Safety Engineer Resume Guide

Safety engineers are responsible for ensuring that products, processes and workplaces meet safety standards. They analyze potential hazards, inspect equipment and facilities to identify any deficiencies or risks, recommend corrective actions to reduce the risk of injury or harm, develop safety procedures and policies for a variety of settings such as factories, construction sites and offices. Additionally they provide training on how to work safely in hazardous environments.

Your expertise in safety engineering could be a major asset to any organization. But hiring managers won’t know of your potential until you present them with an eye-catching resume that portrays your qualifications and experience.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

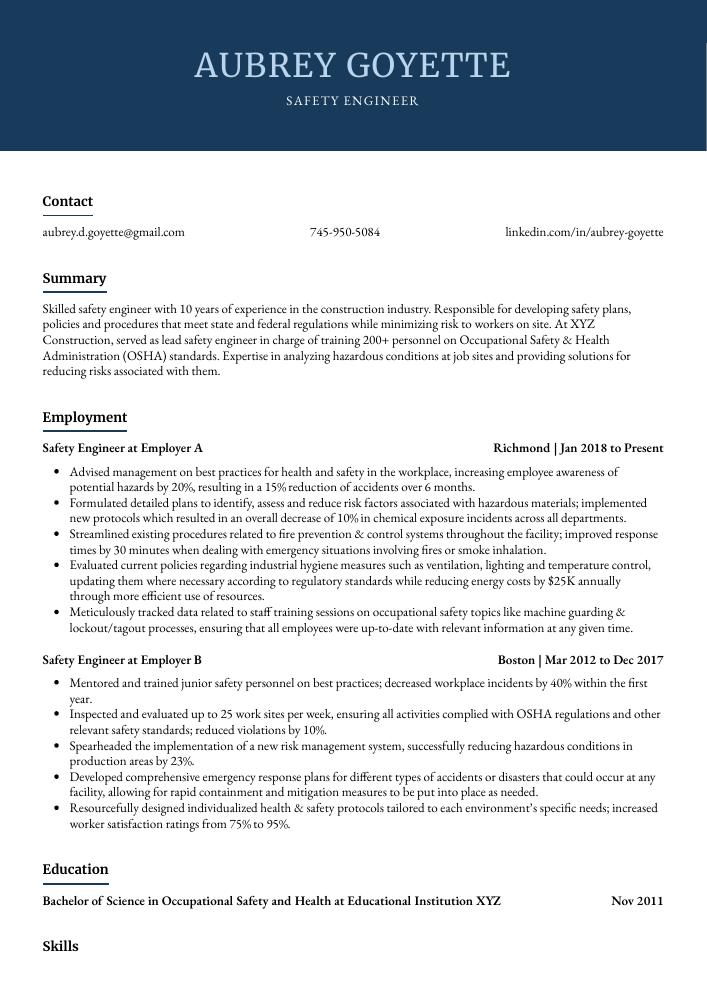

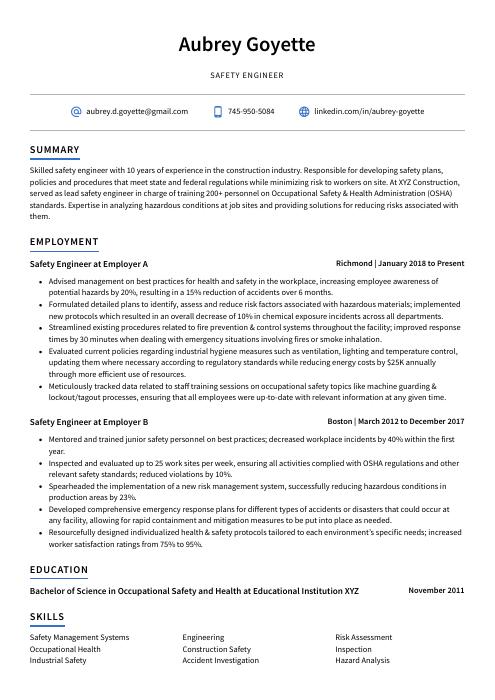

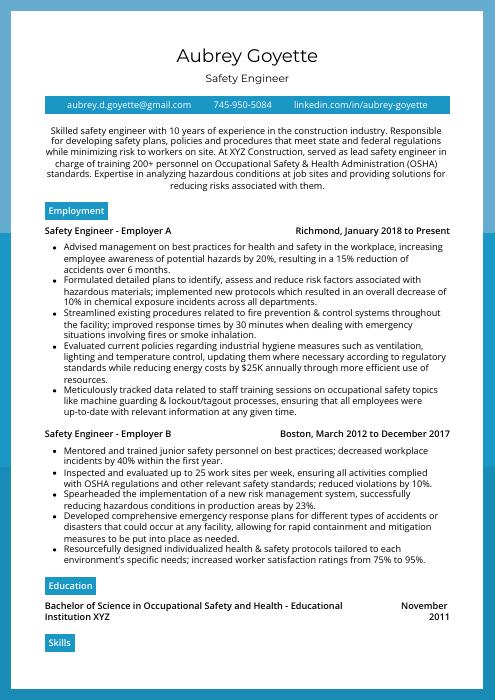

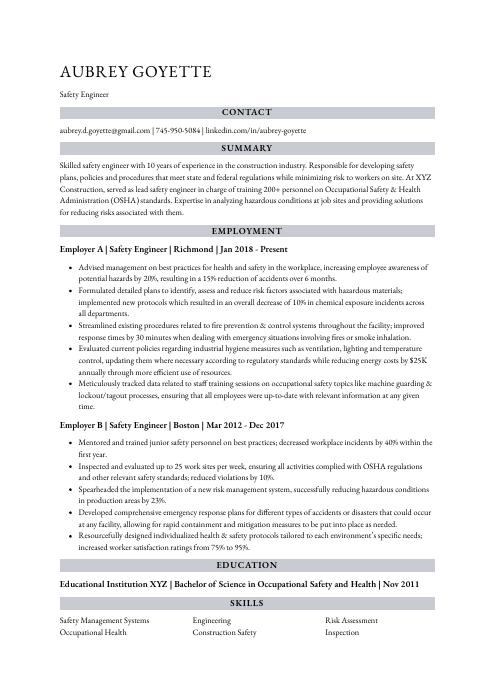

Safety Engineer Resume Sample

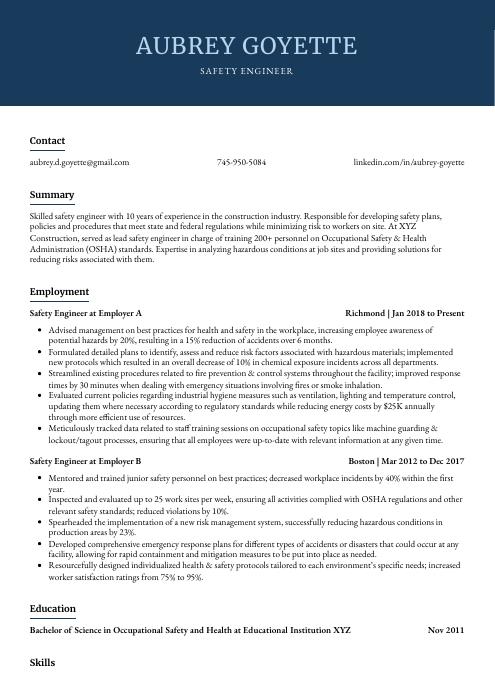

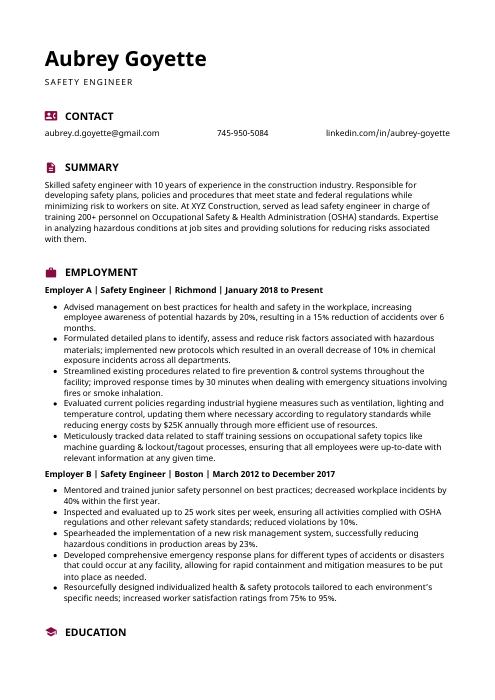

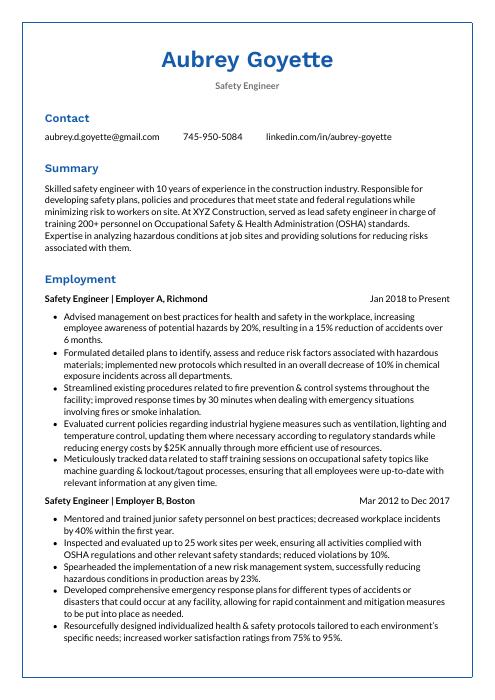

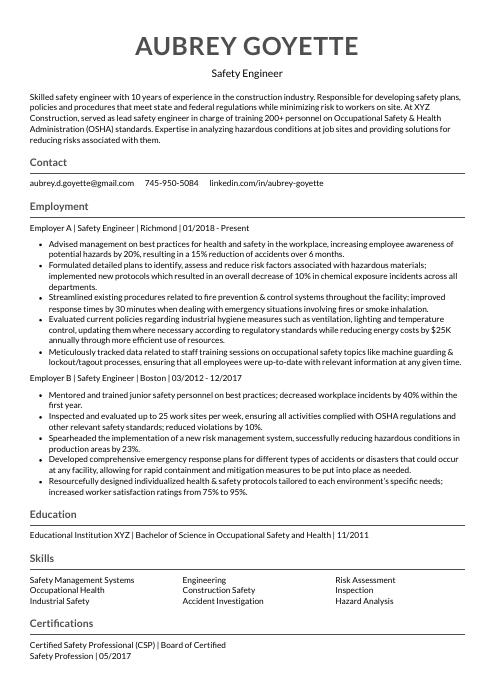

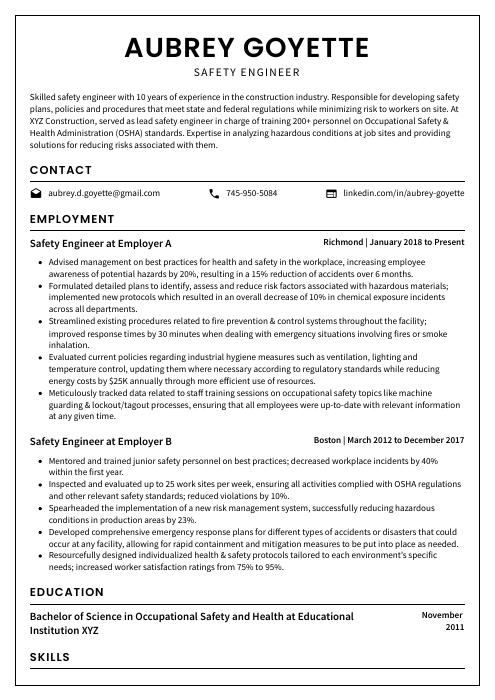

Aubrey Goyette

Safety Engineer

[email protected]

745-950-5084

linkedin.com/in/aubrey-goyette

Summary

Skilled safety engineer with 10 years of experience in the construction industry. Responsible for developing safety plans, policies and procedures that meet state and federal regulations while minimizing risk to workers on site. At XYZ Construction, served as lead safety engineer in charge of training 200+ personnel on Occupational Safety & Health Administration (OSHA) standards. Expertise in analyzing hazardous conditions at job sites and providing solutions for reducing risks associated with them.

