Mechatronics Engineer Resume Guide

Mechatronics Engineers design, develop and install automated systems that combine elements of mechanical engineering, electronics and computing. They work to create efficient machines or processes with a combination of electrical components such as sensors, motors and controllers. Additionally, they are responsible for ensuring the reliability and safety of these systems by performing tests on them in order to detect any issues.

You have the perfect combination of mechanical and electronic engineering expertise, so you’d make a great addition to any mechatronics team. But potential employers don’t know who you are yet. To let them know what you’re capable of, create an eye-catching resume that highlights your skillset.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

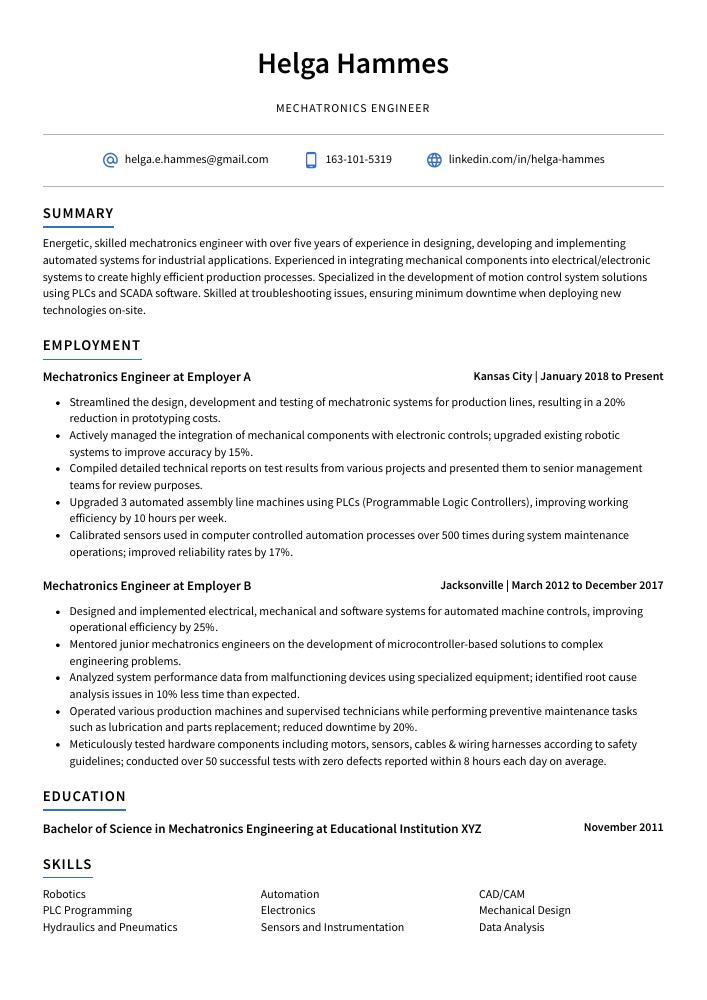

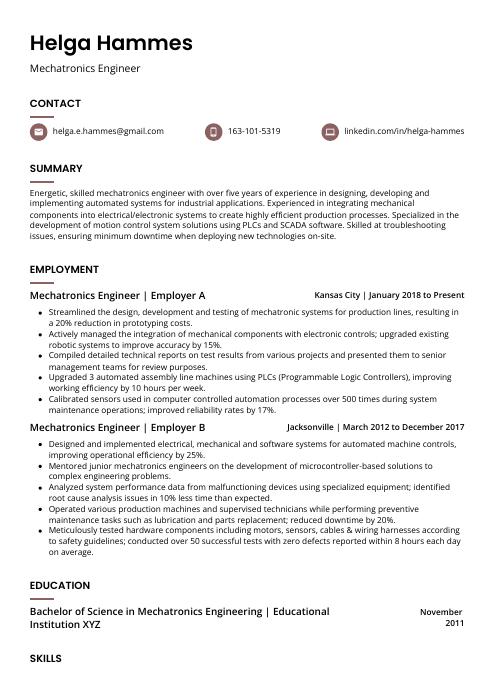

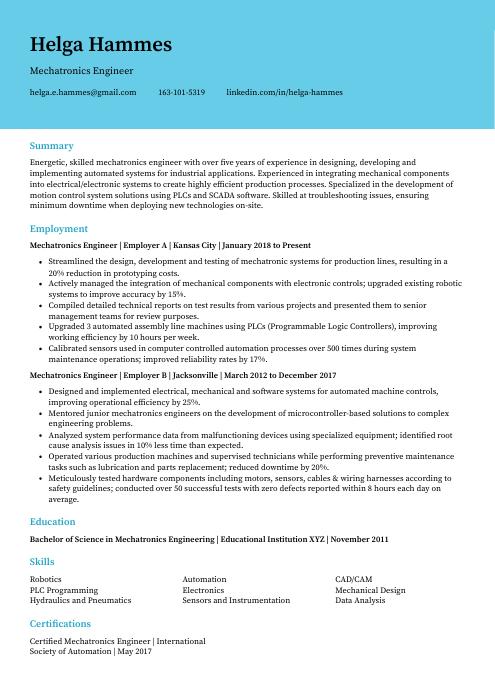

