Composite Technician Resume Guide

Composite Technicians work with composite materials to manufacture and repair parts for aircraft, automobiles, boats and other products. They use specialized tools such as hand lay-up molds, autoclaves and vacuum bags to fabricate components from fiberglass, carbon fibers or kevlar fabrics. They also inspect parts for defects before they are shipped off the production line.

Your composite technician skills are second to none, but employers don’t know who you are yet. Show them what you can do by writing a resume that truly stands out and emphasizes your abilities.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

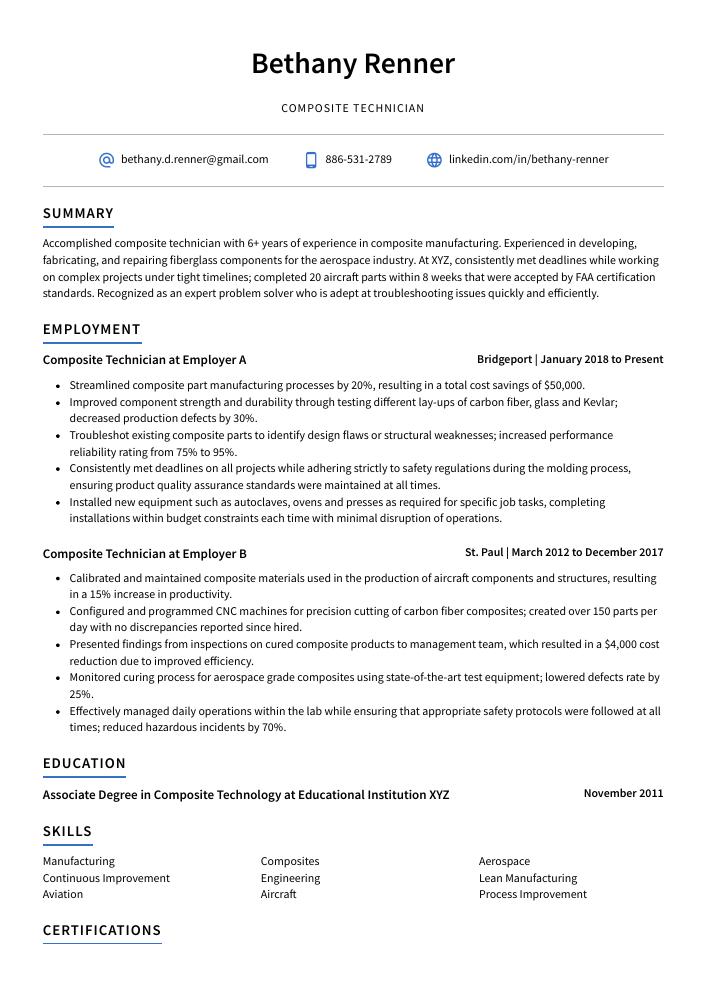

