Rope Access Technician Resume Guide

Rope Access Technicians use specialized equipment and techniques to access hard-to-reach areas from heights. They typically work in the construction, engineering, or oil/gas industry and are responsible for inspecting structures, performing maintenance tasks, installing systems, or providing rescue operations.

Your rope access expertise makes you the perfect fit for any workplace that requires vertical maintenance. However, potential employers aren’t aware of your abilities yet. To let them know what you can do, you must craft a resume to highlight your experience and qualifications.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

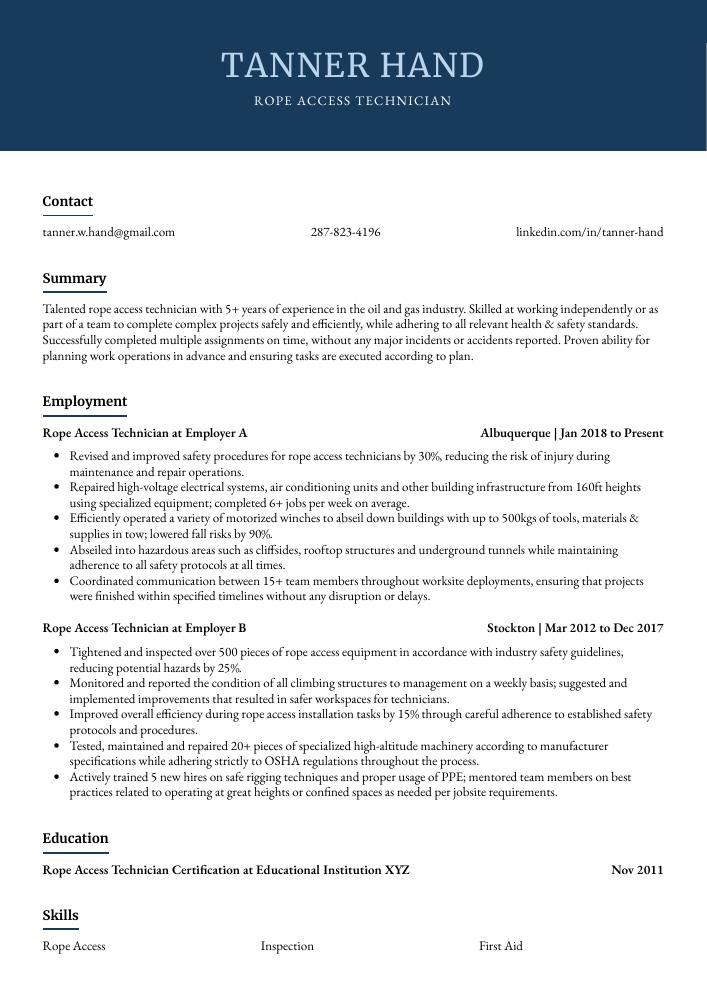

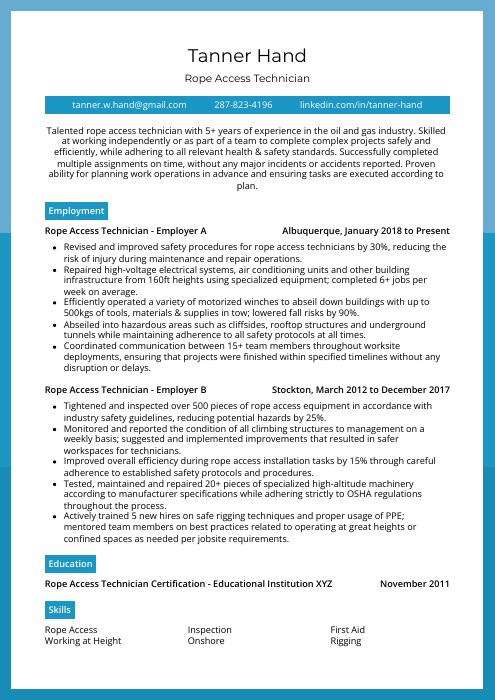

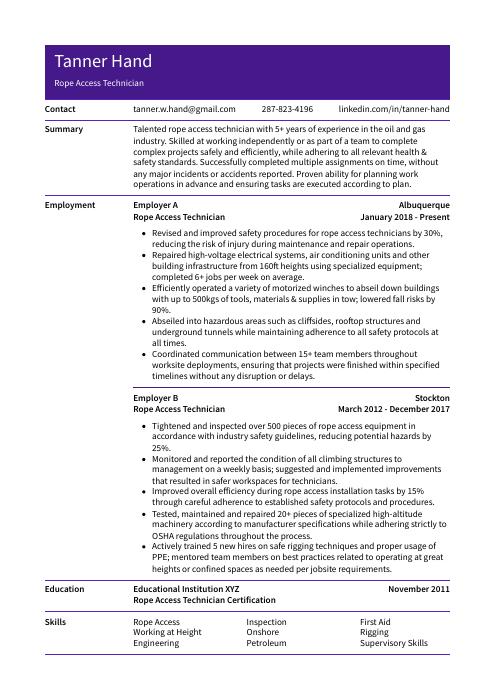

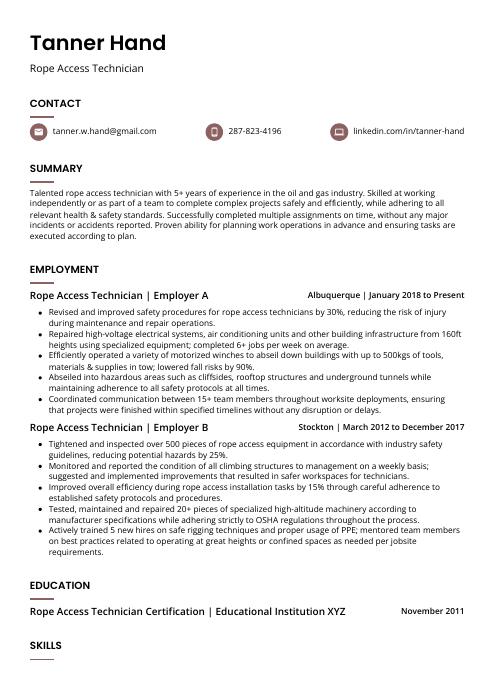

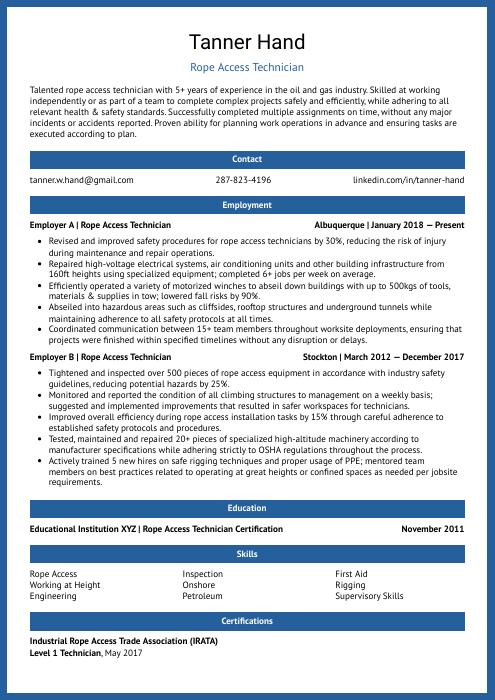

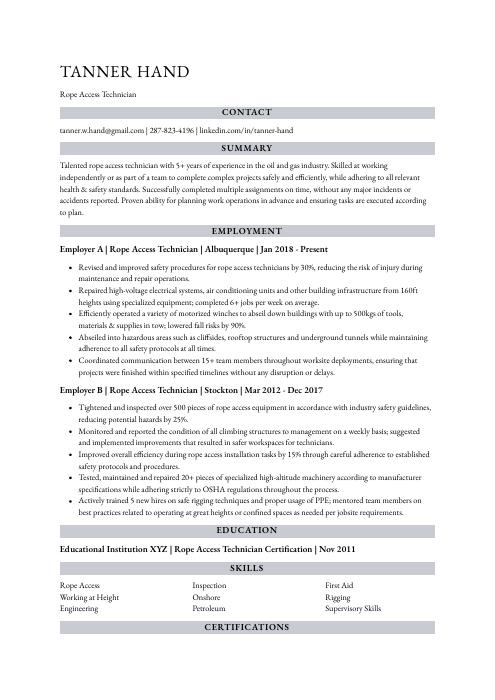

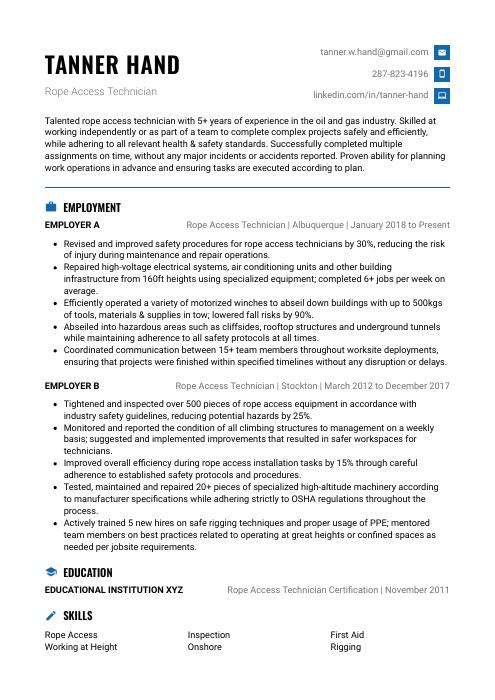

Rope Access Technician Resume Sample

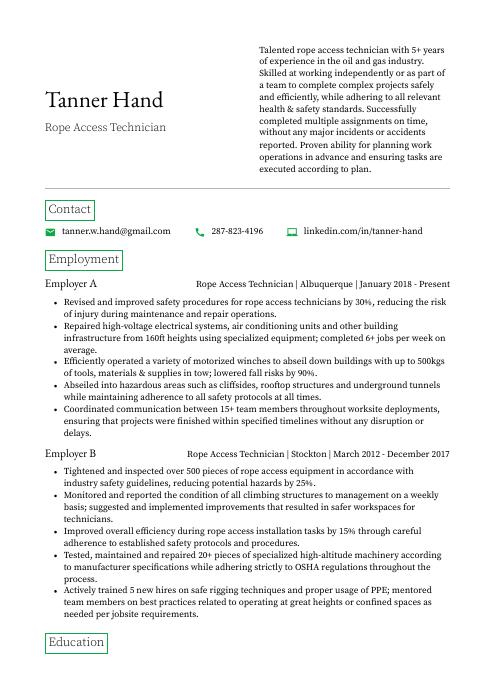

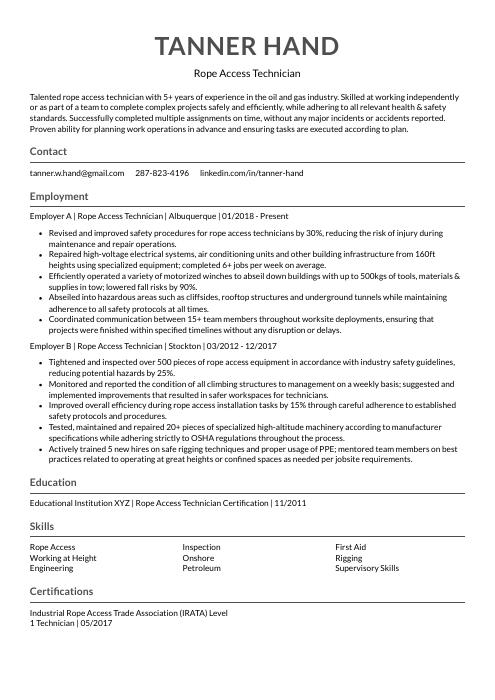

Tanner Hand

Rope Access Technician

[email protected]

287-823-4196

linkedin.com/in/tanner-hand

Summary

Talented rope access technician with 5+ years of experience in the oil and gas industry. Skilled at working independently or as part of a team to complete complex projects safely and efficiently, while adhering to all relevant health & safety standards. Successfully completed multiple assignments on time, without any major incidents or accidents reported. Proven ability for planning work operations in advance and ensuring tasks are executed according to plan.

