Pipe Fitter Resume Guide

Pipe fitters install and maintain piping systems. They measure, cut, thread, and bend pipe to specifications, using hand and power tools. Pipe fitters also install supports for piping systems and attach pipes to structures with clamps or hangers.

You’re an expert pipe fitter with years of experience under your belt. But your resume isn’t getting you any interviews. To increase the response rate from employers, you need to write a more targeted and impressive resume.

This guide will walk you through the entire process of creating a top-notch resume. We first show you a complete example and then break down what each resume section should look like.

Table of Contents

The guide is divided into sections for your convenience. You can read it from beginning to end or use the table of contents below to jump to a specific part.

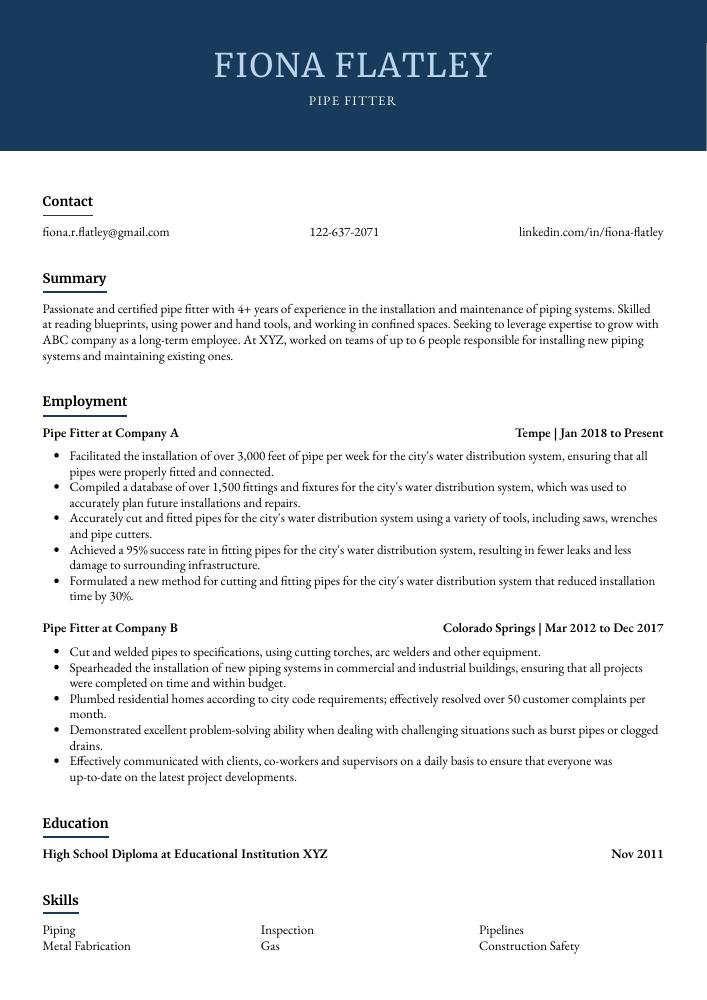

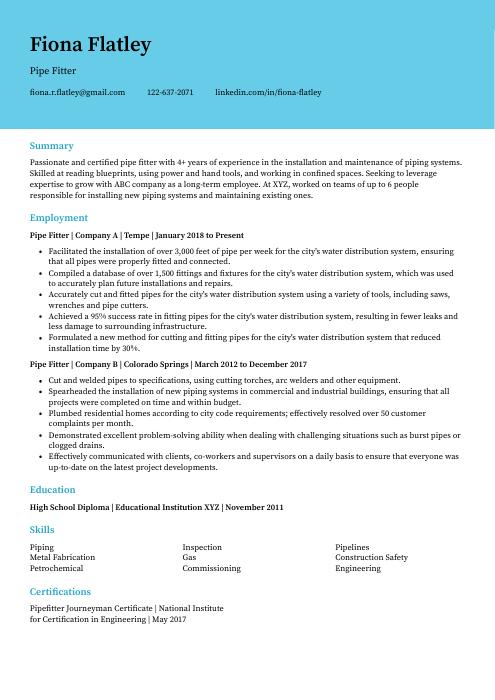

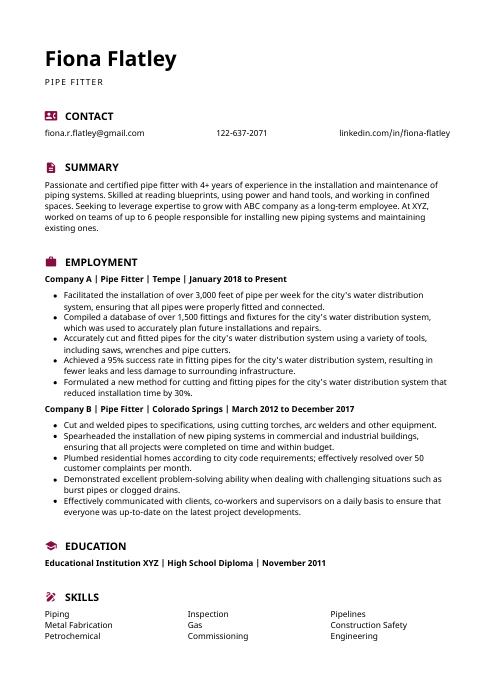

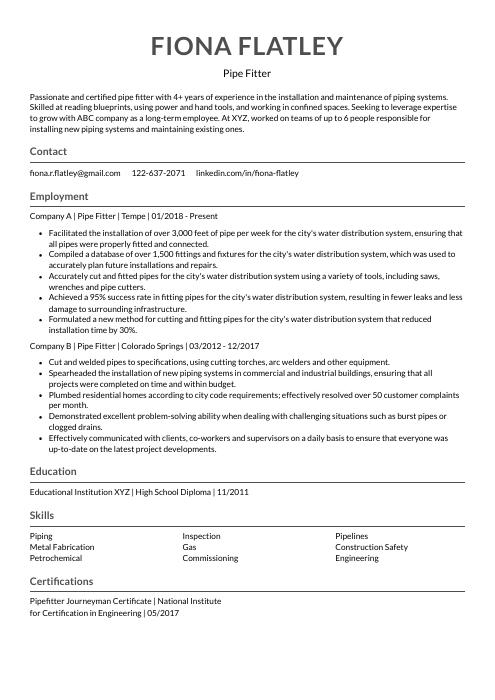

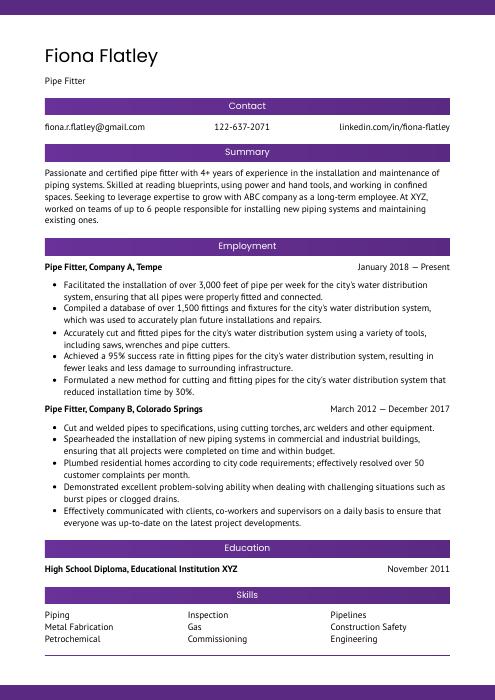

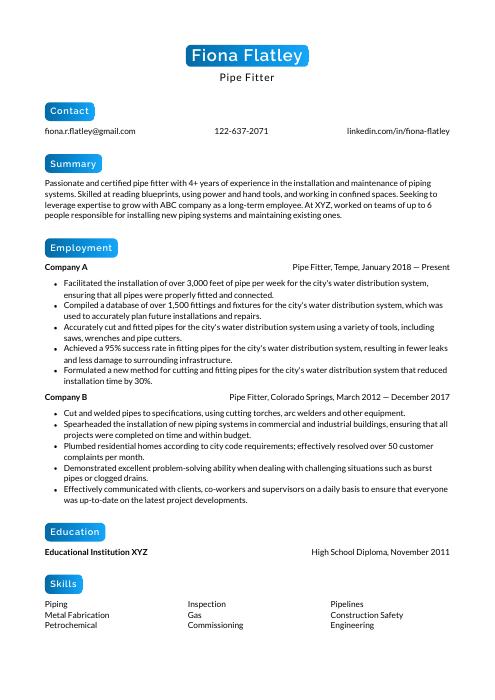

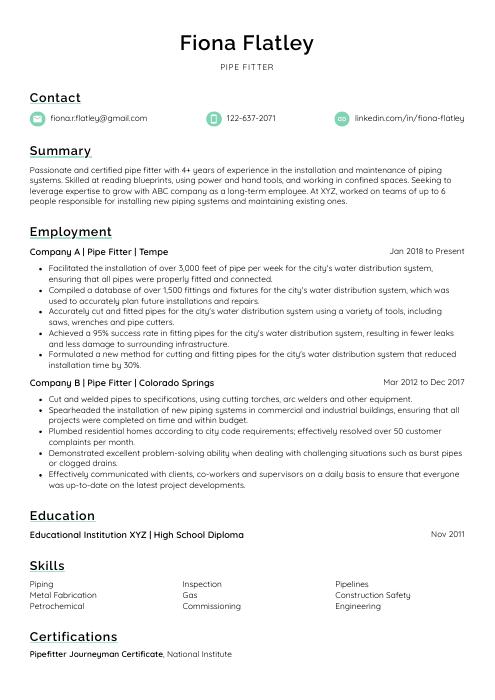

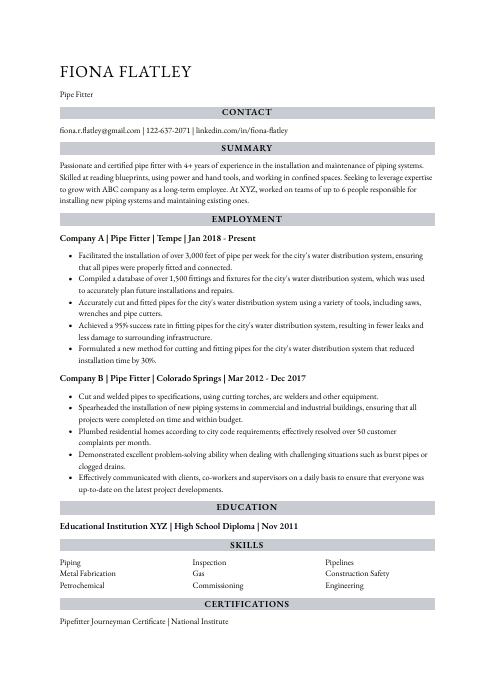

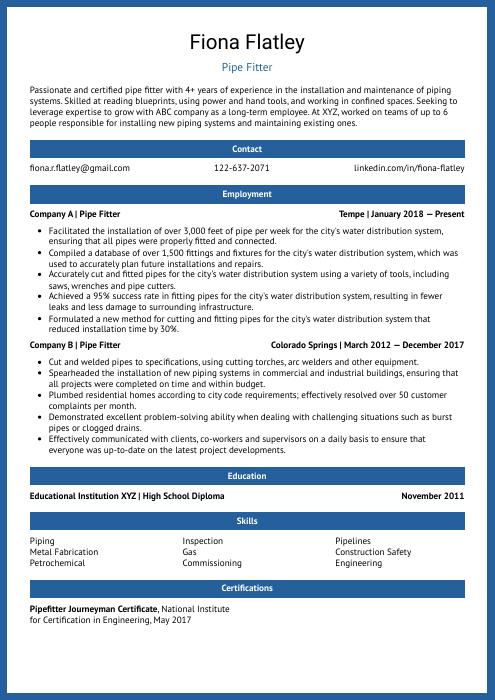

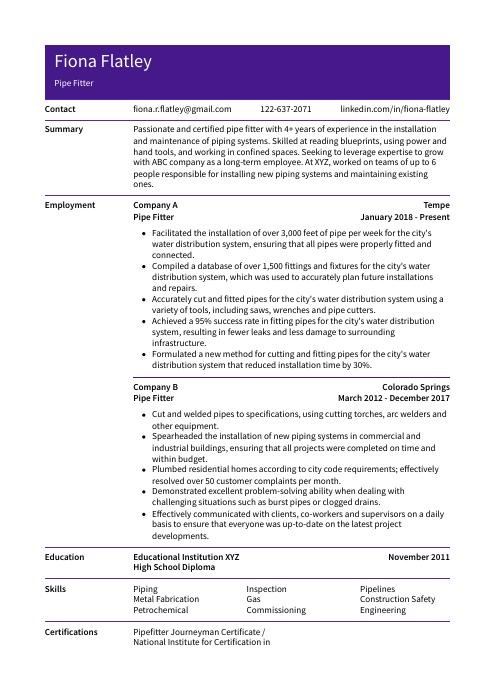

