Plant Engineer Resume Guide

Plant Engineers are responsible for maintaining and improving the performance of industrial plants. They plan, design, construct, install and maintain production machinery and equipment in accordance with safety regulations. Plant Engineers also diagnose problems that occur within the plant’s equipment or processes to ensure efficient operation of all systems.

Your knowledge and experience in plant engineering is second to none. But potential employers don’t know who you are yet, so it’s important that your resume effectively communicates your skills and qualifications.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

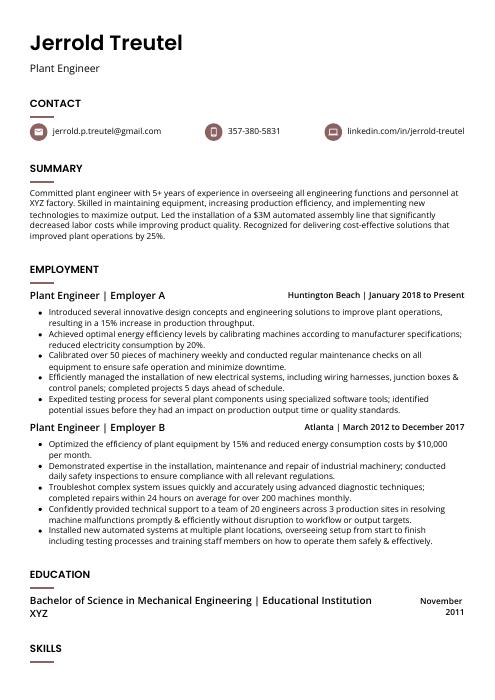

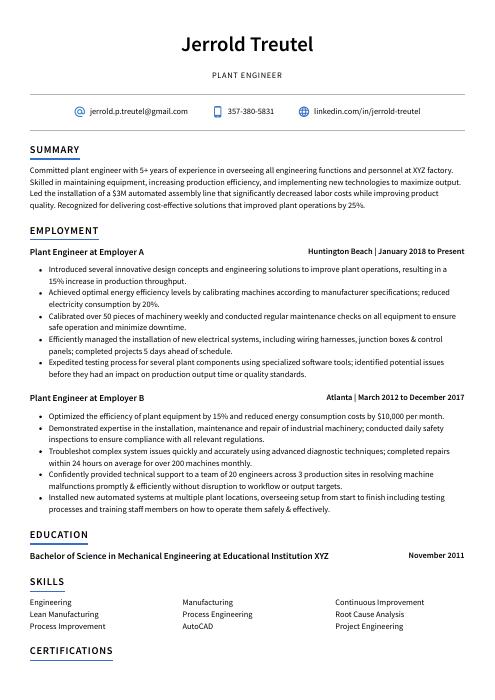

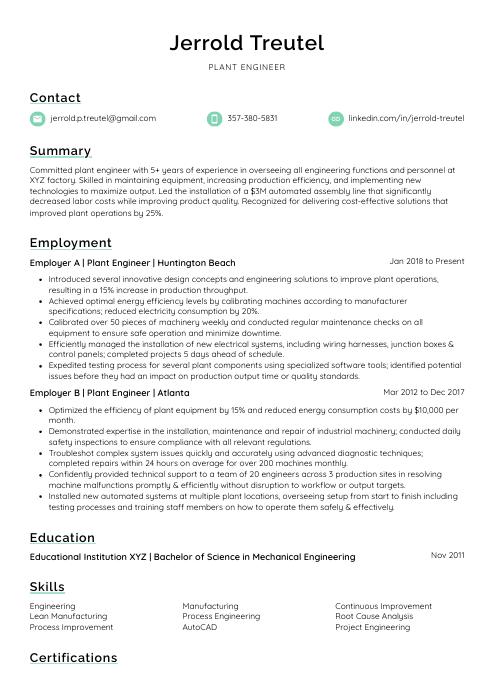

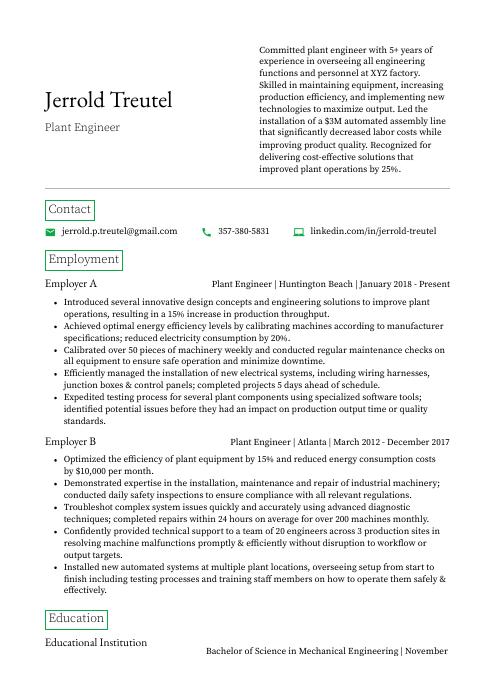

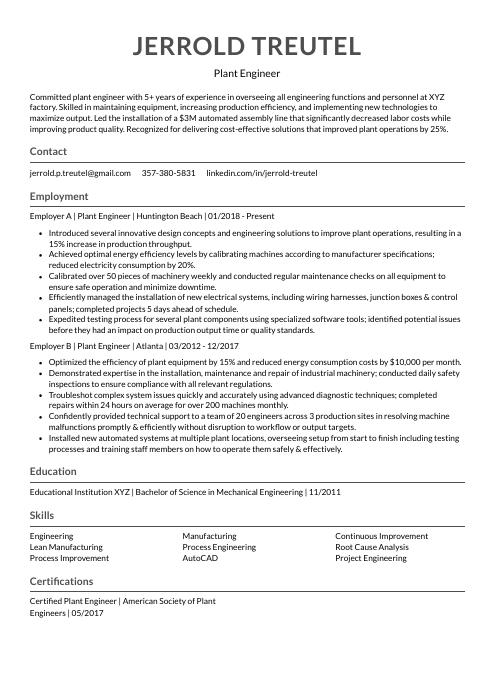

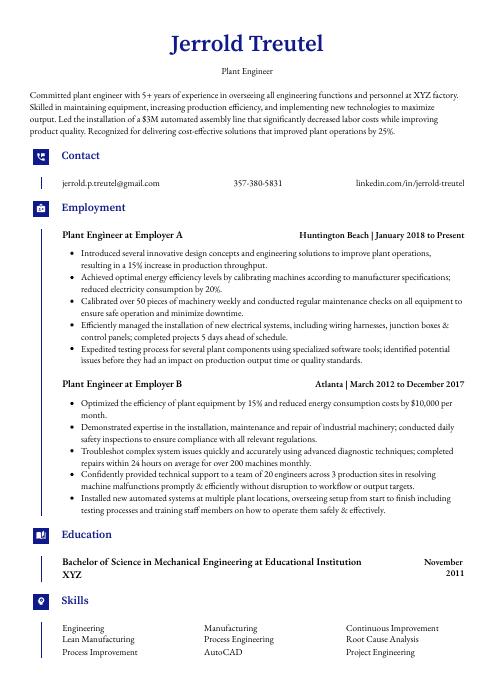

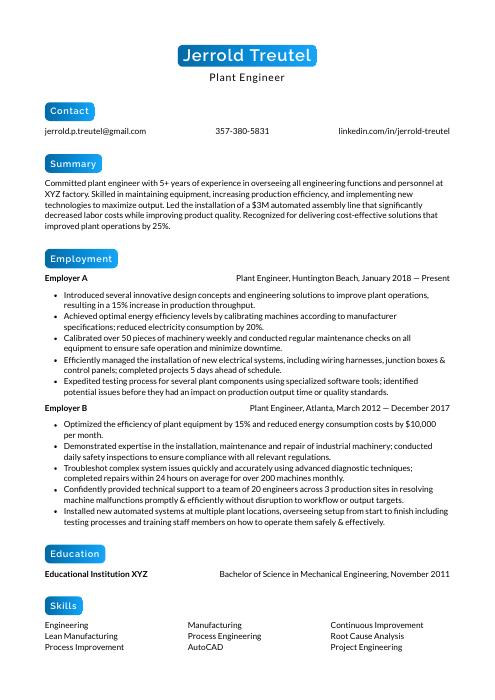

Plant Engineer Resume Sample