Experience

Rope Access Technician, Employer A

Albuquerque, Jan 2018 – Present

- Revised and improved safety procedures for rope access technicians by 30%, reducing the risk of injury during maintenance and repair operations.

- Repaired high-voltage electrical systems, air conditioning units and other building infrastructure from 160ft heights using specialized equipment; completed 6+ jobs per week on average.

- Efficiently operated a variety of motorized winches to abseil down buildings with up to 500kgs of tools, materials & supplies in tow; lowered fall risks by 90%.

- Abseiled into hazardous areas such as cliffsides, rooftop structures and underground tunnels while maintaining adherence to all safety protocols at all times.

- Coordinated communication between 15+ team members throughout worksite deployments, ensuring that projects were finished within specified timelines without any disruption or delays.

Rope Access Technician, Employer B

Stockton, Mar 2012 – Dec 2017

- Tightened and inspected over 500 pieces of rope access equipment in accordance with industry safety guidelines, reducing potential hazards by 25%.

- Monitored and reported the condition of all climbing structures to management on a weekly basis; suggested and implemented improvements that resulted in safer workspaces for technicians.

- Improved overall efficiency during rope access installation tasks by 15% through careful adherence to established safety protocols and procedures.

- Tested, maintained and repaired 20+ pieces of specialized high-altitude machinery according to manufacturer specifications while adhering strictly to OSHA regulations throughout the process.

- Actively trained 5 new hires on safe rigging techniques and proper usage of PPE; mentored team members on best practices related to operating at great heights or confined spaces as needed per jobsite requirements.

Skills

- Rope Access

- Inspection

- First Aid

- Working at Height

- Onshore

- Rigging

- Engineering

- Petroleum

- Supervisory Skills

Education

Rope Access Technician Certification

Educational Institution XYZ

Nov 2011

Certifications

Industrial Rope Access Trade Association (IRATA) Level 1 Technician

May 2017

1. Summary / Objective

A resume summary/objective is the first thing a hiring manager will read and should give them an overview of your experience as a rope access technician. In this section, you can highlight your most impressive qualifications such as certifications in industrial rope access techniques, years of experience working at heights, and any safety awards or recognitions you have received. Additionally, mention how well-versed you are with relevant tools and equipment to show that you’re ready to hit the ground running on day one.

Below are some resume summary examples:

Driven rope access technician with 7+ years of experience in inspecting and repairing high-rise buildings, bridges, towers, and other structures. Competent in operating complex machinery such as the SRL (self-retracting lifeline) system. Committed to safety at all times; led a team that completed a project without any incidents or accidents for ABC Company. Received certification from IRATA International for rope access work on industrial sites.

Hard-working rope access technician with 5+ years of experience in the oil and gas industry. Offering a unique set of skills, including rope climbing techniques, knot tying proficiency, and harness fitting expertise. At XYZ Corp., successfully completed 200+ jobs on time without any safety incidents or injuries reported. Highly skilled at working in extreme heights and dangerous conditions to complete projects safely and efficiently.

Amicable and safety-conscious rope access technician with 7+ years of experience providing specialized service and maintenance to clients in the oil and gas industry. Expertise in executing a range of tasks such as installation, repair, inspection, cleaning works at heights using advanced methods like single line techniques. Seeking to join ABC Oil & Gas as an Rope Access Technician to help maintain its production plant efficiently.

Reliable rope access technician with more than 5 years of experience in industrial rope-based access. Seeking to join ABC Inc.’s team to utilize my knowledge and expertise in performing advanced rigging operations, conducting safety inspections, and providing instruction for those working at height. At XYZ Corp., reduced risk incidents by 20% through implementing a comprehensive approach to the safe use of ropes and harnesses.

