Materials Engineer Resume Guide

Materials Engineers are responsible for developing, processing and testing materials used to create a range of products. They design and supervise the production of industrial machinery, tools, components and structures using metals, ceramics, plastics or composites. Additionally they evaluate material properties such as strength or electrical conductivity in order to determine the best combination of materials for specific applications.

As a materials engineer, you have the expertise to develop and test new materials for various industries. But potential employers don’t know about your capabilities yet. To make them aware of what you can do, writing an impressive resume is essential.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

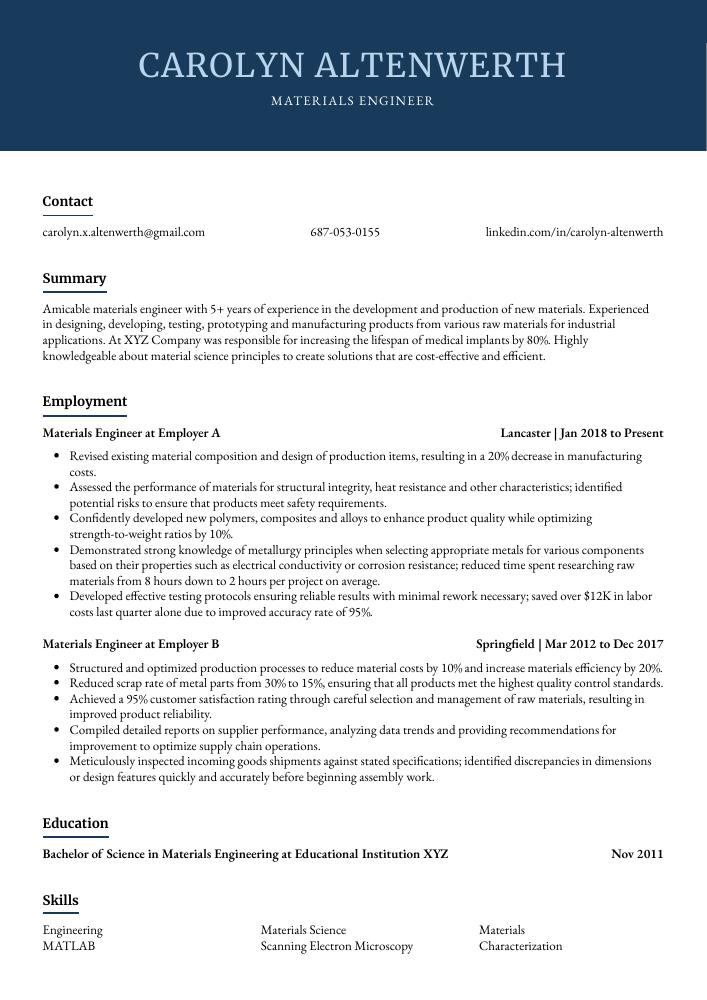

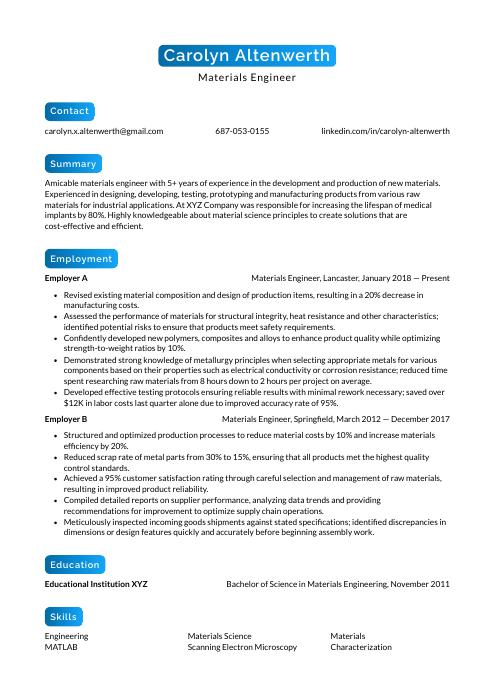

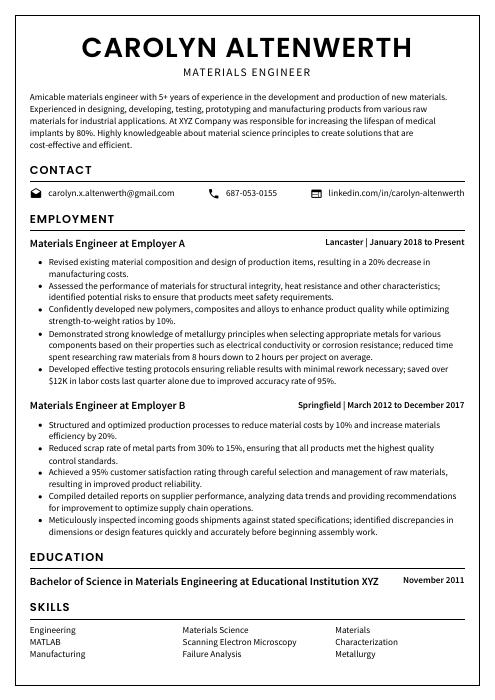

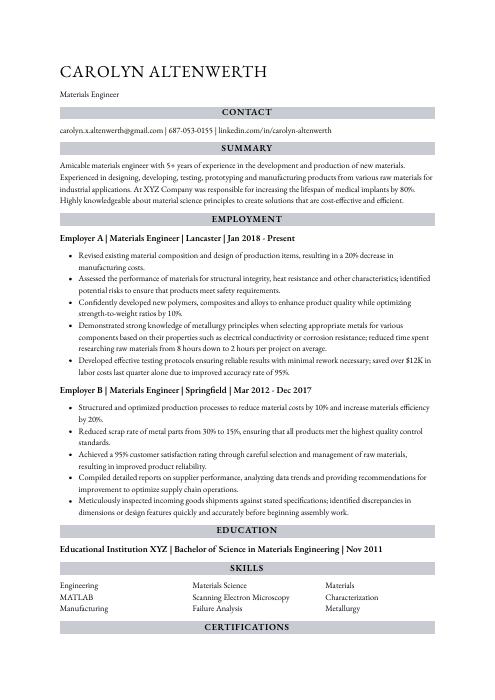

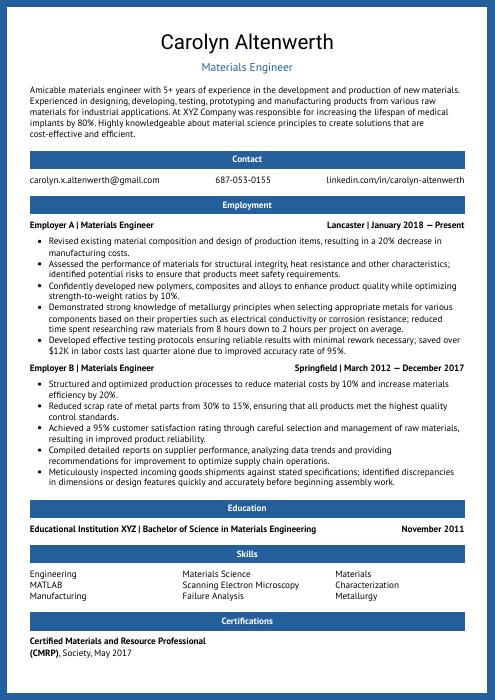

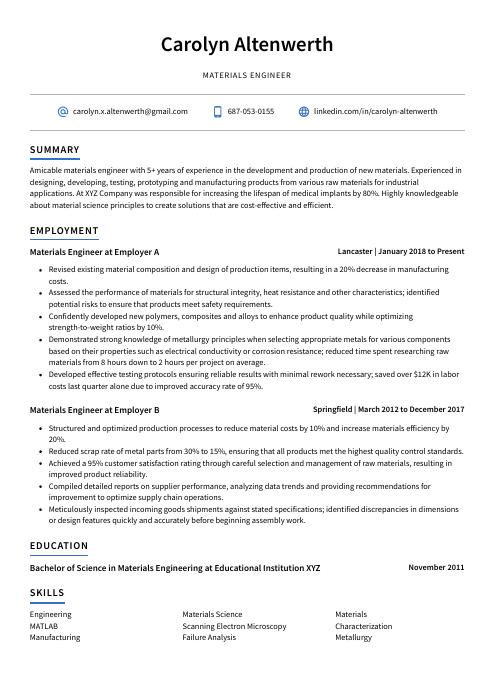

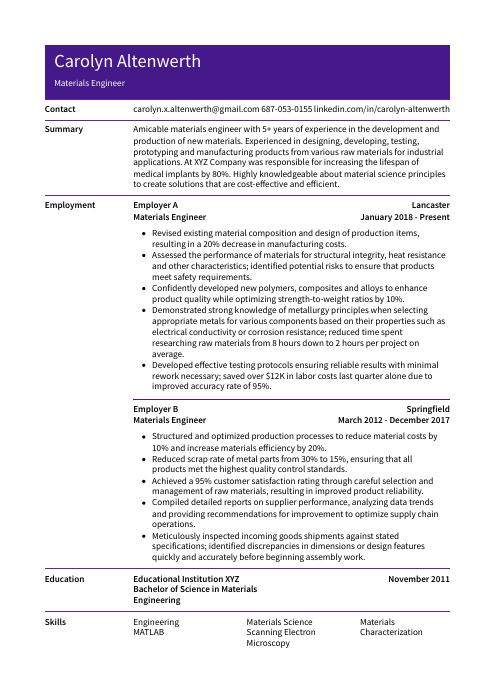

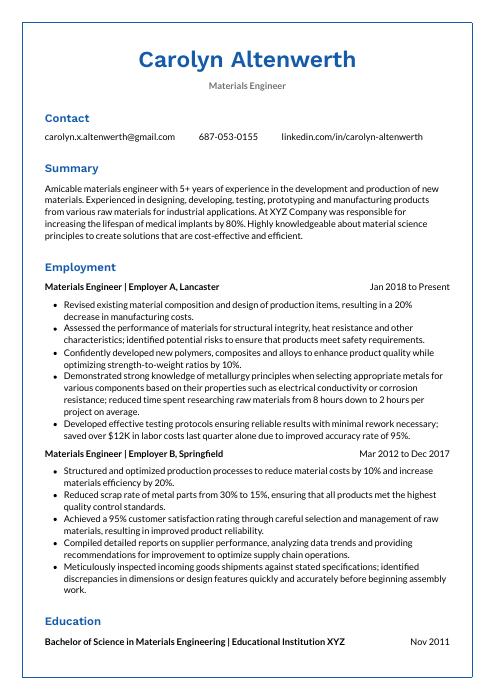

