Product Safety Engineer Resume Guide

Product safety engineers are responsible for evaluating the safety of products and ensuring they meet industry standards. They design tests, analyze data from those tests, identify potential risks and hazards associated with a product’s use, develop strategies to mitigate them, and provide guidance on how to apply relevant regulations.

Your expertise in product safety makes you a valuable asset to any company. But potential employers don’t know about your abilities yet, so writing a resume that highlights them is essential for getting their attention.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

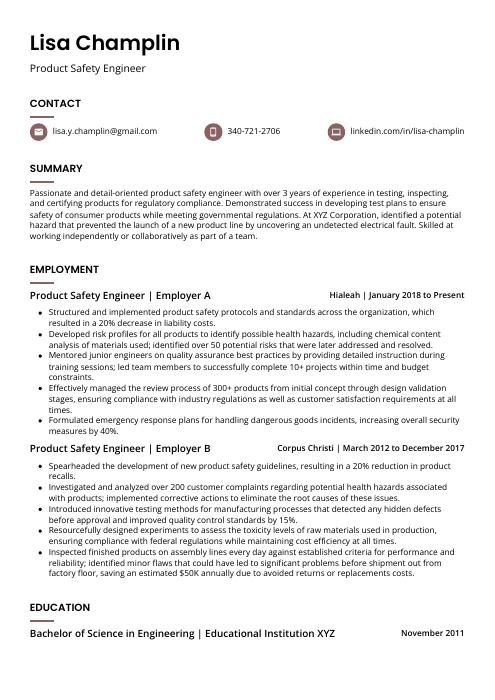

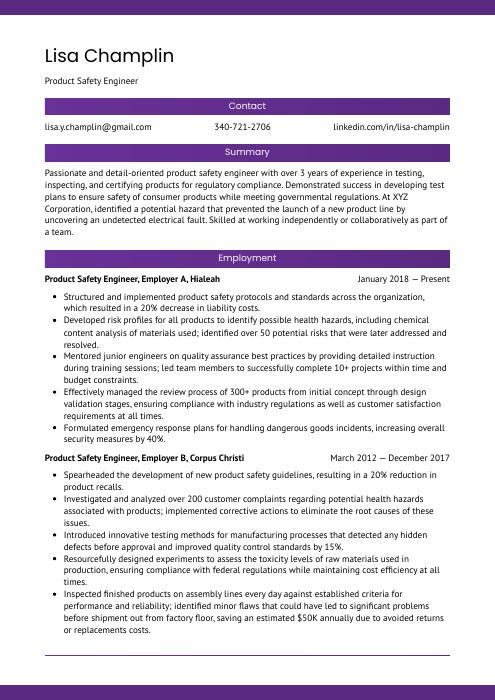

