Punch Press Operator Resume Guide

Punch press operators set up and operate machines to shape metal parts using a single or multiple sets of dies. They monitor the machine’s performance, adjust settings as necessary, and inspect finished products for quality assurance. Punch press operators also ensure that all safety protocols are followed while operating machinery.

You have a knack for operating punch press machinery, but the hiring managers at manufacturing companies don’t know about your expertise. To make them aware of your abilities and experience, you must craft a resume that stands out.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

Punch Press Operator Resume Sample

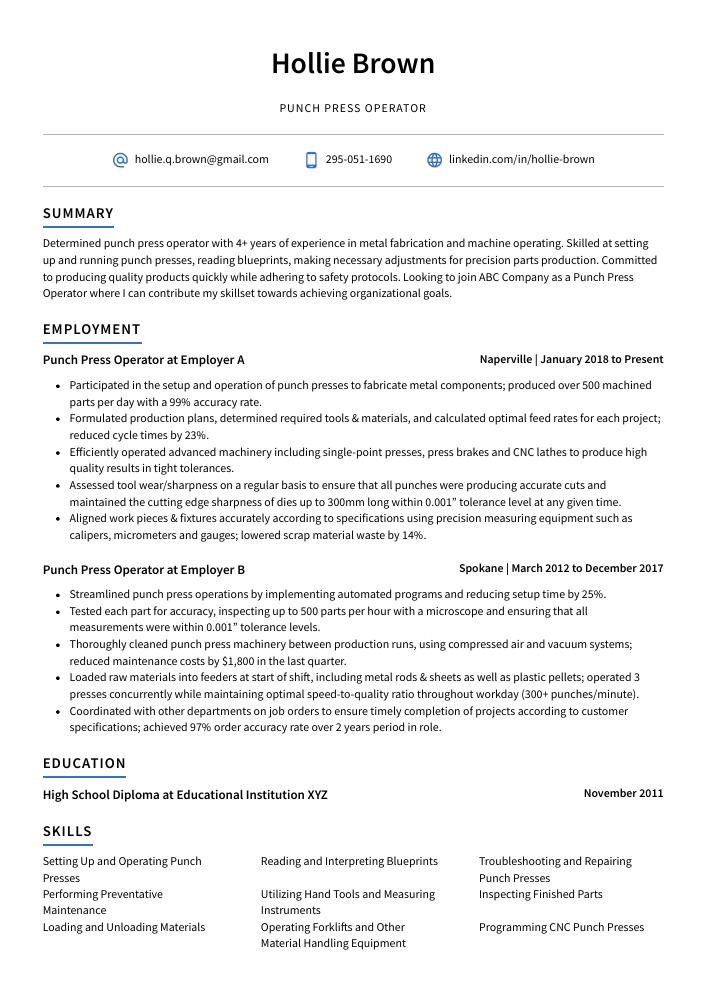