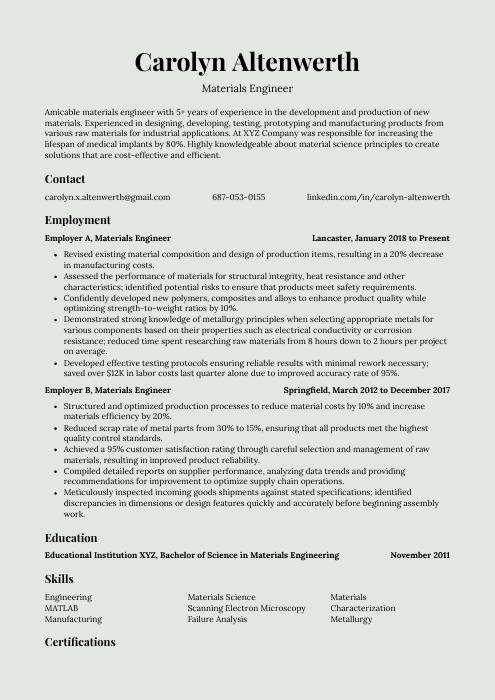

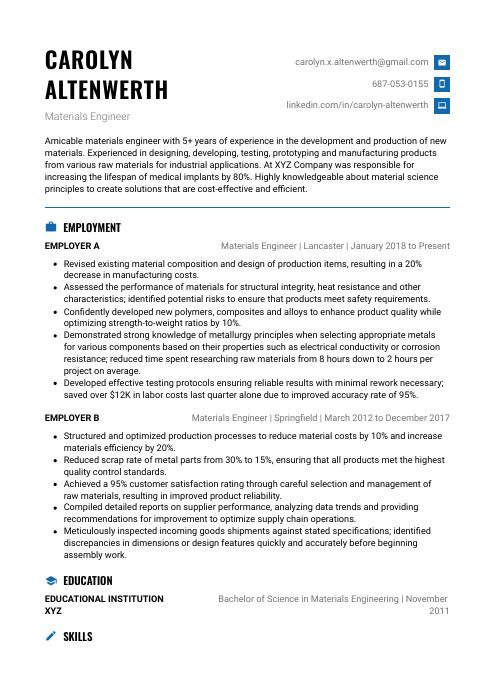

Materials Engineer Resume Sample

Carolyn Altenwerth

Materials Engineer

carolyn.x.altenwerth@gmail.com

687-053-0155

linkedin.com/in/carolyn-altenwerth

Summary

Amicable materials engineer with 5+ years of experience in the development and production of new materials. Experienced in designing, developing, testing, prototyping and manufacturing products from various raw materials for industrial applications. At XYZ Company was responsible for increasing the lifespan of medical implants by 80%. Highly knowledgeable about material science principles to create solutions that are cost-effective and efficient.

Experience

Materials Engineer, Employer A

Lancaster, Jan 2018 – Present

- Revised existing material composition and design of production items, resulting in a 20% decrease in manufacturing costs.

- Assessed the performance of materials for structural integrity, heat resistance and other characteristics; identified potential risks to ensure that products meet safety requirements.