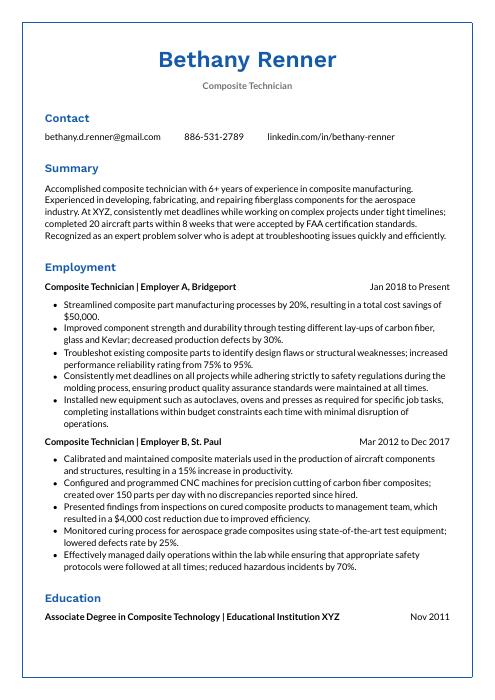

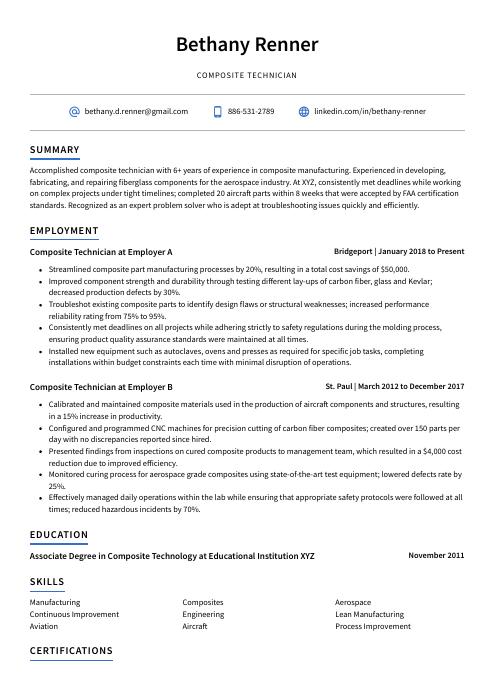

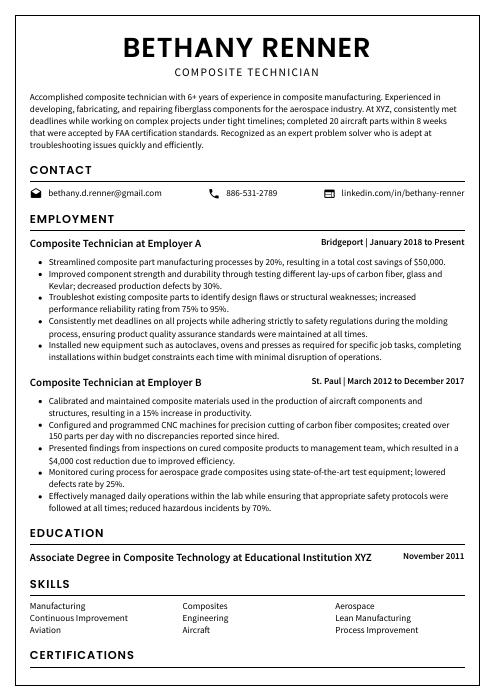

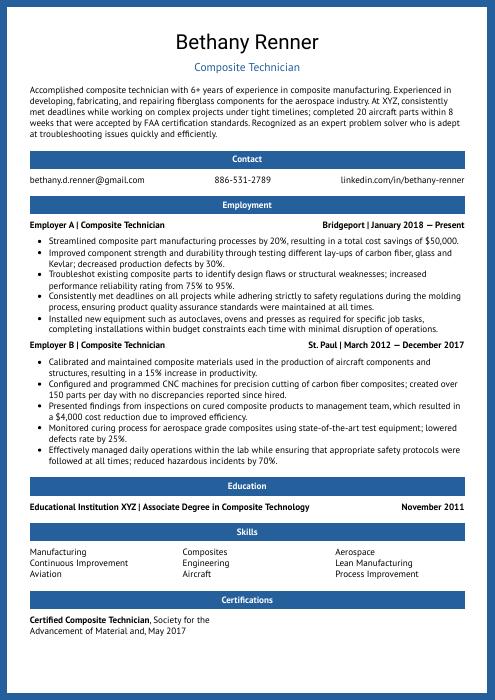

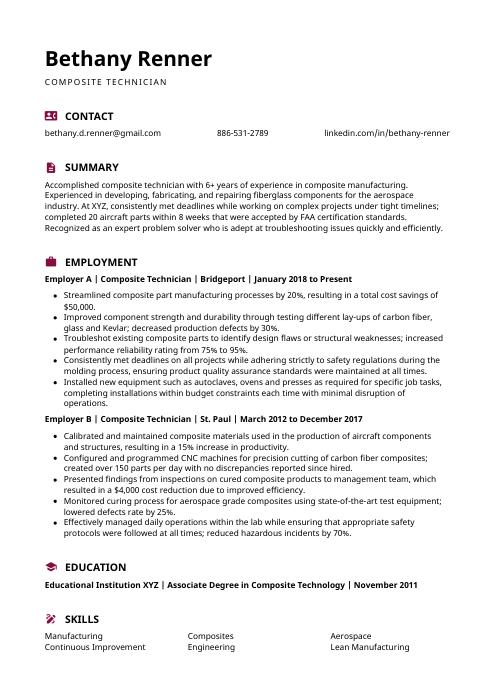

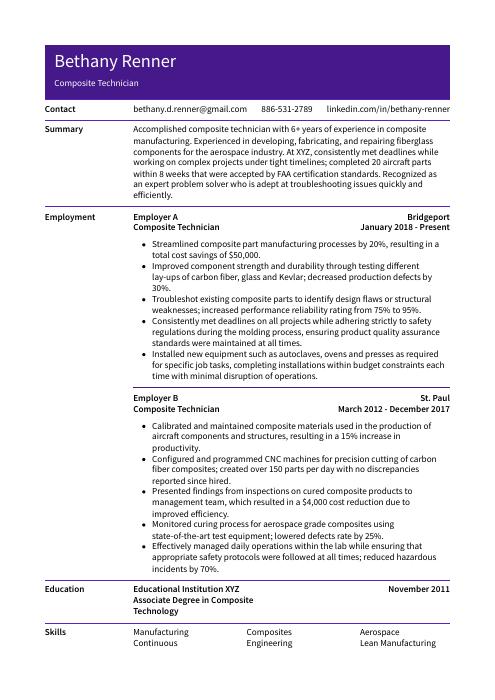

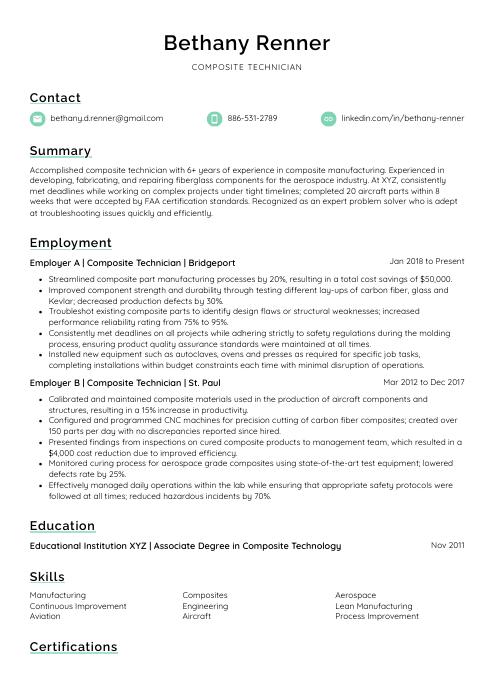

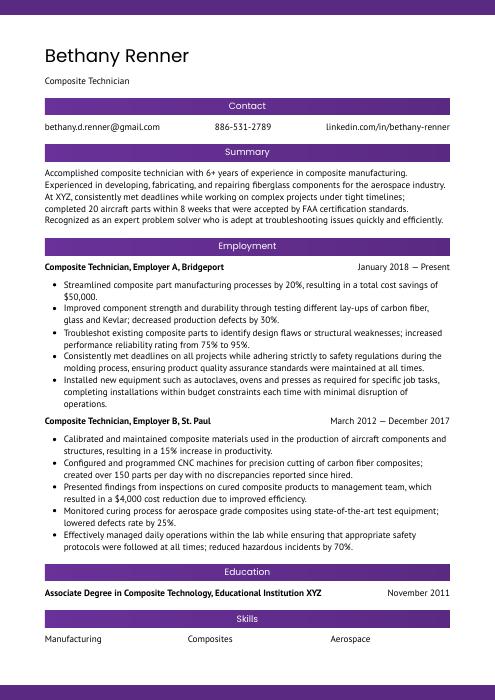