Experience

Safety Engineer, Employer A

Richmond, Jan 2018 – Present

- Advised management on best practices for health and safety in the workplace, increasing employee awareness of potential hazards by 20%, resulting in a 15% reduction of accidents over 6 months.

- Formulated detailed plans to identify, assess and reduce risk factors associated with hazardous materials; implemented new protocols which resulted in an overall decrease of 10% in chemical exposure incidents across all departments.

- Streamlined existing procedures related to fire prevention & control systems throughout the facility; improved response times by 30 minutes when dealing with emergency situations involving fires or smoke inhalation.

- Evaluated current policies regarding industrial hygiene measures such as ventilation, lighting and temperature control, updating them where necessary according to regulatory standards while reducing energy costs by $25K annually through more efficient use of resources.

- Meticulously tracked data related to staff training sessions on occupational safety topics like machine guarding & lockout/tagout processes, ensuring that all employees were up-to-date with relevant information at any given time.

Safety Engineer, Employer B

Boston, Mar 2012 – Dec 2017

- Mentored and trained junior safety personnel on best practices; decreased workplace incidents by 40% within the first year.

- Inspected and evaluated up to 25 work sites per week, ensuring all activities complied with OSHA regulations and other relevant safety standards; reduced violations by 10%.

- Spearheaded the implementation of a new risk management system, successfully reducing hazardous conditions in production areas by 23%.

- Developed comprehensive emergency response plans for different types of accidents or disasters that could occur at any facility, allowing for rapid containment and mitigation measures to be put into place as needed.

- Resourcefully designed individualized health & safety protocols tailored to each environment’s specific needs; increased worker satisfaction ratings from 75% to 95%.

Skills

- Safety Management Systems

- Engineering

- Risk Assessment

- Occupational Health

- Construction Safety

- Inspection

- Industrial Safety

- Accident Investigation

- Hazard Analysis

Education

Bachelor of Science in Occupational Safety and Health

Educational Institution XYZ

Nov 2011

Certifications

Certified Safety Professional (CSP)

Board of Certified Safety Profession

May 2017

1. Summary / Objective

A resume summary for a safety engineer should demonstrate your expertise in creating and maintaining safe work environments. In this section, you can highlight the certifications or qualifications that make you stand out from other applicants, such as OSHA certification, experience with hazardous materials handling protocols, and knowledge of risk management processes. You could also mention any awards or recognition you have received for promoting workplace safety initiatives.

Below are some resume summary examples:

Well-rounded safety engineer with 5+ years of experience in the construction and oil & gas industries. Adept at developing safety plans, conducting risk assessments, and designing job-specific safety protocols to ensure a safe working environment for all employees. At XYZ Co., reduced workplace accidents by 40%, resulting in cost savings of over $250K annually. Highly organized with excellent communication skills; eager to apply expertise towards promoting an injury-free work space at ABC Corp.

Determined safety engineer with 5+ years of experience in industrial, construction and manufacturing safety. Expertise includes risk assessments, audits and inspections to ensure compliance with OSHA regulations. At XYZ Corporation developed a comprehensive hazard recognition program which resulted in a 20% decrease in workplace injuries over 3 months period. Experienced developing emergency response plans that are effective yet cost-effective solutions for maximum efficiency.

Enthusiastic safety engineer with 5+ years of experience in developing and implementing safety protocols, procedures and policies. Adept at conducting risk assessments, identifying potential hazards and providing solutions to reduce or eliminate them. Proven track record of helping organizations adhere to OSHA standards while reducing the number of workplace injuries by 40%. Looking for a role where I can apply my expertise in health & safety engineering at ABC Company.