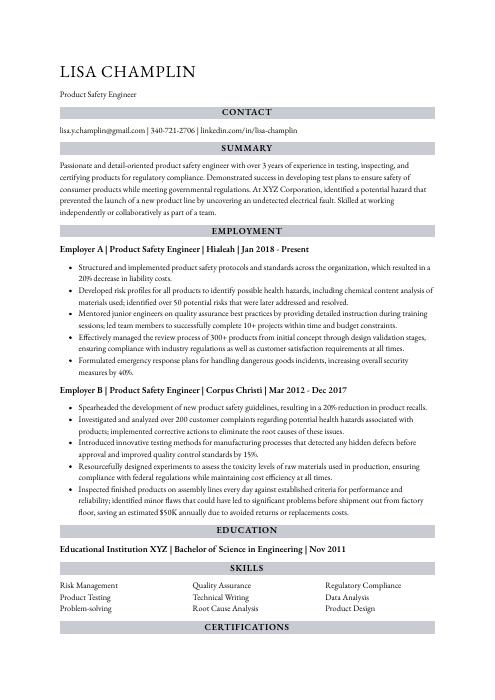

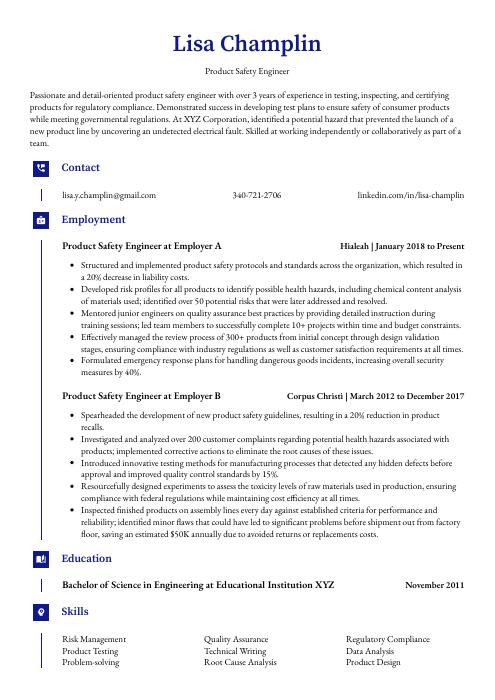

Product Safety Engineer Resume Sample

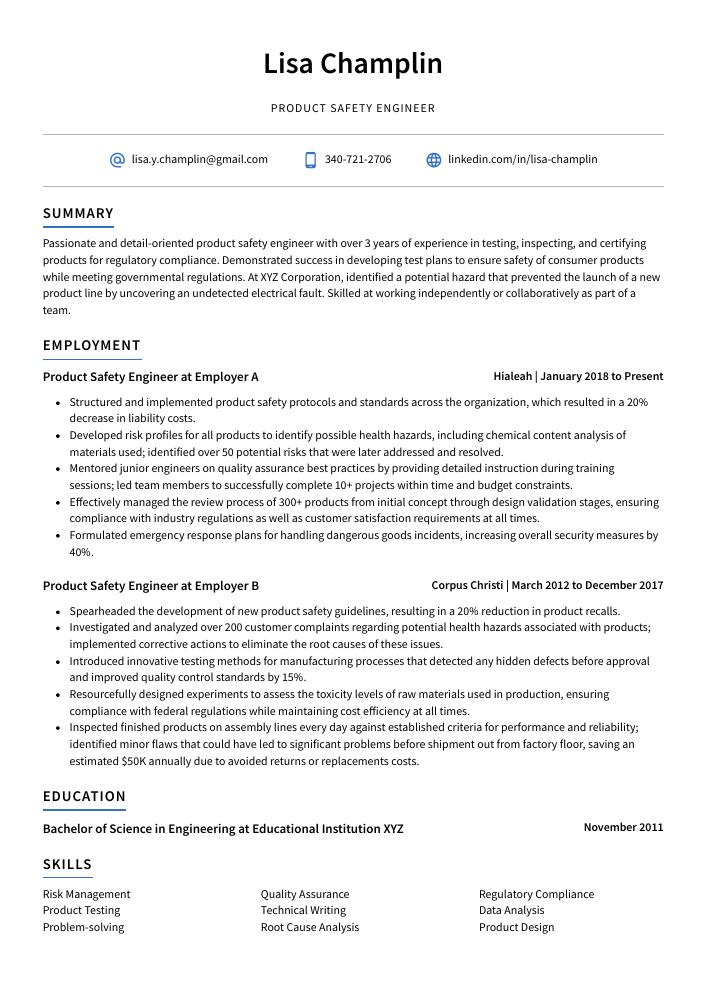

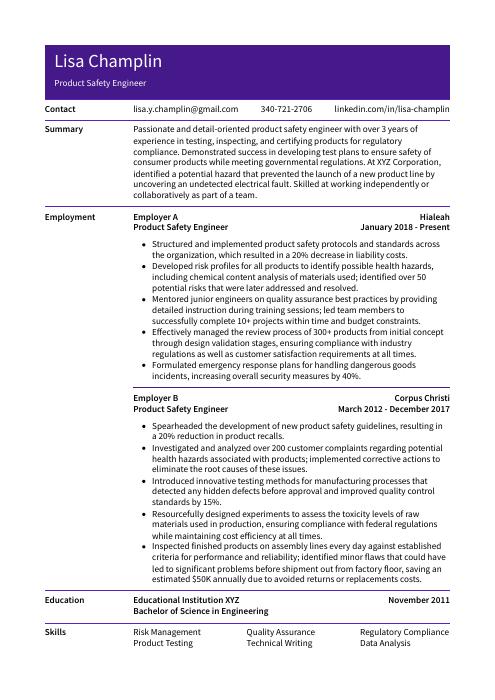

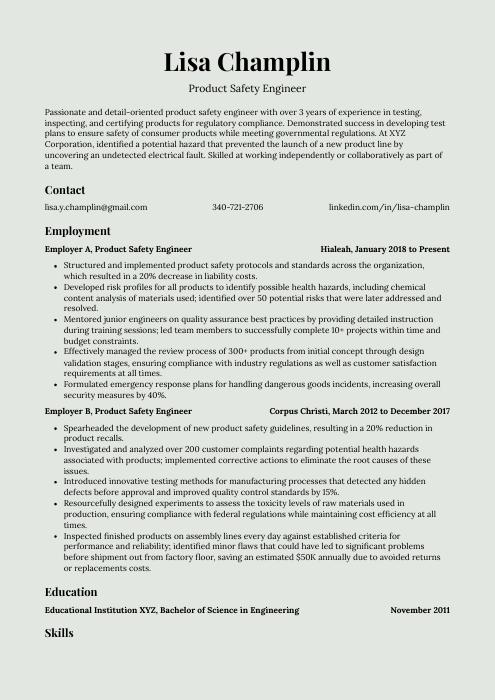

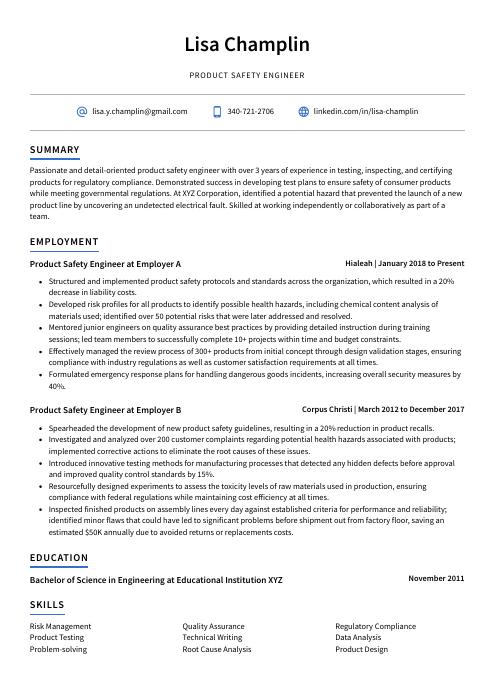

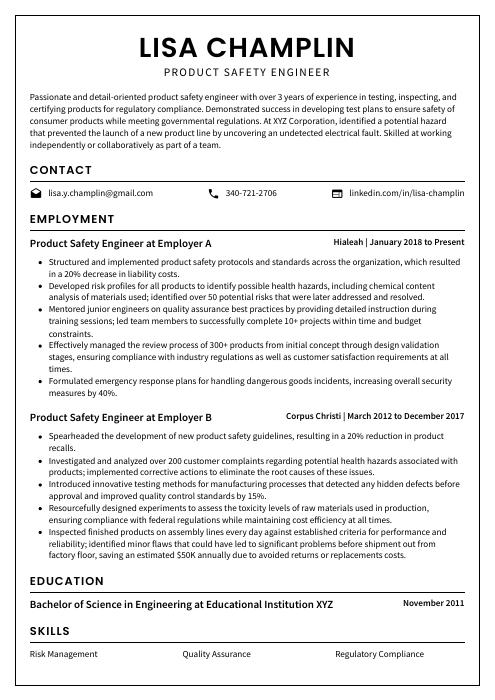

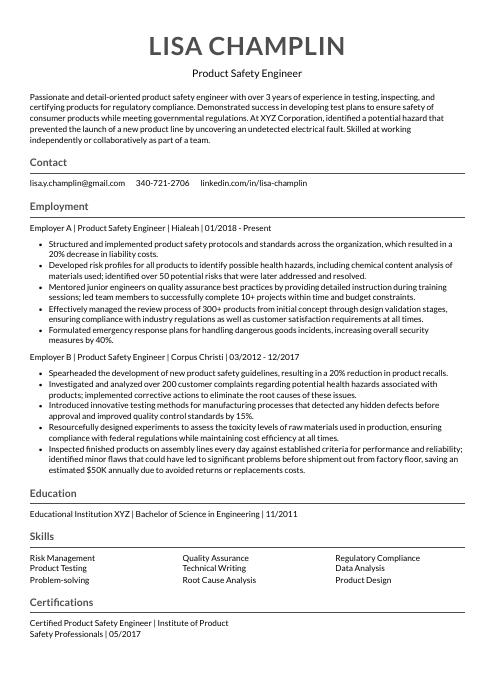

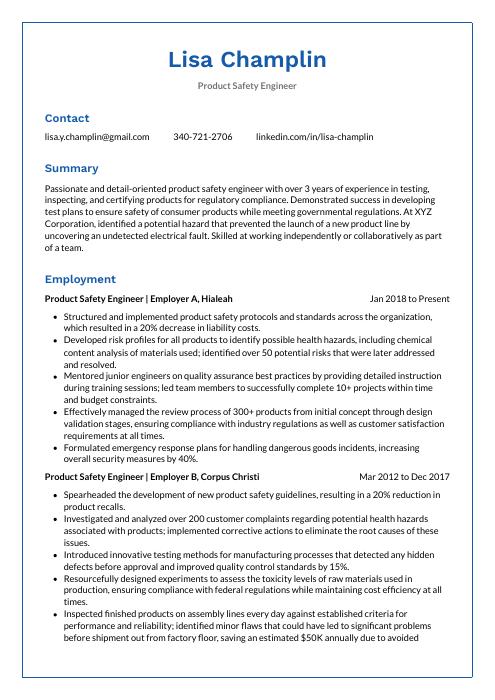

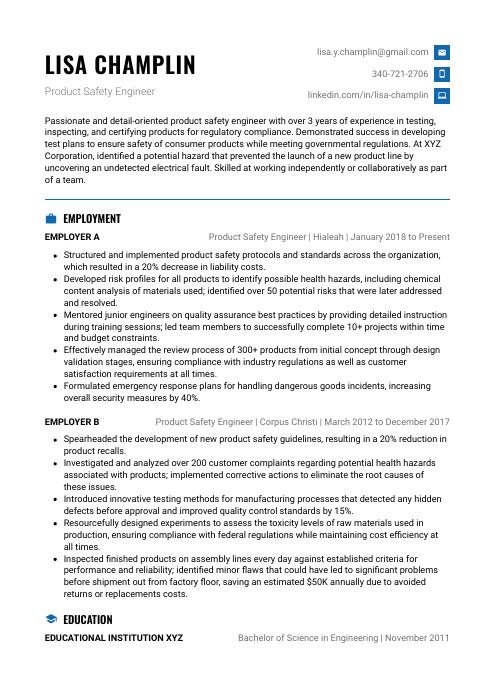

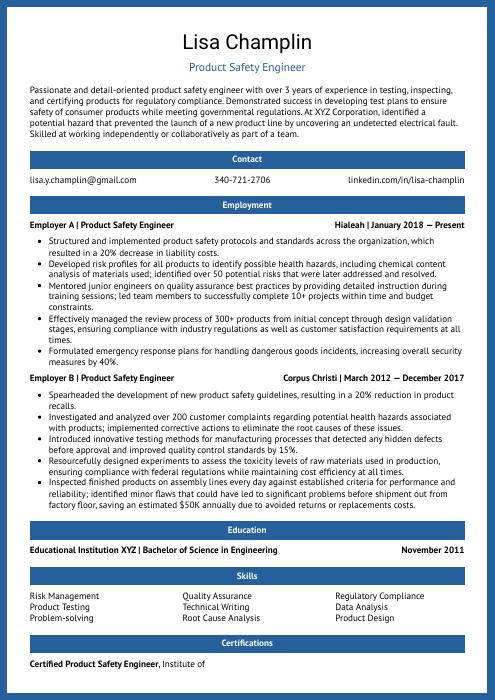

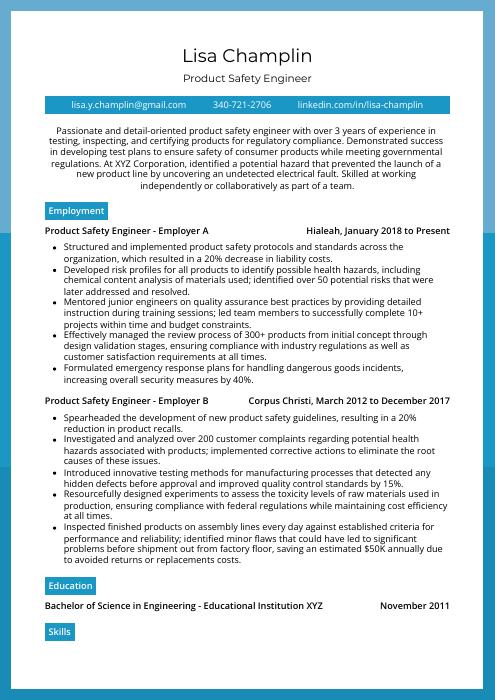

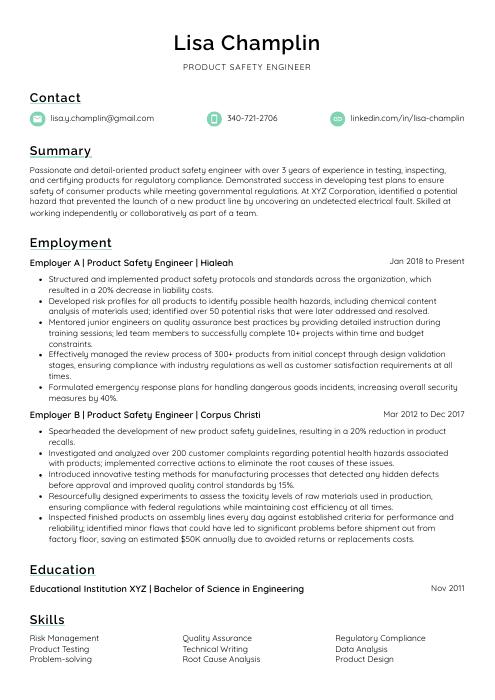

Lisa Champlin

Product Safety Engineer

lisa.y.champlin@gmail.com

340-721-2706

linkedin.com/in/lisa-champlin

Summary

