Supplier Development Engineer Resume Guide

Supplier Development Engineers are responsible for evaluating suppliers, ensuring that they meet quality standards and developing strategies to improve supplier performance. They monitor supplier processes, develop cost reduction initiatives, conduct audits of suppliers and analyze data related to supply chain management.

The supply chain industry is always looking for talented engineers like you. However, hiring managers don’t know of your capabilities yet. To get them to recognize your professional experience and qualifications, you must write a resume that stands out from the crowd.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

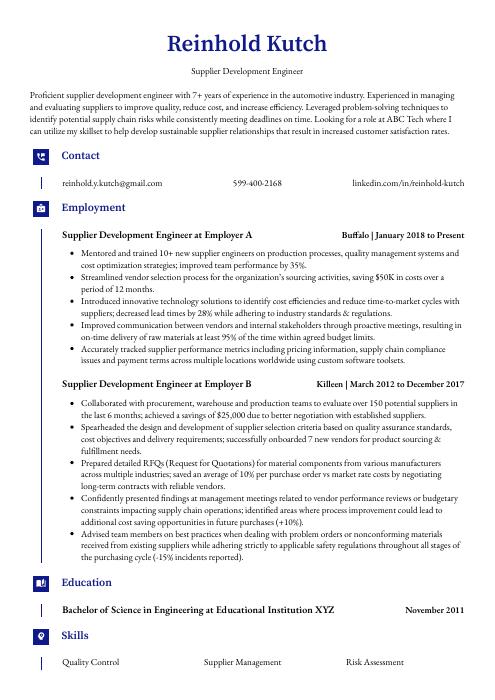

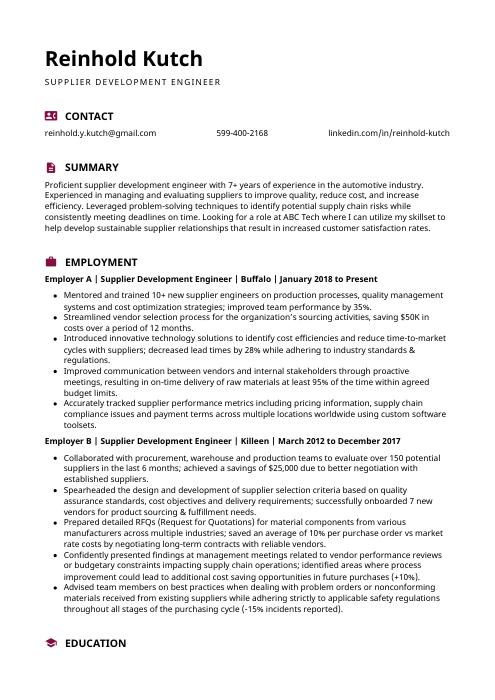

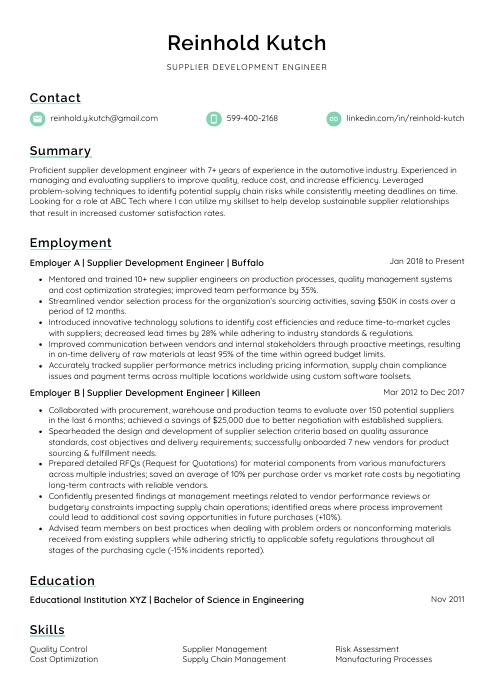

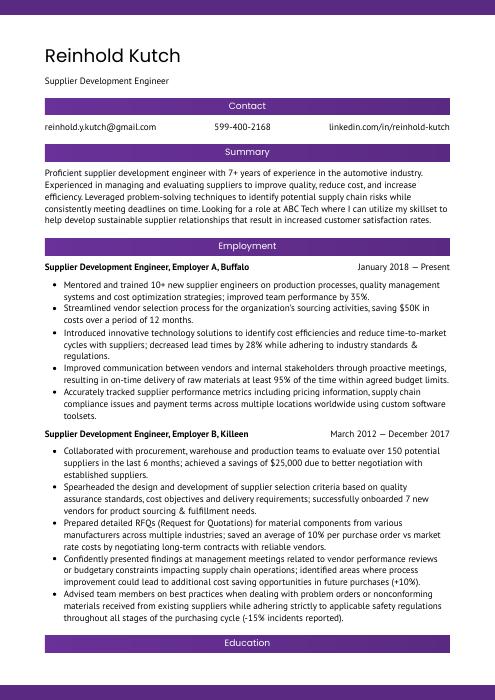

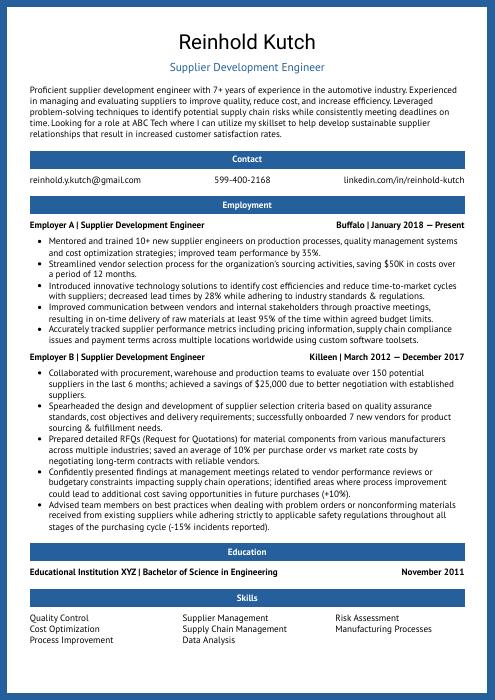