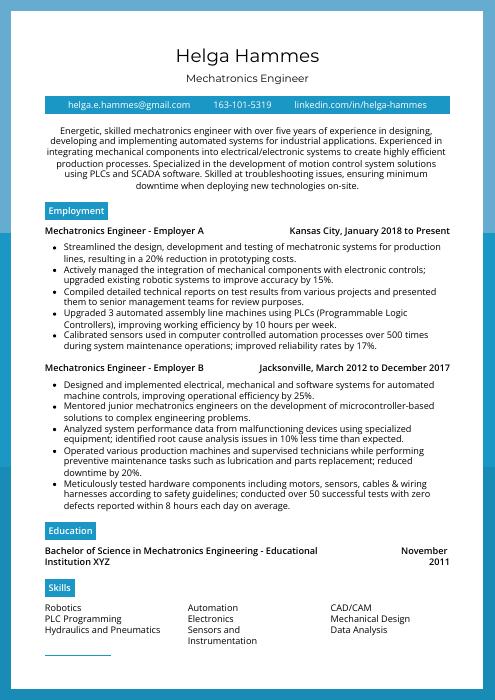

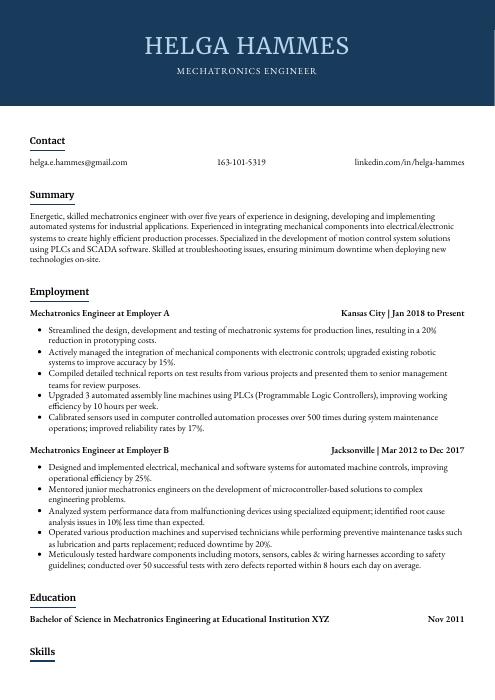

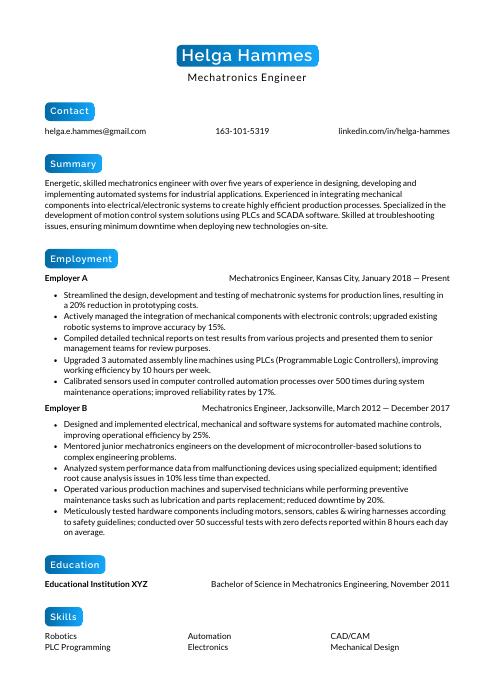

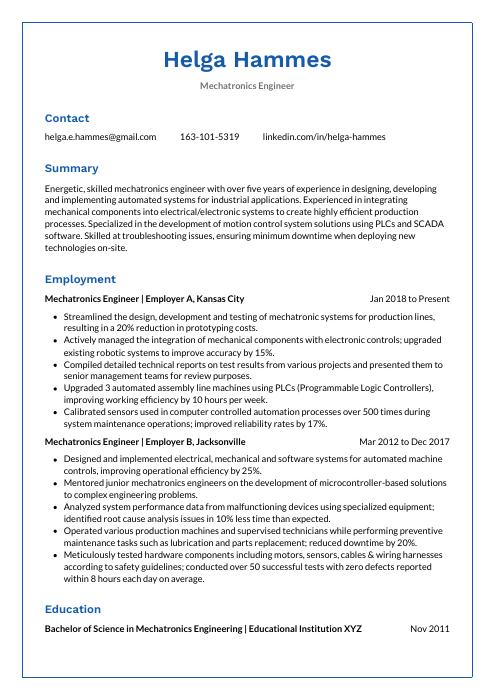

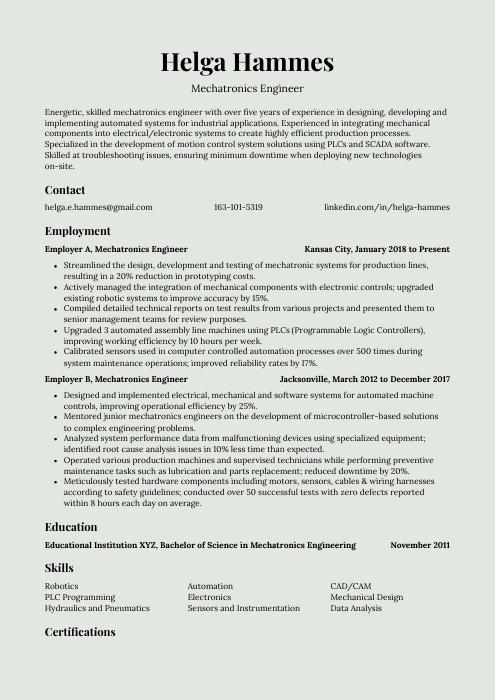

Mechatronics Engineer Resume Sample

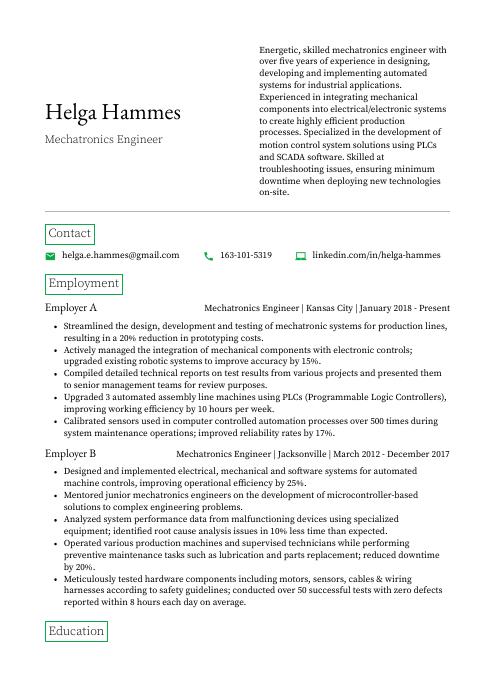

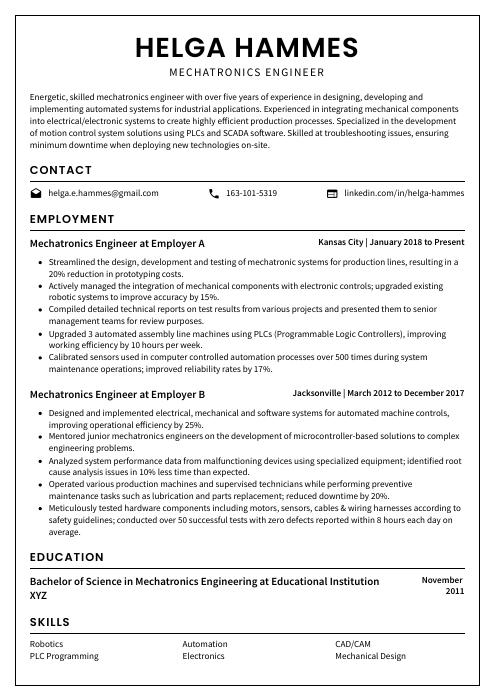

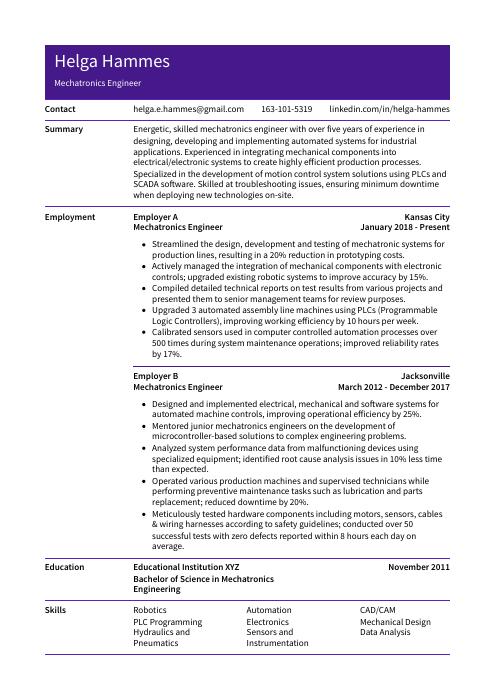

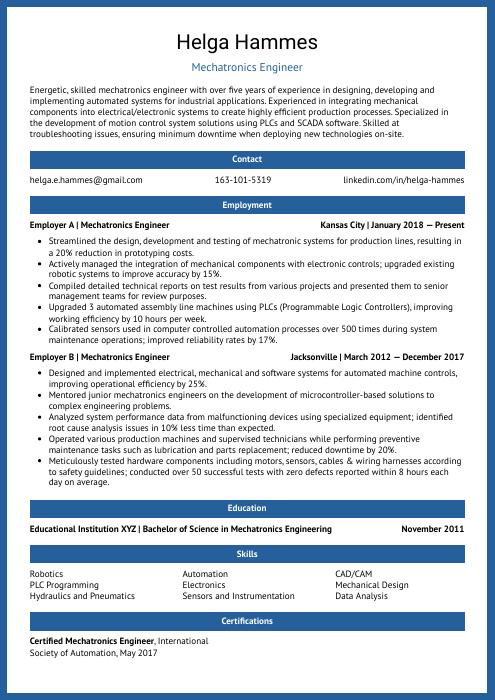

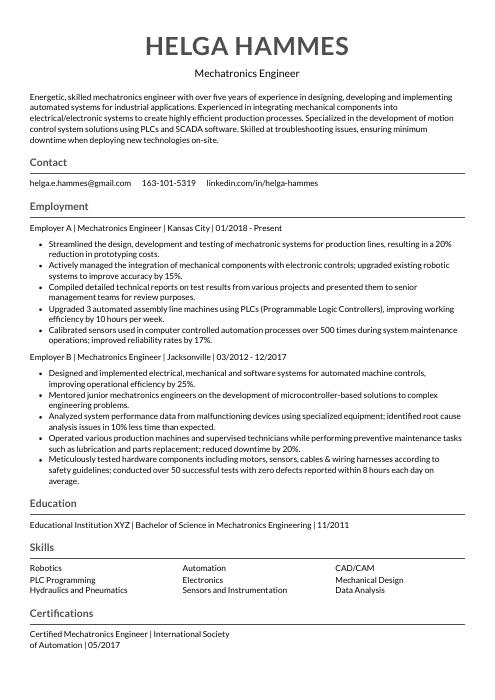

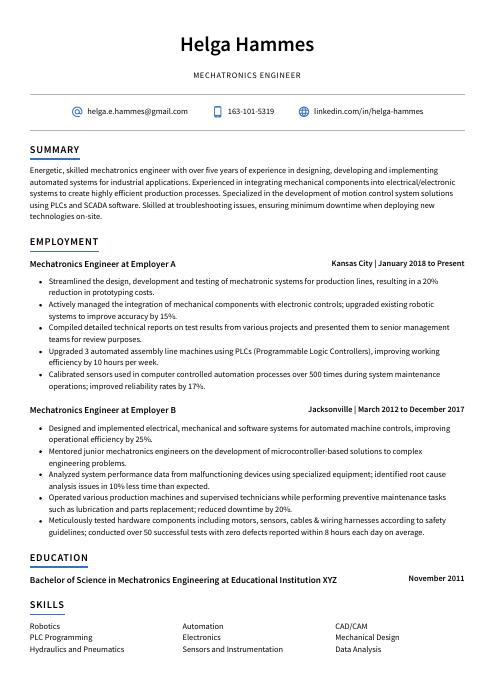

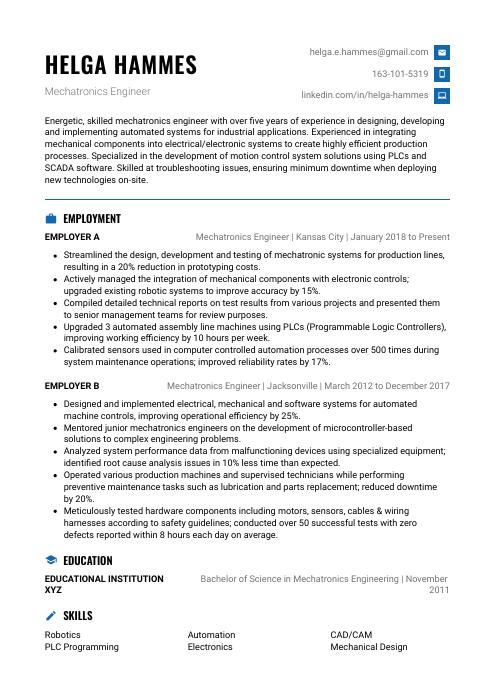

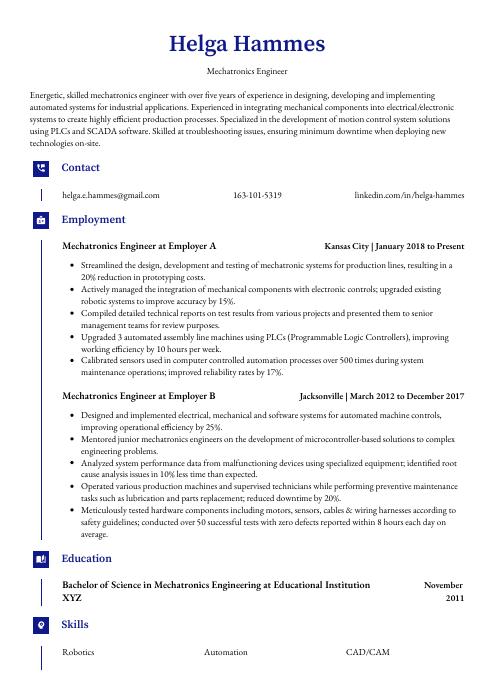

Helga Hammes

Mechatronics Engineer

[email protected]

163-101-5319

linkedin.com/in/helga-hammes

Summary

Energetic, skilled mechatronics engineer with over five years of experience in designing, developing and implementing automated systems for industrial applications. Experienced in integrating mechanical components into electrical/electronic