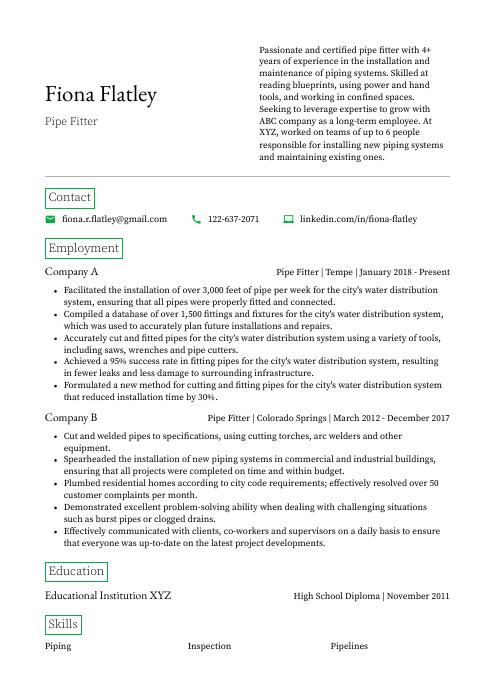

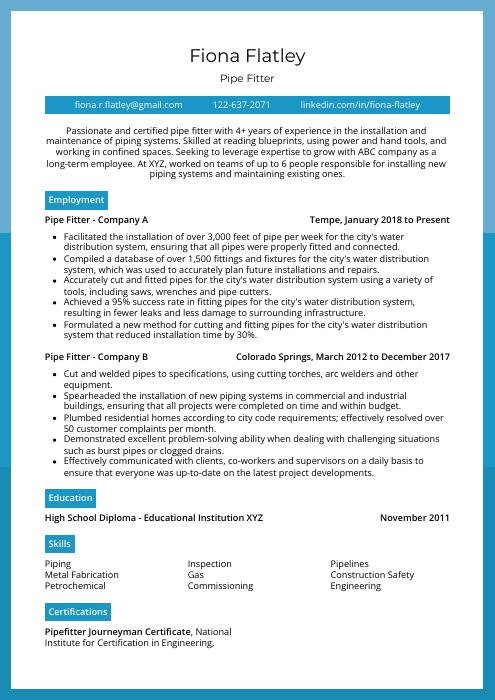

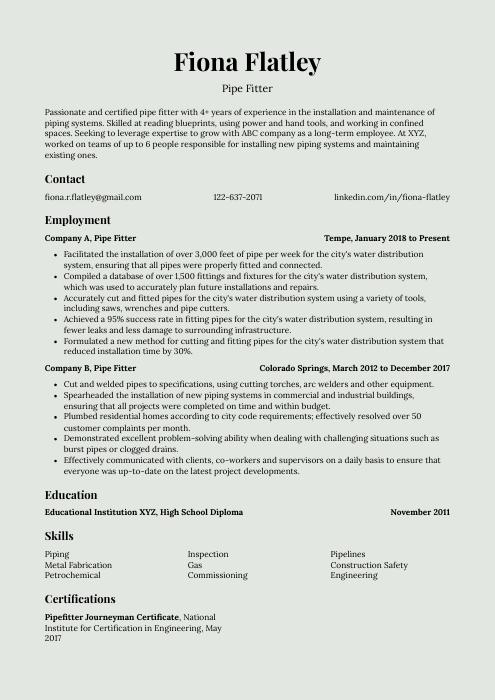

Pipe Fitter Resume Sample

Fiona Flatley

Pipe Fitter

[email protected]

122-637-2071

linkedin.com/in/fiona-flatley

Summary

Passionate and certified pipe fitter with 4+ years of experience in the installation and maintenance of piping systems. Skilled at reading blueprints, using power and hand tools, and working in confined spaces. Seeking to leverage expertise to grow with ABC company as a long-term employee. At XYZ, worked on teams of up to 6 people responsible for installing new piping systems and maintaining existing ones.

Experience

Pipe Fitter, Company ABC

Tempe, Jan 2018 – Present

- Facilitated the installation of over 3,000 feet of pipe per week for the city’s water distribution system, ensuring that all pipes were properly fitted and connected.

- Compiled a database of over 1,500 fittings and fixtures, which was used to accurately plan future installations and repairs.

- Accurately cut and fitted pipes using a variety of tools, including saws, wrenches and pipe cutters.

- Achieved a 95% success rate in fitting pipes, resulting in fewer leaks and less damage to surrounding infrastructure.