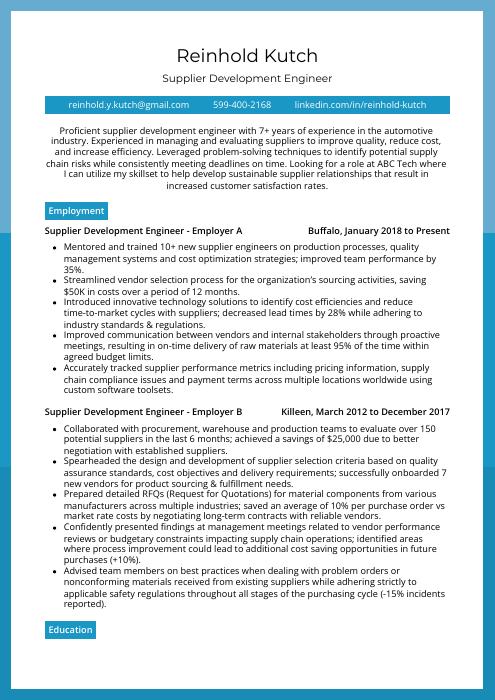

Supplier Development Engineer Resume Sample

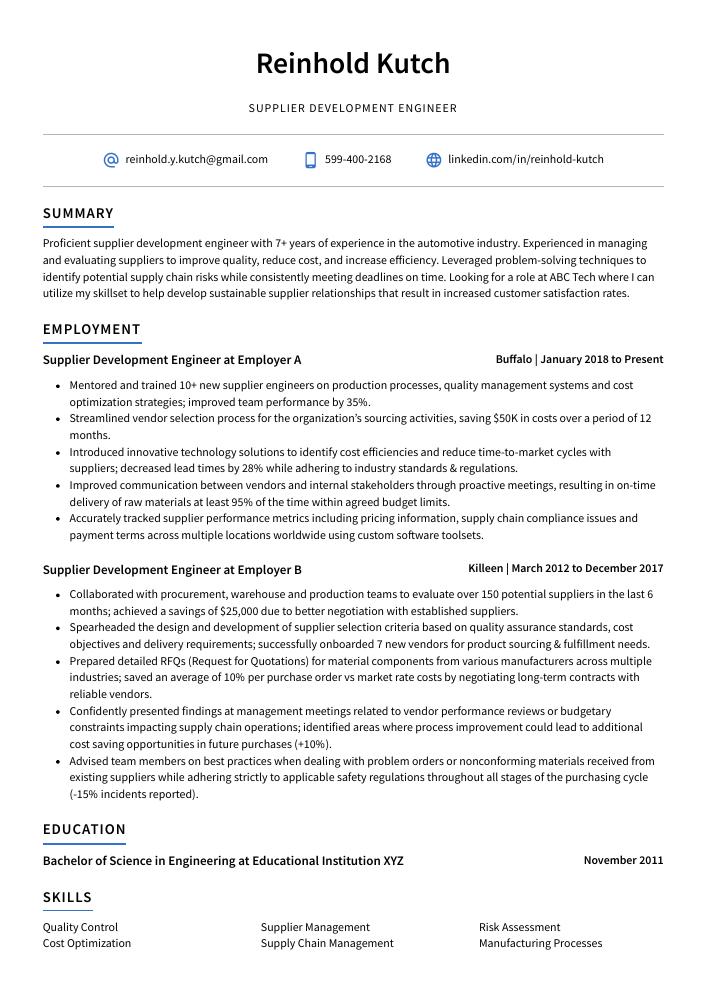

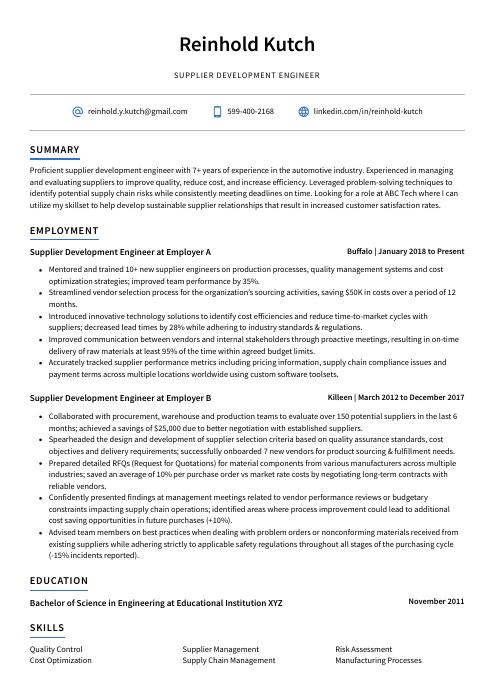

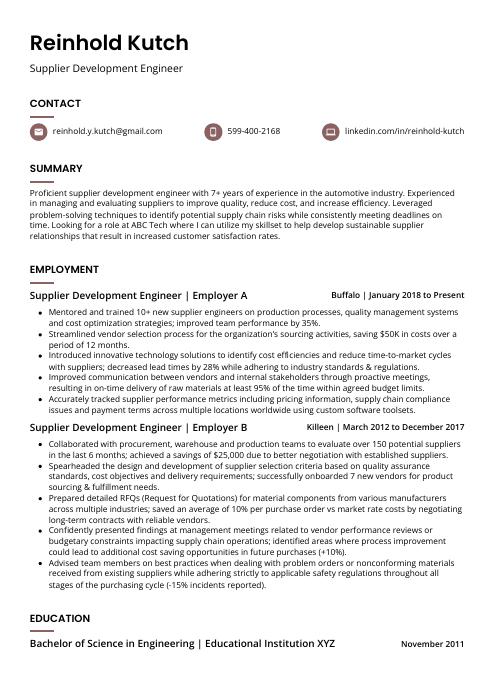

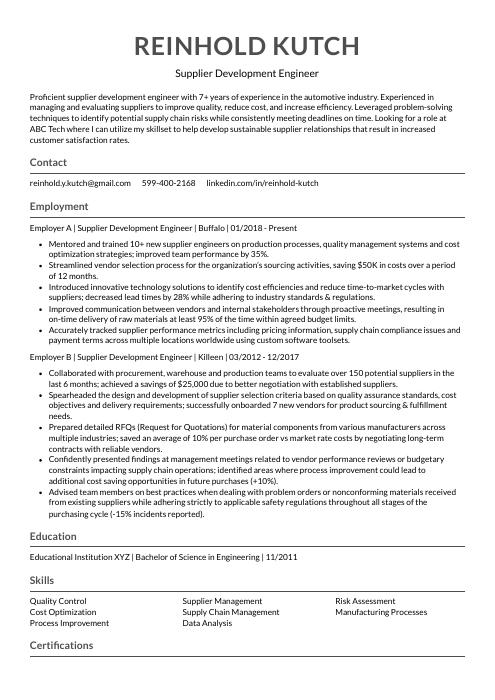

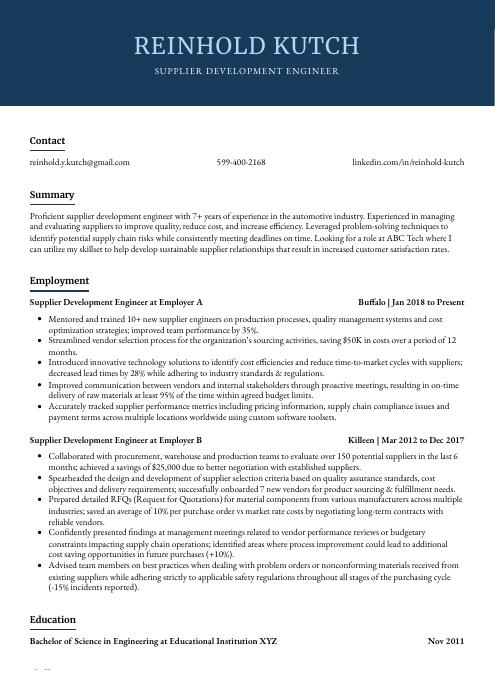

Reinhold Kutch

Supplier Development Engineer

[email protected]

599-400-2168

linkedin.com/in/reinhold-kutch

Summary

Proficient supplier development engineer with 7+ years of experience in the automotive industry. Experienced in managing and evaluating suppliers to improve quality, reduce cost, and increase efficiency. Leveraged problem-solving techniques to identify potential supply chain risks while consistently meeting deadlines on time. Looking for a role at ABC Tech where I can utilize my skillset to help develop sustainable supplier relationships that result in increased customer satisfaction rates.

