Packaging Engineer Resume Guide

Packaging Engineers are responsible for designing, developing and evaluating packaging products to ensure safe storage, transport and delivery of goods. They must consider factors such as cost-effectiveness, product protection requirements, environmental sustainability and consumer convenience when creating new packages. Additionally they may be involved in troubleshooting existing designs or improving existing processes related to package design.

Your knowledge and experience in packaging engineering make you the perfect fit for any business. But to get a hiring manager’s attention, you must write an eye-catching resume that highlights your qualifications.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

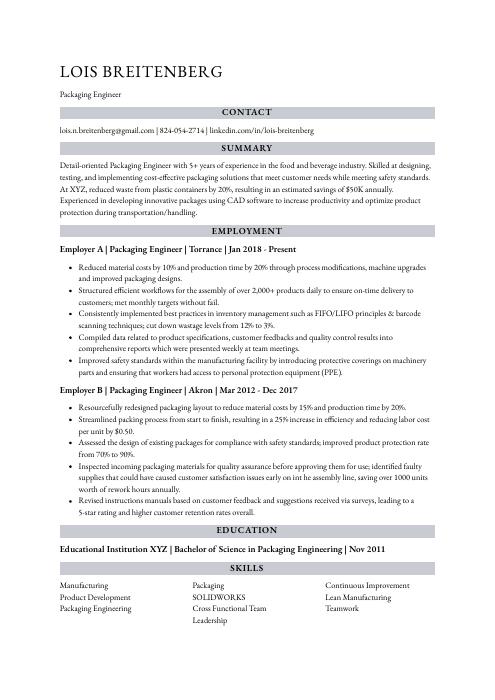

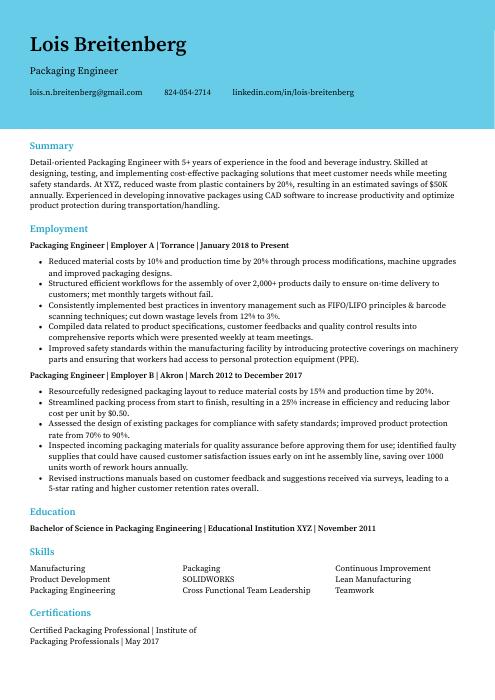

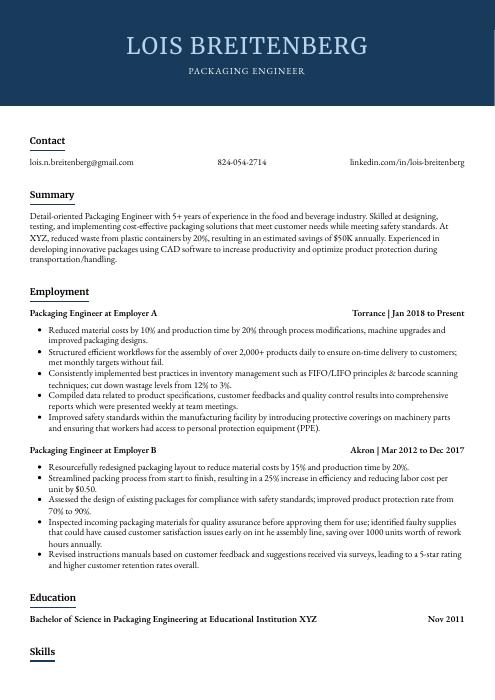

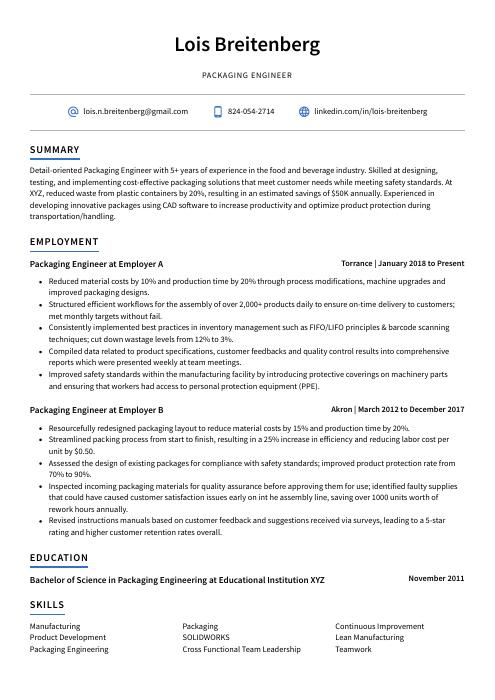

Packaging Engineer Resume Sample

