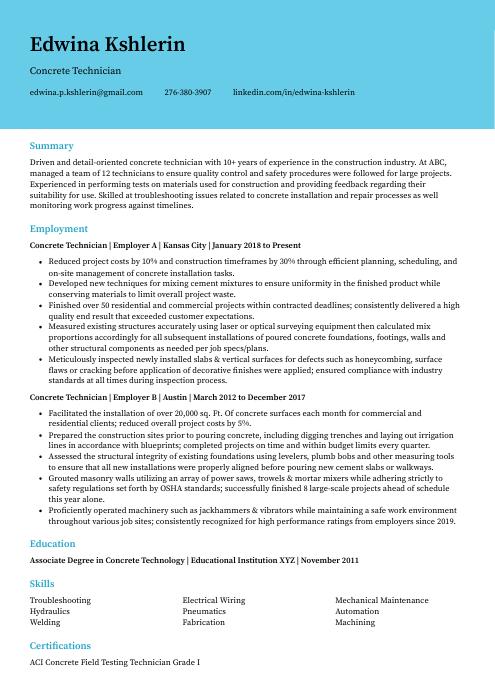

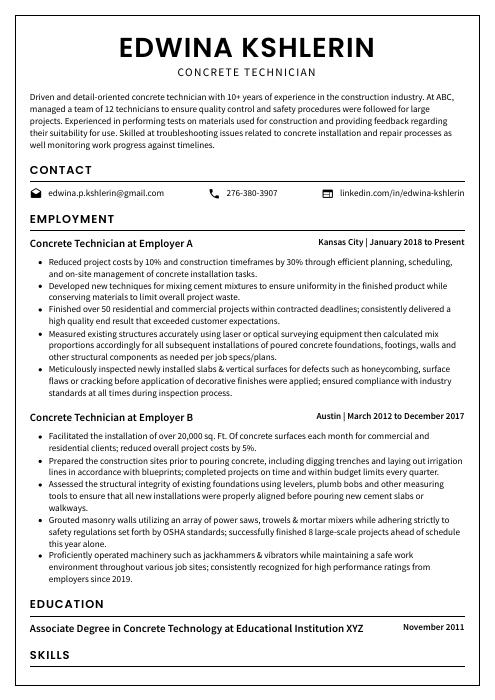

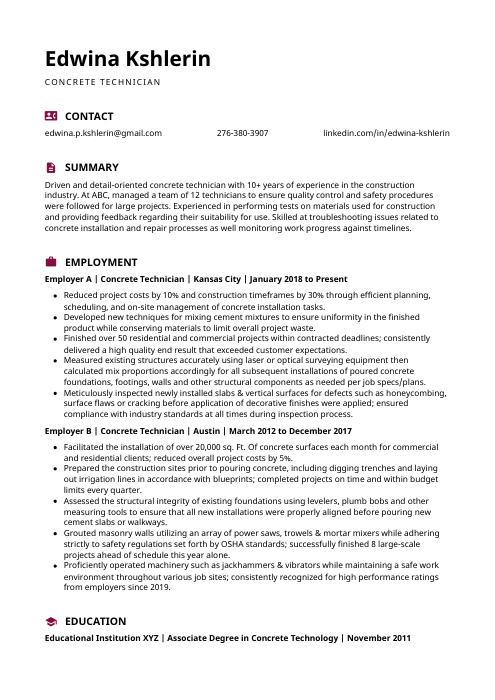

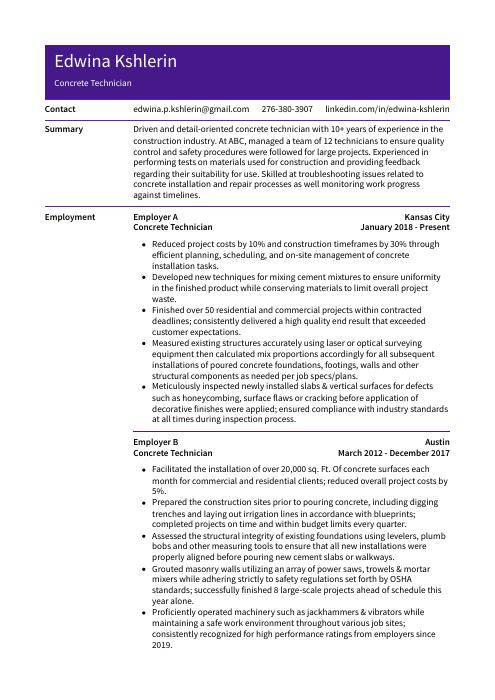

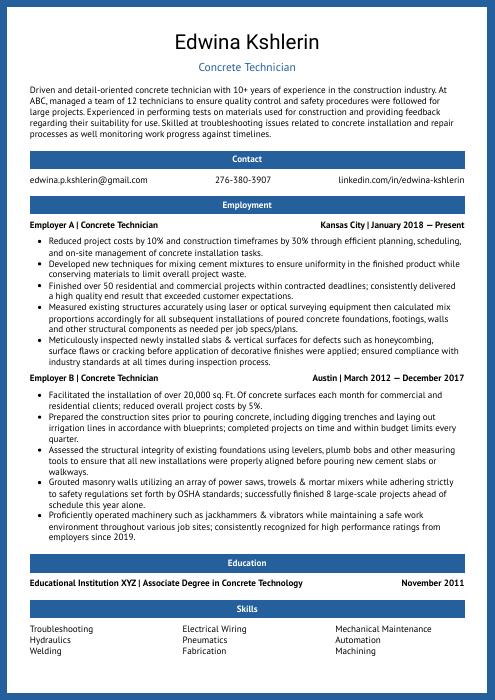

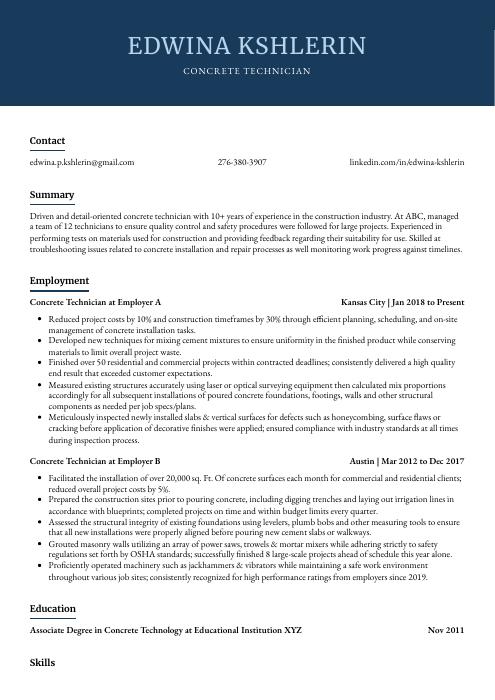

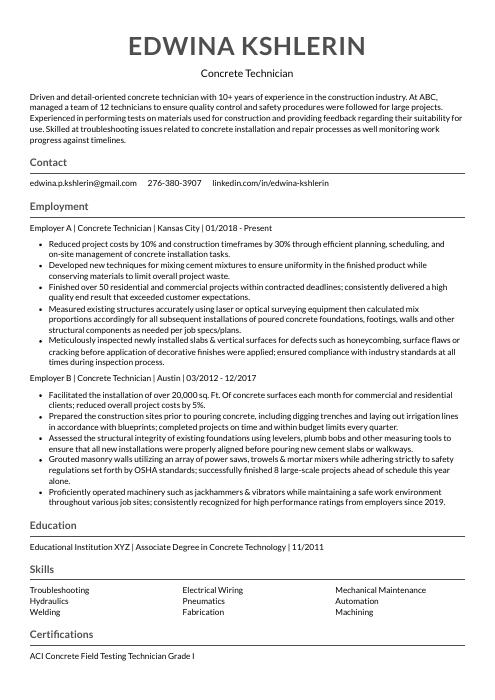

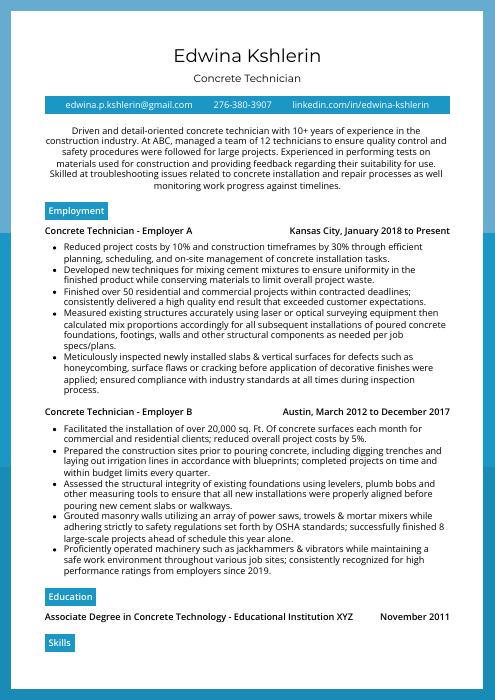

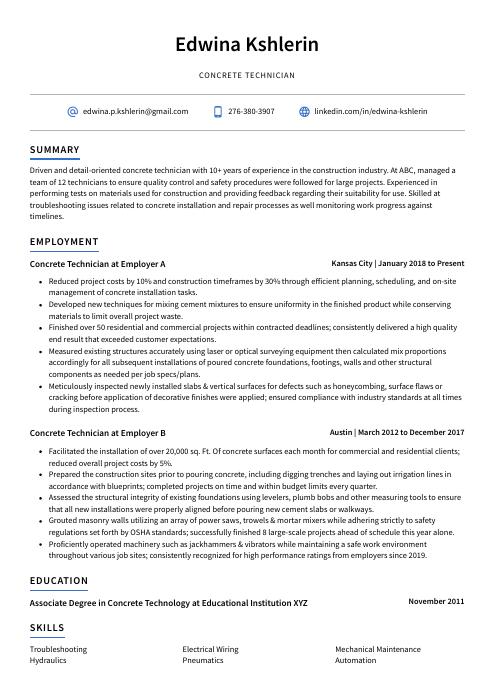

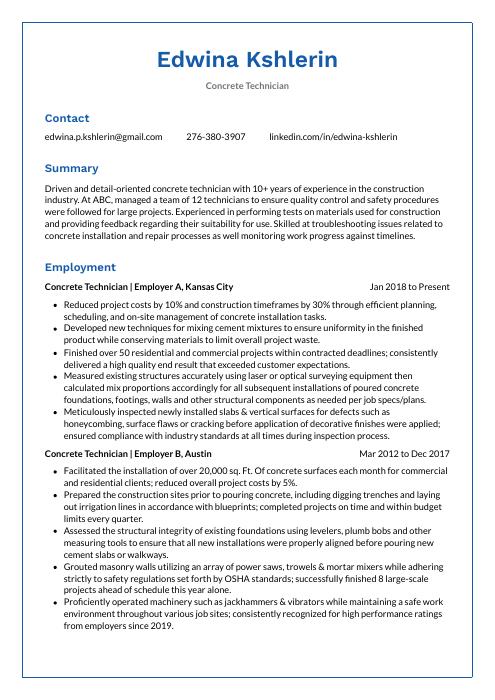

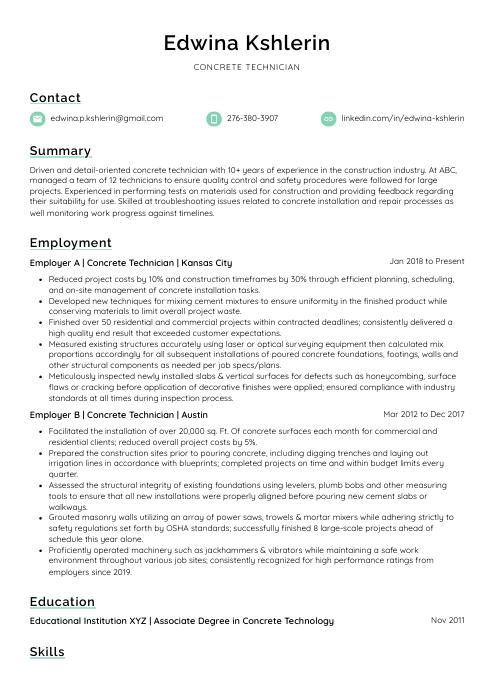

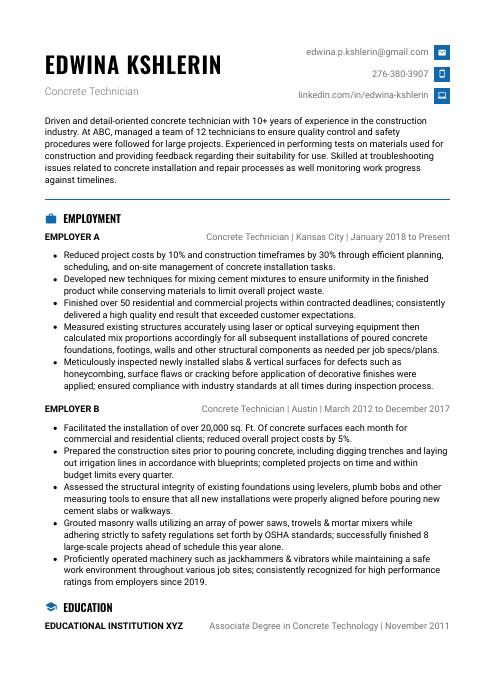

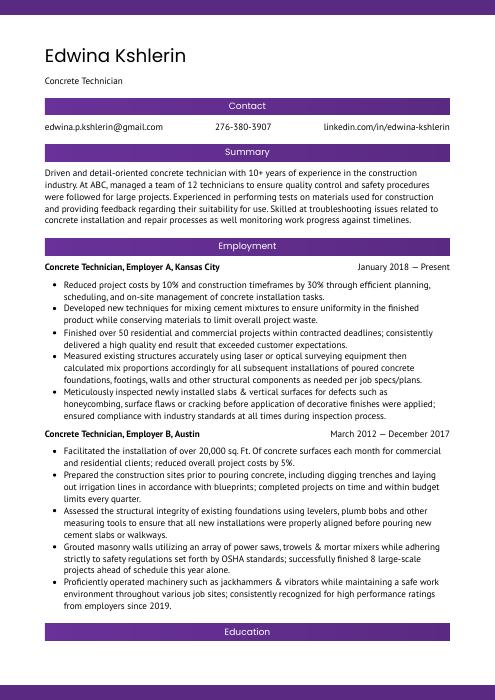

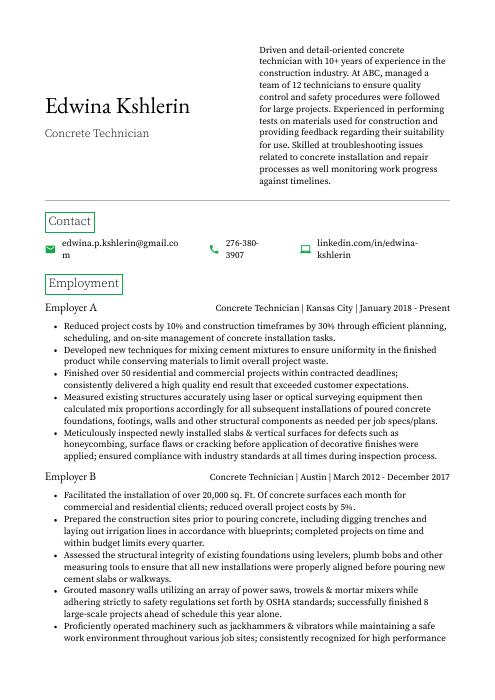

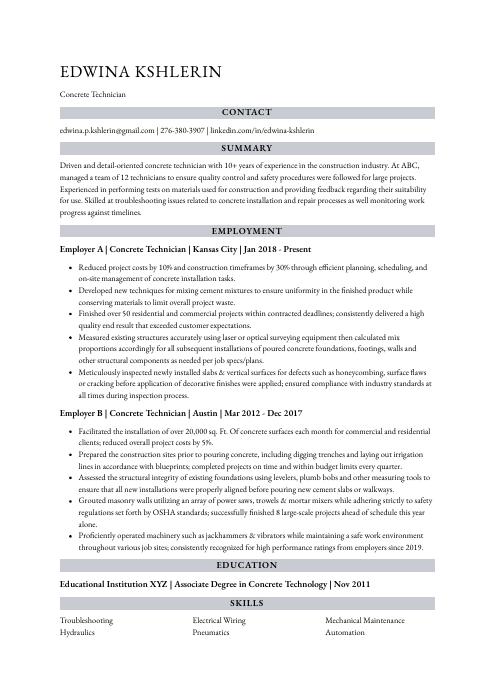

Edwina Kshlerin

Concrete Technician

[email protected]

276-380-3907

linkedin.com/in/edwina-kshlerin

Summary

Driven and detail-oriented concrete technician with 10+ years of experience in the construction industry. At ABC, managed a team of 12 technicians to ensure quality control and safety procedures were followed for large