Experience

Supplier Development Engineer, Employer A

Buffalo, Jan 2018 – Present

- Mentored and trained 10+ new supplier engineers on production processes, quality management systems and cost optimization strategies; improved team performance by 35%.

- Streamlined vendor selection process for the organization’s sourcing activities, saving $50K in costs over a period of 12 months.

- Introduced innovative technology solutions to identify cost efficiencies and reduce time-to-market cycles with suppliers; decreased lead times by 28% while adhering to industry standards & regulations.

- Improved communication between vendors and internal stakeholders through proactive meetings, resulting in on-time delivery of raw materials at least 95% of the time within agreed budget limits.

- Accurately tracked supplier performance metrics including pricing information, supply chain compliance issues and payment terms across multiple locations worldwide using custom software toolsets.

Supplier Development Engineer, Employer B

Killeen, Mar 2012 – Dec 2017

- Collaborated with procurement, warehouse and production teams to evaluate over 150 potential suppliers in the last 6 months; achieved a savings of $25,000 due to better negotiation with established suppliers.

- Spearheaded the design and development of supplier selection criteria based on quality assurance standards, cost objectives and delivery requirements; successfully onboarded 7 new vendors for product sourcing & fulfillment needs.

- Prepared detailed RFQs (Request for Quotations) for material components from various manufacturers across multiple industries; saved an average of 10% per purchase order vs market rate costs by negotiating long-term contracts with reliable vendors.

