Die Cutter Operator Resume Guide

Die Cutter Operators use specialized machinery to cut and shape materials such as paper, plastic, rubber, or leather into specific shapes. They operate the die cutting machine by adjusting feed mechanisms and other controls to ensure proper material flow and cutting pressure. They must also monitor the progress of each job closely in order to ensure accuracy and quality standards are met.

You know the ins and outs of die cutting like no one else, yet employers don’t have a clue who you are. To get their attention and land the job, you must craft an eye-catching resume that highlights your abilities.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

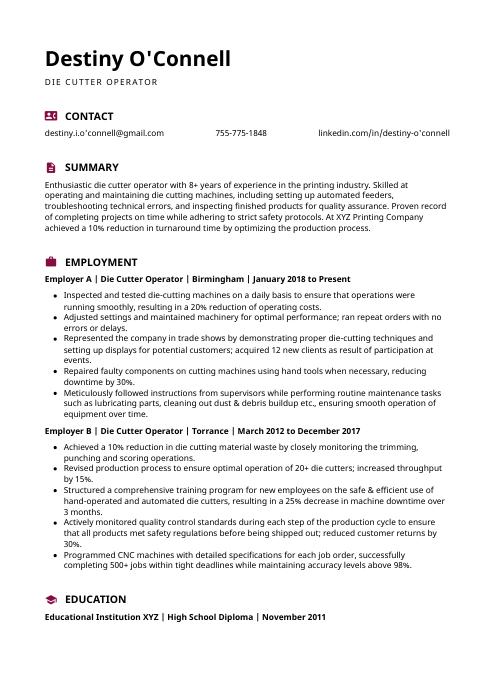

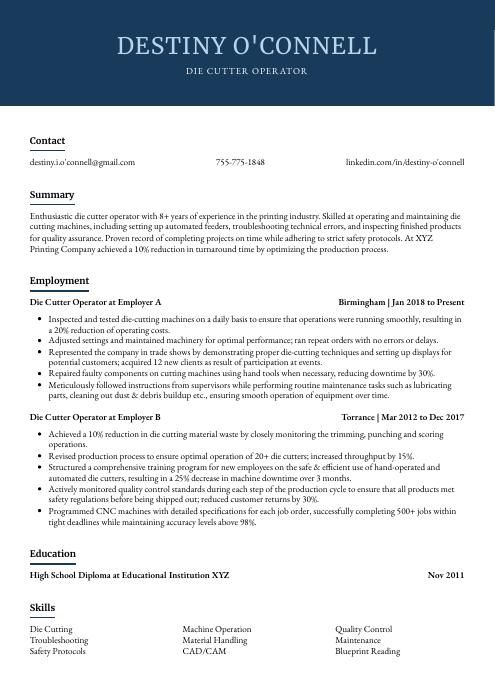

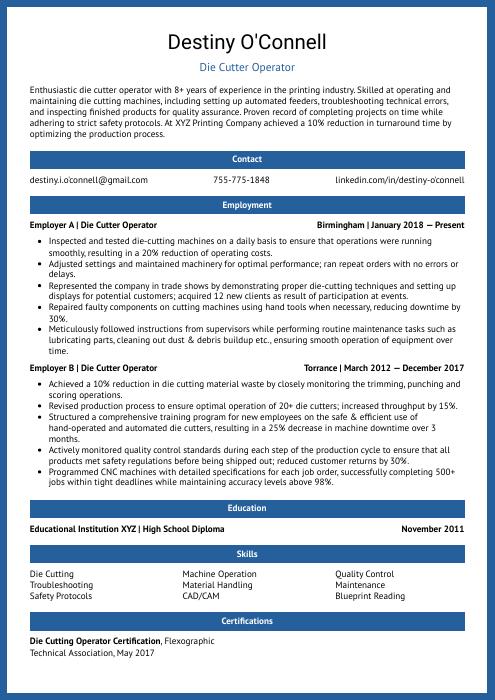

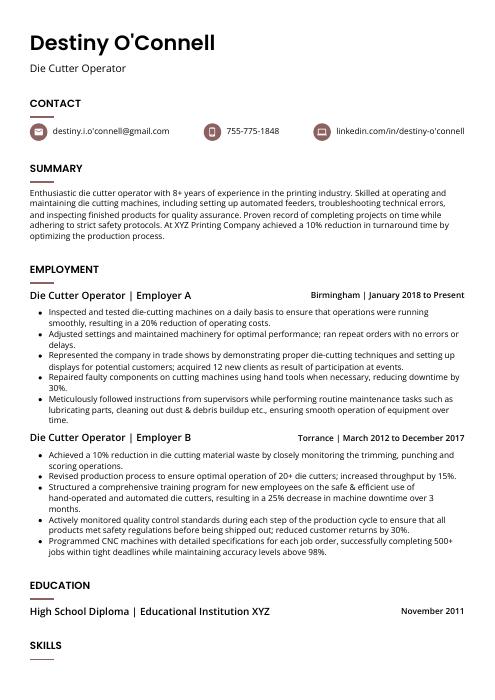

Die Cutter Operator Resume Sample

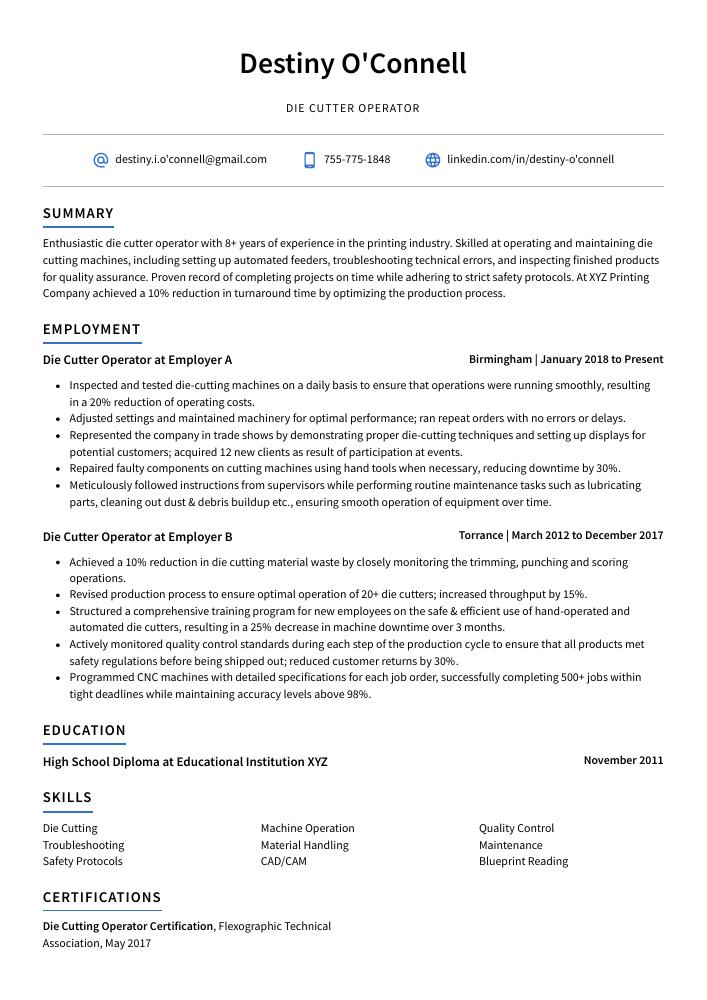

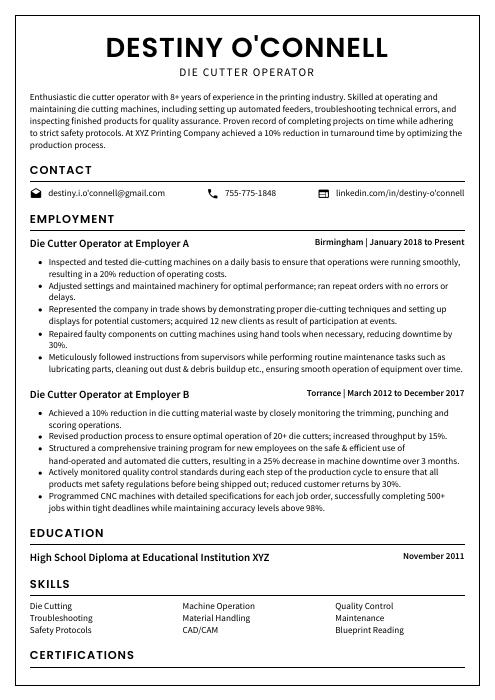

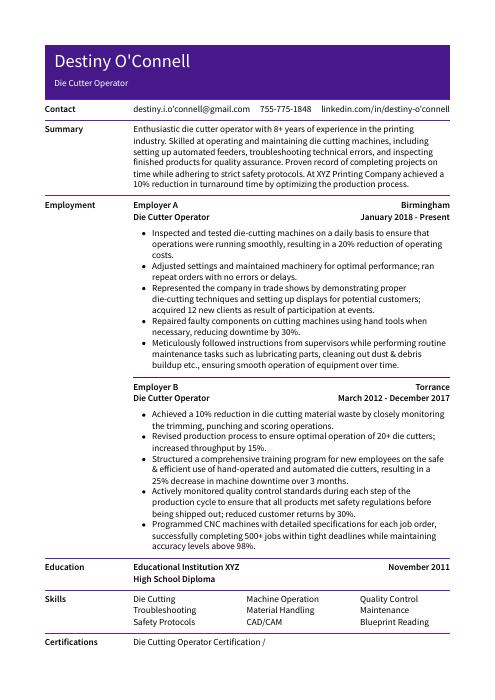