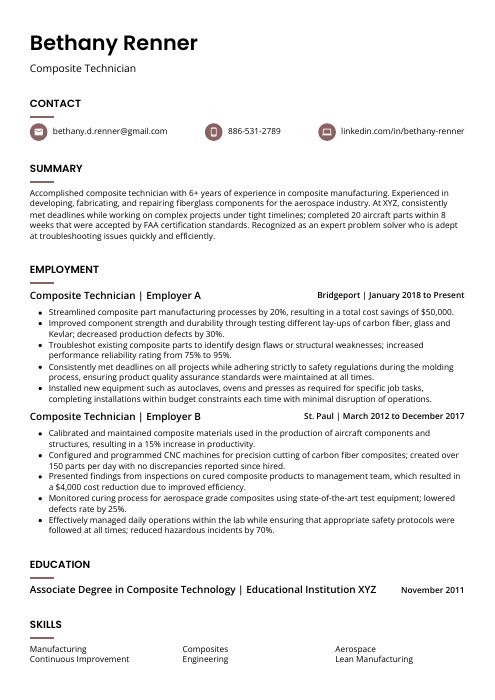

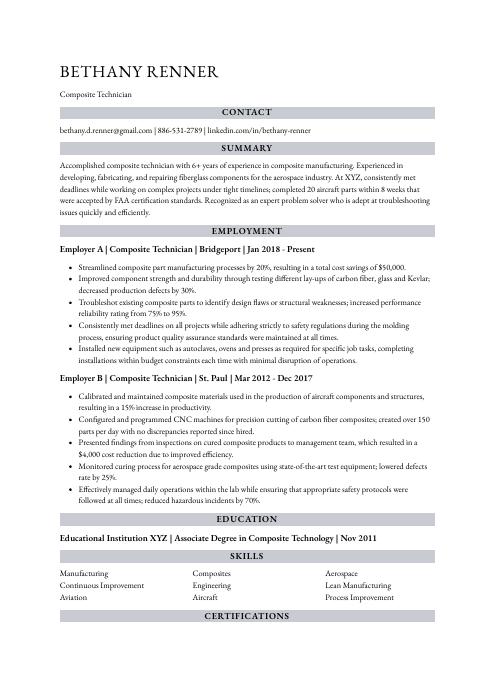

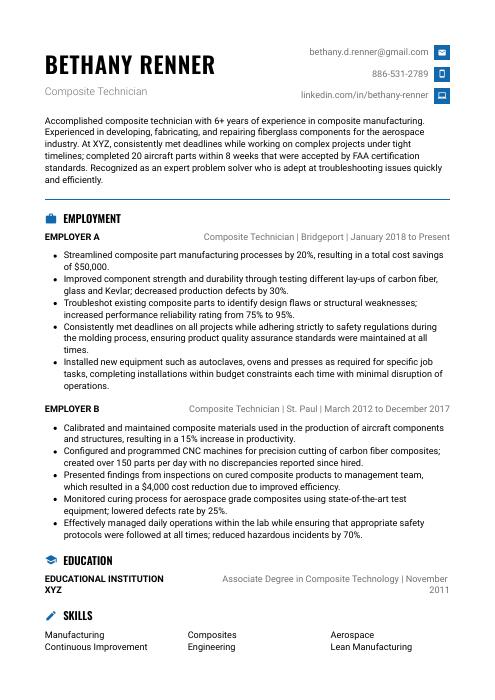

Composite Technician Resume Sample

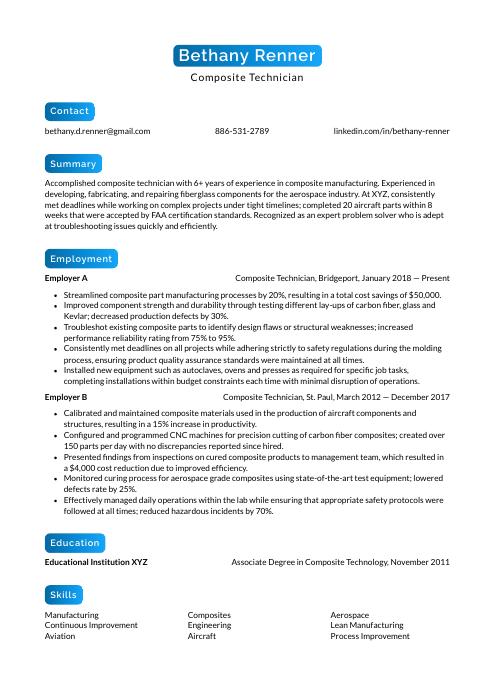

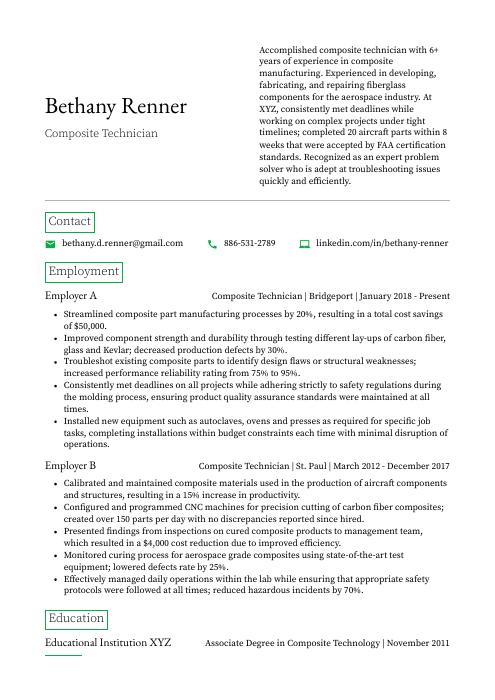

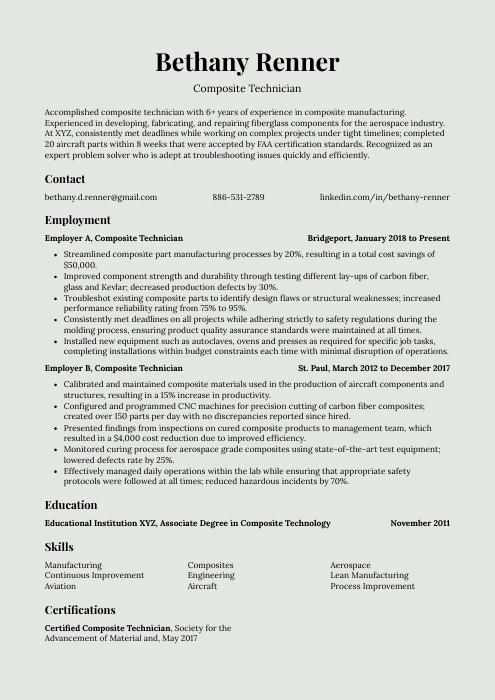

Bethany Renner

Composite Technician

[email protected]