projects. Experienced in performing tests on materials used for construction and providing feedback regarding their suitability for use. Skilled at troubleshooting issues related to concrete installation and repair processes as well monitoring work progress against timelines.

Experience

Concrete Technician, Employer A

Kansas City, Jan 2018 – Present

- Reduced project costs by 10% and construction timeframes by 30% through efficient planning, scheduling, and on-site management of concrete installation tasks.

- Developed new techniques for mixing cement mixtures to ensure uniformity in the finished product while conserving materials to limit overall project waste.

- Finished over 50 residential and commercial projects within contracted deadlines; consistently delivered a high quality end result that exceeded customer expectations.

- Measured existing structures accurately using laser or optical surveying equipment then calculated mix proportions accordingly for all subsequent installations of poured concrete foundations, footings, walls and other structural components as needed per job specs/plans.

- Meticulously inspected newly installed slabs & vertical surfaces for defects such as honeycombing, surface flaws or cracking before application of decorative finishes were applied; ensured compliance with industry standards at all times during inspection process.

Concrete Technician, Employer B

Austin, Mar 2012 – Dec 2017

- Facilitated the installation of over 20,000 sq. Ft. Of concrete surfaces each month for commercial and residential clients; reduced overall project costs by 5%.

- Prepared the construction sites prior to pouring concrete, including digging trenches and laying out irrigation lines in accordance with blueprints; completed projects on time and within budget limits every quarter.

- Assessed the structural integrity of existing foundations using levelers, plumb bobs and other measuring tools to ensure that all new installations were properly aligned before pouring new cement slabs or walkways.