Dependable rope access technician with 5+ years of experience in hazardous and confined spaces. Passionate about safety, precision and efficiency when working at heights up to 200 meters. Seeking a challenging role at ABC Services that will allow me to utilize my skillset as well as gain new experiences. Key achievements include carrying out numerous successful rope access operations for complex projects under tight deadlines.

Skilled rope access technician with 4+ years of experience in the oil and gas industry. At XYZ, trained 12 technicians on proper safety protocols for working at height. Spearheaded a project to improve site safety by creating an innovative new system for secure anchor points that is now used company-wide. Highly experienced in inspecting, maintaining, and repairing equipment from heights up to 300 feet (91 meters).

Energetic and detail-oriented rope access technician with 6+ years of experience in the field. Seeking to join ABC Company as a Rope Access Technician and use my extensive knowledge and skillset to enhance overall safety standards, while also providing exceptional customer service. Previous successes include completing 40 jobs on time or ahead of schedule, ensuring 100% client satisfaction.

Professional Rope Access Technician with 5+ years of experience in the Oil & Gas industry. Skilled at rigging, installing and decommissioning various types of equipment while maintaining safety standards and regulations. Looking to join ABC Tech to apply my expertise in confined space entry, suspension techniques, rescue operations and inspections.

2. Experience / Employment

For the experience section, you should list your employment history in reverse chronological order, with the most recent job listed first.

Stick to bullet points when describing what you did; this makes it easier for readers to quickly digest the information. When writing each point, make sure to provide detail and explain any quantifiable results obtained from your work.

For example, instead of saying “Performed rope access,” you could say “Climbed an industrial chimney using advanced rope techniques and safety equipment while ensuring compliance with OSHA regulations.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Inspected

- Rigged

- Abseiled

- Dismantled

- Assembled

- Repaired

- Adjusted

- Tested

- Monitored

- Secured

- Cleaned

- Lubricated

- Tightened

- Replaced

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Formulated, implemented and adjusted complex rope access systems for over 200 construction projects, reducing installation time by 15%.

- Proficiently operated a variety of powered industrial equipment to perform aerial inspections on structures up to 120 feet high; successfully inspected 1200+ miles of bridges, buildings and towers.

- Assessed safety hazards in the workplace and provided appropriate solutions such as rigging & lifting techniques, fall protection systems and rescue plans; reduced workplace accidents by 20%.

- Cleaned, maintained and tested rope access gear according to manufacturer guidelines; increased life span of all pieces of equipment used during operations by 25%.

- Utilized an array of hand tools including pliers, hammers & screwdrivers while working at heights to install fixtures or repair faulty components with minimal supervision; completed 50+ tasks in 8 hours each day on average.

- Participated in more than 100 rope access projects, successfully installing and repairing HVAC systems on office buildings up to 15 storeys high.

- Demonstrated advanced problem-solving skills to troubleshoot complex issues with ropes, harnesses and other equipment in a fast-paced environment; resolved service requests within schedule 75% of the time.

- Reliably followed safety protocols during jobs at height by performing daily inspections of climbing gear and equipment prior to use; maintained 0 incidents of injury or damage over 2 years onsite work experience.

- Developed innovative techniques for completing high angle tasks faster while reducing risk exposure across 9 separate assignments between 2017 – 2020; reduced overall project completion times by 10%.

- Expedited emergency repairs on hazardous structures using abseiling methods without compromising quality standards or structural integrity; earned commendations from clients for excellence in customer satisfaction ratings.

- Reorganized rope access safety protocols and procedures to ensure the safety of colleagues, clients and other personnel in high-altitude work environments; reduced average incident rate by 80%.

- Meticulously monitored all rope access worksites for potential hazards and risks, ensuring that any necessary repairs or maintenance were addressed promptly before continuing operations.

- Replaced over 100 worn out ropes with durable ones made from synthetic fibers to mitigate the risk of accidents up to heights of 500 ft. ; successfully completed 2 complex projects involving structures higher than 600ft without any incidents in a timely manner.

- Assembled five 10m towers using winch systems within three hours while adhering strictly to industry regulations; presented two seminars on rope access techniques which increased departmental efficiency by 25%.