systems to create highly efficient production processes. Specialized in the development of motion control system solutions using PLCs and SCADA software. Skilled at troubleshooting issues, ensuring minimum downtime when deploying new technologies on-site.

Experience

Mechatronics Engineer, Employer A

Kansas City, Jan 2018 – Present

- Streamlined the design, development and testing of mechatronic systems for production lines, resulting in a 20% reduction in prototyping costs.

- Actively managed the integration of mechanical components with electronic controls; upgraded existing robotic systems to improve accuracy by 15%.

- Compiled detailed technical reports on test results from various projects and presented them to senior management teams for review purposes.

- Upgraded 3 automated assembly line machines using PLCs (Programmable Logic Controllers), improving working efficiency by 10 hours per week.

- Calibrated sensors used in computer controlled automation processes over 500 times during system maintenance operations; improved reliability rates by 17%.

Mechatronics Engineer, Employer B

Jacksonville, Mar 2012 – Dec 2017

- Designed and implemented electrical, mechanical and software systems for automated machine controls, improving operational efficiency by 25%.

- Mentored junior mechatronics engineers on the development of microcontroller-based solutions to complex engineering problems.

- Analyzed system performance data from malfunctioning devices using specialized equipment; identified root cause analysis issues in 10% less time than expected.

- Operated various production machines and supervised technicians while performing preventive maintenance tasks such as lubrication and parts replacement; reduced downtime by 20%.

- Meticulously tested hardware components including motors, sensors, cables & wiring harnesses according to safety guidelines; conducted over 50 successful tests with zero defects reported within 8 hours each day on average.

Skills

- Robotics

- Automation

- CAD/CAM

- PLC Programming

- Electronics

- Mechanical Design

- Hydraulics and Pneumatics

- Sensors and Instrumentation

- Data Analysis

Education

Bachelor of Science in Mechatronics Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Mechatronics Engineer

International Society of Automation

May 2017

1. Summary / Objective

A resume summary/objective is the perfect place to showcase your skills and experience as a mechatronics engineer. In this section, you can highlight your expertise in robotics programming, automation engineering, system design and integration, PLC/HMI development, and other relevant topics. You could also mention any certifications or awards that demonstrate your commitment to excellence in the field of mechatronics engineering.