- Grouted masonry walls utilizing an array of power saws, trowels & mortar mixers while adhering strictly to safety regulations set forth by OSHA standards; successfully finished 8 large-scale projects ahead of schedule this year alone.

- Proficiently operated machinery such as jackhammers & vibrators while maintaining a safe work environment throughout various job sites; consistently recognized for high performance ratings from employers since 2019.

Skills

- Troubleshooting

- Electrical Wiring

- Mechanical Maintenance

- Hydraulics

- Pneumatics

- Automation

- Welding

- Fabrication

- Machining

Education

Associate Degree in Concrete Technology

Educational Institution XYZ

Nov 2011

Certifications

ACI Concrete Field Testing Technician Grade I Certification

American Concrete

May 2017

1. Summary / Objective

Your resume summary should be a concise and compelling overview of your concrete technician skills. In this section, you can highlight the most important aspects of your experience such as certifications or qualifications in concrete technology, knowledge of specialized tools and equipment for testing and analyzing samples, ability to read blueprints accurately, etc. You should also mention any awards or recognition you have received for outstanding performance on previous projects.

Below are some resume summary examples:

Hard-working concrete technician with 6+ years of experience in testing and inspecting concrete structures, materials, and components. Skilled at designing test plans specific to each project’s needs while following the latest ASTM standards. At XYZ Construction, led a team of 10 technicians to complete projects ahead of schedule while maintaining safety protocols. Received recognition from clients for attention to detail and high-quality results on multiple occasions.