Passionate and detail-oriented product safety engineer with over 3 years of experience in testing, inspecting, and certifying products for regulatory compliance. Demonstrated success in developing test plans to ensure safety of consumer products while meeting governmental regulations. At XYZ Corporation, identified a potential hazard that prevented the launch of a new product line by uncovering an undetected electrical fault. Skilled at working independently or collaboratively as part of a team.

Experience

Product Safety Engineer, Employer A

Hialeah, Jan 2018 – Present

- Structured and implemented product safety protocols and standards across the organization, which resulted in a 20% decrease in liability costs.

- Developed risk profiles for all products to identify possible health hazards, including chemical content analysis of materials used; identified over 50 potential risks that were later addressed and resolved.

- Mentored junior engineers on quality assurance best practices by providing detailed instruction during training sessions; led team members to successfully complete 10+ projects within time and budget constraints.

- Effectively managed the review process of 300+ products from initial concept through design validation stages, ensuring compliance with industry regulations as well as customer satisfaction requirements at all times.

- Formulated emergency response plans for handling dangerous goods incidents, increasing overall security measures by 40%.

Product Safety Engineer, Employer B

Corpus Christi, Mar 2012 – Dec 2017

- Spearheaded the development of new product safety guidelines, resulting in a 20% reduction in product recalls.

- Investigated and analyzed over 200 customer complaints regarding potential health hazards associated with products; implemented corrective actions to eliminate the root causes of these issues.

- Introduced innovative testing methods for manufacturing processes that detected any hidden defects before approval and improved quality control standards by 15%.

- Resourcefully designed experiments to assess the toxicity levels of raw materials used in production, ensuring compliance with federal regulations while maintaining cost efficiency at all times.