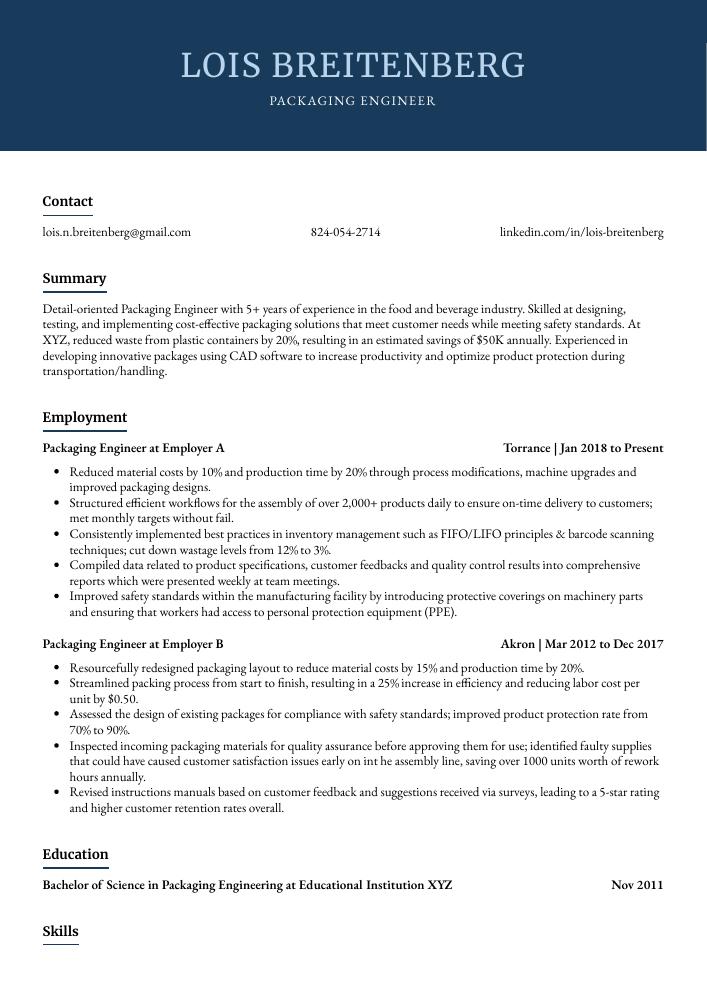

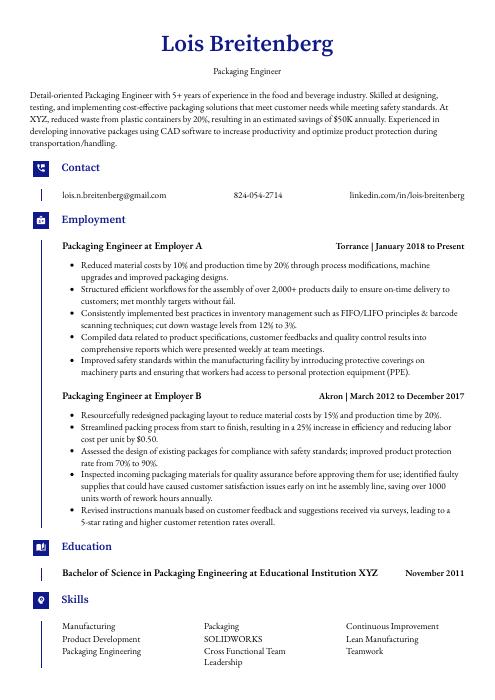

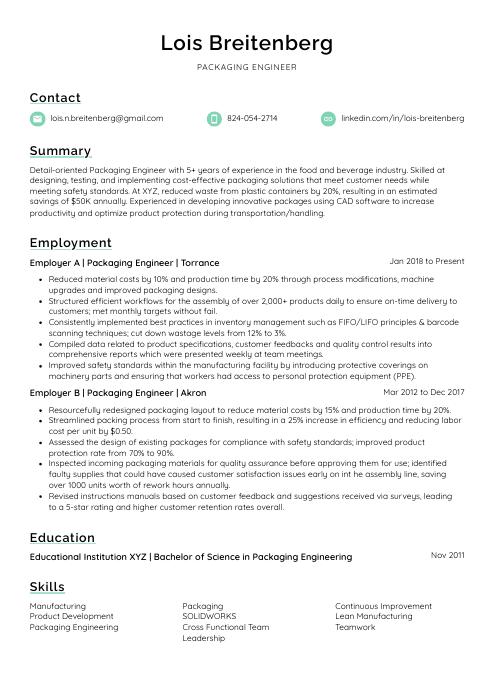

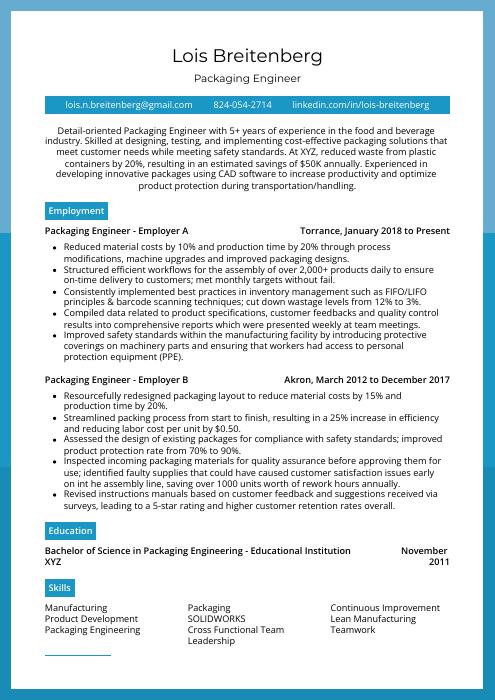

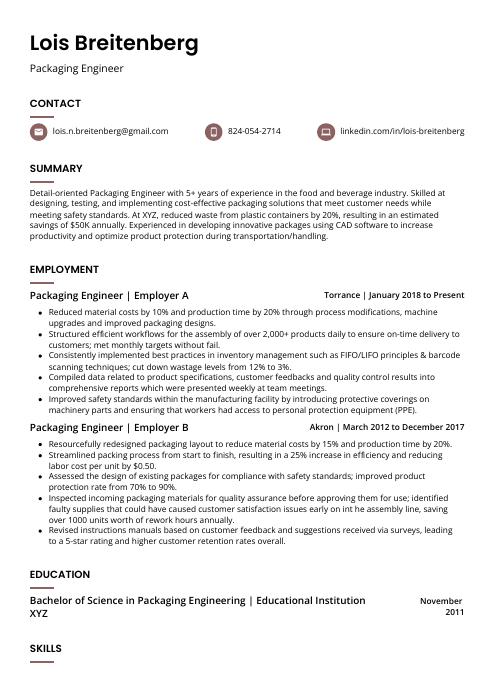

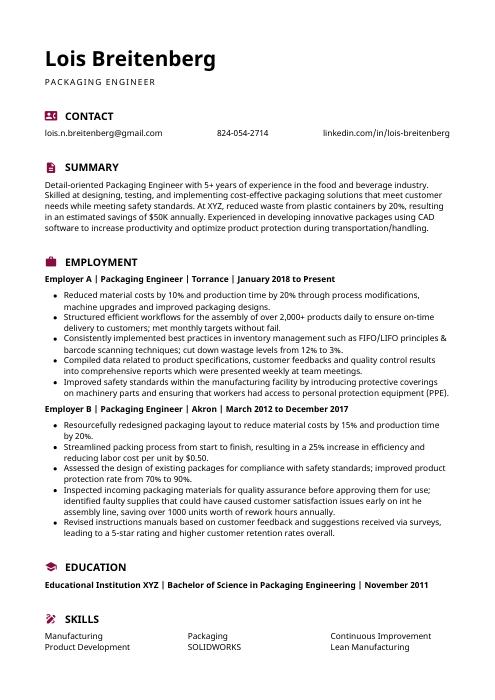

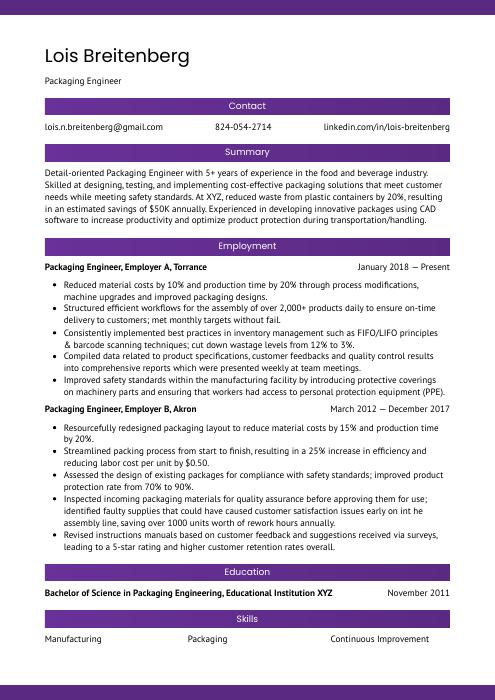

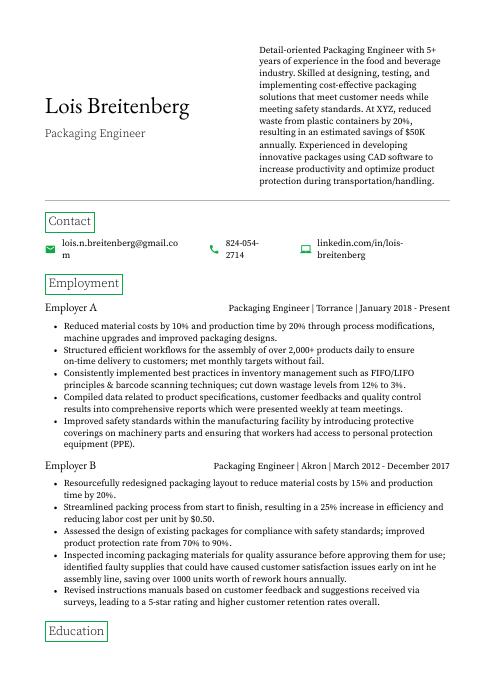

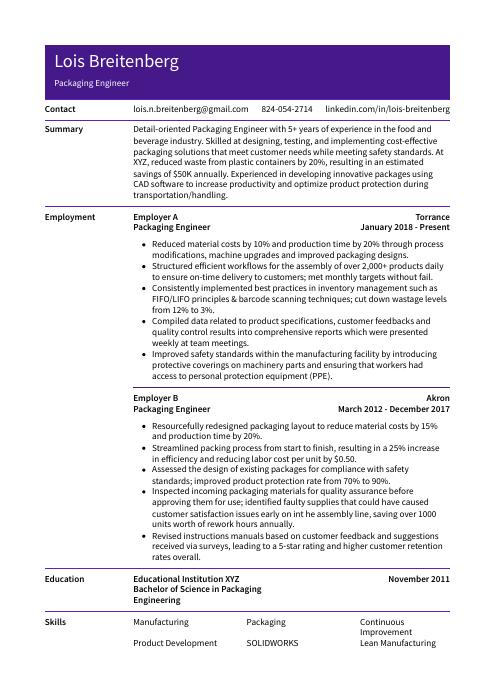

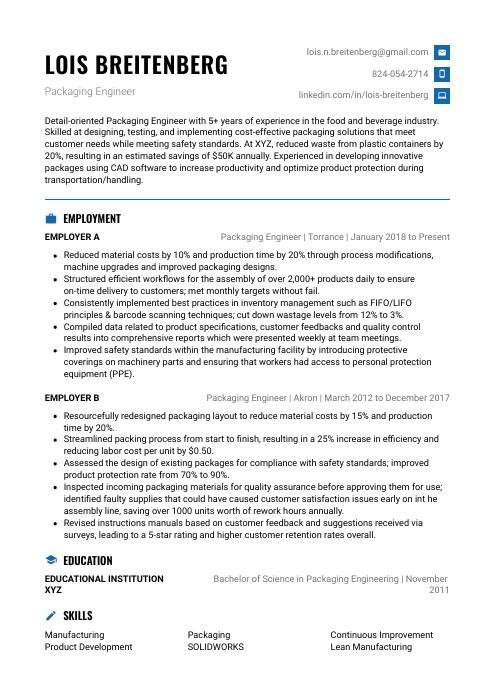

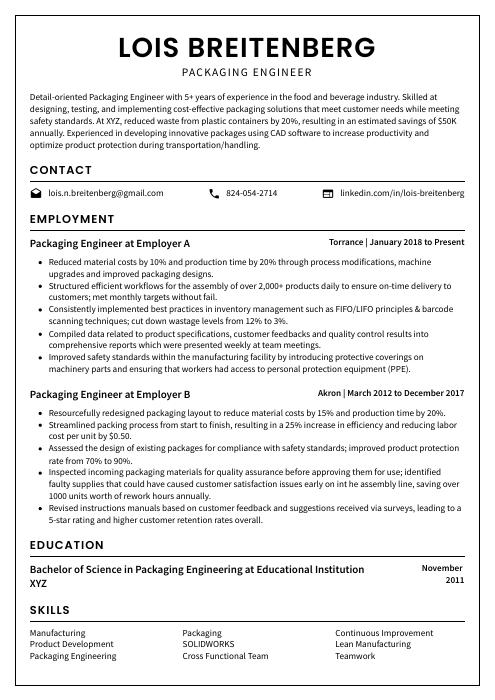

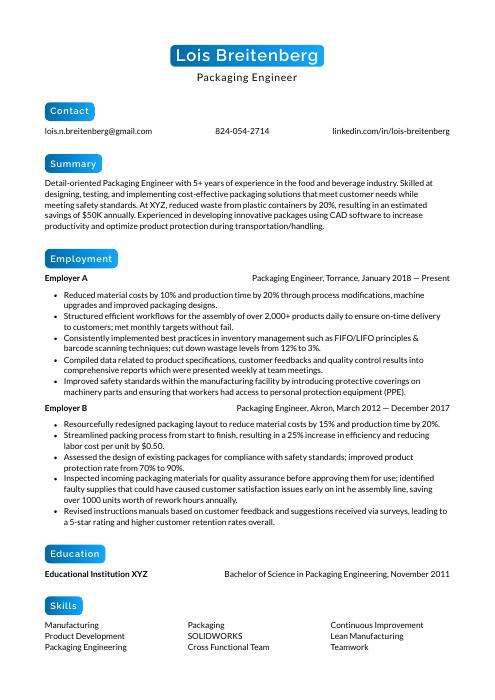