886-531-2789

linkedin.com/in/bethany-renner

Summary

Accomplished composite technician with 6+ years of experience in composite manufacturing. Experienced in developing, fabricating, and repairing fiberglass components for the aerospace industry. At XYZ, consistently met deadlines while working on complex projects under tight timelines; completed 20 aircraft parts within 8 weeks that were accepted by FAA certification standards. Recognized as an expert problem solver who is adept at troubleshooting issues quickly and efficiently.

Experience

Composite Technician, Employer A

Bridgeport, Jan 2018 – Present

- Streamlined composite part manufacturing processes by 20%, resulting in a total cost savings of $50,000.

- Improved component strength and durability through testing different lay-ups of carbon fiber, glass and Kevlar; decreased production defects by 30%.

- Troubleshot existing composite parts to identify design flaws or structural weaknesses; increased performance reliability rating from 75% to 95%.

- Consistently met deadlines on all projects while adhering strictly to safety regulations during the molding process, ensuring product quality assurance standards were maintained at all times.

- Installed new equipment such as autoclaves, ovens and presses as required for specific job tasks, completing installations within budget constraints each time with minimal disruption of operations.

Composite Technician, Employer B

St. Paul, Mar 2012 – Dec 2017

- Calibrated and maintained composite materials used in the production of aircraft components and structures, resulting in a 15% increase in productivity.

- Configured and programmed CNC machines for precision cutting of carbon fiber composites; created over 150 parts per day with no discrepancies reported since hired.

- Presented findings from inspections on cured composite products to management team, which resulted in a $4,000 cost reduction due to improved efficiency.

- Monitored curing process for aerospace grade composites using state-of-the-art test equipment; lowered defects rate by 25%.

- Effectively managed daily operations within the lab while ensuring that appropriate safety protocols were followed at all times; reduced hazardous incidents by 70%.

Skills

- Manufacturing

- Composites

- Aerospace

- Continuous Improvement

- Engineering

- Lean Manufacturing

- Aviation

- Aircraft

- Process Improvement

Education

Associate Degree in Composite Technology

Educational Institution XYZ

Nov 2011

Certifications

Certified Composite Technician

Society for the Advancement of Material and

May 2017

1. Summary / Objective

The summary/objective at the top of your resume is like a teaser – it gives employers an overview of who you are and why you excel as a composite technician. Here is where you can showcase your best qualities. For example, you could talk about the advanced composites materials and processes that are familiar to you, any certifications or training courses related to composite technology that have been completed, and how many years of experience in this field have been gained.

Below are some resume summary examples:

Reliable composite technician with 10+ years of experience in the industry. Skilled at identifying and troubleshooting issues, as well as performing repairs on composite structures for aerospace applications. At XYZ Corporation, successfully implemented a new system to track quality control metrics which resulted in an increase of 15% efficiency across all departments. Committed to delivering high-quality work that meets customer needs and deadlines.

Seasoned composite technician with 10+ years of experience in the production, assembly, and repair of composite structures. Experienced in working on complex structural components for aerospace applications such as wings, fuselages and tail sections. Skilled at using hand & power tools to fabricate high-precision parts while following strict quality guidelines. Proficient in troubleshooting and problem solving techniques to ensure smooth operations.

Passionate composite technician with 5+ years of experience in the aerospace industry. Skilled at creating composite parts, inspecting and repairing components, and working closely with engineering teams to ensure quality control standards are met. Proven track record of efficiently managing multiple projects while meeting tight deadlines. Seeking to leverage expertise in composites into a role as Composite Technician at ABC Aerospace Corporation.

Amicable composite technician with 5+ years of experience in the aviation industry. Proficient in inspecting, repairing, and assembling composite components for commercial aircrafts. Adept at efficiently managing multiple projects while adhering to safety protocols and quality standards. Looking to join ABC Airlines as a Composite Technician where I can apply my skills towards delivering high-quality products for clients globally.

Energetic and passionate composite technician with 6+ years of experience in the aerospace industry. Experienced in fabricating, repairing and inspecting composites for commercial aircraft components. At XYZ Aerospace, implemented a new process that increased production efficiency by 25%. Received multiple awards for exceptional workmanship from customers across several industries.

