Plastics Engineer Resume Guide

Plastics Engineers are responsible for designing and developing products made from plastic materials, as well as testing and evaluating the performance of those products. They work closely with industrial designers to create innovative designs that meet customer needs, while also ensuring that their creations comply with industry standards and regulations.

Plastics engineering is your specialty, and you have the experience to prove it. But potential employers won’t know about your expertise until they read a resume that highlights all of your accomplishments in this field.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

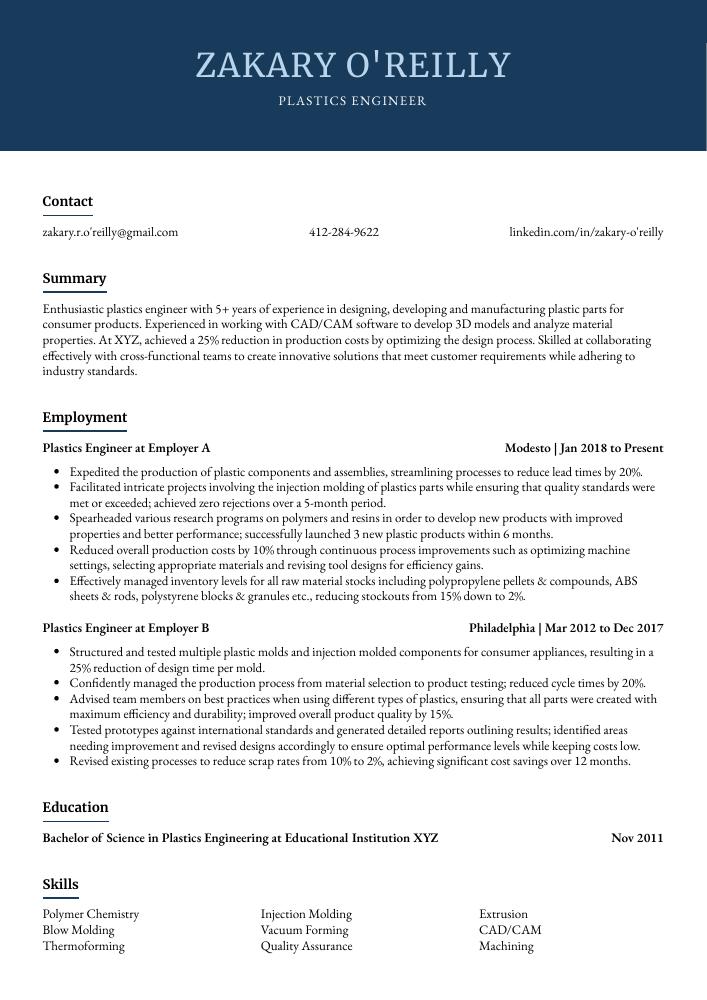

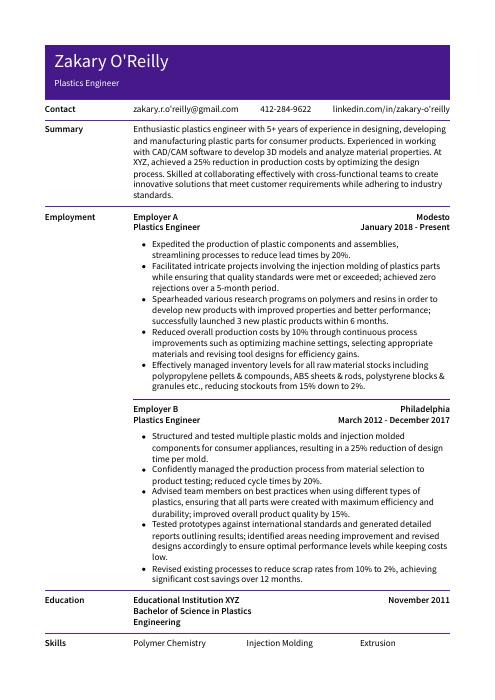

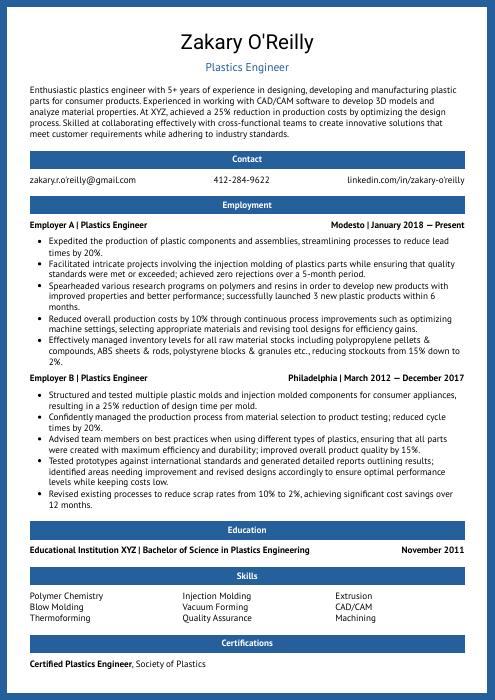

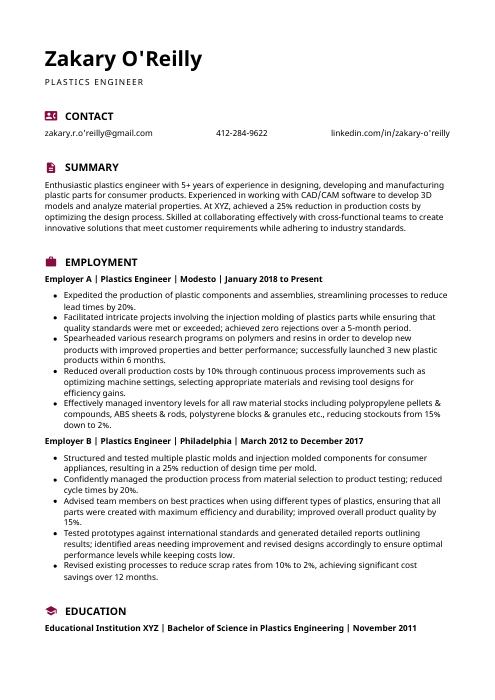

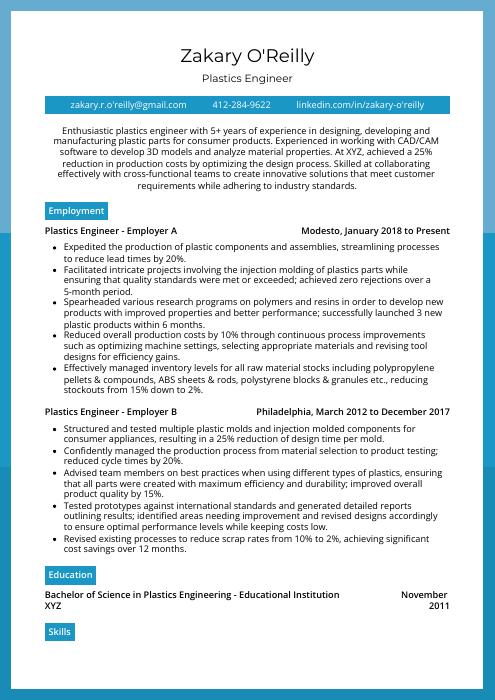

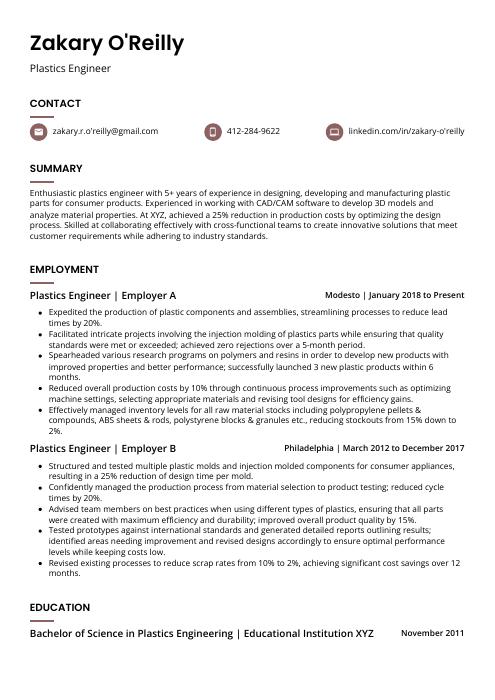

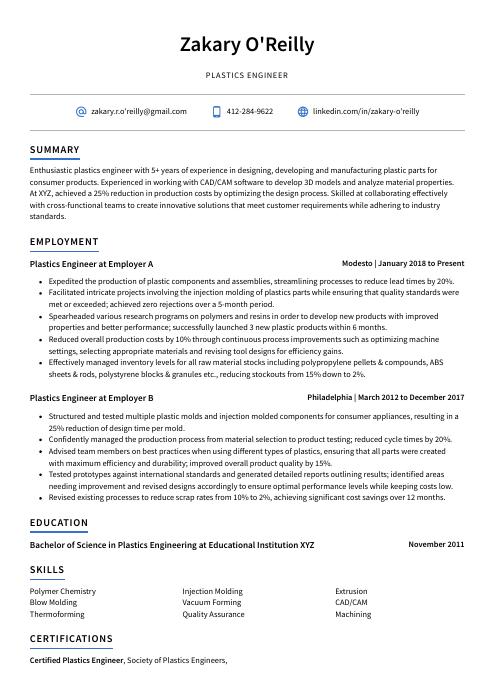

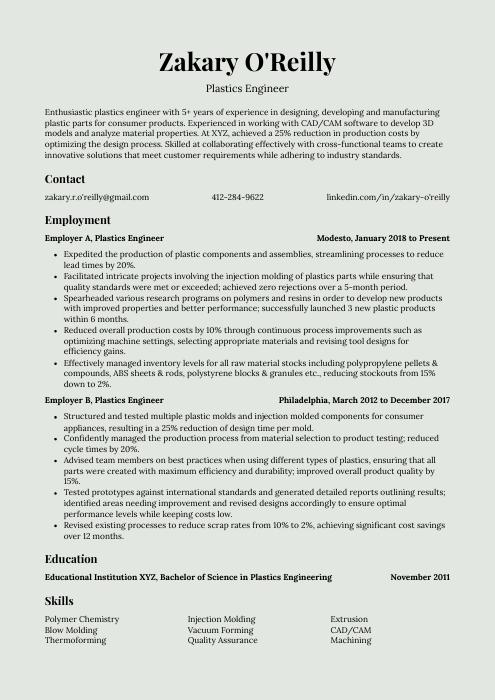

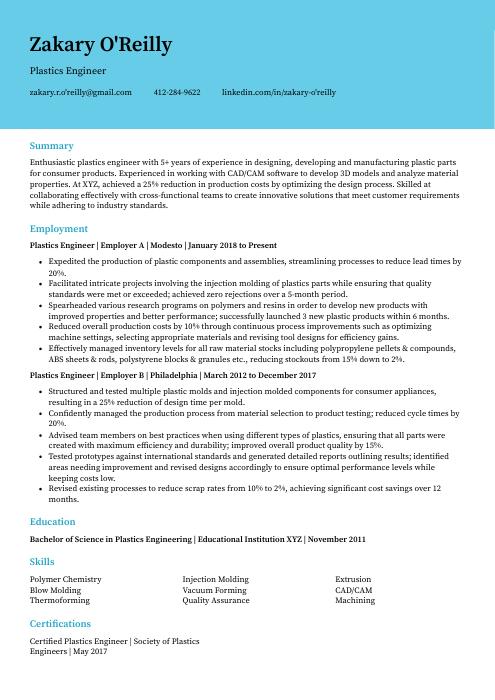

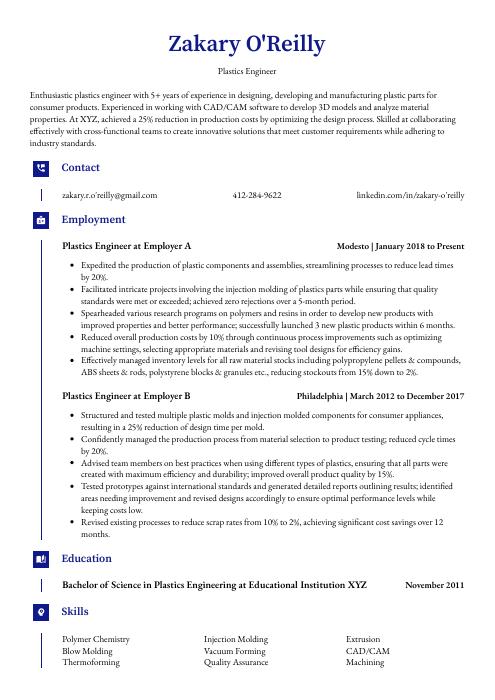

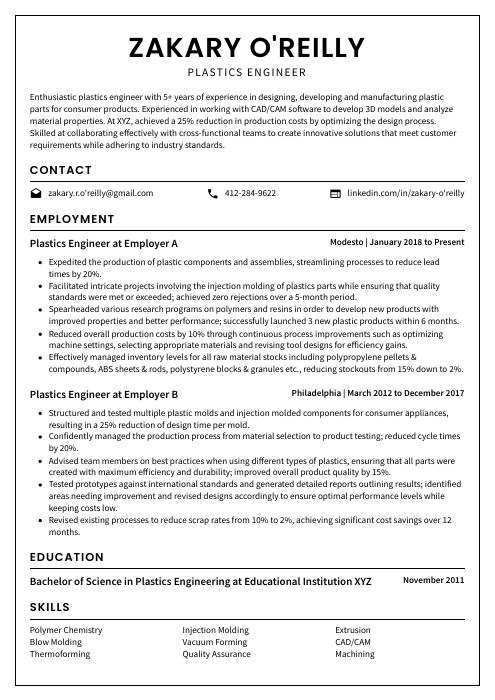

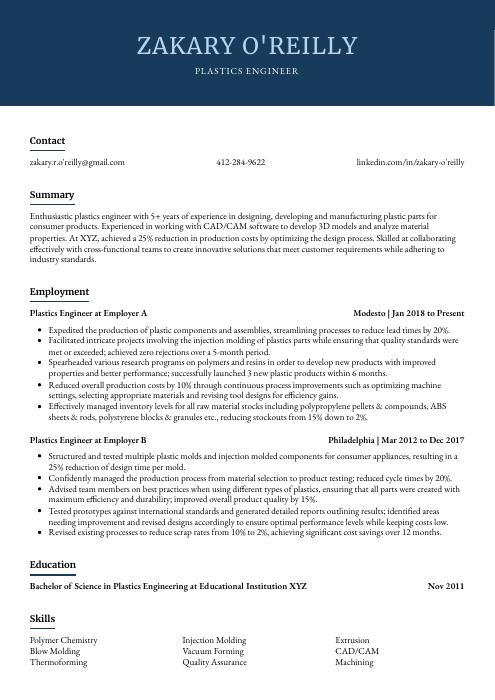

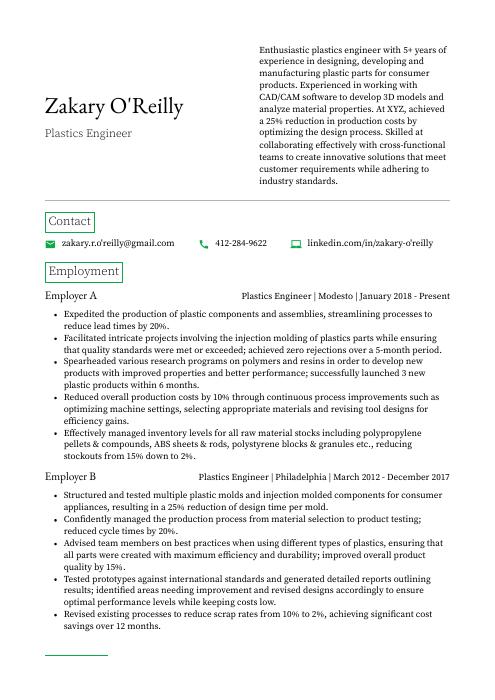

Plastics Engineer Resume Sample

Zakary O’Reilly

Plastics Engineer

zakary.r.o’[email protected]

412-284-9622

linkedin.com/in/zakary-o’reilly

Summary

Enthusiastic plastics engineer with 5+ years of experience in designing, developing and manufacturing plastic parts for consumer products. Experienced in working with CAD/CAM software to develop 3D models and analyze material properties. At XYZ, achieved a 25% reduction in production costs by optimizing the design process. Skilled at collaborating effectively with cross-functional teams to create innovative solutions that meet customer requirements while adhering to industry standards.

Experience

Plastics Engineer, Employer A

Modesto, Jan 2018 – Present

- Expedited the production of plastic components and assemblies, streamlining processes to reduce lead times by 20%.

- Facilitated intricate projects involving the injection molding of plastics parts while ensuring that quality standards were met or exceeded; achieved zero rejections over a 5-month period.

- Spearheaded various research programs on polymers and resins in order to develop new products with improved properties and better performance; successfully launched 3 new plastic products within 6 months.