- Confidently developed new polymers, composites and alloys to enhance product quality while optimizing strength-to-weight ratios by 10%.

- Demonstrated strong knowledge of metallurgy principles when selecting appropriate metals for various components based on their properties such as electrical conductivity or corrosion resistance; reduced time spent researching raw materials from 8 hours down to 2 hours per project on average.

- Developed effective testing protocols ensuring reliable results with minimal rework necessary; saved over $12K in labor costs last quarter alone due to improved accuracy rate of 95%.

Materials Engineer, Employer B

Springfield, Mar 2012 – Dec 2017

- Structured and optimized production processes to reduce material costs by 10% and increase materials efficiency by 20%.

- Reduced scrap rate of metal parts from 30% to 15%, ensuring that all products met the highest quality control standards.

- Achieved a 95% customer satisfaction rating through careful selection and management of raw materials, resulting in improved product reliability.

- Compiled detailed reports on supplier performance, analyzing data trends and providing recommendations for improvement to optimize supply chain operations.

- Meticulously inspected incoming goods shipments against stated specifications; identified discrepancies in dimensions or design features quickly and accurately before beginning assembly work.

Skills

- Engineering

- Materials Science

- Materials

- MATLAB

- Scanning Electron Microscopy

- Characterization

- Manufacturing

- Failure Analysis

- Metallurgy

Education

Bachelor of Science in Materials Engineering

Educational Institution XYZ

Nov 2011

Certifications

Certified Materials and Resource Professional (CMRP)

Society

May 2017

1. Summary / Objective

The summary/objective at the top of your resume is like a trailer – it provides the employer with an overview of who you are and what makes you stand out as a materials engineer. In this section, highlight your most impressive qualifications such as certifications in material science or engineering, experience working on complex projects involving multiple materials, and any awards or recognitions that demonstrate your expertise.