Below are some resume summary examples:

Driven mechatronics engineer with 5+ years of experience in the development, integration and optimization of mechatronic systems. Skilled at leading multidisciplinary teams to develop complex machine designs that integrate mechanical components, electronics and software controls. Experienced in working on a variety of projects ranging from automotive systems to industrial automation applications. Possesses excellent problem-solving skills, analytical thinking and communication abilities.

Dependable mechatronics engineer with 4+ years of experience in product development and engineering. Developed a comprehensive set of tools for automated testing, resulting in an estimated 20% increase in production efficiency at XYZ. Experienced with design & analysis software such as AutoCAD and MATLAB/Simulink to develop mechatronic systems for various applications. Proven record of delivering projects on time, under budget, and meeting customer satisfaction goals.

Amicable and experienced mechatronics engineer with 5+ years of experience in designing and developing custom automation systems. Proven expertise in the integration of mechanical, electrical, computer engineering and control technology to create high-performance automated machinery. At XYZ Corporation, developed a highly efficient assembly line that increased production output by 30%. Skilled at troubleshooting complex problems involving multiple subsystems.

Reliable mechatronics engineer with 7+ years of experience in product development, installation and maintenance. Proactive team player who effectively collaborates with multiple engineering disciplines to ensure successful completion of projects. Seeking a role at ABC Tech where I can leverage my technical expertise and knowledge in robotics, automation, electrical systems and programming languages to create innovative solutions for the company’s clients.

Skilled mechatronics engineer with 8+ years of experience in designing and developing electromechanical systems. Proven track record of successfully completing projects within budget and on time; able to troubleshoot complex engineering problems quickly and efficiently. Experienced with various CAD software tools, Arduino programming, robotic controls, PLCs, etc., as well as strong communication skills for working collaboratively across teams.

Proficient mechatronics engineer with 5+ years of experience designing, developing, and testing integrated hardware/software systems for a variety of industrial applications. Seeking to join ABC Tech to utilize expertise in robotics and automation engineering principles within their innovative product development team. At XYZ Co., reduced system complexity by 27%, resulting in an estimated 10% cost savings over the following 3-year period.

Enthusiastic Mechatronics Engineer with 5+ years of experience in electrical, mechanical and software engineering. Proven track record of successful product design from concept to final prototype for a wide range of industries. Adept at troubleshooting complex problems and creating innovative solutions that exceed customer expectations. Aiming to leverage my expertise as the next Mechatronics Engineer at ABC Tech Solutions.

Well-rounded mechatronics engineer with 8+ years of experience in the design, development and testing of complex electromechanical systems. Proven track record of successful product launches from concept to market. Adept at using CAD/CAM software and PLC programming for robotic automation applications. Seeking to join ABC Tech as a mechatronics engineer to create innovative solutions that exceed customer expectations.

2. Experience / Employment

In the experience section, you will provide details about your work history. This should be written in reverse chronological order, meaning the most recent job is listed first.

Stick to bullet points when writing this section; it allows for easier reading and comprehension of what you have done. You want to make sure that each point provides detail on what you did as well as any quantifiable results achieved from those actions.

For example, instead of saying “Developed new robotic systems,” you could say, “Designed two robotic systems with automated testing capabilities which increased production efficiency by 22%.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Programmed

- Assembled

- Installed

- Calibrated

- Troubleshot

- Tested

- Debugged

- Analyzed

- Fabricated

- Operated

- Monitored

- Upgraded

- Documented

- Optimized

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Spearheaded the design, development and implementation of mechatronics systems for industrial robotics applications; improved automation processes by 25%, resulting in a $10K cost reduction per month.

- Expedited the maintenance process of automated machine components with advanced diagnostic techniques, decreasing downtime from 8 hours to 4 hours on average.

- Utilized programming languages such as C++ and Python to develop robust control algorithms for robotic motion coordination and object recognition tasks; decreased errors rate during product testing by 30%.

- Substantially reduced energy consumption levels by 20% through innovative power management strategies implemented across all production lines in the factory environment.

- Structured and conducted regular technical training sessions that enabled 10+ junior engineers to acquire working knowledge of mechatronic principles within 3 months’ time-frame.

- Reliably designed, tested and maintained mechatronic systems for over 25 clients; reduced engineering cycle time by 30% with the implementation of new automated processes.