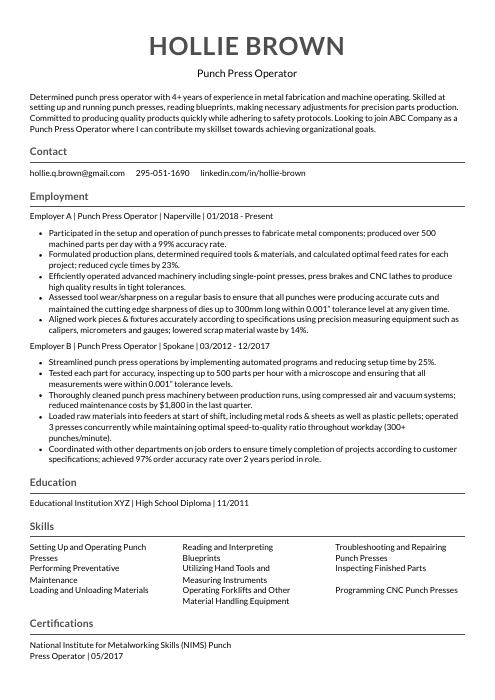

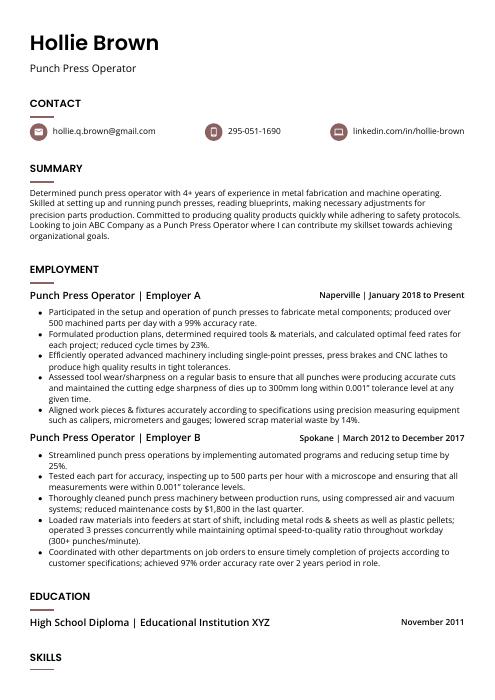

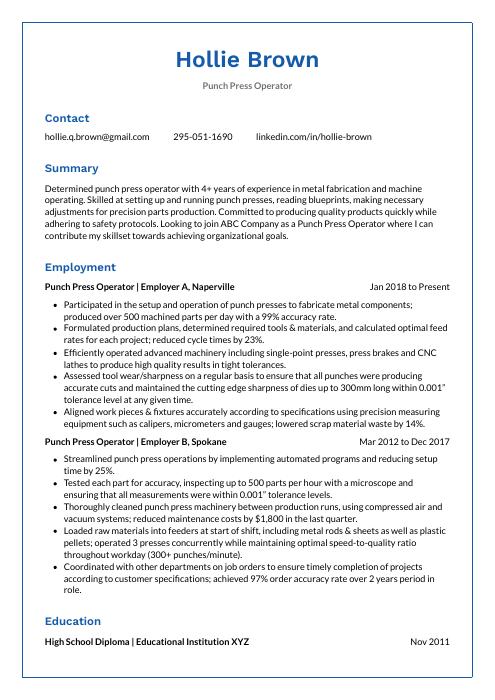

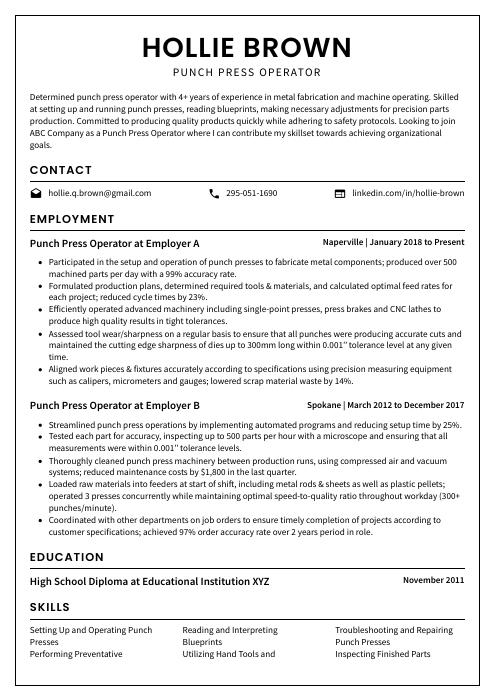

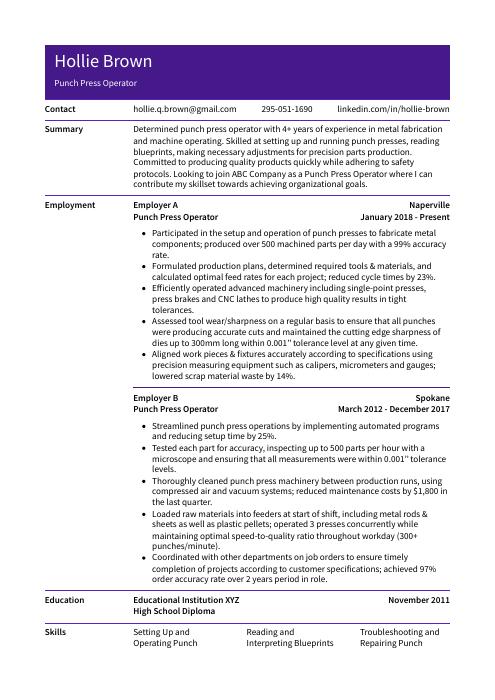

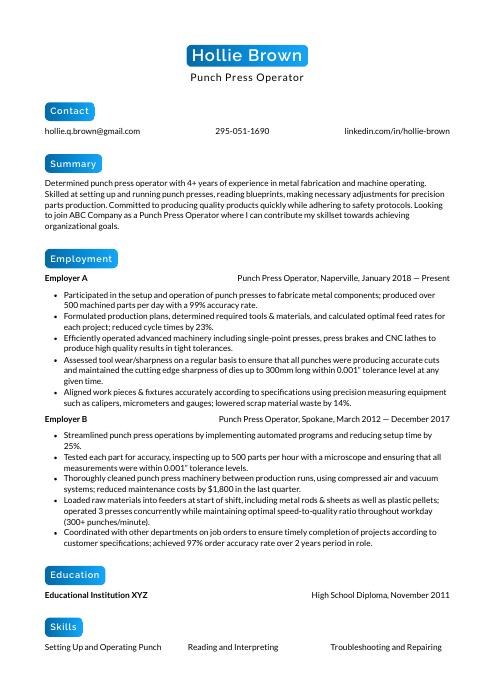

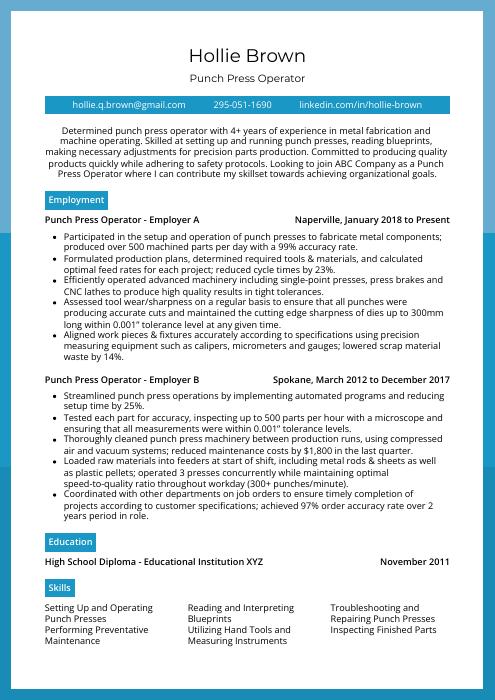

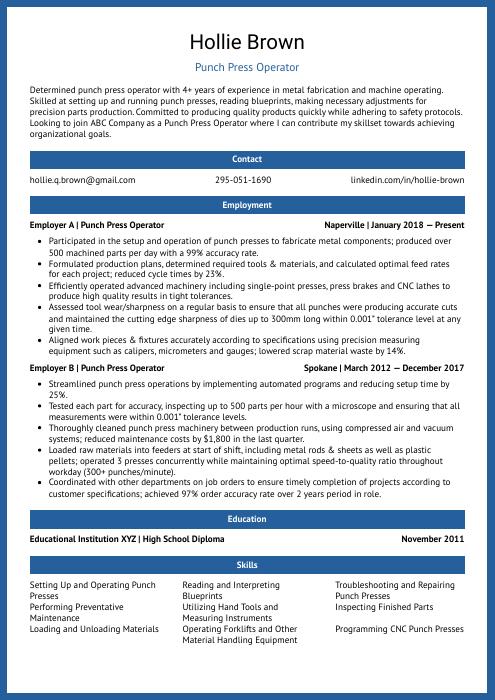

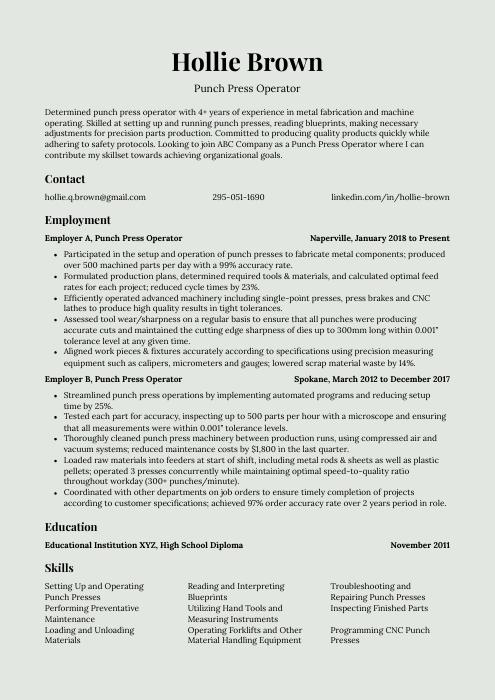

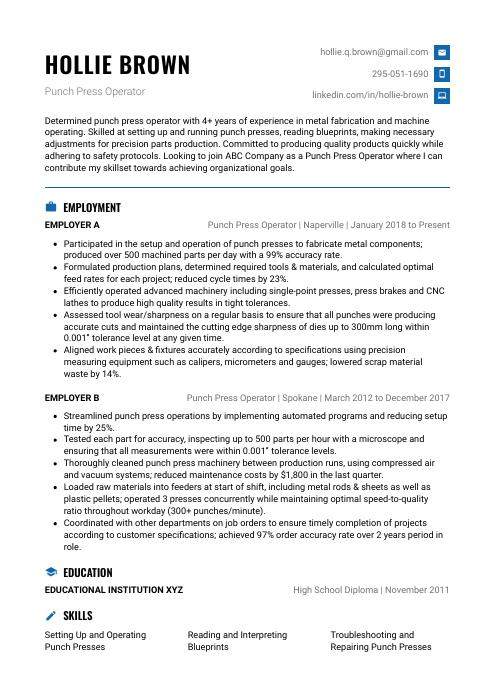

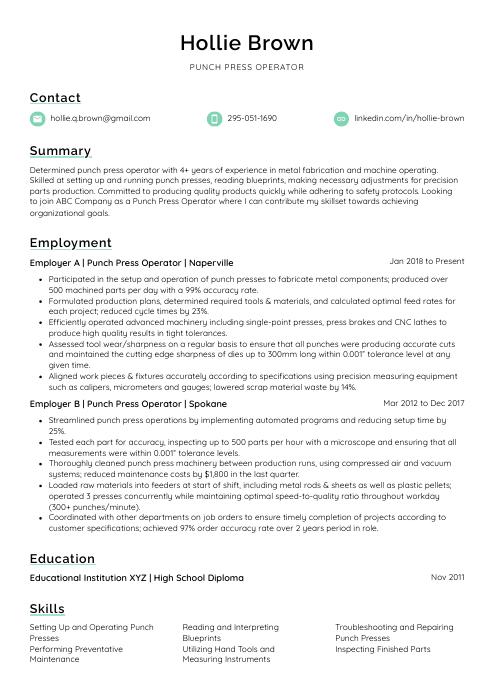

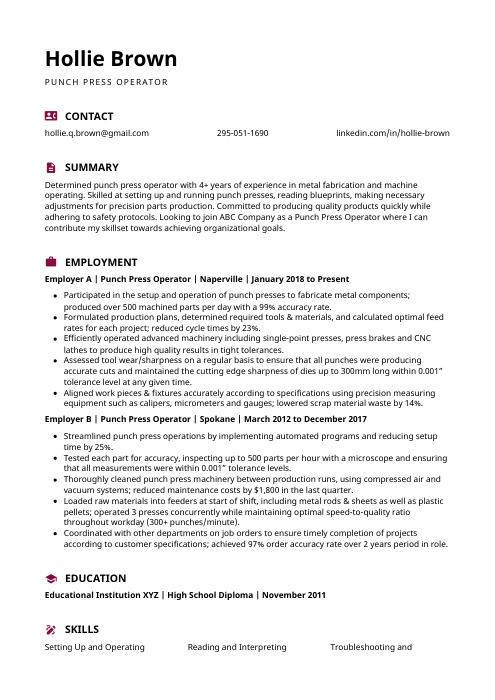

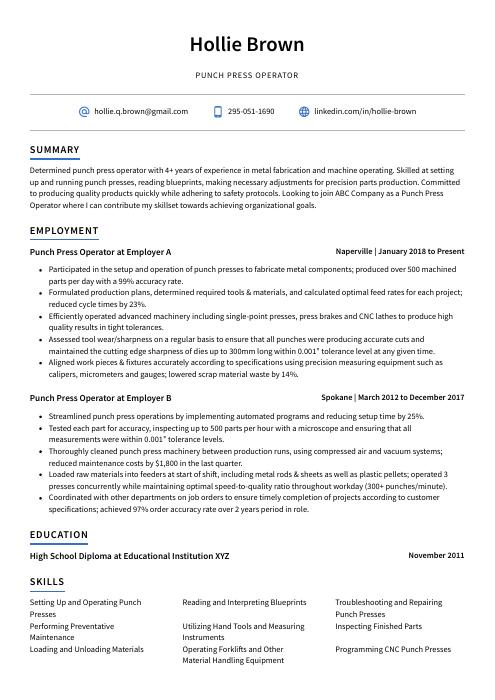

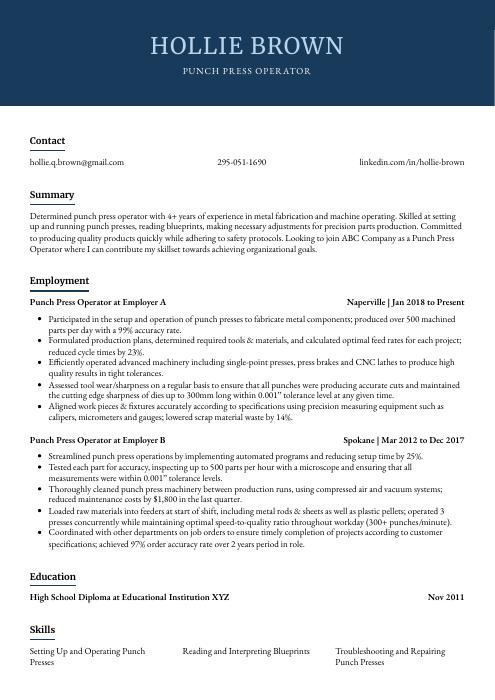

Hollie Brown

Punch Press Operator

[email protected]

295-051-1690

linkedin.com/in/hollie-brown

Summary