- Formulated a new method for cutting and fitting pipes that reduced installation time by 30%.

Pipe Fitter, Company XYZ

Colorado Springs, Mar 2012 – Dec 2017

- Cut and welded pipes to specifications, using cutting torches, arc welders and other equipment.

- Spearheaded the installation of new piping systems in commercial and industrial buildings, ensuring that all projects were completed on time and within budget.

- Plumbed residential homes according to city code requirements; effectively resolved over 50 customer complaints per month.

- Demonstrated excellent problem-solving ability when dealing with challenging situations such as burst pipes or clogged drains.

- Effectively communicated with clients, co-workers and supervisors on a daily basis to ensure that everyone was up-to-date on the latest project developments.

Skills

- Piping

- Inspection

- Pipelines

- Metal Fabrication

- Gas

- Construction Safety

- Petrochemical

- Commissioning

- Engineering

Education

High School Diploma

Educational Institution XYZ

Nov 2011

Certifications

Pipefitter Journeyman Certificate

National Institute for Certification in Engineering

May 2017

1. Summary / Objective

A resume summary/objective is like a teaser for the rest of your resume. It should give the employer an overview of who you are and what makes you an excellent pipe fitter.

Some things you may want to include in your summary are your years of experience, relevant certifications, and notable projects you have worked on.

Below are some resume summary examples:

Diligent and experienced pipe fitter with more than ten years of experience in the installation and maintenance of various piping systems. Proven ability to work independently as well as part of a team. In previous roles, completed all assigned tasks on time and under budget while adhering to company safety standards. Seeking to leverage my skills and experience to become the next pipe fitter at ABC Corporation.

Skilled pipe fitter with 4 years of experience in the installation, maintenance, and repair of various piping systems. At XYZ Company, installed a new sprinkler system that saved an estimated $15,000 per year in water costs. Experienced in reading blueprints and schematics to determine the best course of action for each project.

Dependable and experienced Pipefitter with over 15 years of experience in the trade. Proven ability to read and interpret blueprints as well as follow verbal and written instructions to complete assigned tasks. Experienced in all phases of pipefitting, from layout and fabrication to installation and testing. Committed to safety on the job site and ensuring that all work is completed according to code.

Determined and safety-conscious Pipefitter with 3+ years of experience working on oil rigs and in construction. Seeking to use my attention to detail and problem-solving skills as a Pipefitter at ABC. On previous projects, identified errors that saved the company an estimated $4,500 per month.

Hard-working, certified pipe fitter with 4+ years of experience in the installation and maintenance of all types of piping systems. Experienced in reading blueprints, installing various sizes and types of pipes, and performing leak tests. Seeking to leverage skillset to grow with a company like ABC that offers opportunities for advancement.

Reliable and experienced pipe fitter with more than 5 years of experience working on construction sites, in factories, and in commercial and residential buildings. Seeking to leverage expertise in reading blueprints and installing various types of piping to support the operations of ABC Corporation. In previous roles, completed projects ahead of schedule by an average margin of 17%.

Driven and experienced Pipefitter with 4+ years of experience working in the construction and oil & gas industries. Seeking to leverage expertise in reading blueprints, installing various types of piping systems, and performing welding tasks at ABC. At XYZ, played a key role in the installation of over 1 mile of 6″ Schedule 40 pipe for a natural gas pipeline project.

Enthusiastic pipe fitter with more than 4 years of experience in the installation and maintenance of piping systems. Seeking to leverage my skills and knowledge to fill the pipe fitter role at ABC Corporation. In my previous role, I was responsible for the installation of an irrigation system that saved the company $250,000 per year in water costs.

2. Experience / Employment

The work history/experience section is where you provide information about your previous employment. This should be written in reverse chronological order, with your most recent job listed first.

When stating what you did at each job, it’s best to use bullet points. This allows the reader to quickly digest the information. You want to take some time to think about the in-depth details of what you did and any quantifiable results achieved.

For example, rather than saying “Installed pipes,” you could say, “Successfully installed 500 feet of copper pipe per week on average, adhering to all safety standards.”