Talented safety engineer with 10+ years of experience in the field. Expertise in designing and implementing safe systems for a variety of complex machinery, including computer-controlled systems. Adept at identifying areas of risk, creating safety plans and protocols, and developing training materials to ensure compliance. Seeking to join ABC Company’s engineering team as a Safety Engineer to help create an accident-free working environment.

Seasoned safety engineer with 8+ years of experience in the oil and gas industry. Proven track record of reducing workplace accidents by 50% through the development and implementation of effective safety systems. Skilled at developing safety plans, conducting risk assessments, and training personnel on safe work practices. Experienced in ensuring compliance with OSHA regulations to ensure a safe working environment for employees.

Detail-oriented safety engineer with 5+ years of experience evaluating workplace conditions to ensure compliance with regulations and standards. Proven ability to identify potential risks, develop safety protocols, and train personnel on safe practices. Seeking a position at ABC Company where I can use my expertise in hazard analysis and risk assessment to create a safer working environment for all employees.

Dependable safety engineer with 5+ years of experience in the construction industry. Proven track record in implementing safety protocols and ensuring compliance with OHS regulations. Adept at identifying potential hazards, conducting risk assessments, and preparing incident reports for swift resolution. Looking to join ABC Construction as a Safety Engineer to ensure safe working conditions on all projects.

Proficient safety engineer with 10+ years of experience in developing and implementing strategies to ensure workplace safety. Proven track record of reducing incidents by 50% and increasing compliance rating from 75% to 99%. Aiming to leverage excellent knowledge on OSHA regulations, risk management principles, and hazard analysis techniques at ABC Technologies.

2. Experience / Employment

In the experience section, you should provide details on your employment history. This section should be written in reverse chronological order, which means that the most recent job is listed first.

When writing about what you did for each role, stick to bullet points. Doing so allows the reader to take in the information quickly and easily. When writing out these bullet points, make sure to include detail and explain any quantifiable results achieved from your work.

For example, instead of saying “Created safety protocols,” you could say “Developed a comprehensive set of safety protocols for factory workers that reduced workplace accidents by 45% within six months.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Monitored

- Evaluated

- Investigated

- Implemented

- Inspected

- Enforced

- Trained

- Assessed

- Documented

- Analyzed

- Developed

- Coordinated

- Advised

- Reported

- Resolved

Other general verbs you can use are:

- Achieved

- Compiled

- Demonstrated

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Revised company safety policies and procedures, reducing the risk of workplace injury by 25% over a 3-year period.

- Participated in weekly team meetings to identify current safety hazards and devise solutions to prevent future occurrences; implemented new practices that improved overall employee safety performance by 10%.

- Optimized existing processes for hazardous materials storage, handling and disposal; lowered number of chemical spills from mishandling incidents by 15%.

- Documented all occupational health & safety standards on behalf of the company according to industry regulations; achieved 100% compliance with OSHA guidelines within 6 months.

- Proficiently monitored working environments using advanced analytical tools such as thermal imaging cameras, ultrasonic leak detectors etc., ensuring regulatory conformity at all times.

- Analyzed safety risks in the workplace, recommending and implementing corrective measures to reduce potential hazards; achieved a 38% decrease in employee accidents within 6 months.

- Achieved OSHA compliance through effective safety training of over 800 staff members, ensuring comprehensive understanding of applicable regulations and procedures.

- Represented company at monthly health & safety meetings with local government agencies to discuss current issues and improvement strategies for overall risk management processes.

- Confidently conducted regular inspections of laboratories, manufacturing plants, offices & other sites to identify any deficiencies or violations in safety protocols; presented detailed reports outlining necessary changes required for full compliance with governmental standards and codes.

- Presented formalized plans to executive team regarding new policies on hazardous materials handling techniques as well as fire protection systems installation/maintenance guidelines; successfully reduced fire incidents by 22%.