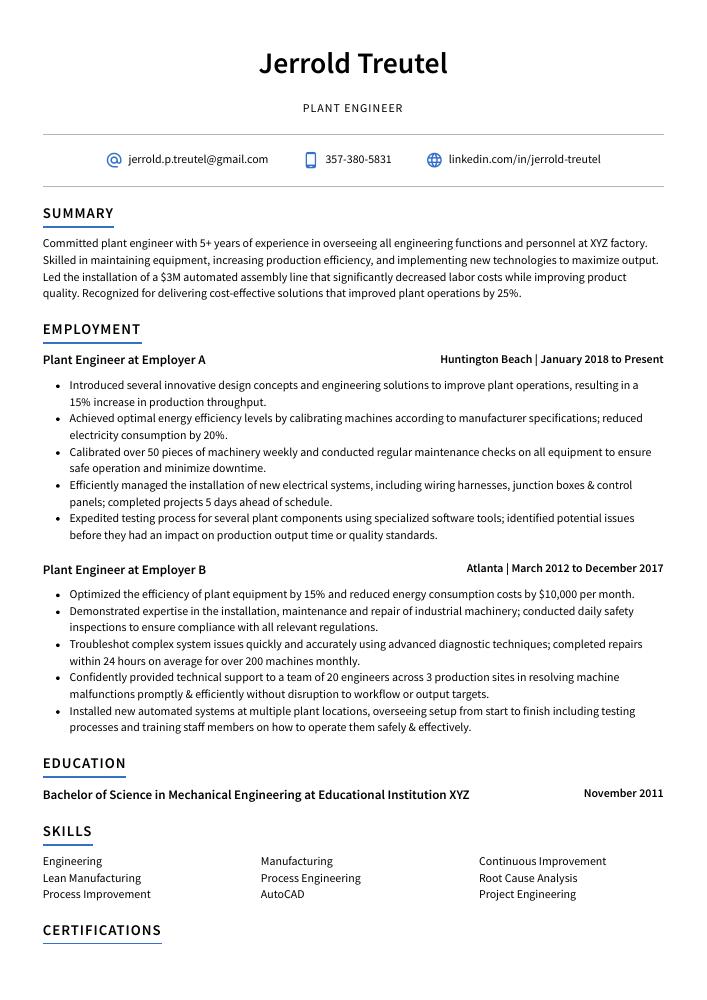

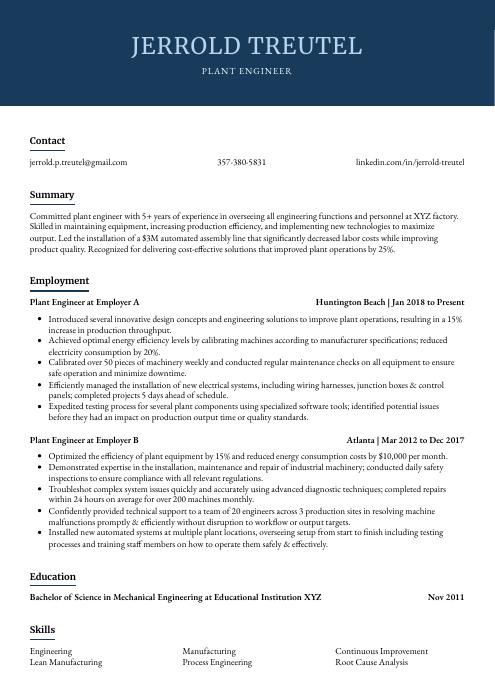

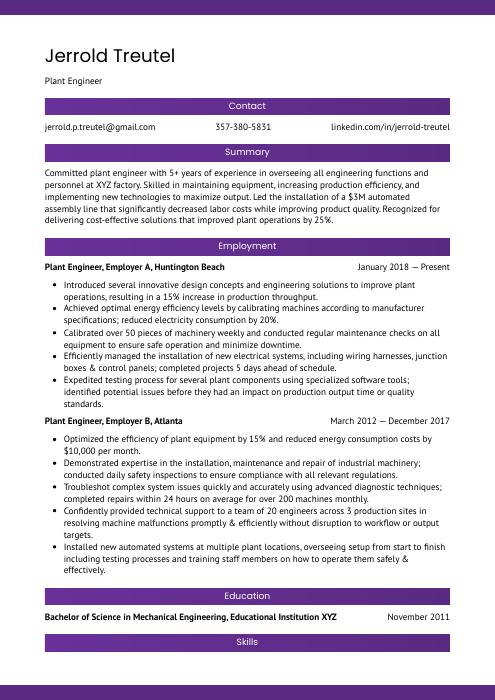

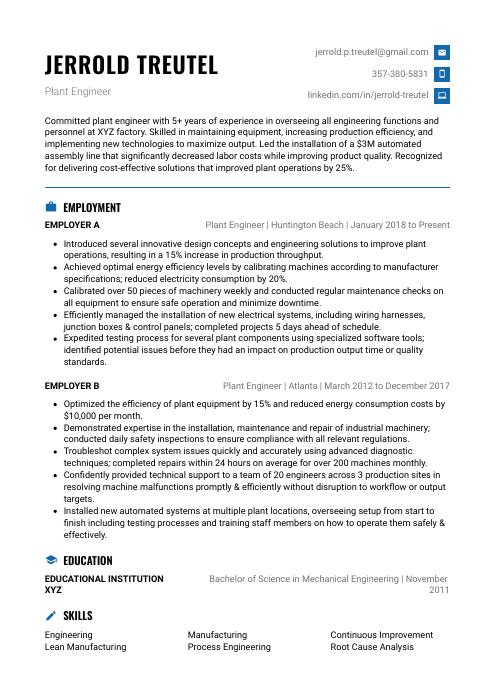

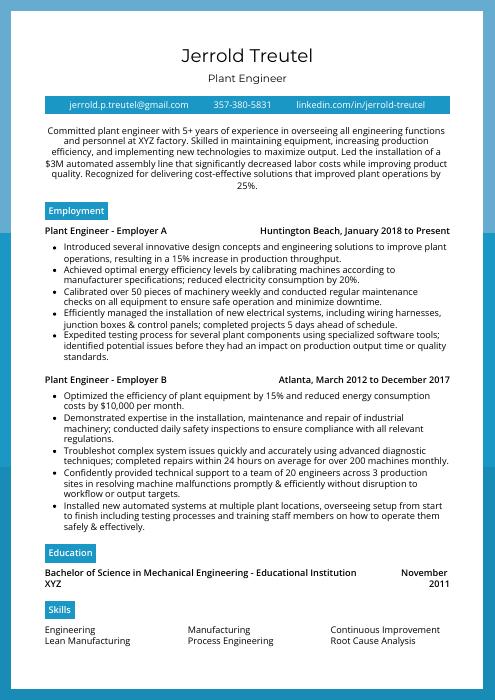

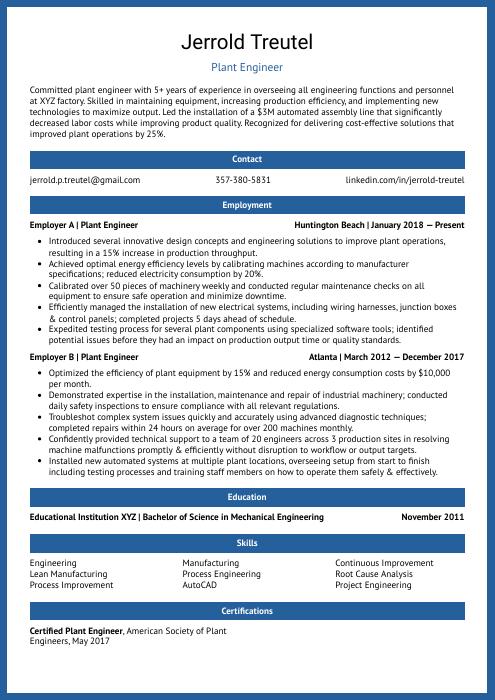

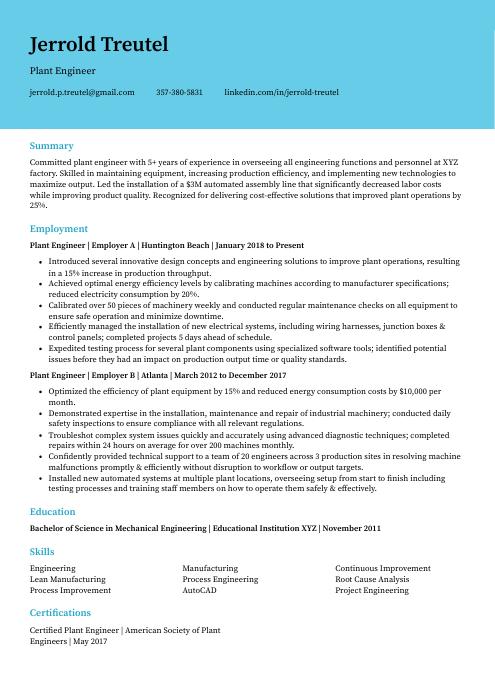

Jerrold Treutel

Plant Engineer

[email protected]

357-380-5831

linkedin.com/in/jerrold-treutel

Summary

Committed plant engineer with 5+ years of experience in overseeing all engineering functions and personnel at XYZ factory. Skilled in maintaining equipment, increasing production efficiency, and implementing new technologies to maximize output. Led the installation of a $3M automated assembly line that significantly decreased labor costs while improving product quality. Recognized for delivering cost-effective solutions that improved plant operations by 25%.

Experience

Plant Engineer, Employer A

Huntington Beach, Jan 2018 – Present