- Inspected finished products on assembly lines every day against established criteria for performance and reliability; identified minor flaws that could have led to significant problems before shipment out from factory floor, saving an estimated $50K annually due to avoided returns or replacements costs.

Skills

- Risk Management

- Quality Assurance

- Regulatory Compliance

- Product Testing

- Technical Writing

- Data Analysis

- Problem-solving

- Root Cause Analysis

- Product Design

Education

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Product Safety Engineer

Institute of Product Safety Professionals

May 2017

1. Summary / Objective

Your resume summary should be a concise overview of your experience and qualifications as a product safety engineer. Include any relevant certifications or degrees, such as an engineering degree from an accredited university. Mention the types of products you have worked with in the past, such as medical devices or consumer electronics. Highlight any special skills that make you stand out from other applicants, like knowledge of international standards for product safety testing and certification processes.

Below are some resume summary examples:

Seasoned product safety engineer with 5+ years of experience specializing in the development and implementation of product safety standards. Experienced in identifying potential hazards, developing risk management strategies, and creating test plans to ensure compliance with applicable regulations. Skilled at collaborating with stakeholders across multiple departments to develop effective solutions that promote a safe environment for consumers.

Well-rounded product safety engineer with 5+ years of experience ensuring compliance and performing risk assessments on a range of products. Experienced in developing comprehensive testing protocols, analyzing data to assess product safety performance, and managing quality assurance teams. Seeking to join ABC Corp as the next product safety engineer and help ensure that their products meet industry standards for customer satisfaction.

Reliable and highly experienced Product Safety Engineer with 10+ years of experience in developing and implementing product safety plans for a variety of industries. Skilled at identifying, analyzing, and mitigating potential risks to ensure the safe use and operation of products. Seeking to join ABC Company’s team as a Product Safety Engineer where my expertise can be utilized to help keep consumers safe while using their products.

Amicable product safety engineer with 5+ years of experience designing and implementing safety protocols for a range of products. Achieved ISO 9001 certification in product quality assurance at XYZ Corporation, developed comprehensive product testing plans to ensure compliance with local/national regulations. At ABC Company, reduced the number of customer complaints by 30% through implementation of detailed process improvements.

Hard-working product safety engineer with 10+ years of experience in the consumer product industry. Possess a deep understanding of safety engineering principles and regulations, ensuring products are designed to meet all local and international standards. Seeking to join ABC Company where I can apply my knowledge of environmental health and safety guidelines to ensure customer satisfaction through quality assurance processes.

Energetic product safety engineer with 7+ years of experience developing product safety standards and managing the implementation of industrial safety protocols. Passionate about creating a safe working environment for all stakeholders, particularly those in hazardous industries. At XYZ Inc., successfully reduced injury incidents by 40% while overseeing the introduction of new technologies to increase overall productivity.

Diligent product safety engineer with 10+ years of experience in product testing, evaluation, and certification across a variety of industries. At XYZ Inc., successfully developed and implemented new protocols for product safety compliance to maintain the highest standards for consumer goods. Highly adept at using CAD software along with advanced engineering principles to analyze products and ensure their safe operation.

Proficient product safety engineer with 5+ years of experience in product development and regulatory compliance. Skilled at researching, analyzing, and implementing industry standards to ensure the highest levels of quality control for all products. Seeking a role as a product safety engineer at ABC Technologies where I can use my expertise to ensure safe production across multiple industries.

2. Experience / Employment

For the experience section, you should list your work history in reverse chronological order, with the most recent job listed first.

Stick to bullet points when writing this section; it makes it easier for the reader to quickly digest what you have to say. When describing what you did, provide detail and explain any results or outcomes that were achieved.

For example, instead of saying “Conducted product safety tests,” you could say, “Performed extensive testing on new products using a variety of methods including vibration analysis and accelerated life cycle testing which resulted in improved customer satisfaction ratings.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Evaluated

- Monitored

- Investigated

- Assessed

- Analyzed

- Implemented

- Inspected

- Researched

- Documented

- Developed

- Tested

- Reported

- Trained

- Advised

Other general verbs you can use are:

- Achieved

- Compiled

- Coordinated

- Demonstrated

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Coordinated day-to-day operations of the product safety department, ensuring that all products met industry standards and regulations; reduced product recall incidents by 25%.