Below are some resume summary examples:

Enthusiastic materials engineer with 5+ years of experience in research and development, materials testing, and product design. Skilled at designing products that meet customer needs while also working within cost constraints. Specialize in creating new alloys for improved performance on a wide range of industrial applications. Looking to join ABC Company as their next materials engineer to continue innovating solutions while meeting deadlines.

Reliable materials engineer with 5+ years of experience in research and development. Experienced in the field of materials science, including metals, polymers, composites, ceramics and nanomaterials. Responsible for leading projects from concept to completion at XYZ Industries resulting in a 40% reduction in production costs. Skilled at creating technical reports summarizing testing results and developing new processes for product improvement.

Skilled materials engineer with 8+ years of experience developing and testing new materials for aerospace applications. Expert in a wide range of engineering techniques, including finite element analysis (FEA), structural mechanics, and computational fluid dynamics (CFD). Proven track record of successful projects completed on-time and within budget. Successfully developed new lightweight material that improved aircraft performance by 15%.

Talented materials engineer with 8+ years of experience in the development, testing and optimization of advanced composite materials. Proven track record for finding creative solutions to complex production problems that result in decreased costs and improved product reliability. Seeking to join ABC Tech’s Materials Engineering team to utilize expertise in design, modeling, prototyping and analysis for cutting-edge projects.

Professional materials engineer with 8+ years of experience in the industry. Experienced in creating and implementing new materials for industrial applications, as well as performing research on existing products. Skilled at utilizing a variety of engineering principles to develop cost-effective solutions that meet customer needs. Highly proficient with CAD software, lab testing equipment, and quality control processes.

Dependable materials engineer with a proven track record of developing and testing materials for industrial applications. 5+ years of experience in conducting experiments, analyzing data, and reporting results to stakeholders. Seeking an opportunity at ABC Corporation where I can utilize my expertise in material engineering to develop innovative solutions that improve performance and reduce cost.

Proficient materials engineer with 7+ years of experience in designing, testing and optimizing new materials for a range of industries. Skilled at utilizing computer-aided design (CAD) software to create 3D models that can be tested and improved upon. Seeking to join ABC Inc., where I will use my expertise in material sciences to help develop innovative products for the company’s clients.

Detail-oriented materials engineer with 5+ years’ experience developing, testing and analyzing materials for various applications. Adept at working on a wide variety of projects from aerospace to medical industries. Seeking to use my knowledge and expertise in research and development to help ABC Technologies develop innovative products that meet customer requirements.

2. Experience / Employment

In the experience section, you should list your employment history in reverse chronological order. This means that the most recent job is listed first.

When writing this section, use bullet points to make it easier for the reader to take in all of the information quickly and efficiently. When talking about what you did on each job, provide detail and include any quantifiable results achieved as a result of your work.

For example, instead of saying “Developed new materials,” you could say “Created 3D printed prototypes from composite polymers which improved product durability by 20%.

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Designed

- Analyzed

- Fabricated

- Optimized

- Evaluated

- Processed

- Formulated

- Manufactured

- Inspected

- Researched

- Developed

- Tested

- Assessed

- Improved

- Monitored

Other general verbs you can use are:

- Achieved

- Advised

- Compiled

- Coordinated

- Demonstrated

- Expedited

- Facilitated

- Introduced

- Mentored

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Introduced new materials and processes to produce stronger, more cost-effective products; improved product durability by 15% while reducing material costs by $2,000 a month.

- Fabricated polymer composites for automotive parts using injection molding process and lasted up to 50k miles of testing with no signs of fatigue or degradation in quality.

- Accurately measured properties such as tensile strength, thermal conductivity and dielectric constants for new materials before production began; reduced scrap rates from 8% to 3%.

- Expedited the design phase of projects through use of CAD/CAE software tools which enabled faster prototyping times (by 20%); contributed towards quicker turnaround on customer orders at 10 days ahead of schedule on average per project.

- Tested performance parameters across different mechanical components including dampers & bushings with rigorous physical tests under extreme climatic conditions; maintained accuracy within 1% deviation over 100+ hours experimentally validated results every time.