- Introduced several innovative design concepts and engineering solutions to improve plant operations, resulting in a 15% increase in production throughput.

- Achieved optimal energy efficiency levels by calibrating machines according to manufacturer specifications; reduced electricity consumption by 20%.

- Calibrated over 50 pieces of machinery weekly and conducted regular maintenance checks on all equipment to ensure safe operation and minimize downtime.

- Efficiently managed the installation of new electrical systems, including wiring harnesses, junction boxes & control panels; completed projects 5 days ahead of schedule.

- Expedited testing process for several plant components using specialized software tools; identified potential issues before they had an impact on production output time or quality standards.

Plant Engineer, Employer B

Atlanta, Mar 2012 – Dec 2017

- Optimized the efficiency of plant equipment by 15% and reduced energy consumption costs by $10,000 per month.

- Demonstrated expertise in the installation, maintenance and repair of industrial machinery; conducted daily safety inspections to ensure compliance with all relevant regulations.

- Troubleshot complex system issues quickly and accurately using advanced diagnostic techniques; completed repairs within 24 hours on average for over 200 machines monthly.

- Confidently provided technical support to a team of 20 engineers across 3 production sites in resolving machine malfunctions promptly & efficiently without disruption to workflow or output targets.

- Installed new automated systems at multiple plant locations, overseeing setup from start to finish including testing processes and training staff members on how to operate them safely & effectively.

Skills

- Engineering

- Manufacturing

- Continuous Improvement

- Lean Manufacturing

- Process Engineering

- Root Cause Analysis

- Process Improvement

- AutoCAD

- Project Engineering

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Plant Engineer

American Society of Plant Engineers

May 2017

1. Summary / Objective

Your resume summary or objective should provide the hiring manager with a snapshot of your qualifications and experience as a plant engineer. In this section, you can mention any certifications or licenses you have obtained, highlight the projects you have worked on in the past that demonstrate your expertise in engineering processes, and showcase how your technical skills have helped to improve efficiency at previous companies.

Below are some resume summary examples:

Determined plant engineer with 10+ years of experience in the manufacturing and production industry. Proven track record of successful implementation, maintenance, and troubleshooting of complex machinery systems to ensure maximum efficiency. Proficient in a variety of computer-aided design (CAD) programs for schematics and blueprints. Seeking an opportunity to join ABC Corporation as Plant Engineer to utilize expertise towards achieving greater success.