- Investigated over 25 potential safety hazards, identifying & mitigating risks to ensure a safe working environment; reduced workplace injuries by 15%.

- Coordinated with engineering staff to develop & implement comprehensive safety protocols and procedures for all industrial operations; ensured full compliance with OSHA regulations.

- Resolved over 20 employee grievances related to health and safety issues within the prescribed timelines; improved morale among workers by 45%.

- Utilized statistical analysis software such as MATLAB, Minitab and RStudio for analyzing data from various sources including incident reports & accident logs in order to identify trends in unsafe practices or equipment malfunctions; helped prevent 39% of future accidents before occurrence.

- Diligently monitored hazardous work areas on a daily basis using advanced tracking systems while ensuring that all employees were trained properly regarding proper use of protective gear at all times; decreased non-compliant incidents by 22%.

- Improved safety protocols and procedures at the workplace by 20%, reducing potential hazards and incidents.

- Actively monitored all safety systems to ensure compliance with OSHA standards, resulting in zero violations during inspection periods.

- Assessed risks associated with various construction projects, developing on-site safety plans for implementation by contractors and subcontractors; reduced job site accidents by 40%.

- Reduced risk of fire related incidents through regular testing of emergency exits & alarms, as well as educating staff members on proper evacuation methods if required.

- Structured a comprehensive training program covering basic health & safety topics such as hazard identification, safe work practices and emergency response planning; trained over 250 employees in the last year alone.

- Facilitated the development and implementation of safety protocols for all employees, resulting in a reduction of workplace related accidents by 20%.

- Prepared detailed risk assessments to identify potential hazards, reducing incident response time by 50% on average.

- Reorganized the layout of workstations based on ergonomics principles which contributed to an increase in efficiency levels across teams by 33%.

- Enforced safety regulations among staff members through regular training sessions; developed/updated safe operating procedures that improved compliance rates from 65% to 85%.

- Effectively monitored industrial processes using advanced technology such as infrared cameras and other thermal imaging equipment; identified risks before they had the chance to cause harm or disruption saving $20,000+ per year in damages & repair costs.

- Expedited safety engineering procedures for over 50 projects, reducing overall project completion time by 25%.

- Compiled detailed technical reports on safety compliance and identified hazards; generated recommendations to reduce risks and increase workplace safety standards.

- Monitored employee activities in the production area to ensure that all OSHA regulations were strictly adhered to; successfully reduced non-compliance incidents by 40% year-over-year.

- Implemented new security protocols such as access control systems, CCTV cameras & fire extinguishers throughout the premise, leading to an improved safety rating of 97%.

- Reliably performed periodic inspections of work areas & equipment according to industry guidelines, detected potential hazards early with 95% accuracy rate per audit results.

- Introduced and implemented a new safety plan that reduced workplace accidents by 45% and improved overall productivity.

- Reported on safety compliance matters to upper management, including conducting regular risk assessments and identifying potential hazards in the factory environment.

- Trained over 250 employees in relevant health & safety protocols such as fire evacuation procedures, manual handling techniques and safe use of equipment; increased employee satisfaction with regards to job security by 20%.

- Independently investigated incidents or near-misses related to hazardous conditions at work sites and developed recommendations for corrective actions within 48 hours of each incident evaluation.

- Demonstrated excellent problem solving abilities when resolving issues relating to workplace injuries or unsafe practices; minimized downtime due to occupational illness/injury occurrences by 25%.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may specialize in safety engineering for the construction industry and Organization XYZ may focus on safety engineering for the automotive sector.

It is important to tailor your skills section of your resume to each job you are applying for because many employers now use applicant tracking systems that scan resumes looking for certain keywords before passing them onto a human.

In addition, it is beneficial to elaborate on some of these skills further in other areas such as the summary or experience section so that recruiters can gain an understanding of how you have applied them throughout your career.