- Evaluated and tested materials for strength, durability and quality; improved product reliability by 45% within a year.

- Monitored the production process of manufacturing materials to ensure compliance with safety standards and regulations; identified gaps in processes and implemented corrective measures that reduced accidents by 12%.

- Inspected raw material samples before purchase to determine their suitability for use in projects, resulting in cost savings of $20,000 over 2 years due to better selection decisions.

- Formulated new blends of various types of metal alloys based on client specifications while also considering environmental impact factors; achieved 3 patents related to these developments within 6 months’ time frame.

- Reliably managed inventory levels at supplier warehouses across multiple locations according to company needs without compromising on quality or quantity requirements, ensuring efficient delivery timelines were met every single time.

- Researched and developed new materials and fabrication processes to increase strength, durability and cost-effectiveness of products; reduced manufacturing costs by 25%.

- Coordinated with vendors to procure raw materials at optimal prices while ensuring that production timeline is met; achieved an average savings of $500 per purchase order.

- Manufactured 50+ prototypes in the last quarter, testing various combinations of metals, plastics and composites for their performance under extreme conditions such as high temperatures or stress loads.

- Mentored junior engineers on proper material selection techniques, providing hands-on training during product design phases which improved quality assurance results by 10%.

- Thoroughly inspected all incoming raw materials for defects before approving them for use in projects; reduced defective parts rate from 2% to 0% within 6 months due to increased attention to detail standards on site inspections.

- Prepared and tested materials samples to identify physical and chemical properties, resulting in the successful selection of optimal material for manufacturing processes which improved operational efficiency by 15%.

- Resourcefully identified alternative raw materials that could be used instead of traditional ones while reducing production costs by $10,000 annually.

- Improved existing product design techniques through careful research and analysis; successfully developed a new polymer-based composite material with enhanced durability that increased customer satisfaction ratings by 20%.

- Represented the company at industry events and conferences to showcase its latest innovations in process engineering technologies; generated over 50 leads from potential buyers within 3 months as a result.

- Utilized advanced software tools such as CAD/CAE/CAM systems to develop digital simulations of components and products prior to prototype fabrication, saving 500+ hours in development time per project cycle on average.

- Spearheaded the development of new materials for prototyping and production, resulting in a 15% reduction in cost and a 20% improvement in product quality.

- Advised senior management on material selection to meet customer requirements, ensuring that the correct combination of properties was achieved within budget constraints.

- Facilitated supply chain operations by negotiating contracts with vendors and monitoring inventory levels; reduced vendor lead times by 25%.

- Efficiently processed over 500 orders per month using modern CAD/CAE tools, leading to an increase in production efficiency of 10%.

- Developed innovative testing protocols for measuring material fatigue performance under various loading conditions; identified weaknesses which allowed corrective measures to be taken before field deployment issues occurred.

- Streamlined the production process of new materials, resulting in a 40% improvement in efficiency and cost reduction by $10K.

- Substantially increased the strength and durability of existing materials through testing modifications to their chemical composition; reduced product defects rate from 4% to 0.3%.

- Designed and developed prototype products for clients using 3D modeling with CAD software, which resulted in improved performance levels that exceeded customer expectations.

- Analyzed material properties such as corrosion resistance, heat tolerance, electrical conductivity and mechanical stress-strain behavior utilizing laboratory equipment; discussed findings with colleagues & formulated recommendations on how to improve design features accordingly.

- Optimized existing material formulation processes while reducing waste output by 25%, ensuring strict adherence to safety regulations throughout all stages of development & manufacturing operations.

- Reorganized the production of materials to reduce costs by 25%, resulting in an annual savings of $200,000.

- Presented reports and findings on the effectiveness of various materials to upper management, using data analysis software such as MATLAB and Minitab.

- Consistently monitored quality control procedures during production and ensured that all safety protocols were strictly followed; decreased product defects from 10% to 3%.