- Structured emergency response plans as part of an effort to reduce overall downtime caused due to unforeseen circumstances during worksite deployments; achieved 0% downtime across more than ten major projects throughout 2020 year alone.

- Achieved a 95% safety rating on all rope access installations and inspected 150+ structures for structural integrity, ensuring compliance with OSHA standards.

- Presented detailed reports to management that outlined the results of inspections, saving an estimated $1,500 in repair costs over a 3-month period.

- Installed new safety equipment such as pulleys and rappel devices at heights up to 100 feet; completed projects ahead of schedule & within budget every time.

- Independently conducted risk assessments for high rise buildings before any rope access activity was initiated; decreased potential injury incidents by 30%.

- Compiled comprehensive data from each job site regarding working conditions, weather patterns and other relevant factors using software programs like Microsoft Excel; identified discrepancies which allowed the team to update their protocols accordingly.

- Advised construction teams on safe rope access procedures and technical solutions, resulting in a 20% reduction of safety incidents.

- Consistently inspected ropes, harnesses and other related gear to ensure proper functionality; identified 4 defective pieces within the first 2 weeks of employment & replaced them with new ones for greater efficiency.

- Utilized specialized skills such as rappelling and high-angle rescue techniques to safely perform maintenance work at difficult heights or locations inaccessible by traditional methods; completed 5 jobs per week without any injuries reported from the team members involved.

- Lubricated climbing equipment regularly using approved substances for better performance & longer lifespan; managed to double the life expectancy of all gear used in each job over a period of 6 months, leading to an overall cost savings of $2000 over that time frame.

- Reduced downtime by 25% during operations through prompt troubleshooting, fast repairs and efficient management strategies which enabled workers to complete their tasks quickly while adhering strictlyto safety regulations at all times.

- Represented the rope access team on more than 30 wind turbine installations, utilizing specialized safety equipment to provide secure and efficient access to every project site.

- Substantially reduced installation time for each site by 12%, minimizing workloads and increasing productivity across the entire team.

- Optimized safety protocols in line with industry regulations; inspected all tools, rigging gear and harnesses prior to use at each job site, ensuring that proper maintenance was upheld at all times.

- Spearheaded a training program which equipped over 50 personnel with advanced skillset in high-level construction duties such as suspended scaffolding movement & elevated rescue operations; successfully trained 3 new recruits within 6 months of joining the organization.

- Facilitated 10+ customer service requests through expert problem solving capabilities during tasks such as aerial inspections, lightening protection systems installation & telecom cable replacements under challenging weather conditions (+15°C).

- Effectively performed rope access operations across multiple projects, completing complex rigging tasks at heights of up to 200 feet and providing technical support in the installation/dismantling of equipment.

- Streamlined operational processes by introducing new safety protocols that reduced accidents by 25%.

- Mentored a team of 15 junior technicians on proper use of tools & climbing techniques; improved their efficiency in carrying out inspections and repairs by 40 hours per month.

- Dismantled high-rise structures safely and efficiently using manual cutting tools, resulting in an average completion time reduction of 45 minutes per project compared to previous methods used before my arrival.

- Introduced innovative solutions such as automated ascent systems that enabled rapid deployment when working at extreme heights while simultaneously minimizing risk exposure for workers below ground level.

- Prepared and maintained safety equipment, harnesses and ropes for over 400 rope access operations per year; reduced set-up time by 30%.

- Accurately inspected up to 150 rigging points a day across multiple construction sites, ensuring that the highest standards of safety were met at all times.

- Secured personnel in full body harnesses and connected them safely with lanyards before each descent or ascent via abseil techniques; completed 100+ training sessions on rescue procedures every quarter.

- Rigged scaffolding systems and provided safe anchorages while working from heights, carefully adhering to industry safety regulations throughout the process; implemented new anchoring methods which cut manufacturing costs by 10%.

- Assisted workers in accessing high structures using swing stages & suspended cradles when necessary; minimized manual labor requirements by 25%, resulting in improved efficiency rates among crew members.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in working with high-voltage power lines, while the other may be more interested in someone who is familiar with wind turbines.