Below is a list of common skills & terms:

- Accident Investigation

- Aerospace

- AutoCAD

- Behavior Based Safety

- Construction Management

- Construction Safety

- Continuous Improvement

- Contract Management

- EHS

- Emergency Management

- Engineering

- Engineering Management

- Environmental Awareness

- Environmental Compliance

- Environmental Management Systems

- Ergonomics

- Fire Safety

- First Aid

- Gas

- HAZOP

- HAZWOPER

- Hazard Analysis

- Hazard Identification

- Hazard Recognition

- Hazardous Materials

- Hazardous Waste Management

- ISO 14001

- Incident Investigation

- Industrial Hygiene

- Industrial Safety

- Inspection

- Lean Manufacturing

- MATLAB

- Manufacturing

- Occupational Health

- Process Engineering

- Process Improvement

- Process Safety

- Program Management

- Project Engineering

- Project Planning

- Risk Assessment

- Risk Management

- Root Cause Analysis

- Safety Engineering

- Safety Management Systems

- Safety Training

- Security Clearance

- Six Sigma

- Supervisory Skills

- Systems Engineering

- Team Leadership

- Teamwork

- Time Management

- Workplace Safety

4. Education

Mentioning your education on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, include an education section below your resume objective. However, if you have significant experience as a safety engineer that is more relevant to the job than anything else, then it might be better to omit this section altogether.

If including an education section is necessary, try mentioning courses related to safety engineering or any other subjects which would help demonstrate why you’re qualified for the role.

Bachelor of Science in Occupational Safety and Health

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and proficiency in a particular field. It is important to include any certifications that are relevant to the job you are applying for on your resume, as it will show potential employers that you have taken the time and effort to become certified in an area of expertise.

Including certifications can also give hiring managers more confidence in your abilities, making them more likely to hire you over other applicants who may not be certified.

Certified Safety Professional (CSP)

Board of Certified Safety Profession

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Aubrey Goyette, this would be Aubrey-Goyette-resume.pdf or Aubrey-Goyette-resume.docx.

7. Cover Letter

Submitting a cover letter is an essential part of any job application. It is a document separate from your resume that allows you to explain why you are the ideal candidate for the role and provide more details about yourself than what’s already included in your CV.

Cover letters should be made up of 2 to 4 paragraphs, usually no longer than one page, and give recruiters additional information about who you are as a professional. Writing one can make all the difference when it comes to getting noticed by employers so it’s well worth taking some time crafting yours carefully!

Below is an example cover letter:

Dear Jadon,

I am writing to apply for the Safety Engineer position with your company. With over 10 years of experience in safety engineering, I have the necessary skills and qualifications to contribute to the success of your organization.

In my current role as a Safety Engineer at [company name], I am responsible for developing and implementing safety programs that meet OSHA standards and regulations. I have been successful in reducing workplace accidents by 30% over the past year through the implementation of new safety protocols and procedures. In addition, I have developed strong relationships with local law enforcement agencies and fire departments, which has resulted in a quicker response time in case of an emergency.

Some of my other key strengths include:

– Strong analytical and problem-solving skills: I have a keen eye for detail and am able to quickly identify potential hazards before they result in an accident or injury.

– Excellent communication skills: I am able to effectively communicate with employees at all levels, from front-line workers to senior management. This has been essential in ensuring that everyone is aware of the latest safety procedures.

– Passionate about safety: My top priority is always keeping people safe while they are at work. This passion drives me to continuously look for ways to improve our safety program so that we can prevent accidents and injuries from happening in the first place.

Attached is my resume which provides additional information on my background and accomplishments. I would welcome the opportunity to discuss how I can be of benefit to your company as your next Safety Engineer.

Sincerely,

Aubrey

Safety Engineer Resume Templates

Axolotl

Axolotl Dugong

Dugong Pika

Pika Bonobo

Bonobo Gharial

Gharial Fossa

Fossa Kinkajou

Kinkajou Lorikeet

Lorikeet Jerboa

Jerboa Saola

Saola Ocelot

Ocelot Echidna

Echidna Hoopoe

Hoopoe Markhor

Markhor Indri

Indri Cormorant

Cormorant Rhea

Rhea Numbat

Numbat Quokka

Quokka Rezjumei

Rezjumei