To write effective bullet points, begin with a strong verb or adverb. Industry specific verbs to use are:

- Assembled

- Installed

- Maintained

- Repaired

- Inspected

- Tested

- Operated

- Adjusted

- Fabricated

- Welded

- Cut

- Measured

- Bent

- Piped

- Plumbed

Other general verbs you can use are:

- Achieved

- Advised

- Assessed

- Compiled

- Coordinated

- Demonstrated

- Developed

- Expedited

- Facilitated

- Formulated

- Improved

- Introduced

- Mentored

- Optimized

- Participated

- Prepared

- Presented

- Reduced

- Reorganized

- Represented

- Revised

- Spearheaded

- Streamlined

- Structured

- Utilized

Below are some example bullet points:

- Reduced installation time of pipes by 20% on average, through the use of power tools and careful coordination with other members of the construction team.

- Measured and cut pipes to size using a variety of hand-held and stationary tools, according to blueprint specifications.

- Fabricated pipe supports, hangers and brackets from raw materials, using welding equipment per project requirements.

- Reliably completed tasks within strict deadlines set by the construction manager, in order to avoid delays in the overall completion of the project.

- Assembled pipes, fittings and valves together using threaded fasteners, gaskets & sealants in order to create a watertight seal; installed piping systems in commercial & residential buildings according to local code requirements.

- Adjusted pipe fittings and plumbing fixtures to ensure optimal water flow through systems, resulting in a 15% decrease in customer complaints.

- Streamlined the process of fitting pipes by developing a new method of measuring and cutting pipes that reduced waste by 20%.

- Substantially increased the efficiency of the pipefitting team by reorganizing the work schedule and assigning tasks based on skill level.

- Structured training programs for new hires that decreased the time it took to get them up to speed by 30%.

- Expedited deliveries of materials to job sites, which resulted in a 10% reduction in project completion times.

- Welded pipes and fittings together using oxy-acetylene welding equipment, in accordance with laid down safety procedures; introduced new welding techniques that improved productivity by 15%.

- Introduced a new system for organizing the workshop and managing tools & materials, which resulted in a 10% reduction in downtime.

- Presented proposals for process improvements to the management team; implemented changes that increased production output by 20%.

- Installed pipes and fittings according to specifications, using hand & power tools; completed all installations within the required timeframe and without any defects or errors.

- Competently carried out all tasks assigned, with minimal supervision; provided support and training to other members of the team as needed.

- Revised the piping system layout for a new production line, reducing the number of required fittings by 18%.

- Independently installed and tested all pipes, valves and fittings according to blueprint specifications.

- Utilized welding equipment to join metal pipes together with precision and without leaks.

- Mentored 2 apprentices on proper safety procedures and techniques for pipe installation and repair.

- Improved work efficiency by 15% through the use of innovative fitting methods learned from previous experience in the field.

- Piped gas, water, air and other fluids through a variety of materials including metal, plastic and glass on a daily basis.

- Bent, cut and threaded pipes to required specifications using hand and power tools; optimized piping layout to minimize material waste.

- Tested installed pipes for leaks using pressure gauges and other tools; efficiently repaired leaks with minimal disruption to operations.

- Installed new piping systems in accordance with blueprint drawings and code requirements; replaced old or damaged piping as needed.

- Inspected completed work to ensure that it met all safety standards before putting it into service; prepared reports detailing inspection results.

- Inspected and repaired a variety of pipes and pipe fittings, using hand and power tools, to ensure that they were functioning properly.

- Maintained an inventory of all the necessary parts and supplies needed for repairs, ordering new items as necessary.

- Resourcefully developed a system to track repair requests from customers, prioritizing urgent cases while ensuring that all requests were addressed in a timely manner.

- Developed strong relationships with clients through providing quality service and always being available to answer any questions or concerns they may have had about their plumbing systems.

- Represented the company in a professional manner at all times when interacting with customers or other industry professionals.

- Diligently followed blueprints and instructions to install, maintain and repair a variety of piping systems used in residential and commercial buildings.

- Coordinated with other tradespeople to ensure that new pipes were installed correctly and in a timely manner.

- Advised customers on the best type of pipe to use for their needs, based on factors such as water pressure, temperature and chemical resistance.

- Operated power tools and equipment safely to cut, thread and bend pipes according to specifications.

- Reorganized the workshop to improve efficiency and safety; reduced accidents by 25%.

- Participated in the installation of over 15 miles of pipe in a variety of settings, including residential, commercial and industrial buildings.

- Prepared pipes for installation by measuring, cutting and threading them according to specifications.

- Thoroughly cleaned all pipes and fittings before assembling them together.

- Repaired leaks in existing piping systems using welding techniques and sealants as necessary.

- Assessed completed piping installations to ensure that they meet all safety and code requirements.