- Reduced overall production costs by 10% through continuous process improvements such as optimizing machine settings, selecting appropriate materials and revising tool designs for efficiency gains.

- Effectively managed inventory levels for all raw material stocks including polypropylene pellets & compounds, ABS sheets & rods, polystyrene blocks & granules etc., reducing stockouts from 15% down to 2%.

Plastics Engineer, Employer B

Philadelphia, Mar 2012 – Dec 2017

- Structured and tested multiple plastic molds and injection molded components for consumer appliances, resulting in a 25% reduction of design time per mold.

- Confidently managed the production process from material selection to product testing; reduced cycle times by 20%.

- Advised team members on best practices when using different types of plastics, ensuring that all parts were created with maximum efficiency and durability; improved overall product quality by 15%.

- Tested prototypes against international standards and generated detailed reports outlining results; identified areas needing improvement and revised designs accordingly to ensure optimal performance levels while keeping costs low.

- Revised existing processes to reduce scrap rates from 10% to 2%, achieving significant cost savings over 12 months.

Skills

- Polymer Chemistry

- Injection Molding

- Extrusion

- Blow Molding

- Vacuum Forming

- CAD/CAM

- Thermoforming

- Quality Assurance

- Machining

Education

Bachelor of Science in Plastics Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Plastics Engineer

Society of Plastics Engineers

May 2017

1. Summary / Objective

A resume summary or objective is your chance to make a great first impression on the hiring manager. As a plastics engineer, you can use this section to highlight your technical expertise and experience in designing and developing plastic components for various applications. You could also mention any certifications or awards you have earned related to plastics engineering, as well as any special projects that demonstrate your problem-solving skills. Finally, don’t forget to include how many years of experience you have in the field so employers know exactly what they’re getting when they hire you!

Below are some resume summary examples:

Detail-oriented plastics engineer with 5+ years of experience designing, developing, and optimizing plastic products for a variety of industries. Skilled in resin selection and injection molding process optimization to create high-quality parts that meet customer specifications. Seeking to join ABC Tech as a Plastics Engineer where I can use my expertise to develop cost-effective designs while meeting aggressive deadlines.

Diligent plastics engineer with 8+ years of experience developing innovative solutions for injection molding processes. Skilled in material selection, tool design and fabrication, and quality control processes. Proven track record of cutting costs by 15% while maintaining high product standards. Seeking to leverage expertise to become the next Plastics Engineer at ABC Tech and help them improve their overall efficiency.

Hard-working and innovative plastics engineer with 8+ years of experience in product design and development. Successfully created 15 new products for ABC Plastics, resulting in increased market share by 25%. Adept at developing cost-effective solutions that meet customer needs while remaining compliant with industry regulations. Looking to bring this expertise to XYZ Corporation as a plastics engineer.

Seasoned plastics engineer with 10+ years of experience in the design, development and implementation of plastic parts for various industries. Adept at leading teams to develop innovative solutions that meet customer needs while achieving cost savings and meeting quality standards. Looking to bring expertise and efficient project management capabilities to ABC Plastics as a senior plastics engineer.

Accomplished Plastics Engineer with 10+ years of experience in the plastics and injection molding industry. Experienced in leading cross-functional teams to develop innovative plastic parts, components, and assemblies for a variety of consumer products. Proven ability to manage projects from concept through production launch while meeting tight deadlines and staying within budget constraints.

Skilled plastics engineer with 5+ years of experience in designing and developing products, processes, and tools that meet customer expectations. Highly experienced in material selection, design optimization to reduce costs while improving performance. At XYZ Company developed a new injection molding process that decreased cycle times by 20%, saving $250K/year in production costs.

Proficient plastics engineer with 7+ years of experience in developing, designing and testing new products for the automotive industry. Skilled at using CAD software to develop 3D models and prototypes from customer designs or drawings. At XYZ, developed a plastic product that was adopted by 10 major OEMs worldwide resulting in increased revenue for the company by 30%.

Amicable plastics engineer with 7+ years in the industry. Seeking to join ABC Company and use my knowledge of injection molding, blow molding, extrusion and thermoforming processes to develop innovative solutions for a global audience. In previous roles saved 15% on manufacturing costs through process optimization and improved product quality by 20%.

2. Experience / Employment

In the experience section, you will detail your employment history. This should be written in reverse chronological order with the most recent role listed first.