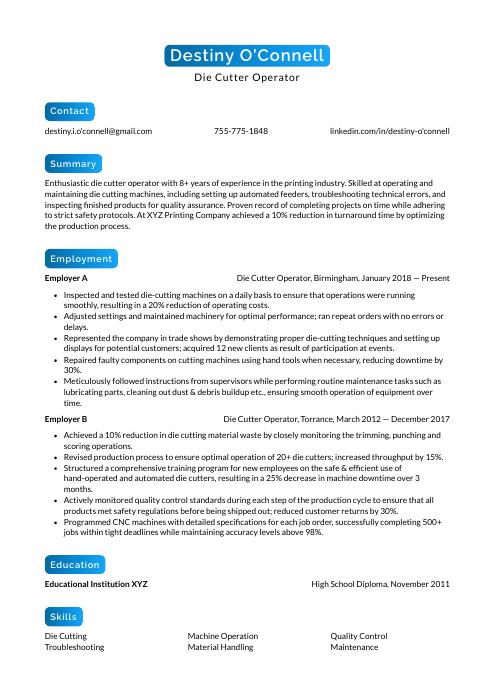

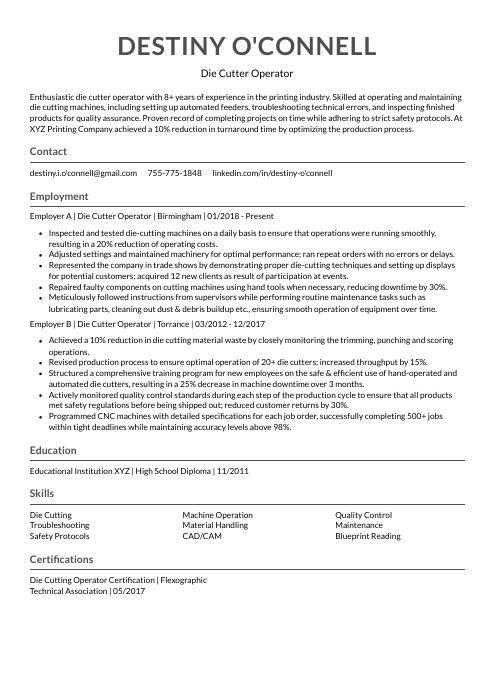

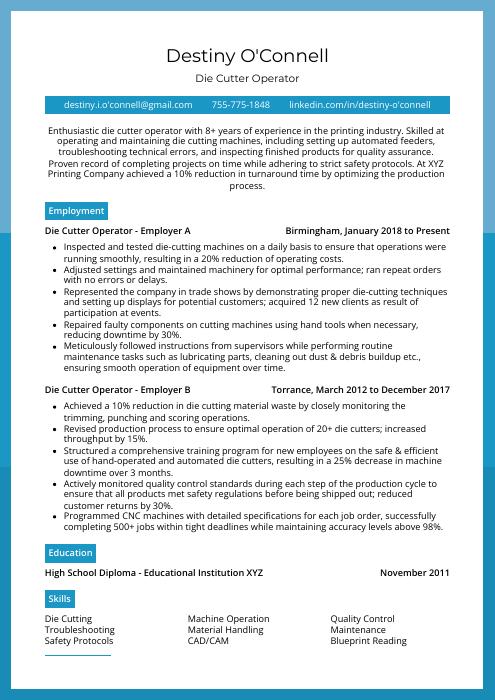

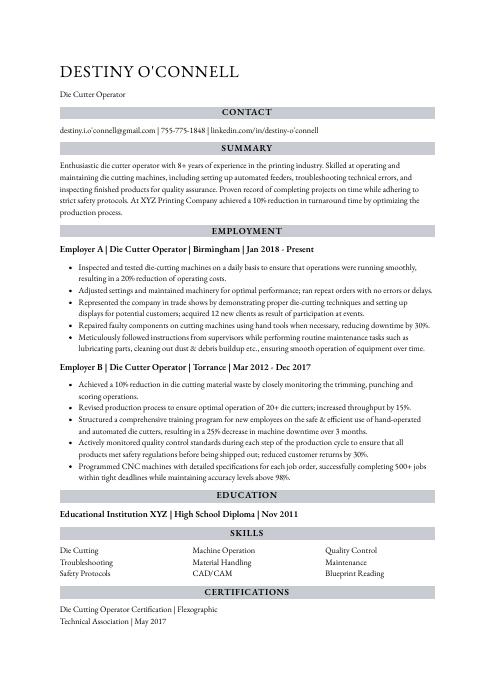

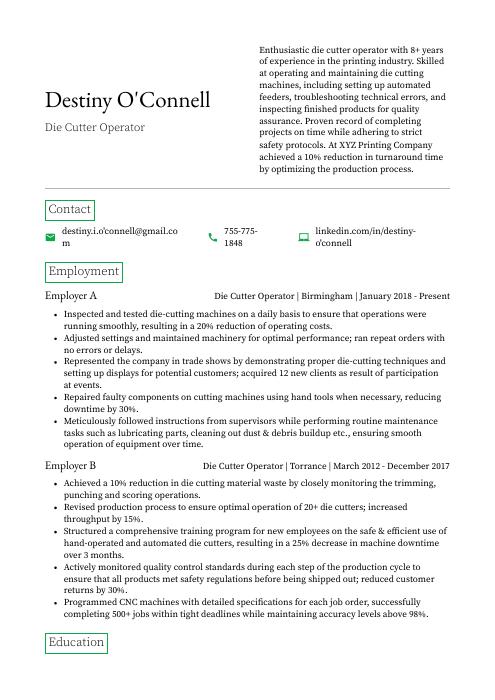

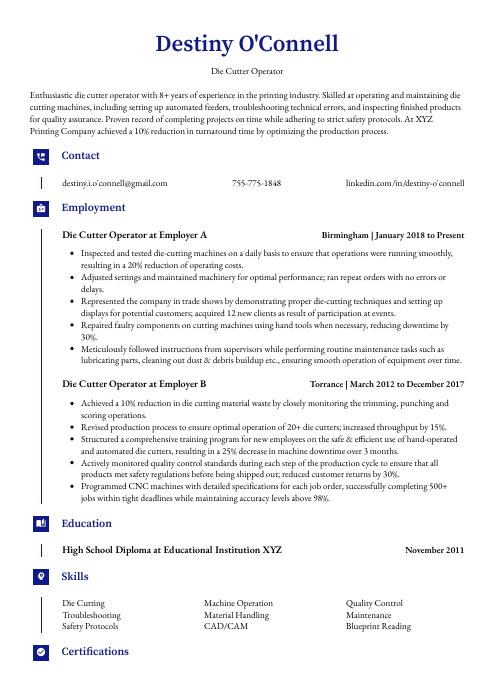

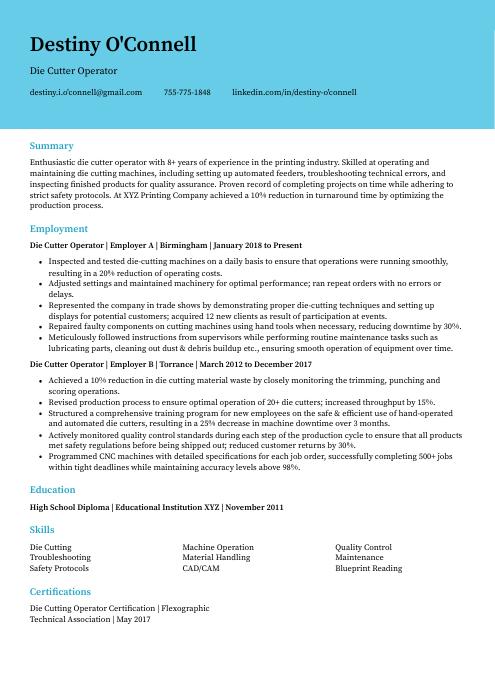

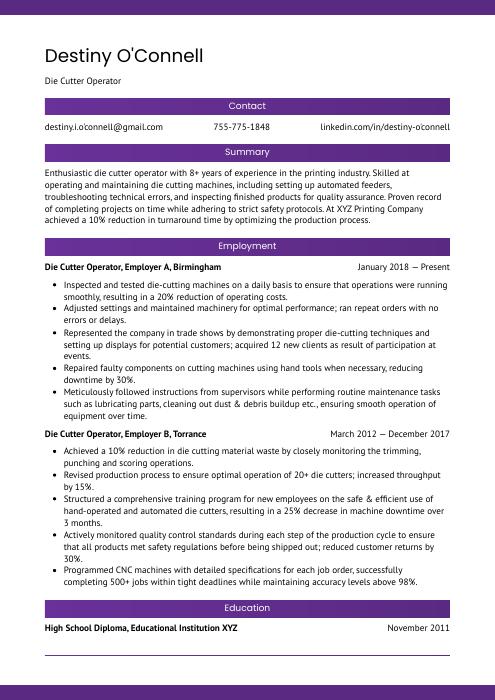

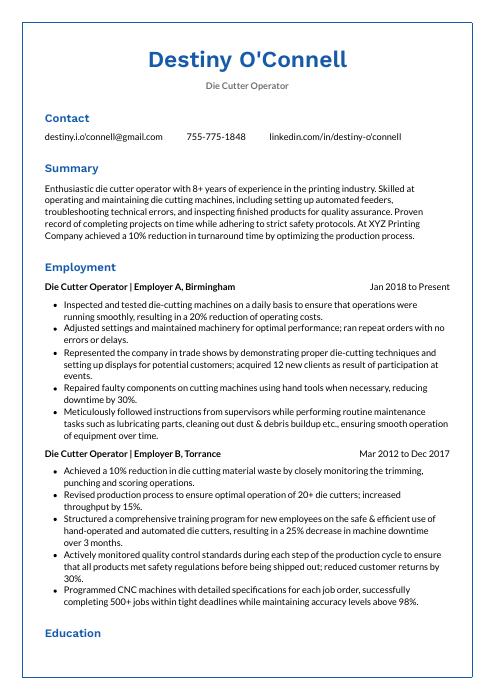

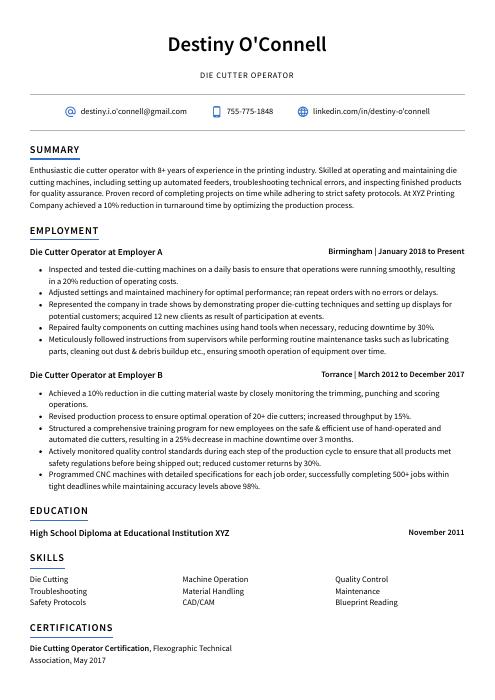

Destiny O’Connell

Die Cutter Operator

destiny.i.o’[email protected]

755-775-1848

linkedin.com/in/destiny-o’connell

Summary

Enthusiastic die cutter operator with 8+ years of experience in the printing industry. Skilled at operating and maintaining die cutting machines, including setting up automated feeders, troubleshooting technical errors, and inspecting finished products for quality assurance. Proven record of completing projects on time while adhering to strict safety protocols. At XYZ Printing Company achieved a 10% reduction in turnaround time by optimizing the production process.