- Participated in team meetings with other engineers for brainstorming new material designs for industrial applications; developed 5+ innovative solutions which are now being implemented across multiple factories worldwide.

3. Skills

Even though two organizations are hiring for the same role, the skillset they want an ideal candidate to possess could differ significantly. For instance, one may be on the lookout for an individual with experience in 3D printing, while another may be looking for someone with expertise in thermoplastics.

Therefore, you want to tailor the skills section of your resume to each job that you are applying for. This is important because many employers use applicant tracking systems these days which scan resumes for certain keywords before passing them on to a human.

In addition to listing your most relevant qualifications here, it would also be beneficial if you could discuss some of them further in other sections such as the summary or work experience area.

Below is a list of common skills & terms:

- Aerospace

- AutoCAD

- Characterization

- Chemical Engineering

- Chemistry

- Coatings

- Composites

- Continuous Improvement

- Data Analysis

- Design of Experiments

- Engineering

- Engineering Management

- Failure Analysis

- Finite Element Analysis

- Lean Manufacturing

- MATLAB

- Manufacturing

- Materials

- Materials Science

- Mechanical Engineering

- Mechanical Testing

- Metallography

- Metallurgy

- Nanotechnology

- Optical Microscopy

- Polymers

- Process Engineering

- Product Development

- Project Engineering

- R&D

- Research and Development

- Root Cause Analysis

- SOLIDWORKS

- Scanning Electron Microscopy

- Six Sigma

- Spectroscopy

- Team Leadership

- Teamwork

- Testing

- Time Management

4. Education

Mentioning an education section on your resume will depend on how far along you are in your career. If you just graduated and have no work experience, include an education section below the resume objective. However, if you have significant work experience to showcase, omitting the education section is perfectly acceptable.

If including an educational background is necessary, try to mention courses related to materials engineering that demonstrate a mastery of material science principles and knowledge of manufacturing processes relevant for this role.

Bachelor of Science in Materials Engineering

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications are a great way to demonstrate your expertise in a particular field and set yourself apart from other applicants. They show that you have taken the time to learn more about an area of work, and are able to back up your knowledge with proof.

Including certifications on your resume is especially important if they relate directly to the job you’re applying for. This will give employers confidence that you possess all the necessary skills required for success in their organization.

Certified Materials and Resource Professional (CMRP)

Society

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Carolyn Altenwerth, this would be Carolyn-Altenwerth-resume.pdf or Carolyn-Altenwerth-resume.docx.

7. Cover Letter

Writing a cover letter is an often overlooked step in the job application process. It is a document that introduces you to potential employers, provides more information about your skills and qualifications and allows you to explain why you’re an ideal fit for the role.

Cover letters usually consist of 2 to 4 paragraphs and should be tailored specifically for each position you are applying for. Though it’s not a mandatory requirement, submitting one can make all the difference in helping recruiters get a better understanding of who you are as a professional — so don’t forget this important step!

Below is an example cover letter:

Dear Josefa,

I am writing to apply for the Materials Engineer position at your company. As a materials engineer with over 5 years of experience in the automotive industry, I have gained a deep understanding of materials science and how it applies to engineering design and manufacturing processes. I am confident that I can use my skills and knowledge to contribute to the success of your company.

In my current role, I work closely with designers and manufacturers to select appropriate materials for new products, ensuring that they meet all required performance specifications. I also conduct testing on prototypes and finished products to assess their durability and safety under various conditions. In addition, I develop methods for optimizing production processes so that they are more efficient and cost-effective.

Through my work, I have demonstrated strong problem-solving and analytical skills as well as a keen eye for detail. My ability to think creatively has enabled me to come up with innovative solutions to difficult challenges. Furthermore, my excellent communication skills allow me to effectively collaborate with team members from different disciplines.

I believe that I would be an excellent addition to your team because of my technical expertise as well as my ability to work effectively in a multidisciplinary environment. If given the opportunity, I am confident that I will make significant contributions towards the success of your organization.

