Mechanical Maintenance Engineer Resume Guide

Mechanical maintenance engineers are responsible for inspecting and maintaining mechanical equipment, diagnosing problems, performing repairs, and recommending solutions to ensure the smooth operation of machinery. They also collaborate with other engineering professionals to develop new systems or modify existing ones.

You’re a master of machinery, and any factory would benefit from your expertise. Before you can be hired though, employers need to know about your skillset – the best way to do this is by writing an impressive resume that highlights all of your achievements in mechanical maintenance engineering.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

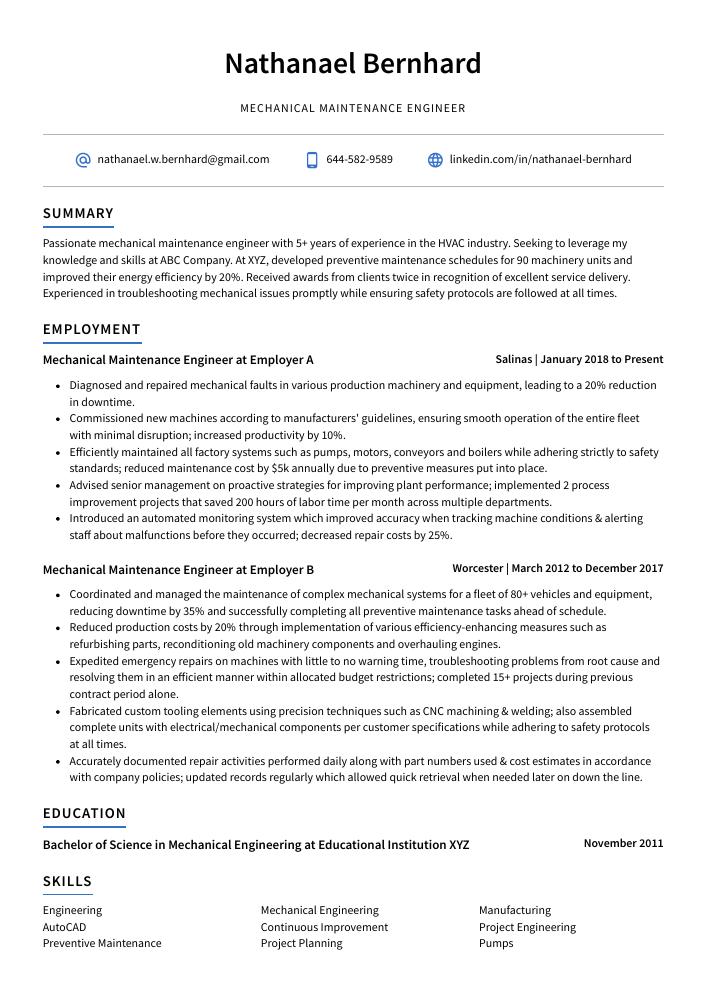

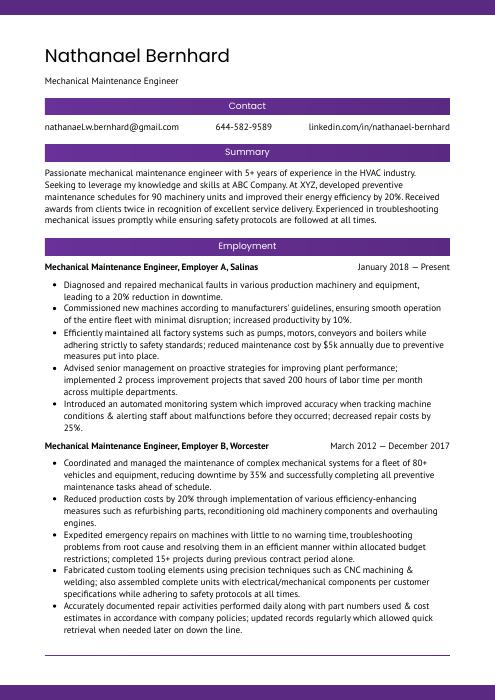

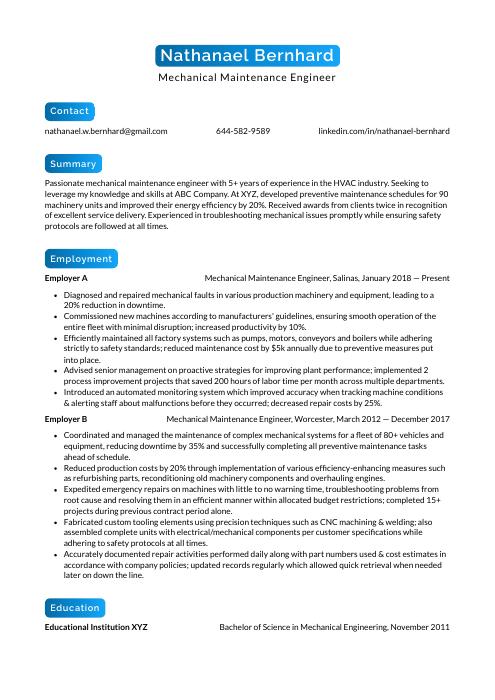

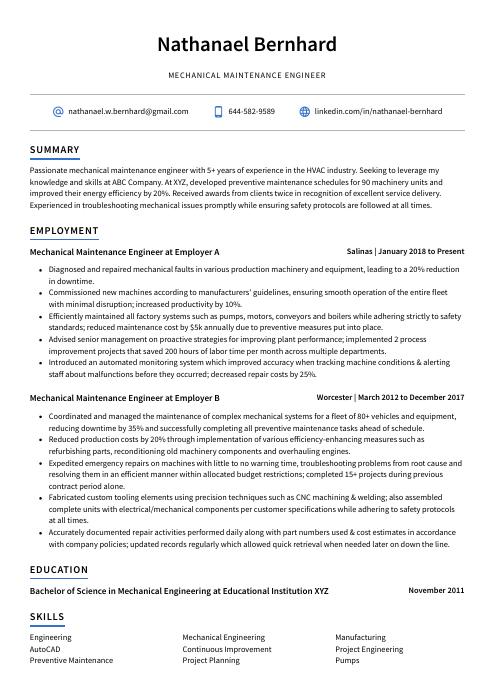

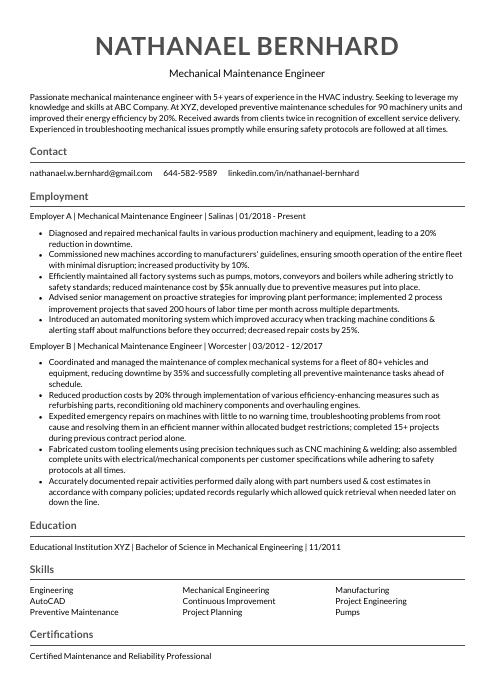

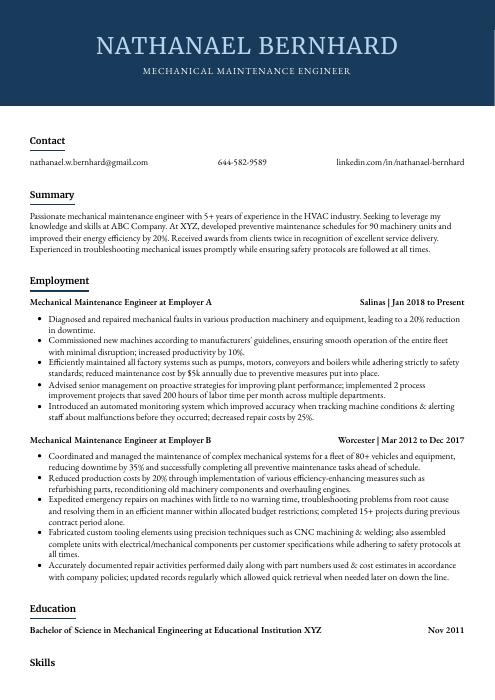

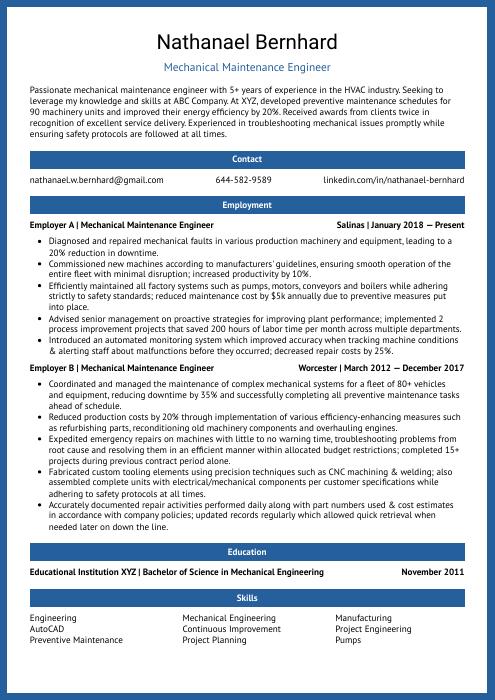