Experience

Die Cutter Operator, Employer A

Birmingham, Jan 2018 – Present

- Inspected and tested die-cutting machines on a daily basis to ensure that operations were running smoothly, resulting in a 20% reduction of operating costs.

- Adjusted settings and maintained machinery for optimal performance; ran repeat orders with no errors or delays.

- Represented the company in trade shows by demonstrating proper die-cutting techniques and setting up displays for potential customers; acquired 12 new clients as result of participation at events.

- Repaired faulty components on cutting machines using hand tools when necessary, reducing downtime by 30%.

- Meticulously followed instructions from supervisors while performing routine maintenance tasks such as lubricating parts, cleaning out dust & debris buildup etc., ensuring smooth operation of equipment over time.

Die Cutter Operator, Employer B

Torrance, Mar 2012 – Dec 2017

- Achieved a 10% reduction in die cutting material waste by closely monitoring the trimming, punching and scoring operations.

- Revised production process to ensure optimal operation of 20+ die cutters; increased throughput by 15%.

- Structured a comprehensive training program for new employees on the safe & efficient use of hand-operated and automated die cutters, resulting in a 25% decrease in machine downtime over 3 months.

- Actively monitored quality control standards during each step of the production cycle to ensure that all products met safety regulations before being shipped out; reduced customer returns by 30%.

- Programmed CNC machines with detailed specifications for each job order, successfully completing 500+ jobs within tight deadlines while maintaining accuracy levels above 98%.

Skills

- Die Cutting

- Machine Operation

- Quality Control

- Troubleshooting

- Material Handling

- Maintenance

- Safety Protocols

- CAD/CAM

- Blueprint Reading

Education

High School Diploma

Educational Institution XYZ

Nov 2011

Certifications

Die Cutting Operator Certification

Flexographic Technical Association

May 2017

1. Summary / Objective

Your resume summary/objective should be like a movie trailer – it should provide the employer with essential information about your experience and qualifications as a die cutter operator. In this section, you can highlight your best qualities; for example, you could mention how many years of experience you have in operating industrial machinery, any certifications or licenses related to cutting machines that you possess, and how well-versed you are in safety protocols.

Below are some resume summary examples:

Reliable and highly skilled Die Cutter Operator with 8+ years of experience in the printing industry. Skilled at operating, troubleshooting and maintaining die-cutting machines to efficiently cut corrugated boards into shapes and sizes as per customer requirements. At XYZ Company, successfully managed a team of 20 operators while ensuring on-time delivery for over 200 orders daily. Achieved an average accuracy rate of 98%.