Sincerely,

Carolyn

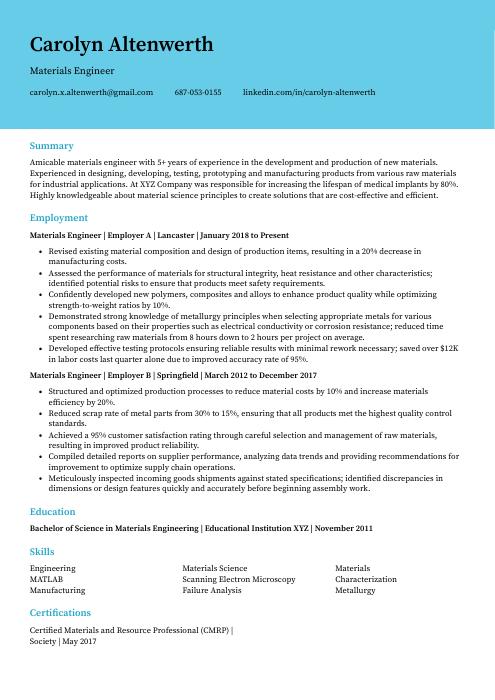

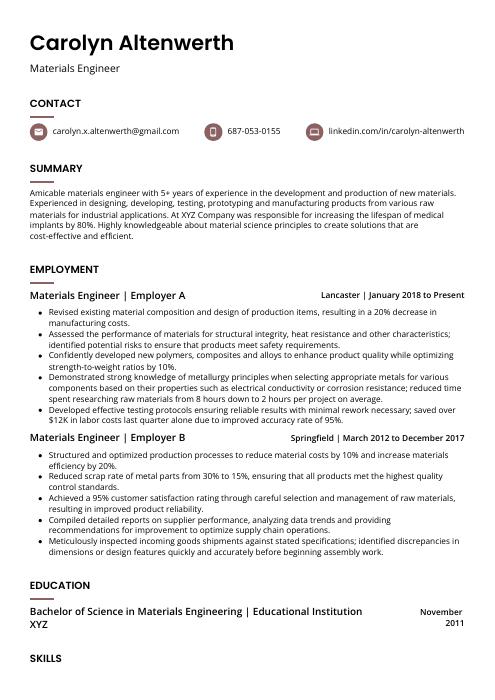

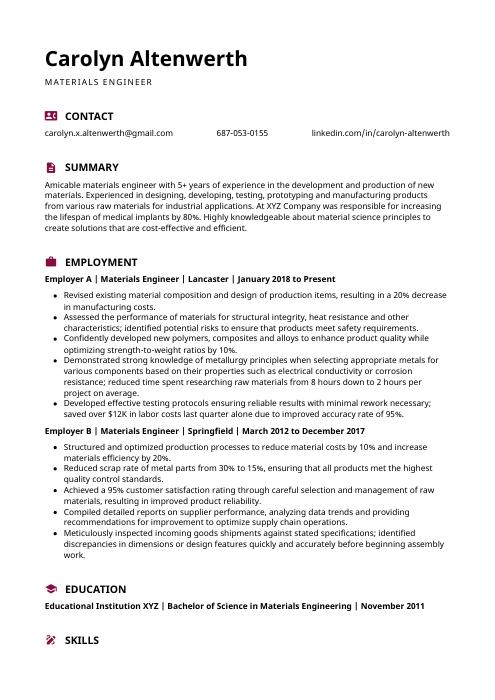

Materials Engineer Resume Templates

Kinkajou

Kinkajou Cormorant

Cormorant Lorikeet

Lorikeet Numbat

Numbat Ocelot

Ocelot Axolotl

Axolotl Bonobo

Bonobo Rhea

Rhea Pika

Pika Markhor

Markhor Quokka

Quokka Jerboa

Jerboa Saola

Saola Dugong

Dugong Fossa

Fossa Hoopoe

Hoopoe Echidna

Echidna Indri

Indri Gharial

Gharial Rezjumei

Rezjumei