- Fabricated custom components from raw materials to create innovative mechatronics solutions with a 98% accuracy rate across all projects.

- Participated in numerous collaborative groups to generate ideas for improving existing machines and creating faster production rates; increased output efficiency by 11%.

- Reorganized parts inventory system at company warehouse resulting in 45 fewer hours spent on restocking per week – substantially reducing labor costs while simultaneously increasing productivity levels by 20%.

- Facilitated team trainings covering topics such as robotics programming, defect resolution techniques & electro-mechanical assembly processes; improved employee knowledge retention rate by 35%.

- Assessed design and manufacturing processes to identify areas of improvement; decreased production time by 12% while increasing quality assurance.

- Efficiently designed, tested and implemented automated control systems for industrial machines using PLCs, HMIs & VFDs; generated $45K in savings due to increased operational efficiency of machinery.

- Developed custom software programs from scratch with C++, Python and Java scripting languages that improved the accuracy rate of robotic arms by 15%.

- Revised electrical schematics for a wide range of complex mechatronic systems including robotics assemblies, smart devices and embedded microcontrollers; reduced debugging time per system by 25 hours on average over five months period.

- Debugged technical issues in existing automation networks quickly and accurately utilizing specialized hardware/software tools such as oscilloscopes/multi-meters along with troubleshooting techniques learnt during training sessions.

- Coordinated and supervised the installation, repair and maintenance of sophisticated mechatronic systems in over 100 industrial sites; ensured that all equipment was functioning properly to maintain production efficiency.

- Installed new automated systems for customers by programming PLCs & HMIs, configuring sensors/actuators and connecting robotic arms with other components; increased automation rate by 25%.

- Represented the company at trade shows seminars and symposiums to showcase its latest products including CNC machines, servo drives & motors, hydraulic pumps etc.; generated $100K+ in sales orders within 3 months of launching a new product line.

- Presented technical reports on various aspects of mechatronics engineering such as motion control system design principles, embedded microcontrollers applications etc., during quarterly team meetings which were highly appreciated by senior management members.

- Successfully reconstructed worn-out actuator parts using modern fabrication techniques like welding and soldering while adhering to safety guidelines; reduced downtime hours from 24hrs per day down to 5 hrs per week on average.

- Diligently designed and fabricated mechanical, electrical, electronic and software systems for mechatronics projects; reduced development time by 15% on average.

- Advised production teams on optimal machine performance, maintenance methods and troubleshooting techniques to improve efficiency in the factory environment.

- Formulated test protocols to evaluate all components of machines before they were shipped out, avoiding any major design flaws or system defects that could have caused costly repairs later down the line.

- Troubleshot a wide range of complex automation problems with precision and accuracy while upholding high safety standards at all times; identified root causes within 2 hours on average per issue encountered making use of advanced diagnostic tools & equipment.

- Reduced energy consumption across multiple industrial sites by 30%, ensuring more efficient operation during peak periods without compromising productivity levels or quality output.

- Tested, maintained and repaired complex mechatronic systems, ensuring that all components worked correctly by troubleshooting issues in a timely manner; improved repair quality rate to 95%.

- Consistently met deadlines while developing prototypes of automated equipment used for production purposes, reducing overall development time by 40 hours on average.

- Documented the detailed design process involved in creating new robotic systems using CAD software, 3D printing techniques and other engineering principles.

- Assembled various parts such as motors, actuators and controllers into complete subsystems with an accuracy rate of 99%, contributing towards increased efficiency within the manufacturing plant operations team.

- Demonstrated strong programming skills when coding PLC software programs to control flow of data between electronic sensors and mechanical devices; reduced machine downtime from 8 minutes per hour to 0 minutes over 6 months’ period.

- Introduced cutting-edge automation technologies and robotics solutions to optimize assembly processes, resulting in a 10% increase in productivity.

- Achieved cost savings of $20K through the design and implementation of automated systems for robotic welding operations.

- Programmed PLCs (Programmable Logic Controllers) using C# and Visual Basic programming languages to control machine functions with precision accuracy up to 0.001mm tolerance levels per customer specifications/requirements.

- Accurately monitored performance parameters such as pressure, temperature & voltage settings on various machines while troubleshooting any errors or malfunctions that arose during production runs; reduced downtime by 15%.

- Developed user manuals outlining operating instructions for new mechatronic systems installed at client sites, ensuring safe use of all machinery components within set guidelines & regulations at all times.