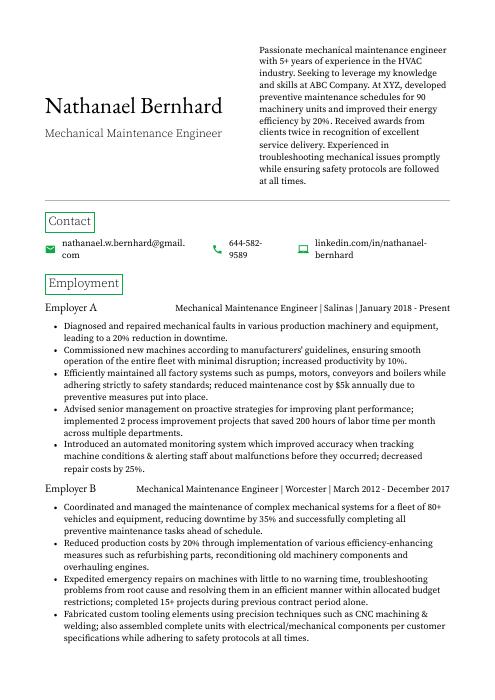

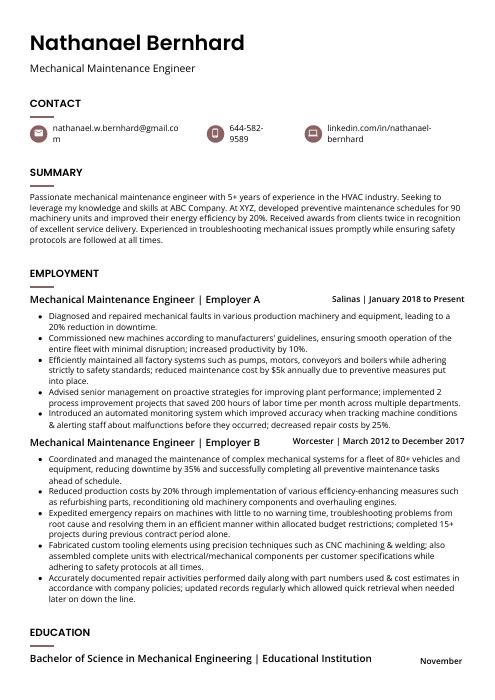

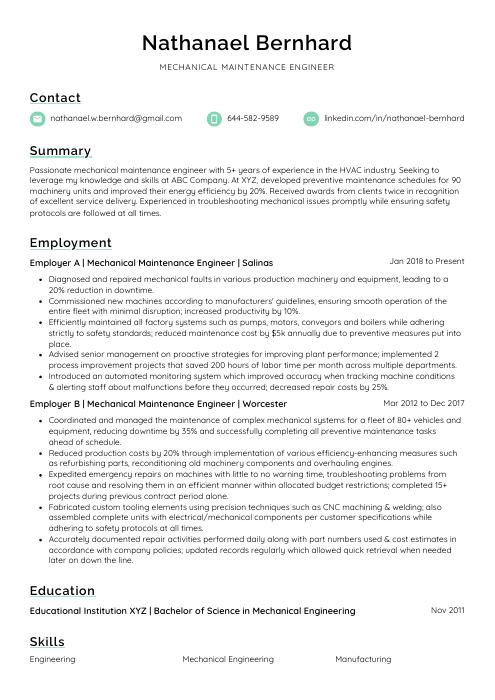

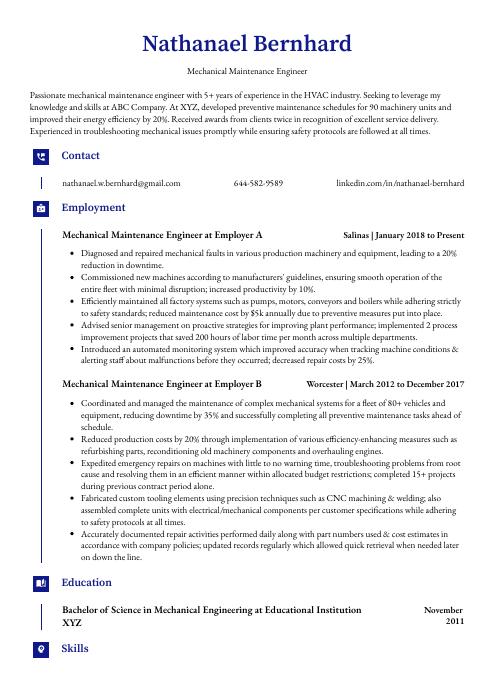

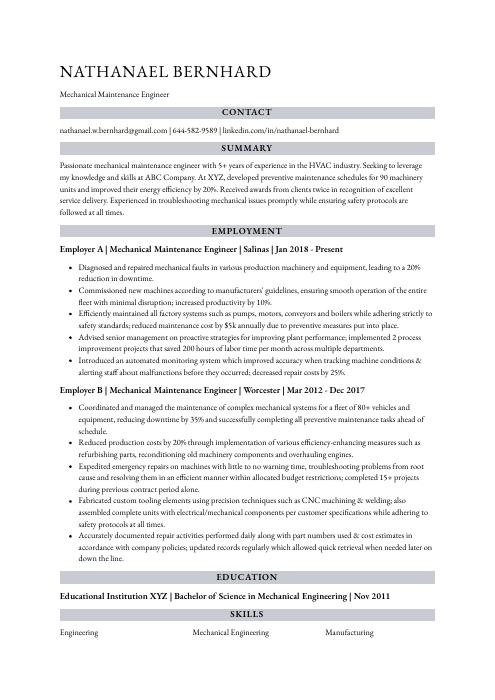

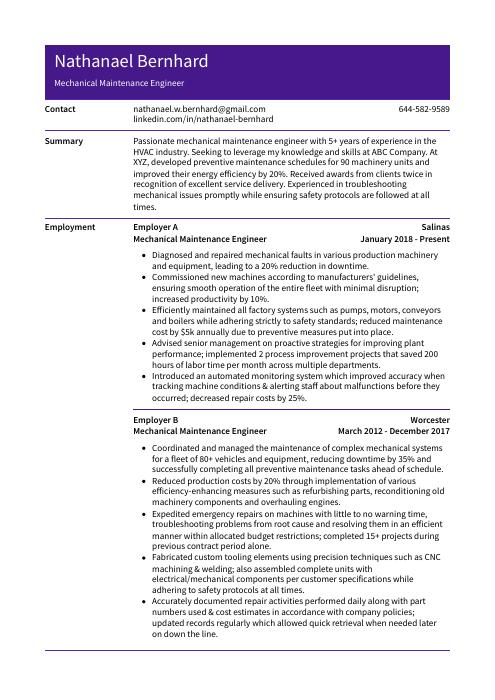

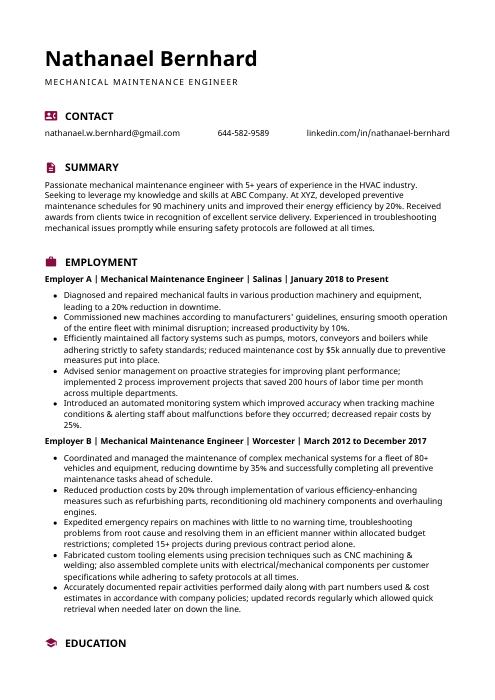

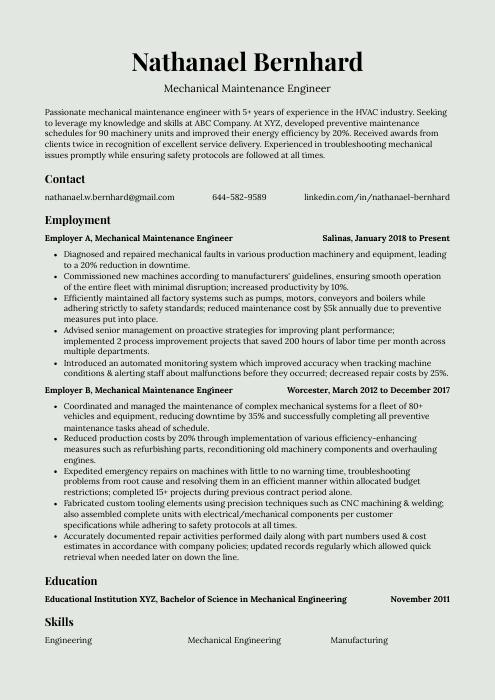

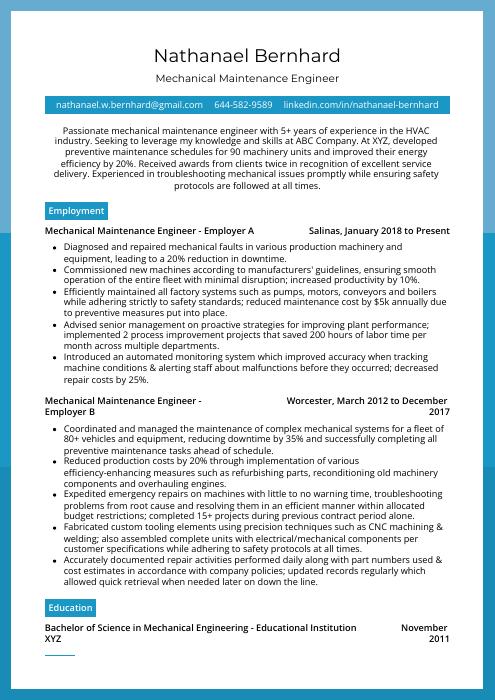

Mechanical Maintenance Engineer Resume Sample

Nathanael Bernhard

Mechanical Maintenance Engineer

[email protected]

644-582-9589

linkedin.com/in/nathanael-bernhard

Summary

Passionate mechanical maintenance engineer with 5+ years of experience in the HVAC industry. Seeking to leverage my knowledge and skills at ABC Company. At XYZ, developed preventive maintenance schedules for 90 machinery units and improved their energy efficiency by 20%. Received awards from clients twice in recognition of excellent service delivery. Experienced in troubleshooting mechanical issues promptly while ensuring safety protocols are followed at all times.