Determined punch press operator with 4+ years of experience in metal fabrication and machine operating. Skilled at setting up and running punch presses, reading blueprints, making necessary adjustments for precision parts production. Committed to producing quality products quickly while adhering to safety protocols. Looking to join ABC Company as a Punch Press Operator where I can contribute my skillset towards achieving organizational goals.

Experience

Punch Press Operator, Employer A

Naperville, Jan 2018 – Present

- Participated in the setup and operation of punch presses to fabricate metal components; produced over 500 machined parts per day with a 99% accuracy rate.

- Formulated production plans, determined required tools & materials, and calculated optimal feed rates for each project; reduced cycle times by 23%.

- Efficiently operated advanced machinery including single-point presses, press brakes and CNC lathes to produce high quality results in tight tolerances.

- Assessed tool wear/sharpness on a regular basis to ensure that all punches were producing accurate cuts and maintained the cutting edge sharpness of dies up to 300mm long within 0.001” tolerance level at any given time.

- Aligned work pieces & fixtures accurately according to specifications using precision measuring equipment such as calipers, micrometers and gauges; lowered scrap material waste by 14%.

Punch Press Operator, Employer B

Spokane, Mar 2012 – Dec 2017

- Streamlined punch press operations by implementing automated programs and reducing setup time by 25%.

- Tested each part for accuracy, inspecting up to 500 parts per hour with a microscope and ensuring that all measurements were within 0.001” tolerance levels.

- Thoroughly cleaned punch press machinery between production runs, using compressed air and vacuum systems; reduced maintenance costs by $1,800 in the last quarter.

- Loaded raw materials into feeders at start of shift, including metal rods & sheets as well as plastic pellets; operated 3 presses concurrently while maintaining optimal speed-to-quality ratio throughout workday (300+ punches/minute).

- Coordinated with other departments on job orders to ensure timely completion of projects according to customer specifications; achieved 97% order accuracy rate over 2 years period in role.