Well-rounded die cutter operator with 10+ years of experience operating die-cutting machines. At XYZ, operated a variety of die cutters and managed the entire process from start to finish. Skilled at troubleshooting machine issues while ensuring production goals are met on time and within budget. Experienced in setting up jobs for cutting, folding, scoring, laminating, and embossing operations with minimal supervision.

Hard-working die cutter operator with 7 years of experience in the fabrication and assembly industry. Successfully set up and operated a wide range of automated die cutting machines to produce parts for various industries, including automotive, aerospace, medical devices and electronics. Gained extensive knowledge on how to troubleshoot machinery issues efficiently using manual dexterity and problem-solving skills.

Determined die cutter operator with 5+ years of experience running and maintaining die cutting machines. Possesses a sharp eye for detail, ensuring that all products meet quality standards. Seeking to leverage expertise in the field to become an integral part of ABC Company’s production team. In previous role reduced waste by 30% while meeting tight deadlines without sacrificing accuracy or safety requirements.

Talented die cutter operator with 3+ years of experience in the printing and packaging industry. Highly skilled at operating die cutters, press brakes, and other machines to produce high-quality products that meet customer requirements while keeping safety a top priority. Seeking to join ABC Corporation as a Die Cutter Operator where I can use my skillset to increase productivity and efficiency.

Committed die cutter operator with 8+ years of experience working in a fast-paced manufacturing environment. Proven record for quickly learning and troubleshooting complex machinery, as well as maintaining safe work practices to minimize downtime and maximize productivity. Seeking to join ABC Group where my skills can be used to increase overall efficiency and quality standards.

Diligent Die Cutter Operator with 7+ years of hands-on experience in the printing and packaging industry. Proven track record for setting up, operating, troubleshooting and maintaining both manual and automated die cutting machines to meet tight deadlines. Seeking to join ABC Co as a Die Cutter Operator where I can utilize my skillset to improve production efficiency.

Driven die cutter operator with 8+ years of experience in a fast-paced production environment. Experienced in operating and maintaining die cutting machines, ensuring quality standards are met while adhering to safety regulations. Seeking to join ABC Manufacturing as the next Die Cutter Operator and use my skillset to deliver efficient results within tight timelines.

2. Experience / Employment

The employment (or experience) section is where you list your work history. It should be written in reverse chronological order, which means that the most recent job is listed first.

In this section, it’s best to stick to bullet points as they make it easier for the reader to take in what you have said quickly and easily. When writing each point, provide detail on what exactly you did and any quantifiable results achieved due to your efforts.

For example, instead of saying “Operated die cutting machines,” you could say “Successfully operated two high-speed die cutters with an average output rate of 5500 pieces per hour.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Operated

- Monitored

- Adjusted

- Inspected

- Troubleshot

- Programmed

- Loaded

- Laminated

- Assembled

- Aligned

- Calibrated

- Tested

- Repaired

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Optimized die-cutting operations by setting up and operating multiple machines at once, reducing production time by 20%.

- Utilized mechanical presses to cut laminated materials into various shapes/sizes for various products; operated over 10 die cutting machines per day with a high degree of accuracy.

- Facilitated the efficient operation of all die-cutting machinery while ensuring that safety procedures were adhered to throughout each shift.

- Assembled dies from individual components as required and inspected finished parts for quality assurance prior to packaging; consistently achieved 100% customer satisfaction rate on orders delivered within deadline requirements.

- Independently managed a variety of work orders simultaneously with minimal supervision, meeting production deadlines without compromising quality standards in accordance with company guidelines at all times.

- Developed die-cut patterns for a variety of materials including paperboard, vinyl, plastic and textiles; increased production efficiency by 15% from better pattern design.

- Demonstrated efficient operation of die cutting machine to produce product based on customer specifications with minimal waste or defects; reduced scrap rate across all jobs by 20%.

- Aligned tools accurately according to set registration marks in order to achieve accurate shape cuts every time and managed inventory levels within the warehouse effectively for timely deliveries.

- Competently operated computer-controlled machines & equipment that were used in the fabrication process such as computers numerical control (CNC) punch presses & hydraulic shears while adhering strictly to safety regulations at all times.

- Formulated creative solutions when encountering obstacles during the die cutting process, which enabled faster completion of projects without compromising quality standards.

- Presented die cutting solutions to over 150 clients and increased revenue by 25% in the last year.

- Introduced innovative die-cutting techniques that improved production time of finished products by 10%.

- Reliably operated industrial die cutters on a daily basis, ensuring accuracy and quality for all parts produced within specified tolerances; reduced material scrap rate from 8% to 2%.

- Expedited production times through continuous operation of multiple machines simultaneously, increasing output capacity by 30%.

- Monitored performance of each machine throughout shift to detect any irregularities or discrepancies in order to prevent spoilage or defective goods being released into the market place.