Experience

Mechanical Maintenance Engineer, Employer A

Salinas, Jan 2018 – Present

- Diagnosed and repaired mechanical faults in various production machinery and equipment, leading to a 20% reduction in downtime.

- Commissioned new machines according to manufacturers’ guidelines, ensuring smooth operation of the entire fleet with minimal disruption; increased productivity by 10%.

- Efficiently maintained all factory systems such as pumps, motors, conveyors and boilers while adhering strictly to safety standards; reduced maintenance cost by $5k annually due to preventive measures put into place.

- Advised senior management on proactive strategies for improving plant performance; implemented 2 process improvement projects that saved 200 hours of labor time per month across multiple departments.

- Introduced an automated monitoring system which improved accuracy when tracking machine conditions & alerting staff about malfunctions before they occurred; decreased repair costs by 25%.

Mechanical Maintenance Engineer, Employer B

Worcester, Mar 2012 – Dec 2017

- Coordinated and managed the maintenance of complex mechanical systems for a fleet of 80+ vehicles and equipment, reducing downtime by 35% and successfully completing all preventive maintenance tasks ahead of schedule.

- Reduced production costs by 20% through implementation of various efficiency-enhancing measures such as refurbishing parts, reconditioning old machinery components and overhauling engines.

- Expedited emergency repairs on machines with little to no warning time, troubleshooting problems from root cause and resolving them in an efficient manner within allocated budget restrictions; completed 15+ projects during previous contract period alone.

- Fabricated custom tooling elements using precision techniques such as CNC machining & welding; also assembled complete units with electrical/mechanical components per customer specifications while adhering to safety protocols at all times.

- Accurately documented repair activities performed daily along with part numbers used & cost estimates in accordance with company policies; updated records regularly which allowed quick retrieval when needed later on down the line.

Skills

- Engineering

- Mechanical Engineering

- Manufacturing

- AutoCAD

- Continuous Improvement

- Project Engineering

- Preventive Maintenance

- Project Planning

- Pumps

Education

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Maintenance and Reliability Professional (CMRP)

Soc

May 2017

1. Summary / Objective

Your resume summary/objective should provide the hiring manager with a snapshot of your experience and qualifications. For example, you could mention the number of years’ experience you have in mechanical maintenance engineering, any certifications or specializations you may possess, and how your troubleshooting skills helped to reduce downtime at previous companies. You can also highlight any awards or recognition that demonstrate your commitment to excellence in this field.