- Confidently presented findings at management meetings related to vendor performance reviews or budgetary constraints impacting supply chain operations; identified areas where process improvement could lead to additional cost saving opportunities in future purchases (+10%).

- Advised team members on best practices when dealing with problem orders or nonconforming materials received from existing suppliers while adhering strictly to applicable safety regulations throughout all stages of the purchasing cycle (-15% incidents reported).

Skills

- Quality Control

- Supplier Management

- Risk Assessment

- Cost Optimization

- Supply Chain Management

- Manufacturing Processes

- Process Improvement

- Data Analysis

Education

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

Certifications

Supplier Development Professional Certification

American Purchasing Society

May 2017

1. Summary / Objective

A resume summary for a supplier development engineer should be written to capture the attention of potential employers. It should highlight your technical skills, such as knowledge of quality management systems and process improvement techniques, as well as any experience you have in developing relationships with suppliers or managing projects. You may also want to mention how you’ve successfully implemented cost-saving measures for companies in the past, along with any certifications or awards that demonstrate your expertise in this field.

Below are some resume summary examples:

Detail-oriented supplier development engineer with 5+ years of experience developing and improving supplier relationships. Adept at identifying, qualifying, and selecting suppliers from various industries according to customer needs while also managing the quality assurance process. Proven track record of reducing costs by 15% through improved sourcing strategies at XYZ Inc. Looking to join ABC Corp as a Supplier Development Engineer for further professional growth opportunities.

Professional supplier development engineer with over 5 years of experience in the field. Proven track record of building strong relationships with suppliers and improving their performance to meet customer demands. Highly skilled in developing supplier evaluation methods, creating cost reduction strategies, and managing supplier quality assurance processes. Committed to driving continuous improvement initiatives that reduce costs while ensuring product quality for customers.

Energetic and experienced supplier development engineer with 8+ years of experience in the automotive industry. Proven track record of successfully managing complex projects and developing strong relationships with suppliers. Skilled at improving process efficiency and reducing costs through innovative problem-solving techniques. At XYZ, developed a new supply chain strategy that resulted in an estimated 15% reduction in total cost over two years.

Well-rounded professional with 8+ years of supplier development engineering experience. Skilled in developing, implementing and maintaining sustainable quality management systems (QMS). Adept at problem-solving complex issues across multiple supply chain functions. Proven track record for driving process improvements that reduced costs by 20%. Seeking to leverage expertise to become the next Supplier Development Engineer at ABC Company.

Enthusiastic supplier development engineer with 5+ years of experience in the automotive industry. Experienced in managing supplier relationships, ensuring product quality and reliability, as well as improving supply chain efficiency. Seeking to leverage proven problem-solving skills and knowledge of lean manufacturing principles at ABC Corp to drive cost reduction initiatives while maintaining high standards of customer satisfaction.

Talented supplier development engineer with 7+ years of experience in the automotive industry. Experienced in supplier management, quality assurance and lean manufacturing principles. Successfully implemented a comprehensive supplier evaluation process to reduce costs by 15%. Proven ability to build relationships with suppliers while ensuring they meet or exceed customer expectations through continuous improvement efforts.

Skilled supplier development engineer with 8+ years of experience in managing, developing, and improving supplier processes. Proven ability to develop cost-effective solutions that optimize quality while reducing costs. At XYZ Corp., led the introduction of new suppliers and developed a comprehensive system for monitoring supplier performance; this resulted in 20% reduction in total procurement costs within one year.

Seasoned supplier development engineer with 8+ years of hands-on experience in the evaluation, selection, and management of suppliers. Proven track record in improving supplier performance metrics while mitigating risk and cost. Seeking to join ABC’s engineering team as a Supplier Development Engineer to ensure that all projects meet quality standards and deadlines on time.

2. Experience / Employment

In the experience section, you should list your employment history in reverse chronological order. You want to use bullet points primarily here, as they make it easier for the reader to take in what you have written quickly.