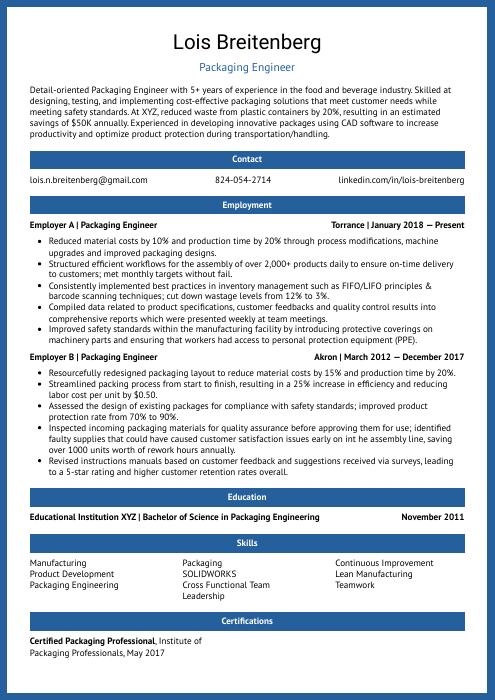

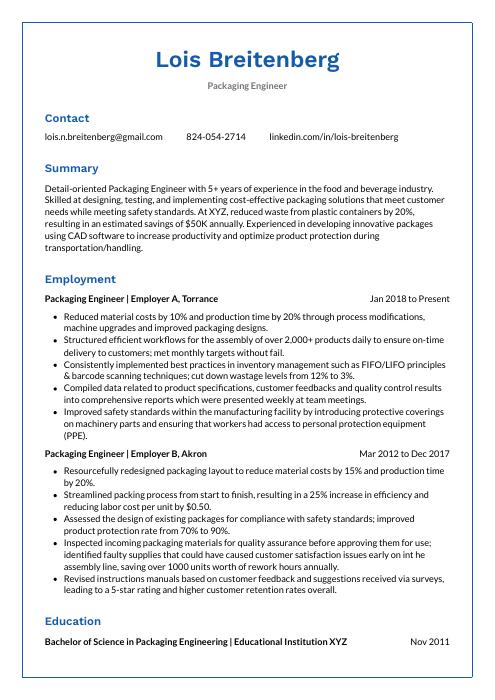

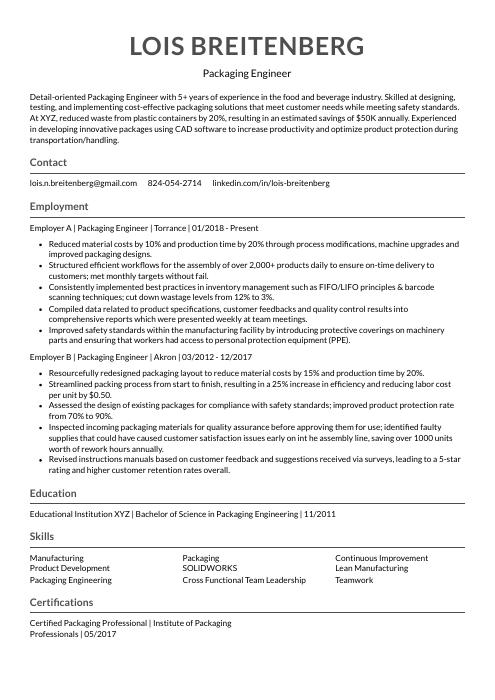

Lois Breitenberg

Packaging Engineer

[email protected]

824-054-2714

linkedin.com/in/lois-breitenberg

Summary

Detail-oriented Packaging Engineer with 5+ years of experience in the food and beverage industry. Skilled at designing, testing, and implementing cost-effective packaging solutions that meet customer needs while meeting safety standards. At XYZ, reduced waste from plastic containers by 20%, resulting in an estimated savings of $50K annually. Experienced in developing innovative packages using CAD software to increase productivity and optimize product protection during transportation/handling.

Experience

Packaging Engineer, Employer A

Torrance, Jan 2018 – Present

- Reduced material costs by 10% and production time by 20% through process modifications, machine upgrades and improved packaging designs.