- Assessed potential hazards in production processes to identify areas for improvement; suggested process amendments which resulted in a 14% decrease in overall risks.

- Participated actively in research initiatives to develop new testing protocols for product performance evaluation, allowing for an improved quality control system with higher accuracy rates (+20%).

- Facilitated training sessions on safety best practices and procedures across multiple departments; educated over 100 employees on compliance requirements, resulting in fewer violations (reduction of 30%).

- Meticulously maintained records of test results and customer feedback data while providing timely reports to management regarding progress updates & any discrepancies found during audits or inspections (+10 hours/week saved).

- Reported product safety issues to management and design teams, resulting in a 35% decrease in product recalls over the past 12 months.

- Researched and identified potential risks with new products through rigorous tests of prototypes; developed preventative measures that reduced safety-related incidents by 27%.

- Trained 15+ coworkers on industry standard product testing protocols, dramatically increasing overall accuracy rates from 78% to 92%.

- Actively sought out ways to further improve existing safety procedures, introducing innovative processes that increased productivity by 25%; earned recognition as Safety Employee of the Year for these accomplishments.

- Demonstrated excellence in problem solving when assessing customer complaints regarding faulty merchandise; reengineered defective parts within 6 hours which enabled timely resolution of all cases reported before month end closure.

- Prepared and reviewed over 200 product safety reports for global regulatory compliance, resulting in a 15% decrease in non-compliance incidents.

- Streamlined existing processes to effectively identify potential hazards and assess risk factors associated with new products; reduced the testing time by 30%.

- Improved customer experience by proactively investigating issues reported against products; identified root causes and implemented corrective solutions within 24 hours on average.

- Reliably collaborated with cross-functional teams across multiple departments to ensure that all product designs met quality standards prior to launch into the market place.

- Implemented corrective actions plans when required, ensuring full traceability of all changes made throughout product lifecycle management activities while also maintaining accurate records of any design modifications or upgrades required along the way.

- Reduced product safety-related incidents by 45% through rigorous product testing and inspection procedures.

- Utilized quality assurance tools to identify potential hazards in products, ensuring compliance with all industry standards and regulations.

- Independently conducted 200+ tests on new and existing products every month; identified defects or malfunctions before they reached customers several times a week.

- Tested raw materials for contaminants, allergens, toxins & other harmful substances according to established protocols; determined safe levels of usage for components used in production processes when necessary.

- Monitored the assembly line during manufacturing operations to ensure that only approved materials were being utilized per company policy; reported any noncompliance issues immediately as soon as observed.

- Documented and evaluated product safety evaluations on over 200 products, ensuring compliance with international standards and regulations; reduced inspection time by 50% through the development of a new process.

- Achieved an 80% reduction in customer complaints related to product safety issues due to rigorous testing procedures and timely corrective actions.

- Expedited production timelines through active collaboration with cross-functional teams while maintaining high levels of quality control within set budget constraints.

- Confidently identified potential risks associated with different materials used in manufacturing processes and ensured that appropriate measures were taken for their mitigation or elimination.

- Presented findings from various investigations into accidental incidents affecting customers before executive team meetings, resulting in improved problem resolution strategies across departments at 20% faster rate than previous year’s average.

- Represented the company in safety committees and successfully implemented initiatives to reduce product related injuries by 35%.

- Efficiently identified potential risks within the production process and proposed cost-effective solutions to ensure compliance with safety regulations; reduced total costs associated with product recalls by $25,000 annually.

- Evaluated current products for risk management purposes using industry standards, analyzing over 300+ components per month with 100% accuracy rate on all findings reported.

- Compiled detailed reports of inspections performed while monitoring quality assurance activities at manufacturing plants; improved operational efficiency by 15%.

- Optimized existing processes through root cause analysis investigations and developed plans that decreased defective rates from 4% to 0%, achieving zero nonconformances in three months’ time period.

- Advised a team of 10+ safety engineers on product design, construction and testing procedures to ensure that all products met stringent industry standards; improved overall quality assurance by 25%.