3. Skills

The necessary skills for pipefitters will vary depending on the employer. For example, some companies might require experience with natural gas lines while others only work with water lines. As a result, it is essential to tailor the skills section of your resume to each job that you are applying for.

This way, you can ensure that the most relevant skills are included and increase your chances of getting past any applicant tracking systems that may be used by potential employers.

In addition to just listing skills here, try to elaborate on them in other sections as well. For example, if you have experience working with natural gas lines, mention this in the experience section and discuss what type of work you did (e.g., installation or repair).

Below is a list of common skills & terms:

- Blueprint Reading

- Boilers

- Commissioning

- Construction Management

- Construction Safety

- Contract Management

- Contractors

- EPC

- Energy

- Engineering

- Factory

- Gas

- HVAC

- Inspection

- LNG

- Metal Fabrication

- Oil

- Oil And Gas

- Onshore

- Petrochemical

- Petroleum

- Pipe

- Pipefitting

- Pipelines

- Piping

- Plumbing

- Project Control

- Pumps

- Refinery

- Subcontracting

- Supervisory Skills

- Welding

4. Education

Mentioning an education section on your resume will depend on how much work experience you have. If you just finished an apprenticeship or trade school and have no professional experience, include your education below your resume objective. However, if you’ve been working as a pipe fitter for years with plenty of responsibilities to showcase, omitting the education section is perfectly fine.

If including an education section, only mention courses and subjects related to the pipe fitting job you are applying for. Examples might be “Apprenticeship in Pipefitting” or “Courses included Blueprint Reading & Sketching, Oxy-Fuel Welding & Cutting.”

High School Diploma

Educational Institution XYZ

Nov 2011

5. Certifications

Certifications demonstrate to a potential employer that you have the skills and knowledge required to do the job. They provide proof that you have taken courses and exams, and that you are competent in your field.

If you are certified by a well-known organization, such as the American Society of Mechanical Engineers (ASME), this will hold more weight than if you were certified by a smaller body. List any relevant certifications in this section of your resume so that hiring managers can see them at a glance.

Pipefitter Journeyman Certificate

National Institute for Certification in Engineering

May 2017

6. Contact Info

Your name should be the first thing a reader sees when viewing your resume, so ensure its positioning is prominent. Your phone number should be written in the most commonly used format in your country/city/state, and your email address should be professional.

You can also choose to include a link to your LinkedIn profile, personal website, or other online platforms relevant to your industry.

Finally, name your resume file appropriately to help hiring managers; for Fiona Flatley, this would be Fiona-Flatley-resume.pdf or Fiona-Flatley-resume.docx.

7. Cover Letter

Writing a cover letter is an opportunity to showcase your personality and expand on the information that is included in your resume. It should be made up of 2-4 paragraphs, with each paragraph serving a different purpose.

The first paragraph of your cover letter should introduce you and explain why you are interested in the role you are applying for. The second paragraph should highlight some of your key skills and experience that make you suited to the role. In the third paragraph, you can talk about your motivation for wanting to work for the company specifically. Finally, in the fourth paragraph, thank the reader for their time and state that you look forward to hearing from them soon.

Below is an example cover letter:

Dear Soledad,

I am writing to apply for the position of Pipe Fitter with your company. I have over 10 years’ experience in the field and am confident that my skills and abilities will contribute to the success of your organization.

As a journeyman pipe fitter, I have gained valuable experience in all aspects of pipe fitting, from installation and repair to welding and fabricating. My attention to detail ensures that all fittings are installed correctly and meet code requirements, while my strong problem-solving skills allow me to troubleshoot issues quickly and efficiently. In addition, my team-oriented approach allows me to work effectively with other tradespeople on site.

I believe that I would be an excellent addition to your team, and I look forward to putting my skills and experience to work for you. Thank you for your time; I look forward to hearing from you soon.