It is best to use bullet points when describing what you did; this makes it easier for the reader to quickly digest what you have said. You want to provide details of what tasks and projects you worked on as well as any results achieved from them.

For example, instead of saying “Developed new plastic products,” say something like “Designed 3D models for 10+ custom injection-molded parts using CAD software, resulting in a 20% reduction in production costs.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Fabricated

- Molded

- Extruded

- Injected

- Formulated

- Analyzed

- Tested

- Inspected

- Troubleshot

- Programmed

- Operated

- Calibrated

- Monitored

- Improved

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Substantially increased production efficiency by 20%, reducing the time for plastic molding from 8 hours to 6 hours.

- Introduced a new process of thermoforming and injection molding, producing over 500 parts daily with minimal waste materials.

- Compiled detailed reports on product performance data and submitted them to management weekly; improved quality assurance processes that resulted in an 18% reduction in customer complaints about product defects.

- Monitored temperature, air pressure and other variables during the plastics manufacturing process to ensure accurate results were achieved within specified tolerances; reduced scrap rate due to errors by 25%.

- Inspected all products after manufacture for accuracy before they left the factory floor; identified any potential faults or flaws early on and took corrective action when necessary which saved up to $15K per month in rework costs.

- Assessed current plastics processing methodologies to identify areas of improvement and developed a comprehensive plan for optimizing production efficiency, resulting in an 18% increase in output.

- Prepared detailed technical drawings based on client specifications and designed new plastic parts while ensuring accuracy; improved CAD design process by 50%.

- Streamlined injection molding processes through the utilization of computer-controlled machinery, enabling faster cycle times with fewer defects – reducing labor costs by $7000 per month.

- Operated various types of 3D printers, CNC machines and other automated equipment used for manufacturing thermoplastics; completed projects within deadlines 100% of the time without compromising quality standards or safety regulations.

- Accurately tested finished products using metrological techniques to verify tolerance levels before packaging them for shipment; successfully reduced customer complaints due to faulty items by 40%.

- Optimized plastic injection molding process, resulting in a 15% increase in production efficiency and saving over $20K annually.

- Extruded polypropylene plastic sheets for consumer packaging applications; conducted extensive research to identify the best resin blends that met customer requirements at minimal cost.

- Utilized CAD software such as AutoCAD and SolidWorks to design technical drawings of molds and die castings for prototyping purposes, ensuring accuracy with all measurements/specifications.

- Competently operated machinery including lathes, millers, grinders & presses while maintaining quality standards throughout the entire manufacturing process; completed assigned tasks within estimated timeframes on average 95% of the time.

- Represented company at various industry events to stay abreast of developments related to plastics engineering processes and technology advancements; reported findings back to senior management team regularly upon request.

- Molded thermoplastic and thermoset materials into parts and components for a variety of industrial applications, which increased production efficiency by 20%.

- Mentored 3 junior engineers in the areas of product design, plastic molding processes, CAD/CAM technologies and quality assurance standards; resulting in successful deployment of 10 new products within 6 months.

- Thoroughly tested all manufactured parts to confirm that they met customer specifications with no defects or discrepancies detected during QC inspections.

- Achieved cost savings up to $25K annually through streamlining production processes & introducing alternative raw material sources for high-volume orders.

- Developed 5 new molds using advanced injection molding techniques while ensuring tight tolerances were maintained throughout the entire manufacturing cycle (+/- 0.005 inch).

- Consistently exceeded production goals by 10% within an 8-hour shift and reduced cycle time of plastic injection molding machines by 25%.

- Presented design ideas to the engineering team that resulted in a net decrease of $1,500 in material costs per month.

- Participated actively in multiple stages of product development from concept generation to prototype testing; successfully developed 4 new products for market launch ahead of schedule.

- Calibrated approximately 50 pieces of equipment and machinery used for plastic manufacturing processes with meticulous attention to detail, ensuring that all safety standards were met before operation began.

- Injected 5000+ tons/yearly into 40+ molds designed for various customers’ requirements while maintaining quality control throughout the entire process; decreased customer complaints related to plastics mold defects by 20%.

- Designed and implemented 3D CAD models of plastic components and assemblies, which resulted in a 20% reduction of tooling costs.

- Resourcefully created cost-effective solutions that improved the efficiency and accuracy of molded parts while reducing production time by 30%.