Determined concrete technician with 5+ years of experience in the field and a proven ability to maintain concrete structures for residential, commercial, and industrial clients. Skilled at ensuring compliance with safety protocols, performing maintenance checks on equipment, troubleshooting issues quickly, and problem-solving complex challenges. Looking to join ABC Company as a Concrete Technician where my expertise can be utilized to ensure quality results.

Talented concrete technician with 8+ years of experience in testing and inspecting concrete materials for quality assurance. Expertise in working with different types of mixing machines, metering equipment, pumps, and other related tools. Proven ability to meet production goals while ensuring compliance with safety regulations. Seeking an opportunity at ABC Construction to use my knowledge and skillset for the benefit of the organization’s projects.

Committed concrete technician with 5+ years of experience in inspecting, measuring and testing concrete for safety and compliance. At XYZ Construction, inspected over 500 projects to ensure that all materials were up to code standards. Received “Employee Of The Month” award three times due to outstanding performance relating to accuracy and attention-to-detail. Ready to apply my knowledge of construction processes and regulations at ABC Company.

Detail-oriented and certified concrete technician with 9+ years of experience in the construction industry. Skilled at completing quality control inspections, preparing materials and mixing concrete, utilizing specialized tools to perform tests, and monitoring compliance with safety regulations. Seeking to leverage expertise as a Concrete Technician for ABC Construction Co., where I can contribute my knowledge towards successful projects.

Passionate concrete technician with 5+ years of experience in testing and inspecting concrete structures. At XYZ, led a team of 3 technicians to inspect over 300 foundations for residential sites. Successfully identified potential issues that were corrected prior to construction saving the company an estimated $25k annually. Received “Employee Excellence” award from ABC Structural Engineering Firm for superior performance on projects.

Reliable concrete technician with 8+ years of experience in the construction industry. Seeking to join ABC Construction as a concrete specialist and contribute expertise towards quality control, materials testing, inspections and maintenance. At XYZ Ltd. , led 5 successful projects that achieved 99% customer satisfaction ratings for structural integrity across all structures completed on-time or ahead of schedule.

Energetic and detail-oriented concrete technician specializing in structural repair, testing and inspection. Over five years of experience providing quality assurance for both commercial and residential projects with an average customer satisfaction rating of 94%. Seeking to apply my skill set to the role of Concrete Technician at ABC Company.

2. Experience / Employment

The work history/experience section of your resume is where you provide details on the roles you have held in the past. It should be written in reverse chronological order, meaning that your most recent job comes first.

When writing this section, stick to bullet points; it makes it easier for a reader to take in what you are saying quickly and efficiently. When stating what duties were performed, try to include quantifiable results or accomplishments whenever possible.

For example, instead of saying “Mixed concrete,” say something like “Mixed over 200 cubic yards of concrete per week according to specific ratios prescribed by engineering standards.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Inspected

- Measured

- Mixed

- Poured

- Finished

- Repaired

- Sealed

- Leveled

- Troweled

- Cured

- Drilled

- Sanded

- Grouted

- Polished

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Competently performed quality control testing on concrete samples and formulated solutions to improve the material’s performance; increased strength of finished products by 15%.

- Polished, repaired and maintained over 500 cubic meters of concrete surfaces for commercial buildings, residential developments and industrial sites using specialized tools.

- Presented detailed reports highlighting test results from various construction projects to clients, supervisors and contractors; saved $7000 in project costs due to early detection of potential problems.

- Revised existing standards related to building codes while adhering strictly with safety guidelines when operating machinery such as vibrators or engravers at all times.

- Formulated effective strategies for optimizing the production rate during large-scale constructions involving hundreds of workers; completed 11 jobs ahead schedule within a 12 month period resulting in cost savings up to $5000 each job site per week.

- Demonstrated advanced knowledge of concrete mixtures and properties when troweling over 200+ cubic yards for residential, commercial and industrial projects; increased durability and strength by 18%.