When writing the bullets, think about providing detail and quantifiable results of what you did at each job. For example, instead of saying “Managed supplier relationships,” say something like “Developed strong relationships with 10+ suppliers resulting in a 20% reduction in costs.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Negotiated

- Analyzed

- Monitored

- Implemented

- Researched

- Developed

- Managed

- Evaluated

- Streamlined

- Coordinated

- Optimized

- Forecasted

- Assessed

- Collaborated

- Facilitated

Other general verbs you can use are:

- Achieved

- Advised

- Compiled

- Demonstrated

- Expedited

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Structured

- Utilized

Below are some example bullet points:

- Successfully evaluated and approved over 50 suppliers for product components, resulting in a cost savings of $20K+ per quarter.

- Revised supplier development processes to improve efficiency by 25% and reduce overall production costs.

- Reorganized supply chain management system with an emphasis on quality control; decreased defects from incoming materials by 35%.

- Managed the coordination between 5 manufacturing sites, ensuring that each site had sufficient supplies to meet its demands within budgetary constraints.

- Developed relationships with 20 new vendors while maintaining existing partnerships through regular communication and timely payment processing; improved vendor responsiveness/delivery times by 10%.

- Forecasted supplier production schedules and delivery timelines, resulting in a decrease of supply chain-related delays by 20%.

- Researched new suppliers to identify cost savings on material purchases; identified 5+ potential vendors that resulted in an overall annual reduction of $20,000 in procurement expenses.

- Reliably managed the onboarding process for all approved vendors, ensuring compliance with company standards and timely submission of documents within 24 hours or less.

- Expedited product development processes through effective communication between internal stakeholders and external partners; reduced time from concept to launch by 45 days on average.

- Implemented supplier quality management systems across multiple sites, improving supplier performance ratings by 15% over one year period while reducing risk exposure significantly.

- Formulated effective sourcing strategies for over 50 suppliers which resulted in a 15% decrease in overall costs.

- Utilized Lean Manufacturing principles to develop and manage supplier performance plans that exceeded customer expectations by 75%.

- Coordinated with cross-functional teams on all purchasing activities, ensuring timely delivery of products while minimizing discrepancies and errors along the supply chain process.

- Negotiated new contracts with vendors, resulting in an average cost savings of $2 million annually across multiple product categories and improved quality ratings from 90% to 99%.

- Independently developed relationships with key stakeholders within the organization, strengthening communication channels between production departments as well as upper management levels for maximum efficiency gains.

- Assessed over 250 suppliers for quality compliance, cost reduction potential and performance optimization initiatives; achieved a 10% overhead cost savings in the last quarter.

- Structured production plans to meet customer demand by successfully onboarding new vendors and renegotiating supplier contracts within tight deadlines (+25% increase in supply chain efficiency).

- Reduced average lead times from 5 weeks to 3 weeks through implementation of process improvements across multiple departments (-43%).

- Achieved an impressive reduction of 20-30% on product costs with strategic sourcing techniques such as competitive bidding and enhanced negotiations with suppliers.

- Thoroughly investigated all incoming material issues reported by customers and resolved them promptly (80+ cases handled annually while maintaining exceptional customer service standards).

- Compiled over 500 supplier profiles and evaluated potential suppliers based on quality, cost, delivery schedule and service capabilities; reduced sourcing costs by 10%.

- Presented detailed technical specifications and performance criteria to over 200 vendors in order to identify suitable candidates for long-term partnerships.

- Represented the company at meetings with key stakeholders from manufacturing sites around the world to discuss supply chain strategy objectives and evaluate progress towards them.

- Monitored KPIs such as lead time accuracy, product arrival quality scores & on-time shipment percentages of existing suppliers; identified gaps in performance between expectations & outcomes across 20+ vendors each month.

- Meticulously tracked material availability issues throughout production cycles; detected problems before they impacted deliveries or caused delays, leading to monthly savings of $7000+.

- Efficiently analyzed cost and quality specifications of existing suppliers to identify areas for improvement; successfully reduced supplier costs by 15% within 3 months.

- Developed relationships with new vendors, identified potential supply chain partners, and negotiated terms & conditions with over 10 manufacturers in the region.