Skills

- Setting Up and Operating Punch Presses

- Reading and Interpreting Blueprints

- Troubleshooting and Repairing Punch Presses

- Performing Preventative Maintenance

- Utilizing Hand Tools and Measuring Instruments

- Inspecting Finished Parts

- Loading and Unloading Materials

- Operating Forklifts and Other Material Handling Equipment

- Programming CNC Punch Presses

Education

High School Diploma

Educational Institution XYZ

Nov 2011

Certifications

National Institute for Metalworking Skills (NIMS) Punch Press Operator

May 2017

1. Summary / Objective

Your resume summary/objective should be a concise summary of your qualifications and experience as a punch press operator. Include information about the types of machines you are familiar with, any safety certifications or training courses you have completed, and how many years of experience in this field you possess. Additionally, mention any awards or recognition that demonstrate your commitment to quality workmanship.

Below are some resume summary examples:

Detail-oriented punch press operator with 5+ years of experience in operating and maintaining punch presses. At XYZ, operated a 1,000-ton stamping press to produce parts for the automotive industry while following safety standards. Skilled at troubleshooting machine malfunctions and identifying necessary repairs quickly to minimize downtime. Committed to working in a safe environment while ensuring accuracy and quality on all projects.

Talented punch press operator with 10+ years of experience in the manufacturing industry. Exceptional ability to set up, operate and troubleshoot a variety of punch presses while ensuring quality and safety standards are met. Proven success increasing production output by 20% using innovative techniques. Seeking to join ABC Manufacturing as their next Punch Press Operator to help them meet their goals for efficiency and growth.

Diligent punch press operator with 4+ years of experience in the manufacturing industry. Handled a variety of machines and tools to produce quality parts according to blueprints, specifications, and customer requirements. Experienced in troubleshooting malfunctions quickly and correctly while maintaining high productivity levels. Committed to learning new processes and technologies as needed for job duties.

Dependable punch press operator with 5+ years of experience in operating and maintaining punch presses. Experienced in inspecting finished products for conformance to quality standards, setting up dies and feed systems, troubleshooting malfunctions, and keeping detailed records of production runs. Known for a strong work ethic and the ability to remain calm under pressure while meeting tight deadlines.

Hard-working and reliable punch press operator with 6+ years of experience in a manufacturing environment. Expertise in operating and troubleshooting various types of presses, including hydraulic, mechanical, and pneumatic models. At XYZ Company consistently achieved production goals while maintaining high safety standards. Skilled at reading blueprints to ensure product meets customer specifications.

Skilled punch press operator with 5+ years of experience running high-speed stamping machines. Successfully produced a range of complex parts to exact specifications while adhering to strict safety standards and maintaining quality control. Seeking an opportunity at ABC Manufacturing to use my knowledge in machine operation, maintenance, troubleshooting, repairs and production planning.

Amicable and detail-oriented punch press operator with five years of experience setting up and operating CNC machinery. Responsible for ensuring quality, accuracy, speed, and safety when producing metal parts for various industries. Seeking to join ABC Manufacturing as a Punch Press Operator to help meet company quotas in a timely manner while maintaining high standards of excellence.

Seasoned punch press operator with 8+ years of experience operating and maintaining a variety of punch presses in the manufacturing industry. Expertise includes reading drawings, setting up tools, troubleshooting process problems, and meeting production goals. Seeking to join ABC Manufacturing as an experienced Punch Press Operator for high-volume orders.

2. Experience / Employment

The work history/experience section is where you talk about your employment history. This should be written in reverse chronological order, which means that the most recent job is listed first.

Stick to bullet points when writing this section; doing so makes it easier for the reader to take in what you have to say quickly and effectively. When providing details on what you did, make sure they are specific and quantifiable whenever possible.

For example, instead of saying “Operated punch press,” you could say, “Successfully operated a CNC-controlled punch press machine with an accuracy rate of 99%, producing over 1 million parts per month.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Operated

- Monitored

- Adjusted

- Inspected

- Troubleshot

- Loaded

- Programmed

- Calibrated

- Tested

- Aligned

- Assembled

- Measured

- Fabricated

- Repaired

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Structured and operated punch press machines to produce parts for the manufacturing process with an output of 2,500+ pieces per hour and a 99% accuracy rate.

- Inspected all incoming materials before loading into the machine to ensure it met quality standards; reduced defects by 16%.

- Successfully set up and programmed multiple CNC computers using CAD/CAM software, allowing production time savings of 22 hours a week on average.