Diligent plant engineer with 8+ years of experience in industrial plant operations and maintenance. Experienced in developing, implementing, and managing preventive/predictive maintenance programs. At XYZ Company, increased production efficiency by 20% through streamlining processes using lean manufacturing principles. Recognized for excellent customer service skills and ability to quickly solve complex problems related to machinery performance issues.

Talented plant engineer with 10+ years of experience in the oil & gas industry. Experienced in designing, installing and maintaining all types of plant equipment to ensure optimal production capacity. Skilled at troubleshooting complex problems and providing cost-effective solutions for shutdowns or repairs quickly and efficiently. Proven track record of managing maintenance staff while ensuring compliance with safety regulations on a global scale.

Professional plant engineer with 8+ years experience in the design and maintenance of industrial processing equipment. Skilled at troubleshooting process problems, optimizing production flows, and developing cost-effective solutions to technical issues. At XYZ Corporation successfully managed over 15 large-scale projects that increased efficiency by 30%. Received accolades for leading a team of engineers through complex engineering challenges.

Reliable plant engineer with 8+ years of experience overseeing mechanical and electrical systems for industrial processes. Expertise in designing, implementing, and managing complex plant operations to ensure smooth functioning and optimal resource utilization. At XYZ Inc., increased production capacity by 32% through improved maintenance schedules. Looking to bring expertise to ABC Tech’s growing team as a Plant Engineer.

Seasoned plant engineer with over 8 years of experience in efficient and safe operations. Experienced in setting up, maintaining, and improving production systems for maximum efficiency. At XYZ Factory successfully implemented a new plant layout that reduced maintenance costs by 40%. Received ISO-9001 certification for adhering to stringent quality standards during the installation process.

Detail-oriented Plant Engineer with 8+ years of experience in the operation and maintenance of production equipment. Seeking to leverage extensive knowledge of mechanical engineering principles, PLCs, and process automation systems to ensure ABC’s plant runs smoothly. Previous success includes increasing production output by 27% while decreasing downtime costs by 10%.

Driven plant engineer with 10+ years of experience in design, development and implementation of new industrial processes. Proven success in developing highly efficient production lines that optimize resources while reducing operating costs by up to 20%. Seeking to leverage expertise at ABC Co., supporting the larger mission through innovative approaches.

2. Experience / Employment

Next comes the work history section, which should be written in reverse chronological order. That means your most recent role is listed first, followed by the other roles you’ve held.

When writing out what you did in each job, stick to bullet points; this makes it easier for the reader to take in all of your information quickly and easily. You want to provide detail here, so focus on quantifiable results that show how successful you were at each job.

For example, instead of saying “Maintained plant equipment,” try something like this: “Performed regular maintenance checks on 10+ pieces of industrial machinery daily, resulting in a 20% decrease in machine downtime.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Monitored

- Operated

- Troubleshot

- Inspected

- Calibrated

- Adjusted

- Programmed

- Fabricated

- Assembled

- Commissioned

- Upgraded

- Analyzed

- Optimized

- Documented

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Thoroughly inspected, tested and maintained plant equipment on a regular basis; increased operational efficiency by 10% through improved maintenance practices.

- Formulated preventative maintenance plans for over 40 pieces of machinery and minimized down time incidents by 15%.

- Prepared technical reports outlining the status of all mechanical components in the facility; saved $4,000 in repair costs due to timely interventions every month.

- Adjusted various production parameters as needed per quality control requirements; achieved 95% compliance with industry standards after 3 months of implementation.

- Coordinated closely with other engineering teams to ensure optimal performance in all areas from power generation to water treatment systems; reduced system downtime hours by 30%.

- Improved operational efficiency of plant equipment by 17%, significantly reducing electricity consumption and associated costs.

- Facilitated maintenance process on all machinery, keeping parts inventory up-to-date and ensuring timely repair/replacement when needed; decreased downtime from 3 to 2 hours per incident.