Therefore, you want to tailor your skills section of the resume to each job that you are applying for. This will help ensure that applicant tracking systems (which many employers use) recognize your qualifications and pass your application on to a human recruiter.

Besides listing out relevant skills here, it would also be beneficial if you discussed them further in other areas such as the summary or work history sections.

Below is a list of common skills & terms:

- BOSIET

- Construction Safety

- Contract Management

- Engineering

- First Aid

- Gas

- Inspection

- Maintenance and Repair

- Metal Fabrication

- Offshore Drilling

- Oil and Gas

- Onshore

- Painting

- Petrochemical

- Petroleum

- Pipelines

- Project Planning

- Rigging

- Risk Assessment

- Rope Access

- Supervisory Skills

- Team Leadership

- Teamwork

- Time Management

- Welding

- Wind Turbines

- Window Cleaning

- Working at Height

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below the objective statement. However, if you have significant work experience to showcase, omitting an education section is perfectly fine.

If including an education section, try to list courses or subjects related to rope access technician roles that demonstrate relevant knowledge and skillset for the job.

Rope Access Technician Certification

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your proficiency in a certain field. Employers are often looking for applicants who have taken the initiative to learn new skills and stay up-to-date with industry trends.

If you have any certifications that are relevant to the job you’re applying for, make sure they’re included on your resume so employers can see them right away. This will help show potential employers that you take professional development seriously and are committed to staying current in your area of expertise.

Industrial Rope Access Trade Association (IRATA) Level 1 Technician

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Tanner Hand, this would be Tanner-Hand-resume.pdf or Tanner-Hand-resume.docx.

7. Cover Letter

Writing a cover letter is an important part of the job application process. It’s a document that contains 2 to 4 paragraphs and should be separate from your resume. Its purpose is to provide more detail, add personality and explain why you are right for the role in question.

Cover letters don’t always need to be submitted with applications but they can help you demonstrate your suitability and interest in the position. They give recruiters greater insight into who you are as a professional, allowing them to get better acquainted with your qualifications and experience prior to inviting you for an interview.

Below is an example cover letter:

Dear Tanya,

I am writing to apply for the position of Rope Access Technician with your company. I am a certified Level 3 IRATA technician with over 10 years of experience in the field. I have worked on a variety of projects, both domestic and international, ranging from small-scale repairs to large construction projects. My experience and certification make me confident that I would be an asset to your team.

In my previous role as a rope access technician, I was responsible for performing monthly inspections of all equipment and ensuring that it met safety standards. I also assisted in the training of new technicians and helped develop new work procedures. On one occasion, when our team was short-staffed, I took on the responsibility of leading a group of four technicians during a challenging project. This required me to think quickly and make decisions under pressure, which is something I excel at doing.

I believe that my skills and experience would benefit your company greatly, and I look forward to discussing this opportunity further with you soon. Thank you for your time and consideration; please do not hesitate to contact me if you have any questions or need any additional information about my qualifications.