Skilled composite technician with 5+ years of experience in the aerospace industry. Seeking to leverage expertise in composite materials and manufacturing processes to create innovative solutions at ABC Aerospace. At XYZ, designed a new layup process that increased production efficiency by 25%. Also reduced material waste by 35%, resulting in an estimated savings of $45K annually.

Diligent Composite Technician with 5+ years of experience in the manufacturing and production industries. Expertise in composite material fabrication, manual machining, assembly and testing processes with a proven track record of meeting deadlines despite tight constraints. Seeking to use these skills at ABC Inc. to ensure safe operations while producing quality products on time.

Detail-oriented composite technician with 10+ years of experience in the aerospace industry. Achieved consistent, on-time completion for a variety of projects, from building aircraft components to repairing damaged structures. Seeking an opportunity at ABC Aerospace where I can leverage my knowledge and expertise to ensure high quality product output.

2. Experience / Employment

The employment (or experience) section of your resume should be written in reverse chronological order, meaning that the job you held most recently is listed first.

When writing this section, use bullet points to make it easier for the reader to digest what you have to say quickly. You want to provide detail on what you did and any results or accomplishments achieved.

For example, instead of saying “Prepared composite materials,” you could say, “Mixed various resins and fibers according to customer specifications; created high-quality parts with an average scrap rate of 3%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Assembled

- Installed

- Inspected

- Calibrated

- Troubleshot

- Repaired

- Soldered

- Programmed

- Configured

- Tested

- Measured

- Adjusted

- Fabricated

- Monitored

- Operated

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Prepared and laid out composite materials, including fiberglass and carbon fiber, according to customer specifications; increased production efficiency by 20%.

- Programmed and operated CNC machines to cut parts with tight tolerances of +-0.010″; reduced scrap rate from 10% down to 5%.

- Coordinated the fabrication process of complex composite structures used in aerospace components utilizing a variety of techniques such as vacuum bagging and resin infusion; completed projects 4 hours ahead of schedule on average.

- Adjusted for discrepancies between CAD drawings/blueprints & actual assemblies by making necessary modifications during dry lay up processes; decreased time spent troubleshooting issues from 8 hours to 2 hours minimum per project.

- Diligently inspected all tooling prior to use ensuring proper fitment and conformance with safety regulations, resulting in zero product defects over an 18 month period.

- Measured and tested the physical properties of composite materials to assess their performance and suitability for client projects; formulated new recipes/formulas that increased impact resistance by 30%.

- Participated in cross-functional team meetings with engineers, designers, suppliers & manufacturers when designing various components from composites; resourcefully solved problems that arose during product development.

- Developed a quality control system based on ASTM standards which reduced nonconformance levels by 10%; consistently verified accuracy of measurement equipment to ensure reliable results at all times.

- Assembled complex parts using hand tools as well as automated machines, reducing production time per part by 40% while maintaining high quality standards throughout every step of the process.

- Crafted prototypes for clients via 3D printer technology and other CAD programs; successfully completed 8 prototype models over 6 months which improved product design efficiency significantly ($20K savings).

- Operated and maintained composite manufacturing equipment, such as mixers and presses; oversaw the production of over 100 components per day while ensuring accuracy and quality.

- Reorganized factory layout to optimize space utilization and reduce downtime; expedited workflow by 15%, resulting in a 30% increase in overall productivity.

- Expedited repairs on defective composite parts by troubleshooting problems quickly, eliminating costly delays due to mechanical failure or material defects.

- Repaired damaged molds using advanced techniques for removing air bubbles from composites; inspected finished products for uniformity before release into market distribution channels with zero non-conformance reports within 6 months of service.

- Meticulously documented all maintenance activities according to safety guidelines, reducing potential hazards associated with working around hazardous materials significantly during repair works.

- Spearheaded the repair and maintenance of composite parts on a fleet of 30+ aircrafts, ensuring that all safety regulations were strictly adhered to; reduced repair time by 15%.

- Reduced the cost of materials used for composite repairs by 10%, negotiating better deals with suppliers in order to facilitate budget planning.

- Demonstrated expertise in using resin infusion techniques, vacuum bagging and other advanced procedures when repairing structural integrity issues caused by cracks or fatigue damage on aircraft components such as wings, tails and fuselages.

- Successfully completed 100+ complex composite repairs within deadlines while overseeing 3 technicians under my supervision; trained 5 new staff members during this period as well.

- Advised management team regarding potential improvements to current processes related to material selection & handling at regular intervals throughout the year; increased efficiency levels by 25%.

- Fabricated composite components for aerospace industry, utilizing advanced composite lay-up techniques and ensuring strict compliance with industry standards; reduced labor time per part by 30%.