- Structured efficient production processes that enabled the completion of seven major jobs on-time in spite of severe weather conditions; saved $15,000 in additional costs.

- Coordinated daily activities with other site personnel to ensure safe working environment under all circumstances; reduced incidents from 8 to 0 within a year through improved safety training procedures.

- Troweled multiple layers for foundations, walls & patios using power tools (tamper/vibrator) while adhering to building codes & standards set by state government departments; completed tasks 80% faster than industry average timeframes due to high level expertise.

- Thoroughly inspected finished surfaces before applying sealants or coatings as per customer specification, reducing rework requirements by 15%.

- Sanded and leveled up to 500 square feet of concrete surfaces with power tools and hand-held abrasives per day, resulting in a 10% reduction in labor costs.

- Improved the quality of existing structures by repairing cracks, filling voids, reinforcing joints and enhancing surface texture; increased cost savings on maintenance materials by 15%.

- Inspected newly poured concrete for proper curing levels prior to installing anchor bolts or other hardware components; reduced errors due to improper installation by 20%.

- Utilized specialized equipment such as laser screeds and trowel machines when finishing slabs according to customer specifications within tight time frames; completed projects 2 days ahead of schedule on average.

- Independently operated heavy machinery such as backhoes & cement mixers while adhering strictly to safety regulations at all times during job sites visits; cut down workplace accidents caused by negligence by 25%.

- Achieved an average of 85% accuracy in testing concrete samples for compliance with ASTM standards, resulting in a 20% increase in productivity.

- Streamlined daily operations by training other technicians on efficient use of equipment and quality control processes; reduced setup time from 30 minutes to 10 minutes per sample test.

- Substantially improved safety protocols when operating heavy machinery and successfully completed 1,500+ hours without any major accidents or injuries reported during 5-year tenure as Concrete Technician.

- Spearheaded the installation of new automated systems to improve batching process efficiency; achieved 3x faster production times while maintaining desired strength levels of the end product at all times.

- Poured over 8 million cubic feet (8MCF) of concrete across various projects throughout career including industrial complexes, hospitals and high-rise buildings; monitored pour density & slump tests regularly to ensure consistent quality results were obtained every time.

- Represented the company in over 50 successful concrete installations, with a record of zero customer complaints.

- Advised on-site teams and clients regarding best practices for mixing, pouring and curing concrete; increased safety standards by 25%.

- Confidently assessed the condition of existing structures to identify any weak points or areas needing repair before new installation work began.

- Mentored 8 junior technicians in the proper use of tools and techniques used when installing reinforced steel rods within fresh slabs; reduced training time by 45%.

- Participated as part of a team that completed 80+ large scale commercial projects ahead of schedule while staying within budget guidelines – saving an average $12K per project compared to initial estimates.

- Effectively drilled, mixed and poured concrete for the construction of commercial and residential buildings; cut down on labor costs by 10%.

- Reorganized workflows in order to expedite completion times; achieved a 20% increase in productivity over 6 months.

- Drilled more than 40 holes per day using electric core drills with precision accuracy while adhering to OSHA safety regulations at all times.

- Introduced new techniques when mixing cement as well as incorporated additives such as polymers, fibers and colorants into various mixtures for strength enhancement or aesthetic appeal purposes.

- Expedited production timelines by utilizing hydraulic jacks & vibrators to compact slabs quickly; completed projects up to 3 days ahead of schedule on average.

- Successfully repaired and leveled concrete sidewalks, curbs, foundations and other structures for commercial and residential customers; saved $3,000 in contractor costs over the last quarter.

- Optimized existing structures by replacing failed areas of concrete with new materials to increase structural integrity; improved load bearing capacity by 32%.

- Compiled detailed reports about current condition of each job site using industry-standard equipment such as lasers levels & inclinometers; completed 25+ inspection surveys per week on average.

- Applied a variety of finishing methods (e.g., troweling & sandblasting) after pouring or laying down the concrete to ensure surfaces were level and free from imperfections before curing process began.

- Performed regular maintenance on all equipment used at work sites including mixers, screeds & vibratory tampers while adhering to relevant safety rules/regulations at all times.