- Inspected production lines regularly for compliance with safety regulations, identifying potential risks before they caused any damage or injury; eliminated 8 hazardous conditions in the last 6 months alone.

- Analyzed existing engineering processes for areas of improvement, developing new protocols that resulted in a 20% increase in product throughput capacity without compromising quality control standards.

- Actively monitored output levels across multiple workstations using advanced sensors & data analytics software; identified 12 issues affecting productivity within first 3 months of employment at this position.

- Meticulously maintained and troubleshot plant machinery to ensure smooth production, reducing downtime by 16% and saving the company $6,000 in operational costs.

- Participated in a variety of projects related to improving safety standards for workers and streamlining processes; achieved 10 process improvements with an average time savings of 15%.

- Fabricated new components using tools such as lathes, welding equipment & 3D printers according to specification requirements; improved quality control checks for more accurate results.

- Advised management on cost-effective ways of enhancing existing systems through automation technologies; implemented 5 automated solutions resulting in increased productivity by 20%.

- Assembled mechanical parts into finished products within specified deadlines while adhering strictly to industry codes and regulations regarding health & safety compliance; reduced product defects rate from 7% to 2%.

- Revised operations protocols for the plant and increased production by 25% within 3 months.

- Assessed existing processes, identified potential areas of improvement and implemented new strategies that reduced energy consumption costs by 15%.

- Substantially lowered wastewater disposal rate from 2 million gallons a month to 1 million gallons in 6 months; saved $10k annually on environmental fees.

- Mentored two junior engineers, providing guidance in troubleshooting technical issues with equipment while completing projects ahead of schedule & under budget constraints.

- Upgraded outdated machinery using lean engineering principles which improved performance output by 30%, resulting in an increase of revenue by $50k per year.

- Documented the daily maintenance and safety protocols of the plant machinery, ensuring that all procedures were compliant with industry regulations; reduced downtime by 30% in the last quarter.

- Reduced energy consumption costs significantly by introducing new processes to optimize system performance; achieved cost savings of $10,000 over a 12-month period.

- Structured preventative maintenance schedules for key equipment such as pumps, valves and motors across multiple teams via effective resource allocation techniques; improved team efficiency by 25%.

- Monitored production metrics on an ongoing basis to identify areas of improvement and maximize output quality throughout each shift; increased overall customer satisfaction ratings from 85% to 95%.

- Competently operated complex systems such as HVACs, boilers and chillers with minimal supervision while adhering strictly to OSHA standards at all times for maximum safety compliance.

- Reorganized and optimized production processes for the plant, resulting in a 25% increase in efficiency and a $12,000 reduction in waste costs.

- Effectively managed all maintenance activities at the plant to ensure equipment was running smoothly; reduced downtime by 30%.

- Developed a comprehensive safety program that cut workplace injuries by 50%, saving nearly $50,000 annually on insurance premiums and medical bills.

- Utilized cutting-edge technology to troubleshoot problems quickly and efficiently; identified over 500 potential issues before they became costly repairs or replacements of components/systems within 5 months of taking up position as Plant Engineer.

- Compiled data from various sources such as sensors & monitors into concise reports that aided decision making process across departments; improved accuracy levels by 75%.

- Presented design plans and engineering specs to the executive team for approval, resulting in a successful commission of four new production sites.

- Resourcefully collaborated with the design & construction teams to identify cost-saving initiatives while maintaining quality standards; reduced expenses by 10%.

- Spearheaded daily operations at multiple plants, ensuring that all equipment was regularly monitored and maintained according to safety protocols.

- Streamlined installation processes for plant machinery, reducing downtime costs by 25% within one month of implementation.

- Commissioned five new state-of-the-art robotic systems across three manufacturing facilities over a two year period; increased efficiency levels by 35%.

- Operated and maintained plant machinery, equipment and systems with a 99.5% uptime rate, ensuring safe and efficient operations at all times.

- Programmed PLCs to control the production process in order to increase output by 15%.

- Reliably monitored energy consumption levels throughout each shift; identified areas of improvement that resulted in an 11% decrease in electricity costs over two years.