- Competently operated a variety of machines to trim, drill and shape composites parts according to customer specifications; successfully completed over 120 projects in the past year.

- Inspected finished products for defects using magnifying tools and other measuring instruments, leading to improved quality assurance results (95% pass rate).

- Revised engineering drawings as necessary when changes were made in production process or design configurations; helped increase on-time deliveries by 15%.

- Developed processes for maintaining mold integrity & surface finish during manufacturing operations, resulting in significant cost savings of $20K annually.

- Compiled and assembled composite parts with consistency and accuracy, completing an average of 25 tasks per day.

- Confidently operated high-tech machines to cut patterns into composites, increasing production efficiency by 20%.

- Introduced new techniques for layering and bonding composite materials together; improved overall strength of finished products by 17%.

- Optimized the use of automated tools such as routers in order to reduce labor costs and wasted materials; saved $1,000 a month on supplies alone.

- Assembled large carbon fiber components for aerospace projects & medical equipment using specialized adhesives within tight deadlines; completed every project 5 hours ahead of schedule on average.

- Facilitated the production of composite material components for aerospace and military applications, achieving a 50% reduction in component weight while maintaining structural integrity.

- Assessed customer requirements to determine the most suitable materials, processes and techniques required to achieve desired results; enabled completion of projects on time with zero rework or delays.

- Achieved cost savings of $25,000 by negotiating supplier contracts for raw materials at competitive prices without compromising quality standards or performance expectations.

- Thoroughly tested all finished products using advanced computer-controlled testing equipment before delivering them to customers; reduced product defects from 15% down to 5%.

- Mentored junior technicians on proper usage of composites manufacturing tools and machinery as well as safety protocols when handling hazardous chemicals; improved new hire onboarding process efficiency by 30%.

- Represented the company in multiple trade shows, exhibiting technical skills and knowledge to generate over $20,000 in sales.

- Utilized advanced composite fabrication materials including carbon fiber composites, epoxies, aluminum honeycomb structures and other lightweight structural materials to fabricate parts for aerospace/automotive industries.

- Actively tested various components of the manufactured items using instruments such as tensile strength testers; reduced defects & rework rate by 30%.

- Soldered electrical connections between metallic components according to industry standards; improved performance efficiency of products by 8%.

- Structured maintenance plans according to customer requirements while ensuring that all safety regulations were met during production processes; maintained high quality standards with zero errors resulting from negligence or improper handling procedures.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in carbon fiber layup, while the other may be looking for someone with knowledge of resin infusion.

It is essential to tailor your skills section according to each job you are applying for – this will ensure that your resume passes through any applicant tracking systems used by employers. You should also elaborate on the most important skills in other areas of the resume; such as, a summary or work history sections.

Below is a list of common skills & terms:

- Aerospace

- Aircraft

- Aircraft Maintenance

- Automotive

- Aviation

- Composite Structures

- Composites

- Continuous Improvement

- Engineering

- Inspection

- Lean Manufacturing

- Maintenance and Repair

- Manufacturing

- Process Improvement

- Program Management

- Team Leadership

- Teamwork

- Troubleshooting

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, include an education section below your resume objective. However, if you have significant work experience that is relevant to the composite technician role, it might be best to omit this section altogether.

If including an education section, try to mention courses or subjects related specifically to composites technology or engineering that could demonstrate any skillset applicable for the job position.

Associate Degree in Composite Technology

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and expertise in a certain field. They show potential employers that you have taken the time and effort to become certified, which is an indication of dedication, commitment, and hard work.

Including certifications on your resume can help you stand out from other applicants who may not be as qualified or experienced. Make sure to list any relevant certifications that are related to the job for which you are applying so they will be noticed by hiring managers.

Certified Composite Technician

Society for the Advancement of Material and

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Bethany Renner, this would be Bethany-Renner-resume.pdf or Bethany-Renner-resume.docx.

7. Cover Letter

Attaching a cover letter to your resume is a great way to enhance your job application and make yourself stand out from the crowd. Cover letters are typically 2 to 4 paragraphs long and provide more information than what’s included in a typical resume.

Cover letters enable you to express why you’re passionate about the role, how you meet all of their requirements, as well as highlighting any additional skills or experiences that could bring value to the company. Even if it isn’t required by an employer, writing a cover letter can help give recruiters further insight into who you are and increase your chances of being hired for the position.

Below is an example cover letter:

Dear Oleta,

I am writing in response to your posting for a Composite Technician on the [website name] website. With more than 10 years of experience working with composites, I am confident that I would make an excellent addition to your team.