- Structured efficient workflows for the assembly of over 2,000+ products daily to ensure on-time delivery to customers; met monthly targets without fail.

- Consistently implemented best practices in inventory management such as FIFO/LIFO principles & barcode scanning techniques; cut down wastage levels from 12% to 3%.

- Compiled data related to product specifications, customer feedbacks and quality control results into comprehensive reports which were presented weekly at team meetings.

- Improved safety standards within the manufacturing facility by introducing protective coverings on machinery parts and ensuring that workers had access to personal protection equipment (PPE).

Packaging Engineer, Employer B

Akron, Mar 2012 – Dec 2017

- Resourcefully redesigned packaging layout to reduce material costs by 15% and production time by 20%.

- Streamlined packing process from start to finish, resulting in a 25% increase in efficiency and reducing labor cost per unit by $0.50.

- Assessed the design of existing packages for compliance with safety standards; improved product protection rate from 70% to 90%.

- Inspected incoming packaging materials for quality assurance before approving them for use; identified faulty supplies that could have caused customer satisfaction issues early on int he assembly line, saving over 1000 units worth of rework hours annually.

- Revised instructions manuals based on customer feedback and suggestions received via surveys, leading to a 5-star rating and higher customer retention rates overall.

Skills

- Manufacturing

- Packaging

- Continuous Improvement

- Product Development

- SOLIDWORKS

- Lean Manufacturing

- Packaging Engineering

- Cross Functional Team Leadership

- Teamwork

Education

Bachelor of Science in Packaging Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Packaging Professional

Institute of Packaging Professionals

May 2017

1. Summary / Objective

A resume summary/objective is your chance to make a great first impression on the hiring manager. As a packaging engineer, you can use this section of your resume to highlight the skills and qualifications that make you an ideal candidate for the job. For example, you could mention any certifications or training courses related to packaging engineering that you have completed, as well as any specialized software programs or technologies with which you are familiar. Additionally, it would be beneficial to discuss how many years of experience in the field that you have and what types of projects/products/processes with which you have been involved.

Below are some resume summary examples:

Seasoned packaging engineer with 5+ years of experience in developing and optimizing packaging solutions for various products. Skilled at designing cost-effective and sustainable materials that meet the requirements of customers while adhering to safety regulations. At XYZ, led a team of 4 engineers in creating 15 new designs within 6 months, reducing development costs by 20%. Proven track record of success in improving performance metrics through innovative problem solving techniques.

Determined packaging engineer with 5+ years of experience in developing and evaluating packaging solutions. Proven track record of streamlining processes to reduce costs, increase efficiency, and improve customer satisfaction. At XYZ Corporation, developed a new packaging solution that resulted in an estimated cost savings of $500K annually. Experienced with various types of materials used for packing products safely and securely during shipment or storage.

Enthusiastic packaging engineer with 5+ years of experience designing and implementing packaging solutions for consumer products. Experienced in utilizing various materials, methods, and processes to ensure safe & efficient delivery of goods. At XYZ Company, designed a new package solution that reduced production costs by 25%. Skilled at creating prototypes quickly while maintaining quality standards and adhering to strict deadlines.

Skilled packaging engineer with 8+ years of experience in the development, optimization and improvement of packaging for a wide range of products. Proven ability to create cost-effective designs that meet customer needs while minimizing waste and environmental impact. Seeking to join ABC Tech as their next Packaging Engineer where I can apply my expertise towards creating innovative solutions for clients worldwide.

Well-rounded packaging engineer with 7+ years of experience developing sustainable, cost-effective packaging solutions for a wide variety of products. Skilled at implementing innovative technologies and materials to streamline production processes while ensuring product safety. Seeking to use my expertise in design optimization and material selection to join ABC Technologies as their next Packaging Engineer.

Committed packaging engineer with 6+ years of experience designing and engineering packaging solutions for a range of products, from consumer electronics to medical devices. Seeking to join ABC Technologies as the next Packaging Engineer. At XYZ Corp., designed and implemented 10 successful projects that improved product protection by 32%, while reducing package size/weight by 20%.

Driven packaging engineer with 5+ years of experience in designing, developing, and testing packaging solutions to optimize product protection and transportation. Experienced in working with a variety of materials such as paperboard, plastics, corrugated board and wood. Looking to leverage my creative problem-solving skills to become the next Packaging Engineer at ABC Corporation.

Talented packaging engineer with 5+ years of experience in designing, manufacturing and testing packaging solutions for a range of products. Proven success in optimizing existing processes to reduce costs while increasing quality and safety. Looking to join ABC Company’s engineering team to create innovative, efficient packaging materials that meet customer needs.

2. Experience / Employment

The work history/experience section should be written in reverse chronological order, meaning your most recent job is listed first. Stick to bullet points here; they make it easier for the reader to take in what you have done and accomplished.