- Represented the company as part of a delegation at industry conferences, effectively communicating new ideas on operational efficiency improvements that were later adopted for implementation within the organization’s plants across North America.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization may require familiarity with industrial software, while another may need experience in managing a production line.

It is important to tailor the skills section of your resume for each job you are applying for because most companies now use applicant tracking systems (ATS). These programs scan resumes looking for certain keywords that match those listed in the job description; if they don’t find them, then your application will be rejected.

You can list all relevant skills here and then further elaborate on them by discussing specific examples from past work experiences or projects.

Below is a list of common skills & terms:

- 5S

- AutoCAD

- Automation

- CAD

- Chemical Engineering

- Commissioning

- Continuous Improvement

- Cross Functional Team Leadership

- Electricians

- Energy

- Engineering

- Engineering Management

- FMEA

- Factory

- ISO

- Kaizen

- Lean Manufacturing

- MATLAB

- Maintenance Management

- Maintenance and Repair

- Manufacturing

- Manufacturing Engineering

- Manufacturing Operations Management

- Mechanical Engineering

- Operations Management

- PLC

- Plant Maintenance

- Power Generation

- Power Plants

- Preventive Maintenance

- Process Control

- Process Engineering

- Process Improvement

- Product Development

- Project Engineering

- Project Planning

- Root Cause Analysis

- SOLIDWORKS

- SPC

- Six Sigma

- TPM

- Team Leadership

- Teamwork

- Troubleshooting

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below the objective statement. However, if you have been working as a plant engineer for years with many different responsibilities to showcase, it is perfectly acceptable to omit an education section altogether.

If including an education section is necessary or desired, list courses and subjects related specifically to the job of a plant engineer that demonstrate relevant knowledge in this area.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field and can be an invaluable asset when applying for jobs. Employers are always looking for candidates who have taken the initiative to stay up-to-date with industry trends and certifications provide proof that you have done just that.

If you possess any relevant certifications, make sure they are included on your resume as this could give you an edge over other applicants.

Certified Plant Engineer

American Society of Plant Engineers

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Jerrold Treutel, this would be Jerrold-Treutel-resume.pdf or Jerrold-Treutel-resume.docx.

7. Cover Letter

Including a cover letter in your job application can help you stand out from the crowd and be remembered by recruiters. It provides an opportunity to explain why you are uniquely qualified for the role and how your skills, qualifications, experience and knowledge make you a great fit.

Cover letters generally consist of 2 to 4 paragraphs that offer more information than what is in your resume. Writing one gives hiring managers a clearer picture of who you are as an individual and allows them to get a better understanding of what value you could bring to their team if hired.

Below is an example cover letter:

Dear Reina,

I am writing to apply for the plant engineer position at [company name]. As a highly skilled and experienced plant engineer with more than 10 years of experience in the field, I am confident I can be an asset to your organization.

In my current role as plant engineer at [company name], I oversee all aspects of the engineering department and manage a team of 12 engineers. I have successfully implemented new processes and technologies that have increased efficiency and productivity while reducing costs. I am also well-versed in safety standards and regulations, and have created several programs that have reduced accidents and injuries in the workplace.

I possess strong problem-solving skills and a keen eye for detail, which has allowed me to identify issues before they become problems. My ability to think critically and develop creative solutions has been instrumental in ensuring smooth operations at our facility. In addition, I have excellent communication and interpersonal skills that allow me to effectively collaborate with other departments within the company.

I am confident that my skillset will enable me to contribute positively to your organization, and I look forward to speaking with you about this opportunity. Thank you for your time & consideration.

Sincerely,

Jerrold

Plant Engineer Resume Templates

Cormorant

Cormorant Numbat

Numbat Pika

Pika Bonobo

Bonobo Jerboa

Jerboa Echidna

Echidna Rhea

Rhea Fossa

Fossa Axolotl

Axolotl Lorikeet

Lorikeet Quokka

Quokka Saola

Saola Ocelot

Ocelot Dugong

Dugong Markhor

Markhor Hoopoe

Hoopoe Indri

Indri Gharial

Gharial Kinkajou

Kinkajou Rezjumei

Rezjumei