- Prepared tools and dies prior to each job run, ensuring that they were in optimal conditions; improved efficiency rates by 4%.

- Expedited work processes through troubleshooting techniques while adhering strictly to safety regulations at all times; achieved zero workplace accidents throughout tenure as Punch Press Operator.

- Calibrated and operated a variety of punch presses to produce high-strength parts and components with precision, resulting in improved product quality by 15%.

- Spearheaded the implementation of an automated process for producing intricate metal designs, significantly reducing production time by 25 hours per week.

- Repaired worn down tools and machinery on a regular basis to keep punch press operations running efficiently; cut downtime costs by $4,000 over six months.

- Fabricated over 2,500 custom parts from steel sheets using CNC machines; reduced scrap material rate from 10% to 5% within three weeks of being hired.

- Accurately read blueprints and adjusted gauges accordingly when operating the punching machine for maximum efficiency; completed projects ahead of schedule 20 times in one year alone.

- Advised and trained 5 new operators on the operation of punch press machinery, significantly reducing machine downtime by 25%.

- Mentored and supervised 8 existing operators to ensure safe practices were followed at all times; successfully improved overall operational efficiency by 30%.

- Effectively monitored and adjusted settings on punch presses in order to produce parts that met customer specifications within tight deadlines; increased production output rate by 15% per hour.

- Reorganized workstations for optimal workflow and minimized material waste through precise cutting using die sets; saved an average of $500 per month in associated costs.

- Reduced setup time from 3 hours to 1 hour when processing orders with multiple tools, resulting in a 40% increase in productivity over a 4-month period.

- Demonstrated exceptional skills in setup and operation of punch press machines; produced 500+ parts with a 99.8% accuracy rate within given deadlines on weekly basis.

- Utilized micrometers, calipers, rulers and other measuring equipment to inspect finished products for quality assurance purposes; reduced defective items by 15%.

- Assembled components using presses and die-casting tools to create production molds that were then used in the manufacturing process as per customer specifications.

- Competently operated CNC punch presses at high speeds while maintaining safety standards throughout each shift and adhering to company regulations regarding machine care & maintenance procedures set forth by management team.

- Represented the organization’s commitment towards safe operations during industry trade shows attended both locally and internationally over a period of 2 years; increased brand recognition among peers by 25%.

- Presented cost-effective production solutions to increase output of punch presses by 15%, resulting in a $10,000 saving for the company.

- Revised existing operating procedures and implemented new ones; improved overall punch press accuracy rate from 70% to 95%.

- Substantially reduced scrap waste levels by 25%, leading to an annual savings of over $5,000 on materials costs.

- Introduced automated programming systems into the workplace which enabled operators to set up machines quickly and accurately; saved 5 hours per week in setup time on average across all departments.

- Developed safety protocols that ensured compliance with OSHA standards while maintaining efficient operation of punch presses; minimized downtime due to accidents or injuries by 40%.

- Optimized punch press operations by reducing setup time per job order by 25%, resulting in a $2,400 increase in production output.

- Measured and adjusted tooling components within 0.0001” accuracy to ensure precise tolerances were met on all parts produced; improved quality control standards while minimizing scrap material rate from 8% to 3%.

- Compiled daily reports of punch press activities and performance metrics for management review; identified areas for improvement which led to an overall 10% reduction in machine downtime over the course of three months.

- Monitored production progress regularly, making necessary changes as needed based on customer specifications and industry regulations; increased work efficiency by 35%.

- Proficiently operated multiple kinds of CNC punch presses including Amada Pega 344, Trumpf TCL 3030 & Wila PressBrake 2500 with minimal guidance or supervision required at all times.

- Facilitated the production of over 500,000 precision parts using a punch press machine to exacting standards, resulting in a 15% increase in quality output.

- Troubleshot and corrected any issues with the punch press system quickly and accurately to minimize downtime; reduced repair costs by 12%.

- Adjusted various settings on the punch press as needed and ensured correct tool alignment for optimal performance; increased productivity rate by 10%.

- Achieved 100% accuracy when operating the CNC punch presses according to company specifications while maintaining safety protocols at all times.

- Confidently operated 3+ different types of servo-driven mechanical punches with minimal supervision, increasing efficiency levels by 25%.