Below are some resume summary examples:

Enthusiastic mechanical maintenance engineer with 7+ years of experience in the automotive industry. Skilled at diagnosing and troubleshooting mechanical problems, designing preventive maintenance systems, preparing technical reports for management review, and providing training to technicians on repair procedures. Aiming to join ABC Company as a Mechanical Maintenance Engineer where I can apply my expertise in creating reliable production equipment.

Committed mechanical maintenance engineer with 8+ years of experience in the industrial field. Skilled in troubleshooting, repair and preventive maintenance for a variety of mechanical systems such as HVAC, pumps, motors and other process equipment. At XYZ Company I improved production efficiency by 40%, reduced downtime costs by 25% and ensured that all safety regulations were followed to the letter while maintaining OSHA standards compliance.

Diligent and experienced mechanical maintenance engineer with 10+ years of experience in the field. Possesses strong knowledge and expertise in maintaining, repairing, installing, and operating industrial machinery. At XYZ Corporation successfully executed preventive maintenance activities to minimize downtime on production lines. Developed innovative strategies for cost reduction while ensuring quality standards are maintained at all times.

Seasoned mechanical maintenance engineer with 8+ years of experience developing and managing repairs, inspections, and preventive maintenance programs. Highly skilled in utilizing the latest tools to diagnose system faults quickly and accurately. Seeking to join ABC Technologies as a Maintenance Engineer where I can utilize my knowledge to increase operational efficiency while also decreasing downtime on complex machinery.

Amicable mechanical maintenance engineer with 8+ years of experience in the field. Skilled at troubleshooting and repairing mechanical systems, as well as performing preventive maintenance tasks to ensure optimal system performance. At XYZ Engineering, reduced downtime by 20% through proactive management and preventative care. Experienced in developing efficient plans for maintenance activities based on safety standards.

Determined and highly experienced mechanical maintenance engineer with 8+ years of experience in the industrial and manufacturing sector. Seeking to join ABC Tech where I can utilize my expertise in troubleshooting, preventive maintenance, and predictive analysis to improve plant efficiency and reduce downtime. Achieved a 25% cost reduction at XYZ Manufacturing by introducing an innovative approach to asset management.

Driven mechanical maintenance engineer with 5+ years of experience maintaining and repairing industrial machinery. Seeking to join ABC as a mechanical maintenance engineer, leveraging skills in troubleshooting, problem-solving, and safety protocols for the benefit of all stakeholders. At XYZ Company identified machine faults that were causing downtime by 33%, increasing productivity levels by 21%.

Reliable mechanical maintenance engineer with 8+ years of experience in installation and repair of industrial machinery. Skilled at troubleshooting, preventive maintenance and root cause analysis to maintain optimal functioning of equipment. Successfully managed the deployment of $1M worth of new automated machines for ABC Company while ensuring minimal downtime throughout the process.

2. Experience / Employment

For the experience section, you should list your employment history in reverse chronological order. This means that the most recent job is listed first.

In this section, it’s best to use bullet points when describing what you did and the results achieved. Doing so makes it easier for the reader to take in all of the information quickly. When writing out each bullet point, make sure to provide detail on what was done and any quantifiable outcomes obtained from those actions.

For example, instead of saying “Installed new machines,” you could say, “Successfully installed 10+ complex machinery systems within a 3-month period with minimal downtime.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Installed

- Assembled

- Inspected

- Troubleshot

- Calibrated

- Repaired

- Adjusted

- Replaced

- Tested

- Operated

- Monitored

- Diagnosed

- Programmed

- Fabricated

- Commissioned

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Reliably maintained and repaired mechanical systems in a factory setting, completing up to 40 maintenance tasks per week with no incidents or safety violations.

- Replaced defective components of machines such as bearings, gears, valves and motors with 95% accuracy; reduced downtime by 23%.

- Demonstrated expertise in troubleshooting various types of electrical control panels for pumps, fans & other motor-driven equipment; identified root cause of issues within the first hour on average.

- Installed new equipment when necessary according to industry standards and customer requirements while ensuring that all operational parameters were met effectively; completed projects 10 days ahead of schedule resulting in cost savings over $6k annually.

- Participated actively in continuous improvement initiatives which resulted in reducing energy costs by 15%, increasing plant productivity levels by 22% and lowering maintenance expenses by 11%.

- Streamlined mechanical processes and operations, reducing maintenance costs by 15% in a year.

- Compiled detailed reports on all mechanical systems and machines to ensure optimal performance; identified potential issues before they arose, resulting in fewer downtime hours across the board.