- Participated in the installation and maintenance of die cutting machinery, ensuring successful operation for over 500 production runs per day.

- Calibrated die cutters to meet customer specified dimensions with accuracy up to 0.1mm; reduced materials wastage by 8%.

- Troubleshot mechanical issues in machine components such as stamping dies, rollers and heat plates; improved equipment uptime from 70% to 95%.

- Improved work efficiency by 30%, using computer-controlled systems when adjusting settings on machines used for various printing processes like embossing and debossing operations.

- Effectively operated a variety of manual/semi-automatic cutting presses while adhering strictly to safety protocols at all times; zero incidences reported in two years of service.

- Operated die cutting machine to produce over 3,000 parts per hour with a 98% accuracy rate.

- Accurately cut and laminated corrugated board, fabric, paper and other materials for industrial packaging applications; reduced production times by 17%.

- Laminated multiple layers of paper stock using heat-activated adhesives; maintained consistent quality levels while increasing output speed by 15%.

- Loaded die cutters with materials according to customer specifications in order to ensure efficient operation; minimized downtime due to incorrect settings or setup issues by 20%.

- Assessed finished product against predetermined standards and identified discrepancies quickly when they occurred; inspected 200+ pieces daily while maintaining 0 defects rate on all orders shipped out from the facility.

- Advised production supervisors on the best methods for die cutting various materials, resulting in a 15% decrease of rejected products.

- Reduced production costs by 20% through optimizing and streamlining the setup process prior to each job; designed efficient cutting paths where applicable.

- Compiled comprehensive reports detailing all jobs completed during shift including product number, quantity cut and total time spent using MS Excel spreadsheets.

- Efficiently operated an array of die-cutting machines such as swing arm presses with magnetic cylinders & hydraulic shearing systems while maintaining accuracy to 0.005” tolerances or better on every project run.

- Prepared substrates for printing operations by accurately trimming excess material from finished goods within tight deadlines; produced over 500 pieces per day at peak times.

- Streamlined production processes to increase die cutting efficiency by 25%, resulting in a drop of 4 hours per shift.

- Proficiently operated an automated die cutter machine and cut up to 1000 pieces of cardstock, corrugated paper and other materials for packaging purposes daily.

- Tested the quality of cuts using measuring tools and ensured that dimensions met customer specifications; eliminated production errors by 15%.

- Spearheaded the implementation of new safety policies as part of OSHA regulations, ensuring all personnel adhered to proper safety protocols during operation procedures.

- Coordinated with graphic designers on developing layouts for print jobs; produced 500+ custom-made boxes meeting high standards within tight deadlines each week.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one might require the candidate to have experience with a specific type of die cutting machine, while another may be looking for someone who is knowledgeable about different types.

Therefore, it’s important that you tailor your skills section in each resume to fit the job requirements listed in the posting. This will ensure that an applicant tracking system (which many employers use) can easily recognize which keywords are relevant and filter out those resumes that don’t meet their criteria.

In addition to listing your skills here, you should also discuss them further throughout other sections such as summary or work history; this will give recruiters more insight into how well-equipped you are for handling this role.

Below is a list of common skills & terms:

- Blueprint Reading

- CAD/CAM

- Die Cutting

- Fabrication

- Machine Operation

- Maintenance

- Material Handling

- Quality Control

- Safety Protocols

- Troubleshooting

4. Education

Adding an education section to your resume will depend on how far along you are in your career. If you recently graduated and have no work experience, it is a good idea to include an education section below your resume objective. However, if you have several years of die cutting experience under your belt, omitting the education section may be best as employers will likely focus more on what skills and qualifications you bring from past jobs instead.

If including an education section, try to mention courses or subjects that relate directly to the role of a die cutter operator such as safety training or industrial machine operation classes.

High School Diploma

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to a potential employer that you have achieved a certain level of proficiency in your field. They also show that you are dedicated to professional development and keeping up with industry trends.

Including certifications on your resume is an excellent way to demonstrate your qualifications for the job, as it shows employers that you possess the necessary skills and knowledge required for success in the role.

Die Cutting Operator Certification

Flexographic Technical Association

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Destiny O’Connell, this would be Destiny-O’Connell-resume.pdf or Destiny-O’Connell-resume.docx.

7. Cover Letter

A cover letter is an important part of the job application process. It is a written document that expands on your resume and provides more detail about why you are the right candidate for the role.

Cover letters can help you stand out from other applicants by providing recruiters with greater insights into who you are, what makes you unique, and how your skillset aligns perfectly with their requirements. Even though they may not be required in some cases, writing one could give your application an edge over those who do not submit them.

Below is an example cover letter:

Dear Raymundo,

I am writing to apply for the Die Cutter Operator position at your company. With over 10 years of experience in the printing industry, I have the skills and knowledge to operate die-cutting machines and produce high-quality products.