- Improved quality and efficiency of punch press operations by 10% through careful calibration and maintenance of machinery.

- Reliably operated a variety of automated precision metal-working equipment including CNC presses, lathes, shears, saws and grinders to produce intricate parts within tight tolerances.

- Operated hydraulic punches with accuracy to create precise holes in steel plates without damaging surrounding material; achieved an output rate 30 pieces/hour on average while maintaining quality standards.

- Programmed computer numerical control (CNC) machines according to blueprints & customer specifications; produced up to 500 components per day for use in the automotive industry with minimal wastage or defects reported upon inspection.

3. Skills

Two organizations that have advertised for a position with the same title may be searching for individuals whose skills are quite different. For instance, one job might require the candidate to be familiar with CNC programming, while another may call for experience in manual punch press operation.

It is therefore essential that you tailor your skills section of your resume to each specific job posting. This will help ensure that it passes through any applicant tracking systems used by employers, which are computer programs designed to scan resumes for certain keywords before passing them on to a human.

In addition, you should also include details about the most important skills in other sections such as the summary or work history – this allows you to provide more information and demonstrate how these abilities have been applied successfully in past roles.

Below is a list of common skills & terms:

- Inspecting Finished Parts

- Loading and Unloading Materials

- Operating Forklifts and Other Material Handling Equipment

- Performing Preventative Maintenance

- Programming CNC Punch Presses

- Reading and Interpreting Blueprints

- Setting Up and Operating Punch Presses

- Troubleshooting and Repairing Punch Presses

- Utilizing Hand Tools and Measuring Instruments

- Working With a Variety of Metals and Alloys

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no prior experience, mention your education below the resume objective. However, if you already have significant work experience as a punch press operator that is worth showcasing, omitting an education section might be best.

If including an education section, try to list courses related to the punch press operator job or any other relevant qualifications such as certifications or licenses obtained during studies.

High School Diploma

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and expertise in a particular field. They show potential employers that you have taken the time to gain additional qualifications, which can be beneficial when applying for jobs.

Including certifications on your resume is an excellent way to prove that you are knowledgeable about the job requirements and have obtained relevant skills or training necessary for success in the role. Be sure to include any industry-specific certifications as these will help you stand out from other applicants.

National Institute for Metalworking Skills (NIMS) Punch Press Operator

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Hollie Brown, this would be Hollie-Brown-resume.pdf or Hollie-Brown-resume.docx.

7. Cover Letter

Writing a cover letter is a great way to show employers why you’re the perfect candidate for their role. It should be made up of 2 to 4 paragraphs and include information that isn’t already mentioned in your resume.

Cover letters provide an opportunity for you to explain why your skills, qualifications and experience make you the ideal person for a position. Plus, they give recruiters insight into who you are as an individual beyond what’s written on paper – which can be extremely beneficial during the selection process!

Below is an example cover letter:

Dear Alia,

I am writing in response to your ad for a Punch Press Operator at your company. With my background in operating and setting up punch presses, as well as my experience working with other machinery, I am confident that I would be a valuable asset to your team.

In my current role, I operate a variety of machines including punch presses, shears, and brakes. I have also been responsible for performing routine maintenance on the machines, as well as troubleshooting any issues that may arise. My experience has taught me how to work quickly and efficiently while maintaining a high level of accuracy. In addition, I have excellent problem-solving skills that enable me to find creative solutions to challenges.

I am excited about the opportunity to join your team and contribute to your company’s success. I believe that my skills and experience make me an ideal candidate for this position. I look forward to speaking with you soon so that we can discuss the details of this role further. Thank you for your time and consideration.

Sincerely,

Hollie

Punch Press Operator Resume Templates

Jerboa

Jerboa Gharial

Gharial Numbat

Numbat Indri

Indri Fossa

Fossa Markhor

Markhor Cormorant

Cormorant Pika

Pika Kinkajou

Kinkajou Rhea

Rhea Ocelot

Ocelot Dugong

Dugong Quokka

Quokka Saola

Saola Echidna

Echidna Lorikeet

Lorikeet Hoopoe

Hoopoe Axolotl

Axolotl Bonobo

Bonobo Rezjumei

Rezjumei