- Confidently diagnosed problems within hydraulic & pneumatic systems, as well as engines & motors; replaced or repaired components accordingly while adhering to safety protocols at all times.

- Adjusted settings of industrial machineries including lathes, millers and grinders using precision tools such as micrometers and calipers for consistent results every time; conducted quality control tests with zero defects reported over the last four months following changes made in each machine system’s setup processs.

- Facilitated smooth working environment by performing preventative maintenance tasks regularly that involved inspecting belts/bearings/shafts/gears etc.; improved operational efficiency of equipment by 35%.

- Spearheaded the installation and maintenance of over 100 industrial mechanical components, leading to a 10% reduction in machine downtime and $15,000 savings annually.

- Revised existing preventive maintenance plans for all machinery, resulting in improved quality assurance standards by 15%.

- Tested advanced safety systems on equipment to ensure compliance with industry regulations; implemented changes that reduced oil leakage incidents by 30%.

- Actively troubleshot complex issues related to HVAC, pumps, conveyors and other manufacturing machines within tight deadlines; achieved an average resolution rate of 95%.

- Inspected various automated parts regularly for signs of corrosion or wear-and-tear damage; successfully identified 25 potential defects before they occurred and averted costly repairs/replacements accordingly.

- Programmed, tested and maintained mechanical systems, resulting in a 15% increase in efficiency of existing machines.

- Represented the engineering team at weekly meetings with clients to discuss new project requirements; identified potential solutions for cost-effective maintenance of equipment and materials.

- Meticulously inspected machinery components on a regular basis, troubleshooting any issues that arose promptly and taking preventive measures to avoid future malfunctions or breakdowns; reduced downtime by 12%.

- Formulated complex technical drawings according to customer specifications using CAD software; completed projects within tight deadlines while maintaining accuracy levels above 95%.

- Optimized production processes through careful analysis of machine performance data, leading to an average reduction in energy consumption costs by 10% over 3 months.

- Repaired a wide range of mechanical equipment and components, including engines, motors and pumps; improved overall performance by 40% in just 6 months.

- Achieved a 20% cost reduction on maintenance material inventory through careful planning and implementation of preventive maintenance programs.

- Thoroughly inspected all machinery for any signs of wear or damage to ensure they were functioning properly at all times; identified issues before they became major problems resulting in $2,000 saved over the past quarter alone.

- Prepared detailed reports outlining repair costs, recommended parts & replacement items after completing inspection assignments and submitted them promptly to management for timely decision-making processes related to repairs & replacements needed for efficient operations.

- Reorganized tools & supplies used during daily maintenance tasks into dedicated storage compartments which allowed easy access when required while simultaneously increasing the orderliness of work environment significantly by 70%.

- Competently maintained, repaired and overhauled mechanical systems in a manufacturing environment; successfully completed over 500 maintenance tasks with 98% accuracy in the past year.

- Utilized advanced diagnostic tools to evaluate performance of machinery and identify potential faults before they occur; decreased machine downtime by 17%.

- Developed preventative maintenance plans for all assigned machines, ensuring that components were checked regularly to meet safety standards and reduce the risk of accidents at work place.

- Presented comprehensive monthly reports on equipment condition, repair costs & operational efficiency levels across 15 production lines; reduced annual budget expenditure by $10,000+.

- Troubleshot complex engineering problems within given deadlines while adhering to established safety protocols & quality assurance processes; resolved 80% issues within 1 hour of occurrence timeframes.

- Mentored and trained 6 junior mechanical engineers in the basics of maintenance engineering, helping them understand complex equipment and troubleshooting techniques; reduced downtime by 25%.

- Improved operational efficiency through proactive maintenance activities such as lubrication checks and replacement of parts; saved $10,000 annually on servicing costs.

- Resourcefully troubleshot a wide range of electrical & mechanical issues in production machinery with minimal guidance from senior engineers over 50+ times per month.

- Structured preventative maintenance plans to ensure that all machines were serviced regularly according to manufacturer recommendations, proactively avoiding breakdowns resulting in up to 8 hours fewer unplanned stoppages each week.

- Monitored performance of key mechanical systems daily using software diagnostic tools and manual tests; identified potential problems before they occurred 90% of the time.

- Calibrated and maintained a variety of mechanical and electro-mechanical equipment, such as pumps, valves and motors; substantially reduced system downtime by 10%.

- Assembled complex machinery components using hand tools and hydraulic jacks; installed new systems in accordance with manufacturer instructions.

- Assessed the performance of multiple machines on a daily basis to identify potential issues before they escalated into major malfunctions; saved $7000 in maintenance costs over 3 months.