- Reorganized the existing product safety protocols and implemented new policies which reduced liability risks by 40% while increasing customer satisfaction ratings by 15%.

- Accurately identified potential hazards in various prototype designs using detailed analysis techniques; averted 2 major accidents due to faulty components with a collective value of $100,000+.

- Analyzed over 500 product-related incidents reported internally & externally since 2016; formulated an effective strategy for reducing similar occurrences in future releases at a rate of 20% year-on-year.

- Revised outdated regulations governing the production process as per current market trends and designed appropriate training materials for workers accordingly; achieved 95% compliance within 5 months from launch date.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may require the candidate to be proficient with ISO 9001, while organization XYZ may prefer expertise in IEC 62368.

It is important that you tailor your resume’s skills section accordingly as many employers use applicant tracking systems (ATS). These computer programs scan resumes for certain keywords before passing them on to a human. If they don’t find what they are looking for then your application will not make it through the first round of selection.

Once listed here, you should also discuss these qualifications further in other sections such as the summary or experience section.

Below is a list of common skills & terms:

- Data Analysis

- Problem-solving

- Product Design

- Product Safety Protocols

- Product Testing

- Quality Assurance

- Regulatory Compliance

- Risk Management

- Root Cause Analysis

- Technical Writing

4. Education

Including an education section on your resume will depend on how much experience you have in the field. If you are just starting out and don’t have any work experience, make sure to include an education section below your resume objective. However, if you already have a few years of product safety engineering under your belt, omitting the education section is perfectly acceptable.

If including an education section, try to mention courses or subjects related to product safety engineering that could be beneficial for the job role you are applying for.

Bachelor of Science in Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your knowledge and proficiency in a certain field. Employers often look for certifications when reviewing resumes, as it shows that you have taken the initiative to learn more about the industry and stay up-to-date with current trends.

If you have any relevant certifications related to the job you are applying for, make sure they are included on your resume so potential employers can see them right away. This will help give you an edge over other applicants who may not be certified in those areas.

Certified Product Safety Engineer

Institute of Product Safety Professionals

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Lisa Champlin, this would be Lisa-Champlin-resume.pdf or Lisa-Champlin-resume.docx.

7. Cover Letter

Submitting a cover letter along with your resume is a great way of introducing yourself to prospective employers. It provides them with more information about who you are and what makes you an ideal candidate for the role.

Cover letters typically contain 2 to 4 paragraphs and should be tailored specifically for each job application. They should not just reiterate what’s already stated in your resume, but instead provide recruiters with additional insights that make you stand out from other applicants.

Below is an example cover letter:

Dear Beatrice,

I am writing to apply for the Product Safety Engineer position at XYZ Corporation. With over six years of experience in product safety and compliance, I have the knowledge and skills necessary to excel in this role.

In my current position as a Product Safety Engineer at ABC Corporation, I am responsible for ensuring that our products meet all applicable safety standards. I have conducted numerous safety audits and assessments, developed and implemented safety plans, and provided training on product safety procedures. My attention to detail and commitment to quality has helped me identify potential hazards before they become problems.

I am confident that I can bring the same level of dedication and excellence to your organization. In addition to my technical skills, I have strong communication and interpersonal skills that will enable me to work effectively with your team. I am also familiar with the relevant regulations governing product safety, including those of the Consumer Product Safety Commission (CPSC).

I would welcome the opportunity to discuss how my experience could benefit XYZ Corporation as your next Product Safety Engineer. Thank you for your time and consideration; please do not hesitate to contact me if you have any questions or need additional information about my qualifications.

Sincerely,

Lisa

Product Safety Engineer Resume Templates

Dugong

Dugong Quokka

Quokka Bonobo

Bonobo Pika

Pika Saola

Saola Axolotl

Axolotl Cormorant

Cormorant Indri

Indri Markhor

Markhor Kinkajou

Kinkajou Hoopoe

Hoopoe Echidna

Echidna Ocelot

Ocelot Rhea

Rhea Lorikeet

Lorikeet Fossa

Fossa Jerboa

Jerboa Numbat

Numbat Gharial

Gharial Rezjumei

Rezjumei