In my current role as a Die Cutter Operator at ABC Printing, I operate two automatic die-cutting machines and one manual machine. I am responsible for setting up the machines, loading them with paper, and running test cuts to ensure that the settings are correct. I also perform regular maintenance on the machines and troubleshoot any issues that arise. In addition, I keep track of inventory levels and place orders for new supplies when necessary.

Through my experience, I have developed strong attention to detail and an eye for quality control. My ability to follow instructions carefully has resulted in few errors and happy customers. In addition, my excellent time management skills allow me to work efficiently without sacrificing quality.

I would be a great asset to your team because of my experience operating die-cutting machines as well as my commitment to producing high-quality products. Please find attached a copy of my resume for your review; if you have any questions or would like additional information about me or my qualifications, please do not hesitate to contact me at [phone number] or [email address]. Thank you very much for your time!

Sincerely,

Destiny

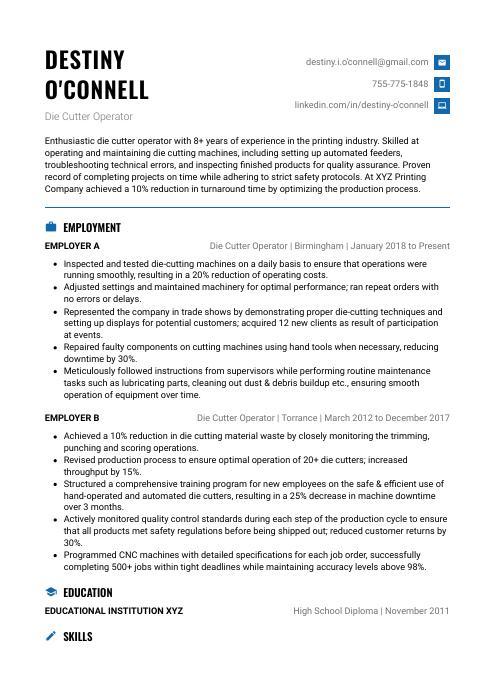

Die Cutter Operator Resume Templates

Echidna

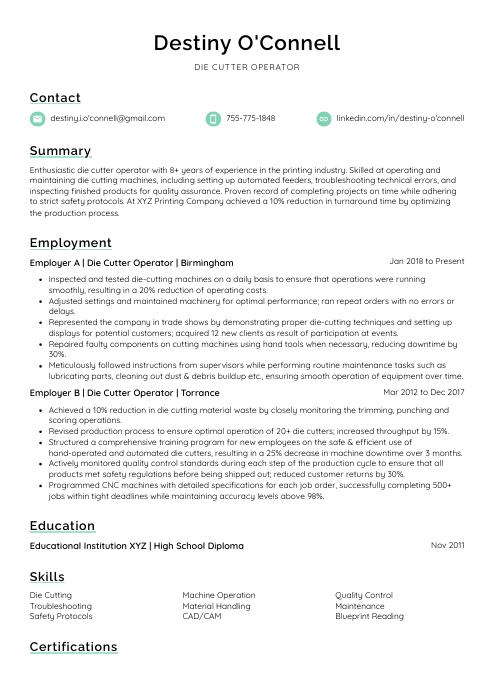

Echidna Lorikeet

Lorikeet Saola

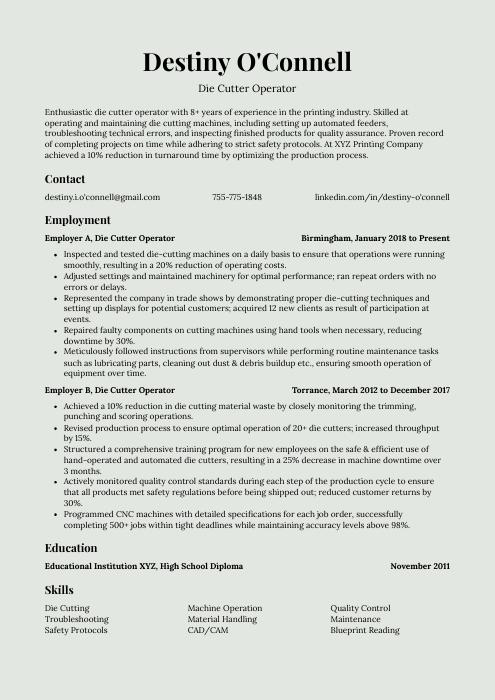

Saola Cormorant

Cormorant Pika

Pika Kinkajou

Kinkajou Indri

Indri Hoopoe

Hoopoe Bonobo

Bonobo Ocelot

Ocelot Fossa

Fossa Rhea

Rhea Numbat

Numbat Quokka

Quokka Gharial

Gharial Dugong

Dugong Jerboa

Jerboa Markhor

Markhor Axolotl

Axolotl Rezjumei

Rezjumei