- Consistently operated a concrete mixer and other equipment to mix materials for batches of up to 10 cubic yards, reducing time-per-batch by 35%.

- Mixed various components such as cement, sand, gravel and water in accordance with established safety protocols; managed 5 successful pours per week.

- Sealed joints and edges between forms using caulk or epoxy sealant for the placement of sidewalks, patios and driveways; achieved 98% accuracy when sealing surfaces on over 40 installations each month.

- Cured newly installed concrete structures according to industry standards through the application of curing compounds & blankets; reduced drying times by 15% while maintaining quality of workmanship throughout projects.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization may require extensive knowledge of concrete testing, while another may be more interested in someone with experience in the installation and maintenance of concrete structures.

Therefore, it is important to tailor your skills section to each job you are applying for – this will help ensure that the right keywords make their way into your resume so that applicant tracking systems can identify them.

It’s also a good idea to elaborate on these skills further by discussing them in other areas such as the summary or work history sections.

Below is a list of common skills & terms:

- Automation

- Electrical Wiring

- Fabrication

- Hydraulics

- Machining

- Mechanical Maintenance

- Pneumatics

- Robotics

- Troubleshooting

- Welding

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, it is important to include an education section below your resume objective. However, if you have significant work experience that showcases the skills necessary for a concrete technician role, omitting the education section may be best.

If including an education section, try to mention courses and subjects related to concrete technology or construction management that demonstrate knowledge of the field relevant to this job position.

Associate Degree in Concrete Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to potential employers that you have the necessary knowledge and skills for a particular job. They also show that you are committed to staying up-to-date with industry trends and developments.

Including certifications on your resume is an excellent way of showing hiring managers that you possess the qualifications they are looking for in their ideal candidate. Make sure to list any relevant certifications, as this can be a great way of making yourself stand out from other applicants.

ACI Concrete Field Testing Technician Grade I Certification

American Concrete

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Edwina Kshlerin, this would be Edwina-Kshlerin-resume.pdf or Edwina-Kshlerin-resume.docx.

7. Cover Letter

A cover letter is an essential part of any job application. It provides potential employers with a more detailed view into who you are and why you’re the right person for the role.

Cover letters usually consist of 2 to 4 paragraphs that expand on your resume, but they can also be used to explain gaps in employment history or address other issues not mentioned on your CV. Even if it’s not required by the employer, writing one is highly recommended as it showcases your professionalism and demonstrates how passionate you are about securing the position.

Below is an example cover letter:

Dear Kaylin,

I am writing in response to your ad for a Concrete Technician. With more than 7 years of experience working with concrete, I am confident I have the skills and knowledge you are looking for.

In my current role as a Concrete Technician at ABC Corporation, I am responsible for conducting compressive strength tests, slump tests, and density tests on concrete samples. I also create mix designs based on customer specifications and oversee the production of concrete according to those specifications. In addition, I provide support to customers by troubleshooting issues with their concrete mixes and providing recommendations for solutions.

Through my work experience, I have developed strong attention to detail and problem solving skills that enable me to produce high quality work. My ability to follow instructions and meet deadlines has resulted in consistent positive feedback from my supervisors. In addition, my interpersonal skills allow me to effectively communicate with co-workers and customers alike.

I believe that my qualifications make me the perfect candidate for this position and look forward to discussing how I can be an asset to your team. Thank you for your time and consideration; please do not hesitate to contact me if you have any questions or would like additional information about my qualifications.

Sincerely,

Edwina

Concrete Technician Resume Templates

Dugong

Dugong Fossa

Fossa Gharial

Gharial Cormorant

Cormorant Hoopoe

Hoopoe Pika

Pika Ocelot

Ocelot Bonobo

Bonobo Indri

Indri Rhea

Rhea Axolotl

Axolotl Markhor

Markhor Lorikeet

Lorikeet Echidna

Echidna Jerboa

Jerboa Quokka

Quokka Kinkajou

Kinkajou Saola

Saola Numbat

Numbat Rezjumei

Rezjumei