- Analyzed mold designs to identify flaws and develop improvements; tested sample products for structural integrity, dimensional accuracy & surface finish according to customer specifications.

- Coordinated with other engineering teams to ensure timely completion of projects and meet quality standards; oversaw 10+ injection molding processes during peak seasons without any delays or errors reported from customers.

- Reorganized assembly procedures resulting in a 40% increase in productivity rates within 6 months; reduced scrap materials by 15%.

- Improved efficiency of injection molding process by 20% by programming and testing 3D CAD models for various plastic components.

- Programmed CNC machines to fabricate custom-made molds, fixtures and tools from polymers such as nylon, PEEK and acrylics with precision accuracy within 0.001 inches tolerance level.

- Reliably produced 30+ different types of plastic products using the latest extrusion techniques; reduced defective rate from 10% to 6%.

- Formulated high performance thermoplastic compounds with desired properties that met customer specifications in terms of color, flame retardancy, impact strength etc., helping save $7000/month on raw material costs.

- Developed an automated system for quality control processes which decreased inspection time per product line by 42 hours per week while maintaining optimal production standards.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in injection molding, while the other may be looking for someone with expertise in thermoforming.

Therefore, it is important to tailor your skills section to each job you are applying for. This will help ensure that the applicant tracking systems used by many employers can recognize the relevant keywords associated with a particular role and pass your resume on accordingly.

In addition to listing these abilities here, you should also discuss them further when talking about yourself in other sections of your resume such as the summary or work experience section.

Below is a list of common skills & terms:

- Blow Molding

- CAD/CAM

- Extrusion

- Injection Molding

- Machining

- Polymer Chemistry

- Quality Assurance

- Thermoforming

- Troubleshooting

- Vacuum Forming

4. Education

Including an education section in a plastics engineer resume depends on your experience level. If you just graduated and have no prior work history, mention your education below the resume objective. However, if you are an experienced professional with plenty of accomplishments to showcase, it may be best to omit this section altogether.

If including an education section is necessary for the job application process, try to include courses and subjects related to the plastics engineering role that you are applying for.

Bachelor of Science in Plastics Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a certain field. They show potential employers that you have been tested and certified by an industry-recognized organization, making you more qualified than other applicants.

Including certifications on your resume is especially important if the job advertisement emphasizes specific skills or qualifications that are related to the certification you possess. This will help make sure hiring managers take notice of your credentials and give weight to them when considering who should be hired for the position.

Certified Plastics Engineer

Society of Plastics Engineers

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Zakary O’Reilly, this would be Zakary-O’Reilly-resume.pdf or Zakary-O’Reilly-resume.docx.

7. Cover Letter

Providing a cover letter with your job application is a great way to make a good first impression with the hiring manager. It should be 2 to 4 paragraphs long and provide additional information that isn’t already included in your resume.

Cover letters are an opportunity for you to explain why you’re the perfect fit for the role, highlight any relevant achievements or experiences, and showcase other qualities that can’t easily be seen on paper. While they may not always be required by employers, including one could help give you an edge over other candidates vying for the same position.

Below is an example cover letter:

Dear Dawson,

I am writing to apply for the plastics engineer position at your company. I am a recent graduate of the engineering program at XYZ University and have experience working with plastics in a manufacturing setting.

In my previous job, I worked as a junior engineer at ABC Plastics. There, I was responsible for quality control and testing of plastic products. I also assisted in the development of new products and processes. My experience has given me a strong foundation in working with plastics and has developed my problem-solving skills.

I am confident that I can be an asset to your team. In addition to my technical skills, I have excellent communication and interpersonal skills. I am able to work independently as well as part of a team.

Please find attached my resume for your review. If you have any questions, please do not hesitate to contact me at [your phone number] or [your email address]. Thank you for your time and consideration, and I look forward to hearing from you soon.

Sincerely,

Zakary

Plastics Engineer Resume Templates

Pika

Pika Ocelot

Ocelot Kinkajou

Kinkajou Hoopoe

Hoopoe Markhor

Markhor Echidna

Echidna Lorikeet

Lorikeet Jerboa

Jerboa Rhea

Rhea Fossa

Fossa Axolotl

Axolotl Saola

Saola Dugong

Dugong Gharial

Gharial Indri

Indri Numbat

Numbat Cormorant

Cormorant Bonobo

Bonobo Quokka

Quokka Rezjumei

Rezjumei