When writing each point, provide detail on what you did and the results achieved. For example, instead of saying “Designed packaging,” say something like “Developed innovative designs for protective packaging that reduced product damage by 20%.”

Include any awards or recognition received as well as certifications obtained related to this field of work if applicable.

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Assembled

- Inspected

- Packaged

- Labeled

- Shipped

- Monitored

- Operated

- Tested

- Troubleshot

- Calibrated

- Programmed

- Documented

- Improved

- Analyzed

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Developed and implemented innovative packaging solutions that improved the structural integrity of products and reduced damage during transit by 45%.

- Formulated cost-effective production plans for over 200 different types of packaging materials per month, resulting in a decrease of $3,000 on monthly supply costs.

- Designed prototypes for new product packages utilizing CAD software to ensure functionality and aesthetic appeal; successfully launched 7 new designs in 6 months with positive customer feedback regarding ease of use & overall look/feel.

- Monitored quality control processes throughout all stages from raw material sourcing through manufacturing to final delivery; rectified issues quickly when identified, leading to a reduction in defective goods rate from 5% to 2%.

- Effectively communicated with other departments such as warehouse, operations and logistics teams on design changes needed for efficient shipping methods without compromising safety standards or performance levels.

- Packaged over 200+ products daily in accordance with customer requirements, safety regulations and industry standards; reduced package damage rate by 12%.

- Documented all packaging process designs, modifications and test results for future reference; created an improved workflow that increased production speed by 15%.

- Participated in design reviews to ensure the accuracy of each product’s packaging specifications; implemented 5 new processes to reduce printing errors within 3 months of joining the team.

- Programmed automated machinery used in packing operations according to established parameters while ensuring proper functioning throughout production runs; completed programming tasks up to 10% faster than expected timelines on average.

- Confidently interacted with customers regarding their individual product needs and addressed any issues promptly without compromising quality assurance standards or delivery deadlines (+10 satisfied clients).

- Operated and maintained packaging machinery and equipment, ensuring that over 500 products were packed safely and efficiently into boxes every day.

- Presented innovative solutions to reduce package wastage by 20%, resulting in cost savings of $25,000 annually.

- Calibrated testing instruments for product quality assurance; ensured all packages met customer requirements with zero defects reported in the last quarter.

- Troubleshot mechanical issues on the assembly line quickly and accurately to minimize downtime by 40%.

- Actively participated in improvement projects that resulted in a reduction of 50% in errors associated with manual packaging processes within six months’ time frame.

- Reorganized and streamlined the packaging design process, reducing costs by 10% and increasing operational efficiency by 20%.

- Advised production teams on appropriate material selection based on product requirements; improved quality of products packing with well-executed protection techniques.

- Competently developed custom packaging solutions for a variety of goods, including food, medical supplies and electronics; reduced damage rate in transit to less than 0.5%.

- Coordinated closely with suppliers and vendors to ensure timely delivery of materials at optimal cost; managed an annual budget of $100K+ for procuring necessary resources without exceeding it.

- Expedited prototype testing processes from 4 weeks to 2 weeks using advanced software tools such as SolidWorks 3D CAD/CAM Systems & FEA Stress Analysis Software packages.

- Facilitated the design of over 100 new packaging designs for products, resulting in a 13% increase in customer satisfaction and $20,000+ cost savings.

- Demonstrated expertise in creating innovative package solutions to ensure product protection during shipping; reduced product damage rate by 20%.

- Represented the company at trade shows and industry conferences to showcase the latest packaging innovations; developed relationships with 15+ leading suppliers.

- Shipped 5 million packages per year while ensuring that all safety protocols were followed promptly and accurately; decreased shipment delays by 10%.

- Diligently monitored production processes and prepared detailed reports on material usage, equipment performance/maintenance requirements & quality control measures as needed.

- Successfully designed and developed over 100 packaging solutions for various products, resulting in a 20% reduction of package size and a 15% improvement in product safety.

- Prepared detailed design specifications for all new packages according to customer requirements; managed costs within budget by controlling raw material use, machine settings and overall production time.

- Spearheaded the development of an automated quality inspection system that identified defects on packaged products with 90% accuracy at high speed (>8000 units/hour).

- Mentored junior engineers on how to develop efficient packaging materials, tools & processes while maintaining strict safety standards; increased team productivity by 10%.

- Achieved recognition from upper management as one of the top-performing packing engineers through consistently exceeding project deadlines while upholding exceptional levels of product & customer satisfaction throughout each project cycle.

- Utilized CAD software to develop new packaging designs that met customer specifications, reducing cost and environmental impact by 10%.

- Tested different materials in order to optimize package integrity while ensuring the highest quality standards; improved shelf-life of products by 15%.

- Analyzed production data to identify areas for improvement regarding product protection, transport optimization and sustainability; successfully reduced waste with recyclable packaging options.