In my current role as a Composite Technician at [company name], I work closely with engineers and designers to create composite parts and assemblies that meet customer specifications. I have gained extensive knowledge of various composite materials and manufacturing processes through my hands-on experience, and I am adept at troubleshooting issues that may arise during production. My attention to detail ensures that all parts are manufactured to the highest quality standards, which has resulted in high levels of customer satisfaction.

In addition to my technical skills, I also have strong interpersonal and communication skills that enable me to effectively collaborate with others. My ability to take direction well and follow instructions precisely makes me an ideal candidate for this position.

I believe that my skills and experience make me an ideal candidate for the Composite Technician position at your company, and I look forward to discussing how I can contribute to your organization’s success. Thank you for your time and consideration; please do not hesitate to contact me if you have any questions or would like additional information about my qualifications.

Sincerely,

Bethany

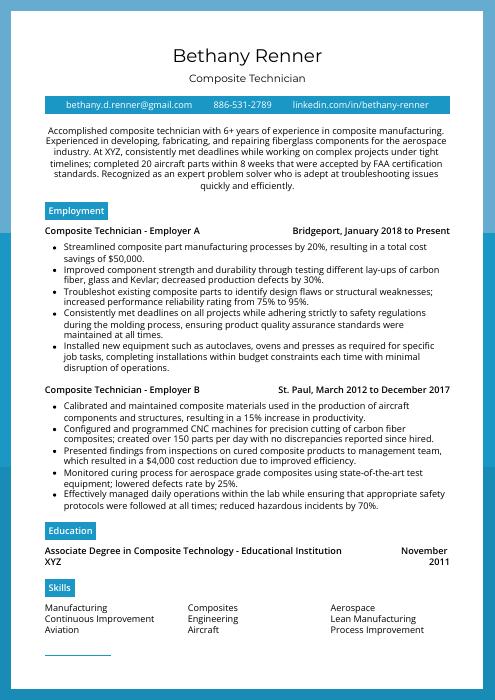

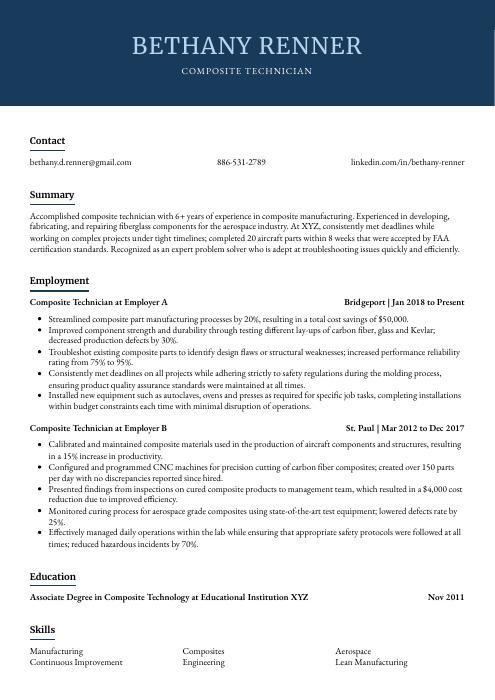

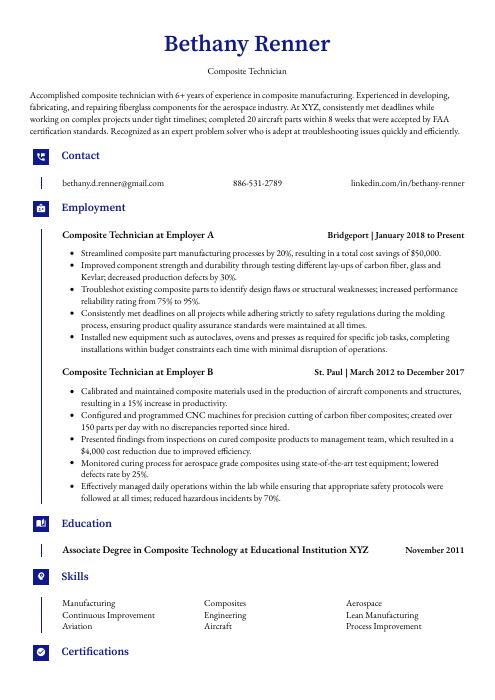

Composite Technician Resume Templates

Rhea

Rhea Bonobo

Bonobo Gharial

Gharial Markhor

Markhor Axolotl

Axolotl Cormorant

Cormorant Dugong

Dugong Ocelot

Ocelot Kinkajou

Kinkajou Quokka

Quokka Saola

Saola Indri

Indri Hoopoe

Hoopoe Pika

Pika Lorikeet

Lorikeet Jerboa

Jerboa Fossa

Fossa Numbat

Numbat Echidna

Echidna Rezjumei

Rezjumei