- Operated various power tools including grinders, presses and lathes while troubleshooting problems with electrical circuits, pneumatic controls & hydraulics systems according to safety protocols & industry standards.

- Substantially improved machine reliability through preventive maintenance measures that included oiling moving parts, cleaning filters and replacing worn out components before scheduled intervals (+20%).

3. Skills

Skill requirements will differ from one employer to the next; this can easily be ascertained from the job posting. Organization A may be looking for a maintenance engineer with experience in hydraulic systems, while Organization B may be seeking someone who can troubleshoot electrical issues.

Therefore, it is important to tailor the skills section of your resume to each job you are applying for. This will help ensure that applicant tracking systems (computer programs used by many employers these days) recognize your resume as being relevant and pass it on to a human.

In addition to listing skills in this section, you should also discuss them more thoroughly in other areas such as the summary or experience sections.

Below is a list of common skills & terms:

- 5S

- AutoCAD

- CAD

- Commissioning

- Continuous Improvement

- Energy

- Engineering

- Factory

- Finite Element Analysis

- Gas

- Hydraulics

- Inspection

- Lean Manufacturing

- MATLAB

- Machining

- Maintenance

- Maintenance Engineering

- Maintenance Management

- Maintenance and Repair

- Manufacturing

- Mechanical Engineering

- Metal Fabrication

- Piping

- Planned Preventative Maintenance

- Plant Maintenance

- Preventive Maintenance

- Process Engineering

- Product Development

- Project Engineering

- Project Planning

- Pumps

- Root Cause Analysis

- SAP

- SOLIDWORKS

- Team Leadership

- Teamwork

- Time Management

- Troubleshooting

- Welding

4. Education

Including an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, mention the relevant courses or subjects related to mechanical maintenance engineering below your resume objective. However, if you have significant work experience that is more impressive than any educational background, it may be best to omit the education section altogether.

If an education section is included, try to highlight topics such as fluid mechanics and electrical systems which are pertinent for a mechanical maintenance engineer role.

Bachelor of Science in Mechanical Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field. They show potential employers that you have taken the time and effort to become certified, which is an indication of dedication and commitment.

Including certifications on your resume can be beneficial if they are relevant to the job position you are applying for. Make sure to include any professional development courses or industry-related knowledge that may be applicable as well.

Certified Maintenance and Reliability Professional (CMRP)

Soc

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Nathanael Bernhard, this would be Nathanael-Bernhard-resume.pdf or Nathanael-Bernhard-resume.docx.

7. Cover Letter

Attaching a cover letter to your job application is a great way to capture the attention of potential employers. It provides an opportunity for you to showcase who you are and why you would be an ideal candidate for the role.

A cover letter should include between 2-4 paragraphs, with each one focusing on different aspects of your experience or skills that make you suitable for the position. However, it shouldn’t simply repeat everything that’s already in your resume; rather, use this as a chance to explain more about yourself and what makes you stand out from other applicants.

Below is an example cover letter:

Dear Sincere,

I am writing in response to your ad for a Mechanical Maintenance Engineer. With my experience in overseeing the maintenance of industrial machinery and equipment, as well as developing and implementing preventive maintenance programs, I am confident that I would be an asset to your team.

In my current role at [company name], I oversee a team of 12 technicians who maintain production machinery used in the manufacturing process. In addition to ensuring that all machines are running smoothly and efficiently, I also develop preventative maintenance programs to minimize downtime due to machine malfunctions. As a result of these efforts, production has increased by 15% over the past year.

I am also experienced in conducting root cause analysis to identify underlying issues causing frequent machine breakdowns. Once the root cause is identified, I work with the relevant teams (e.g., engineering, purchasing) to implement corrective actions. This approach has helped me resolve many complex issues and improve overall equipment reliability by 30%.

Lastly, I have a strong background in mechanical engineering and hold a Bachelor’s degree from XYZ University. My combination of technical knowledge and hands-on experience makes me uniquely qualified for this position.

I would welcome an opportunity to discuss how my skills and experience can benefit your organization further during an interview at your earliest convenience.

Sincerely,

Nathanael

Mechanical Maintenance Engineer Resume Templates

Dugong

Dugong Cormorant

Cormorant Markhor

Markhor Jerboa

Jerboa Echidna

Echidna Kinkajou

Kinkajou Axolotl

Axolotl Indri

Indri Bonobo

Bonobo Ocelot

Ocelot Quokka

Quokka Fossa

Fossa Lorikeet

Lorikeet Gharial

Gharial Numbat

Numbat Pika

Pika Hoopoe

Hoopoe Saola

Saola Rhea

Rhea Rezjumei

Rezjumei