- Reliably coordinated orders between suppliers and vendors, as well as maintained inventory control systems in accordance with desired stock levels at all times.

- Introduced automated solutions for packing processes which increased efficiency by 20% and decreased labor costs significantly each year.

- Efficiently developed and tested over 200 packaging prototypes to help optimize product preservation, resulting in a 15% increase of shelf life.

- Labeled products with barcodes and RFID tags for accurate inventory tracking; saved the company 600 hours in manual item counting.

- Optimized existing industrial packaging machinery for improved production efficiency; reduced production time by 25%.

- Assembled shipping crates, boxes and pallets according to safety regulations and customer specifications; prevented any damages during transport of goods worth $20k+.

3. Skills

The skillset employers require in an employee will likely vary, either slightly or significantly; skimming through their job adverts is the best way to determine what each is looking for. One organization might be seeking someone with experience in the design and development of flexible packaging, while another might require knowledge of automated packaging systems.

It is important to tailor your skills section accordingly; that way you can make sure it contains all the keywords an applicant tracking system (ATS) will be looking for. ATSs are computer programs used by many employers these days to scan resumes for certain characteristics before they pass them on to a human being.

In addition, you may want to discuss some of your key skills more thoroughly in other sections such as the summary or work history – this gives potential employers a better understanding of what value you bring and how well-suited you are for their position.

Below is a list of common skills & terms:

- 5S

- Adobe Illustrator

- AutoCAD

- Automotive

- CAD

- Communication

- Consumer Products

- Continuous Improvement

- Corrugated

- Cross Functional Team Leadership

- Data Analysis

- Design of Experiments

- Engineering

- Food Packaging

- GMP

- Illustrator

- Injection Molding

- Kaizen

- Lean Manufacturing

- MATLAB

- Manufacturing

- Materials

- Minitab

- Packaging

- Packaging Design

- Packaging Engineering

- Plastics

- Problem Solving

- Process Engineering

- Process Improvement

- Product Design

- Product Development

- Quality Assurance

- Quality System

- R&D

- Retail Packaging

- Root Cause Analysis

- SAP

- SOLIDWORKS

- Six Sigma

- Supply Chain

- Supply Chain Management

- Teamwork

- Testing

- Time Management

- Validation

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention your education below the resume objective. However, if you have significant work experience to showcase, it is perfectly fine to omit an education section altogether.

If including an education section is necessary for the job application process, try mentioning courses or subjects related to packaging engineering that could be relevant for the position.

Bachelor of Science in Packaging Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are an important part of any resume as they demonstrate to potential employers that you have the necessary skills and knowledge for a particular job. They also show that you are committed to staying up-to-date with industry trends and developments, which is highly valued by many hiring managers.

If you possess certifications relevant to the position you’re applying for, make sure to include them in your resume so that recruiters can easily recognize your qualifications.

Certified Packaging Professional

Institute of Packaging Professionals

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Lois Breitenberg, this would be Lois-Breitenberg-resume.pdf or Lois-Breitenberg-resume.docx.

7. Cover Letter

Submitting a cover letter with your job application can be a great way to make an impression on the hiring manager. It provides you with an opportunity to explain why you’re a perfect fit for the role and is usually made up of 2 to 4 paragraphs separate from your resume.

Cover letters are not mandatory, however they help provide recruiters with more information about who you are as a professional and allow them to get better insights into what makes you unique compared to other candidates applying for the same position.

Below is an example cover letter:

Dear Mariela,

I am writing in response to your posting for a packaging engineer. With experience designing and managing the production of packaging for food, beverage, and consumer goods companies, I am confident I would make an excellent addition to your team.

In my current role as packaging engineer at [company name], I have been responsible for developing creative solutions to complex packaging challenges while adhering to strict quality and safety standards. My experience with both primary and secondary packaging has given me a well-rounded perspective that I can use to improve efficiency and reduce costs in your operation. In addition, my background in project management has taught me how to effectively coordinate multiple projects simultaneously while ensuring all deadlines are met.

The attached resume outlines my professional achievements in detail. I would welcome the opportunity to discuss how my skills and experience could benefit your organization further during an interview at your earliest convenience. Thank you for your time and consideration; I look forward to hearing from you soon.

Sincerely,

Lois

Packaging Engineer Resume Templates

Gharial

Gharial Lorikeet

Lorikeet Rhea

Rhea Saola

Saola Numbat

Numbat Dugong

Dugong Bonobo

Bonobo Axolotl

Axolotl Fossa

Fossa Hoopoe

Hoopoe Jerboa

Jerboa Quokka

Quokka Pika

Pika Echidna

Echidna Cormorant

Cormorant Kinkajou

Kinkajou Ocelot

Ocelot Markhor

Markhor Indri

Indri Rezjumei

Rezjumei