Sincerely,

[Your name]

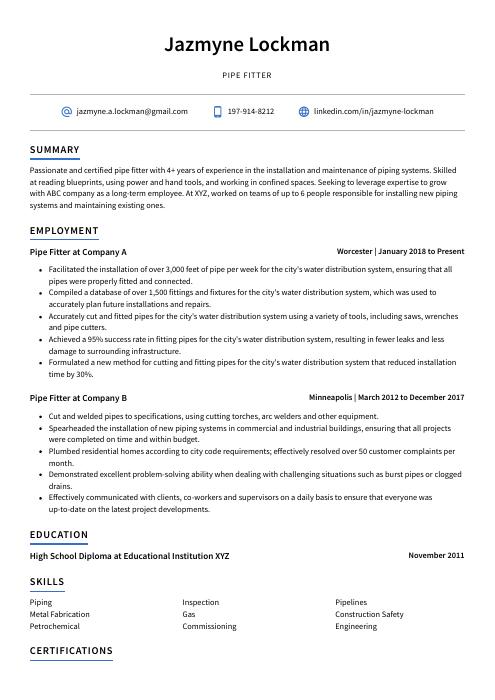

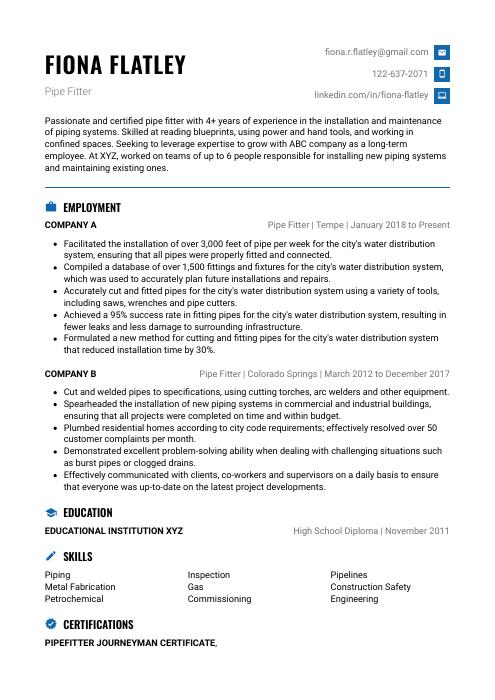

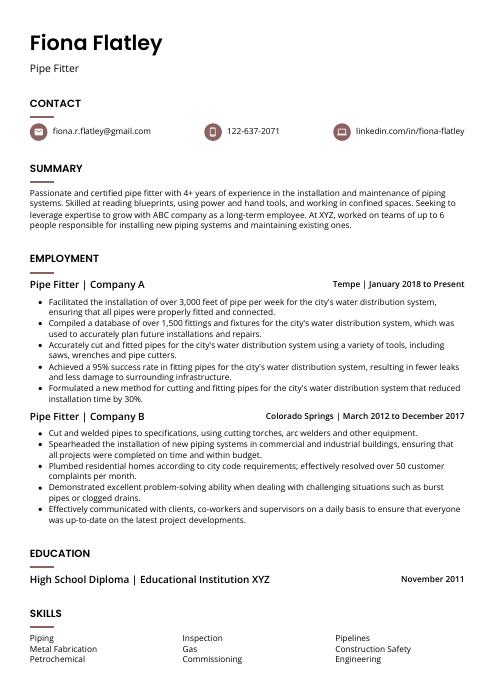

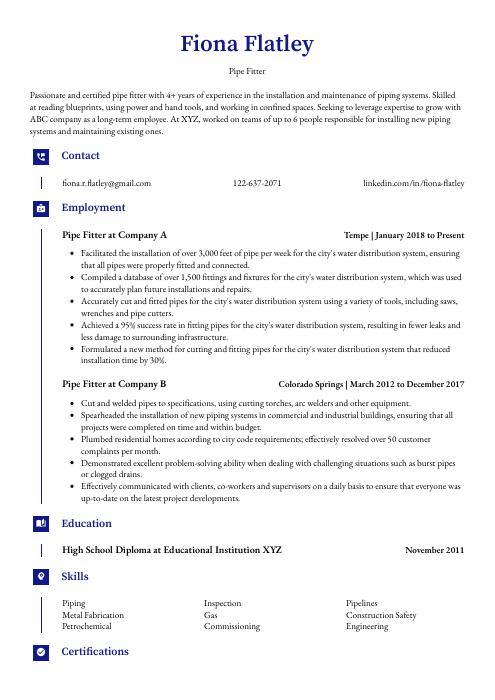

Pipe Fitter Resume Templates

Axolotl

Axolotl Bonobo

Bonobo Cormorant

Cormorant Dugong

Dugong Echidna

Echidna Fossa

Fossa Gharial

Gharial Hoopoe

Hoopoe Indri

Indri Jerboa

Jerboa Kinkajou

Kinkajou Markhor

Markhor Numbat

Numbat Ocelot

Ocelot Pika

Pika Quokka

Quokka Rhea

Rhea Saola

Saola Rezjumei

Rezjumei