- Prepared detailed design schematics, models and drawings of mechatronic systems used in factory automation operations; improved system accuracy by 15%.

- Optimized existing software for robotic arms and automated conveyors to enhance production speeds; reduced cycle times by 10% with minimal downtime.

- Improved fault tolerance levels of control algorithms for process monitoring systems, resulting in a 20% reduction in machine errors over the past year.

- Resourcefully identified opportunities to leverage IoT technologies within industrial settings to automate manual processes, saving 3 hours per task on average while increasing safety standards across all facilities.

3. Skills

Skill requirements will differ from employer to employer – this can easily be determined via the job advert. Organization ABC may be looking for a mechatronics engineer with experience in robotics, while Organization XYZ may require someone who is knowledgeable about automation systems.

It’s important to tailor the skills section of your resume to each job you are applying for because many employers use applicant tracking systems these days. These computer programs scan resumes for certain keywords before passing them on to a human reviewer.

Once listed here, it would also be beneficial if you could elaborate on the most important ones in other areas such as the summary or experience sections of your resume.

Below is a list of common skills & terms:

- Automation

- CAD/CAM

- Data Analysis

- Electronics

- Hydraulics and Pneumatics

- Mechanical Design

- PLC Programming

- Robotics

- Sensors and Instrumentation

4. Education

Mentioning your education on your resume will depend on the level of experience you have. If you are a recent graduate and lack professional experience, include an education section below your resume objective. However, if you have several years of work history to showcase, omitting the education section is perfectly acceptable.

If including an education section, try to mention courses or subjects related directly to mechatronics engineering that demonstrate knowledge and skill in this field.

Bachelor of Science in Mechatronics Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise and knowledge in a particular field. They are also an excellent indicator of the level of commitment you have towards professional development, as they require dedication and hard work to obtain.

Including certifications on your resume is beneficial for employers because it shows that you possess the necessary skillset required for the job. It can be especially helpful if there are specific qualifications or certifications mentioned in the job description, so make sure to include them if applicable!

Certified Mechatronics Engineer

International Society of Automation

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Helga Hammes, this would be Helga-Hammes-resume.pdf or Helga-Hammes-resume.docx.

7. Cover Letter

Writing a cover letter is an important part of the job application process, as it gives you a chance to explain why you are the best candidate for the role. It should be made up of 2-4 paragraphs and give additional information that cannot be found on your resume.

Cover letters can help recruiters get a better understanding of who you are and what makes you unique, which is why they are often recommended even if not required by employers. Crafting one well could make all the difference in securing your dream job!

Below is an example cover letter:

Dear Alexa,

I am writing to apply for the Mechatronics Engineer position at XYZ Corporation. As a highly skilled and experienced engineer with more than 10 years of experience in mechatronics engineering, I am confident that I can make a significant contribution to your company.

My experience includes designing, developing, testing, and troubleshooting mechatronic systems for a variety of industries, including automotive, aerospace, and consumer electronics. I have also gained valuable experience managing teams of engineers and technicians. In my most recent role as Mechatronics Engineering Manager at ABC Corporation, I was responsible for leading a team of 12 engineers and technicians in the development of new mechatronic products.

I possess excellent problem-solving skills and have a proven track record of successfully resolving complex technical issues. My strong analytical skills enable me to quickly identify root causes of problems and develop effective solutions. I am also an excellent communicator with both technical and non-technical staff members alike.

I am knowledgeable in a wide range of programming languages (C/C++/Java/Python) and software platforms (Linux/Windows). In addition, I have experience working with various types of sensors (temperature/pressure/flow) and actuators (motors/valves). My hands-on experience combined with my theoretical knowledge makes me uniquely qualified for this position.

If given the opportunity to join your team, I will work diligently to exceed your expectations by delivering high-quality work on time and within budget while maintaining the highest standards of safety & compliance. Thank you for your time & consideration; I look forward to hearing from you soon!

Sincerely,

Helga

Mechatronics Engineer Resume Templates

Fossa

Fossa Dugong

Dugong Rhea

Rhea Bonobo

Bonobo Kinkajou

Kinkajou Markhor

Markhor Saola

Saola Quokka

Quokka Cormorant

Cormorant Pika

Pika Ocelot

Ocelot Indri

Indri Axolotl

Axolotl Lorikeet

Lorikeet Jerboa

Jerboa Echidna

Echidna Gharial

Gharial Numbat

Numbat Hoopoe

Hoopoe Rezjumei

Rezjumei