Sincerely,

Tanner

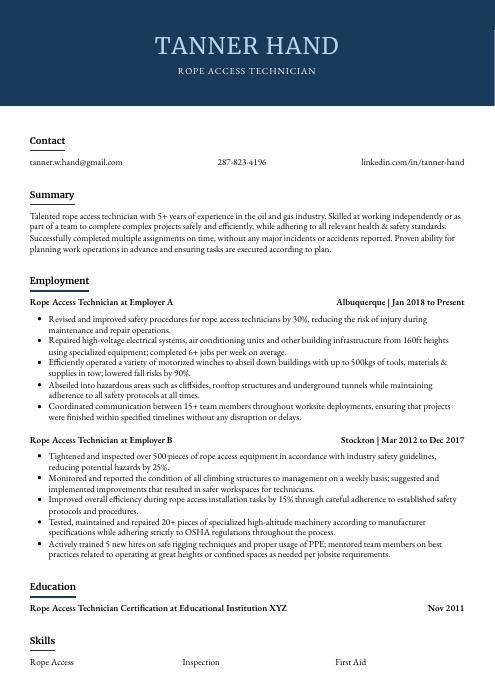

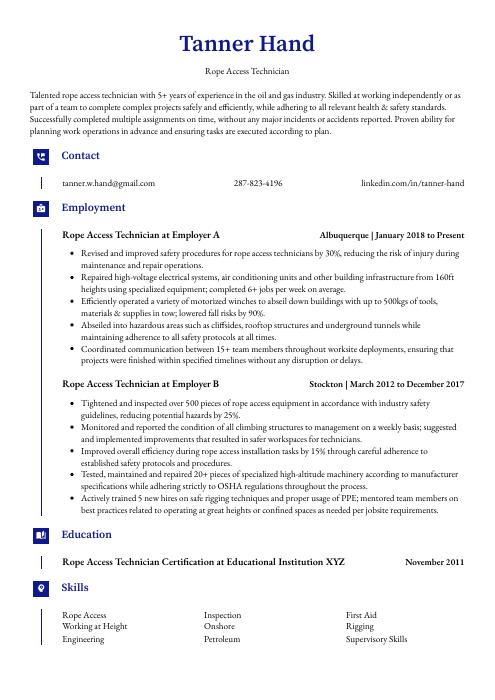

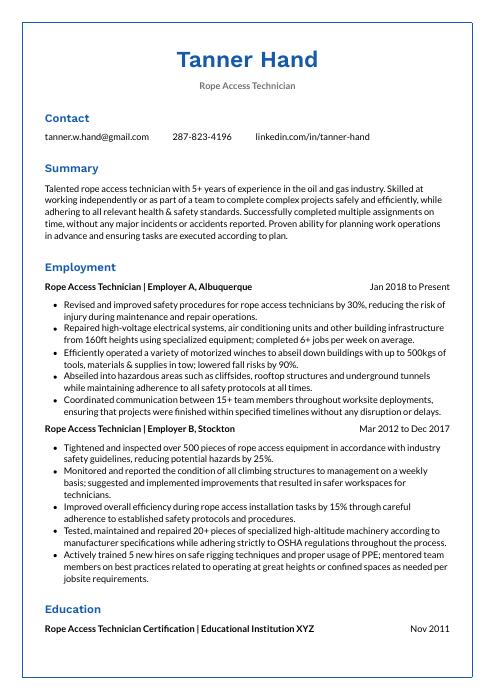

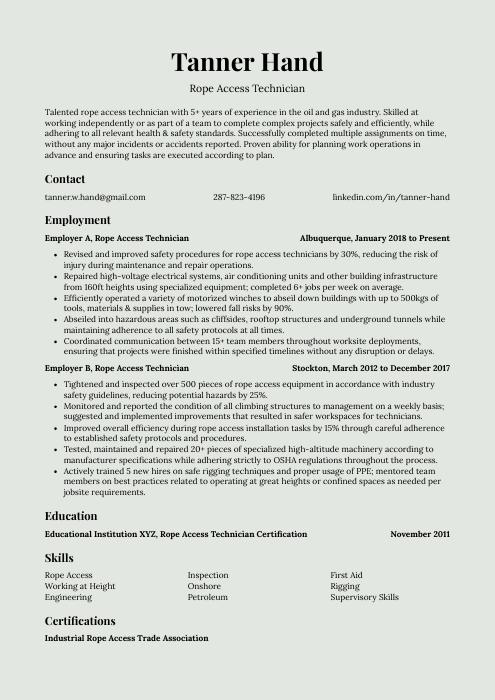

Rope Access Technician Resume Templates

Rhea

Rhea Hoopoe

Hoopoe Axolotl

Axolotl Pika

Pika Kinkajou

Kinkajou Bonobo

Bonobo Gharial

Gharial Markhor

Markhor Quokka

Quokka Indri

Indri Dugong

Dugong Lorikeet

Lorikeet Fossa

Fossa Saola

Saola Cormorant

Cormorant Jerboa

Jerboa Ocelot

Ocelot Numbat

Numbat Echidna

Echidna Rezjumei

Rezjumei