- Facilitated smooth transition from old to new vendor sources while ensuring no disruptions in the supply chain processes or delivery schedules; maintained a 99% on-time delivery rate during entire period.

- Optimized sourcing strategies through comprehensive market research of competitor pricing structures, product availability cycles and industry trends; saved $20K per quarter after implementing changes suggested by report findings.

- Utilized problem solving skills to resolve any issues related to supplies/inventory management such as late deliveries or incorrect shipments quickly and effectively without compromising customer satisfaction levels (+30 NPS).

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require a supplier development engineer with experience in Lean Manufacturing, while Organization XYZ may need someone who is knowledgeable about Six Sigma.

It’s important to tailor the skills section of your resume accordingly as many companies use applicant tracking systems these days – computer programs that scan resumes for certain keywords before passing them on to a human.

Once listed here, you can further elaborate on each skill by discussing it in more detail in other areas such as the summary or experience section.

Below is a list of common skills & terms:

- Cost Optimization

- Data Analysis

- Manufacturing Processes

- Process Improvement

- Quality Control

- Risk Assessment

- Supplier Management

- Supply Chain Management

4. Education

Adding an education section to your supplier development engineer resume depends on how much experience you have in the field. If you are just starting out and don’t yet have any work experience, mention your education below your resume objective. But if you already have significant professional history to highlight, it is perfectly acceptable to omit an education section altogether.

If including an education section, focus on courses related to supplier development engineering that demonstrate relevant knowledge and skills for the job position you are applying for.

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and expertise in a particular field. They can be used to prove that you have the necessary qualifications for a job, as well as show potential employers that you are committed to staying up-to-date with industry trends.

It is important to include any certifications relevant to the position on your resume so hiring managers know what skills and abilities you possess. This will help them determine if you are qualified for the role or not.

Supplier Development Professional Certification

American Purchasing Society

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Reinhold Kutch, this would be Reinhold-Kutch-resume.pdf or Reinhold-Kutch-resume.docx.

7. Cover Letter

Providing a cover letter with your application is a great way to showcase your skills and qualifications in more detail. This document usually consists of 2 to 4 paragraphs that are separate from the resume and provide additional information about why you’re an ideal candidate for the job.

Though it isn’t always necessary, writing a cover letter can be beneficial as it provides recruiters with further insight into who you are, what sets you apart from other applicants and how qualified you really are for the role.

Below is an example cover letter:

Dear Carley,

I am interested in the Supplier Development Engineer position at XYZ Corporation. With more than eight years of experience working with suppliers to improve quality and delivery, I am confident that I would make a valuable contribution to your organization.

In my current role as Supplier Quality Engineer at ABC Corporation, I lead a team of four engineers who are responsible for supplier development, quality assurance, and supplier audits. I have developed strong relationships with suppliers across Asia, Europe, and North America. My experience has taught me how to effectively manage cross-cultural differences and navigate complex supply chains.

I am also well-versed in various quality management tools and methods such as Six Sigma, 8D problem solving, Ishikawa diagrams, FMEA analysis, SPC charts, MSA studies etc. In addition, I have a solid understanding of ISO 9001/TS 16949 standards and automotive industry specific requirements (e.g., AIAG core tools). My knowledge in these areas would be beneficial in improving supplier performance and ensuring compliance with internal quality standards.

Please find attached my resume for your review. I will follow up next week to discuss the details of this opportunity further and answer any questions you may have. Thank you for your time and consideration!

Sincerely,

Reinhold

Supplier Development Engineer Resume Templates

Dugong

Dugong Pika

Pika Cormorant

Cormorant Gharial

Gharial Hoopoe

Hoopoe Lorikeet

Lorikeet Jerboa

Jerboa Axolotl

Axolotl Fossa

Fossa Indri

Indri Bonobo

Bonobo Kinkajou

Kinkajou Saola

Saola Echidna

Echidna Markhor

Markhor Quokka

Quokka Ocelot

Ocelot Rhea

Rhea Numbat

Numbat Rezjumei

Rezjumei